Patents

Literature

102results about How to "Low acid concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bile Acid Recycling Inhibitors for Treatment of Hypercholemia and Cholestatic Liver Disease

InactiveUS20130108573A1Relieve symptomsReduce recurrenceBiocideCyclic peptide ingredientsDiseaseHepatic bile

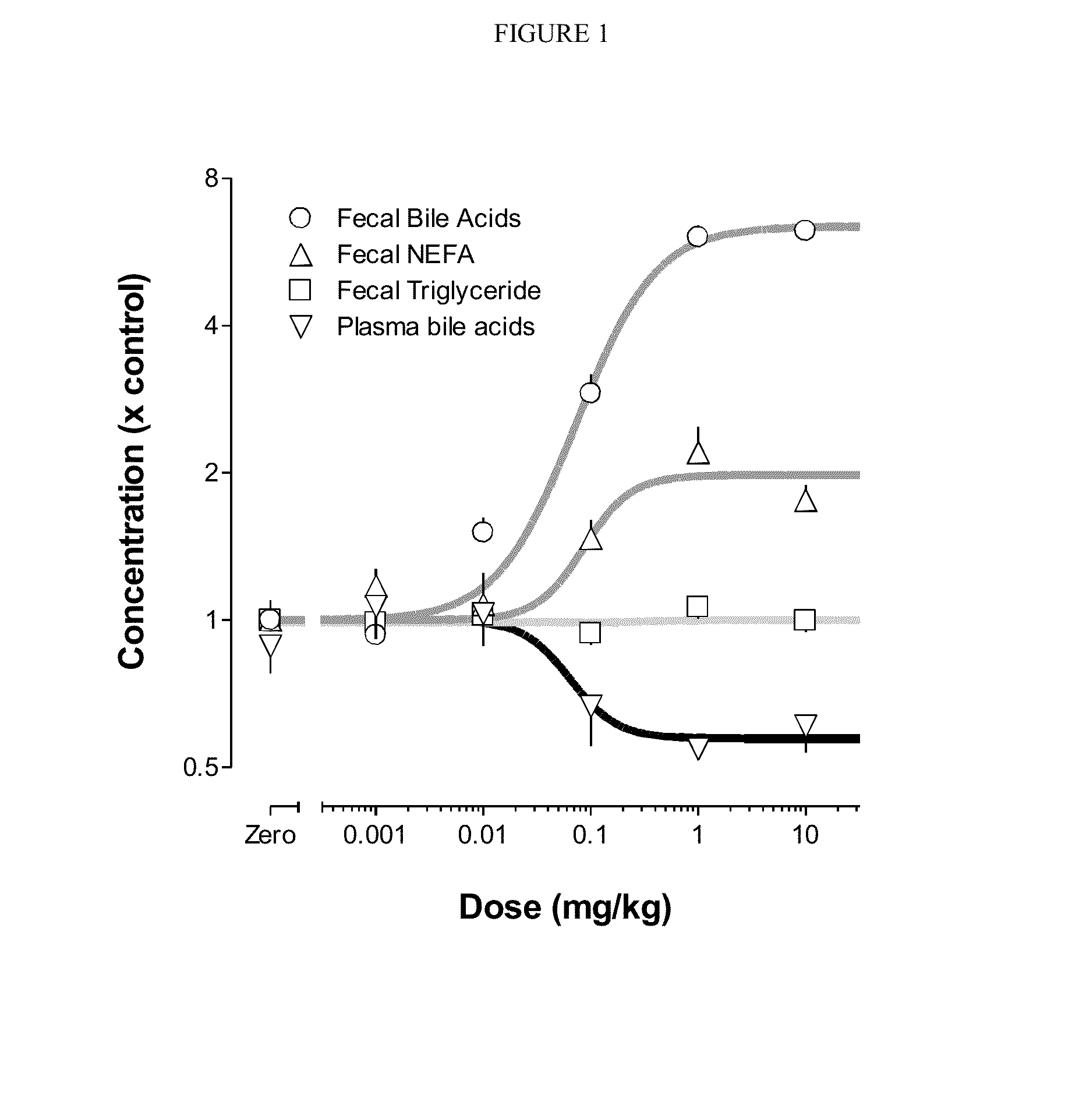

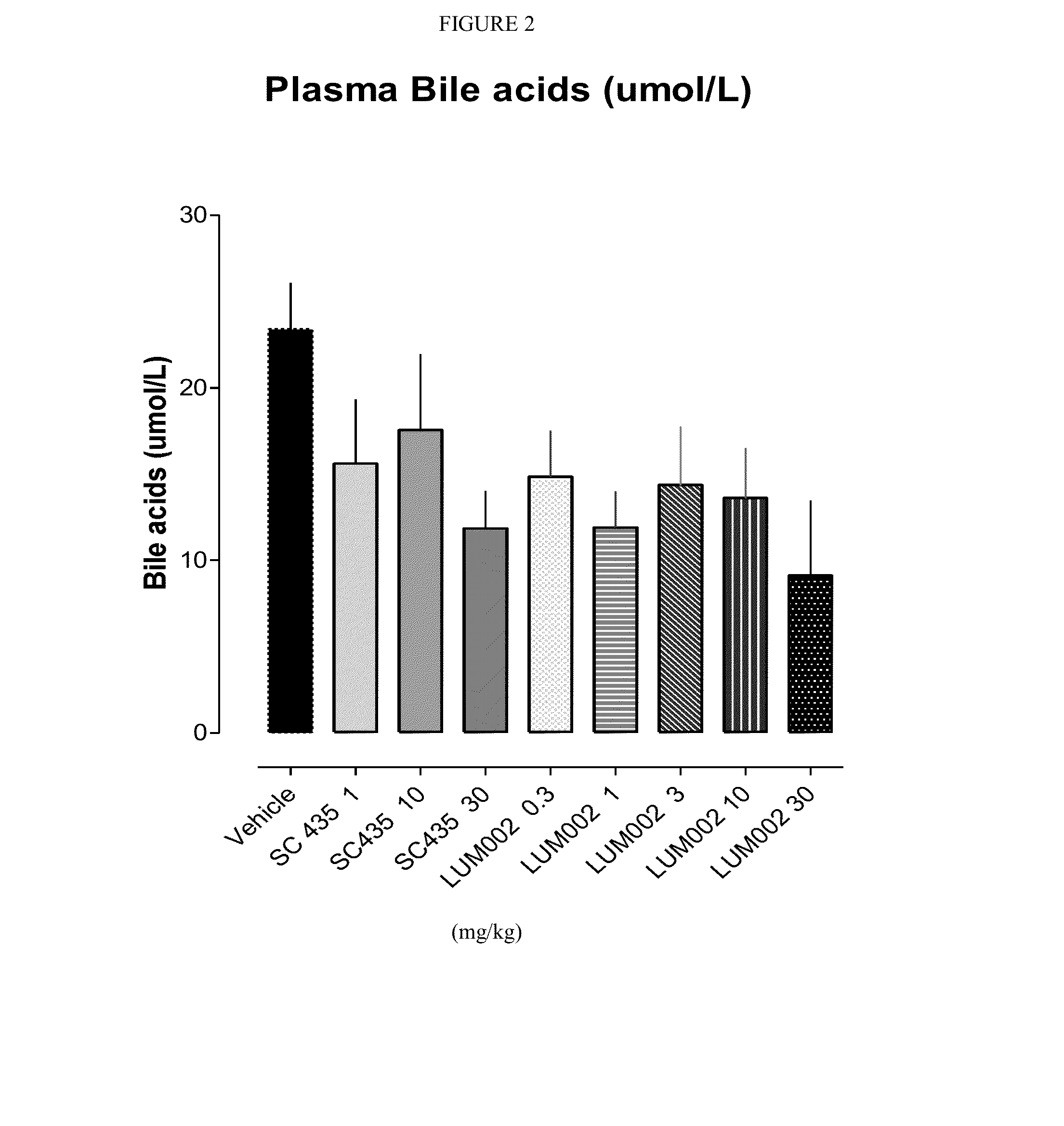

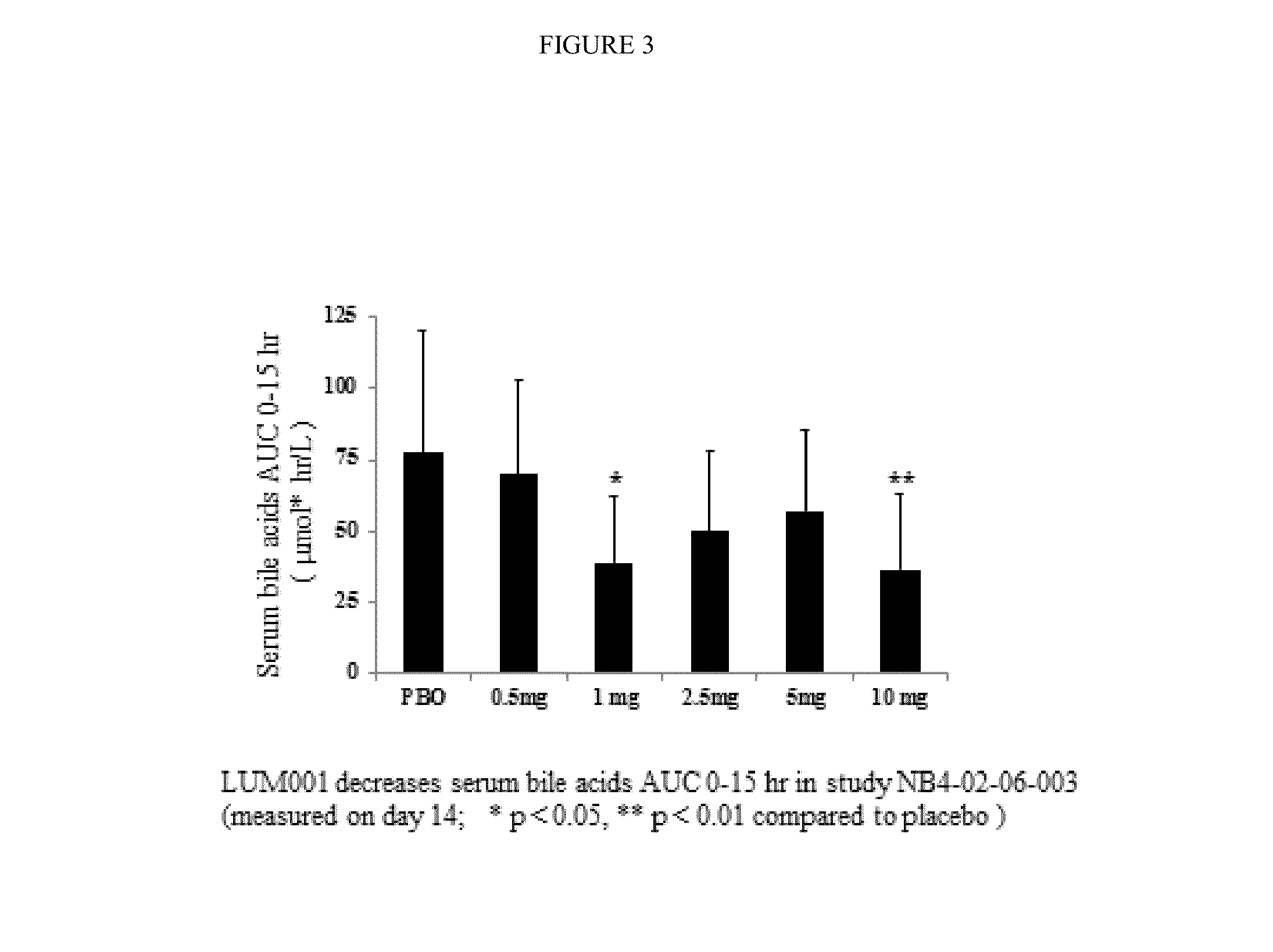

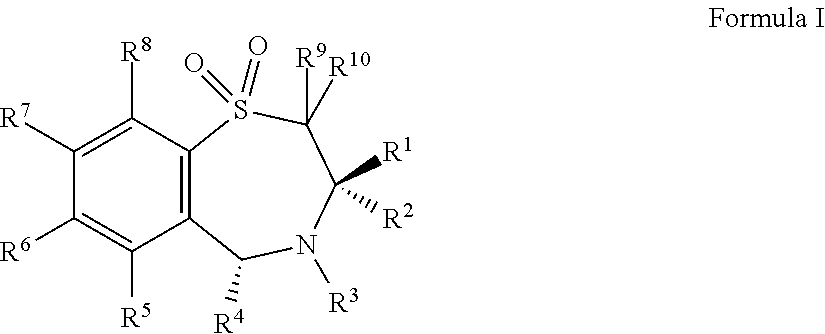

Provided herein are methods of treating or ameliorating hypercholemia or a cholestatic liver disease by administering to an individual in need thereof a therapeutically effective amount of an Apical Sodium-dependent Bile Acid Transporter Inhibitor (ASBTI) or a pharmaceutically acceptable salt thereof. Also provided are methods for treating or ameliorating a liver disease, decreasing the levels of serum bile acids or hepatic bile acids, treating or ameliorating pruritis, reducing liver enzymes, or reducing bilirubin comprising administering to an individual in need thereof a therapeutically effective amount of ASBTI or a pharmaceutically acceptable salt thereof.

Owner:LUMENA PHARMA INC

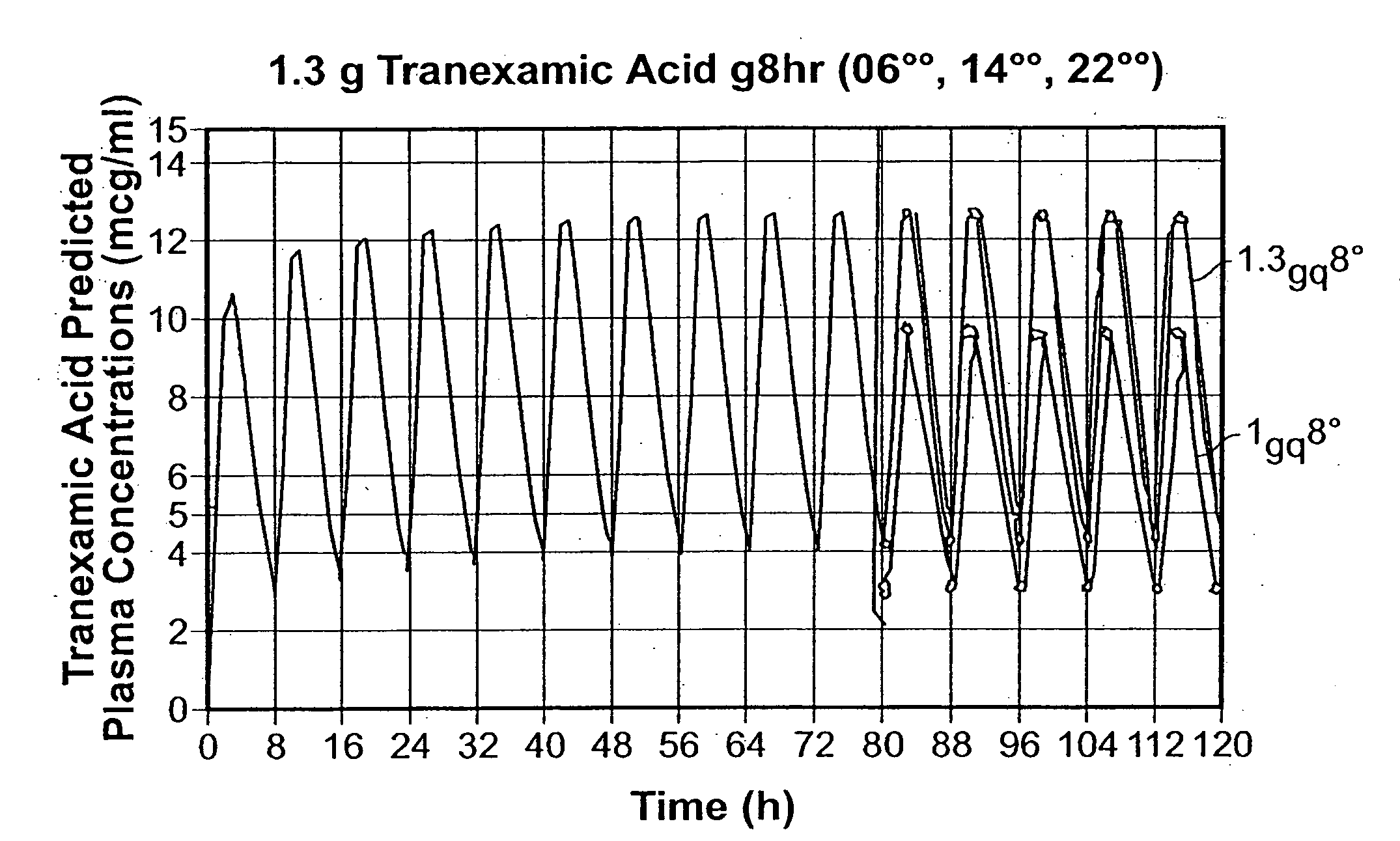

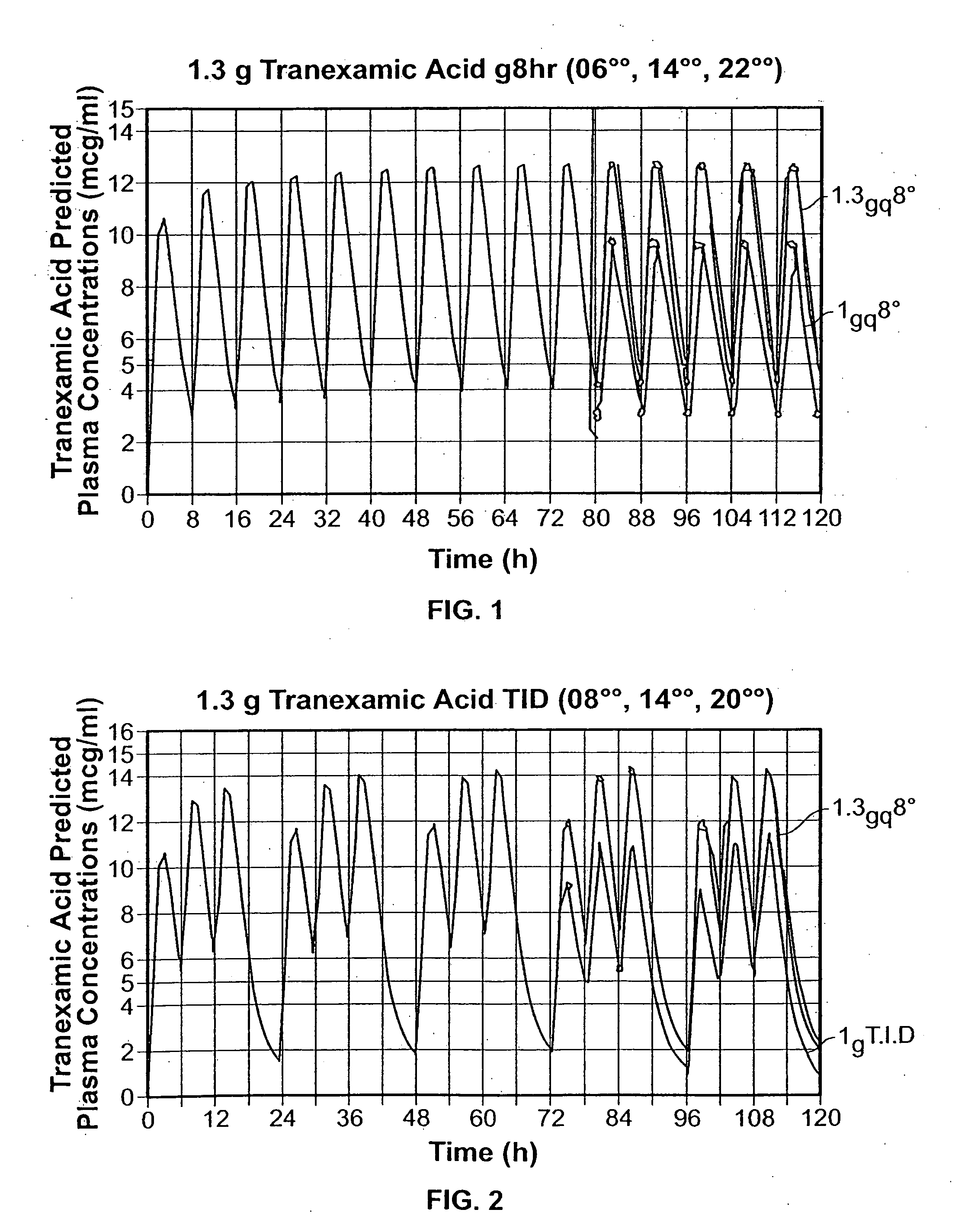

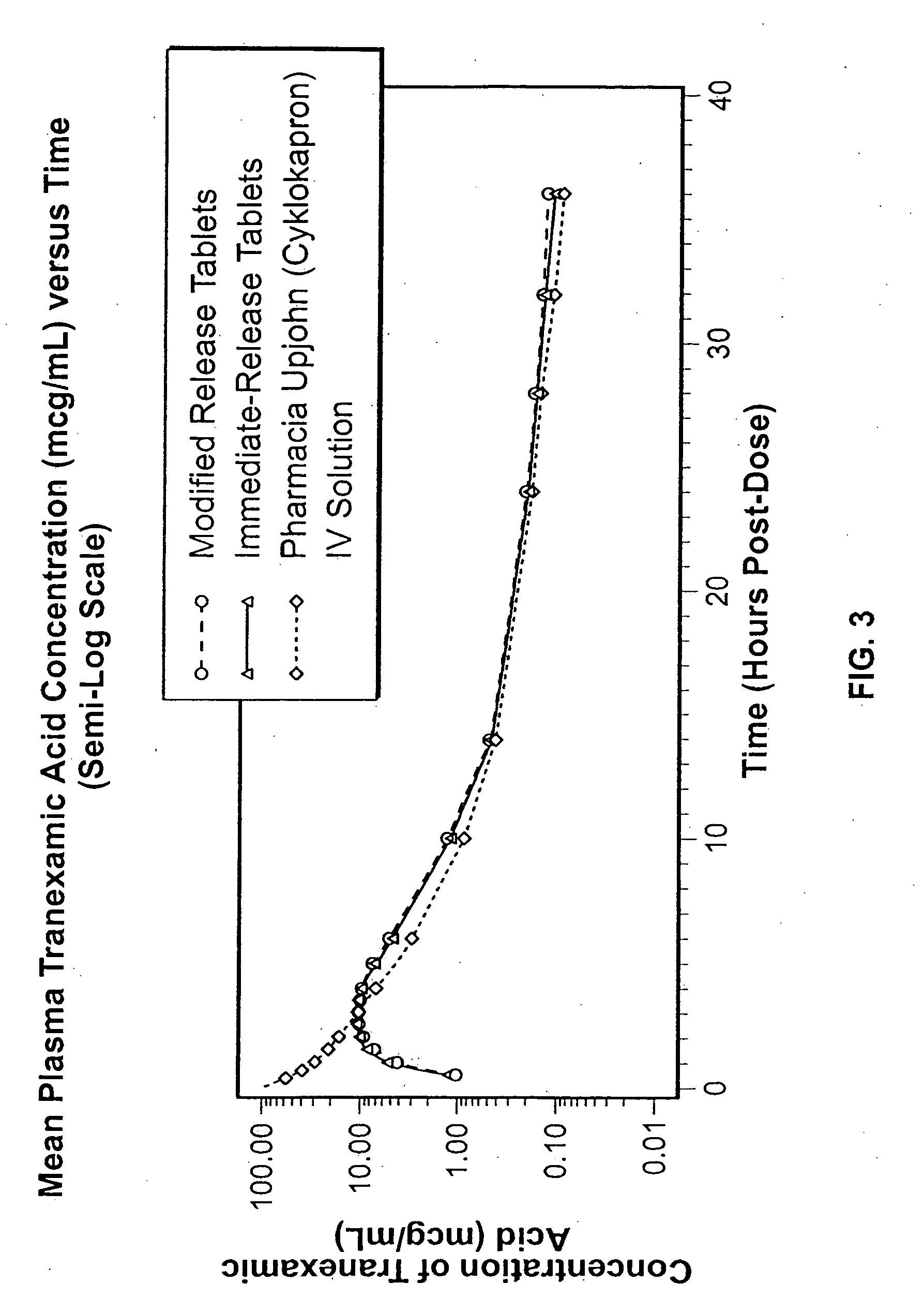

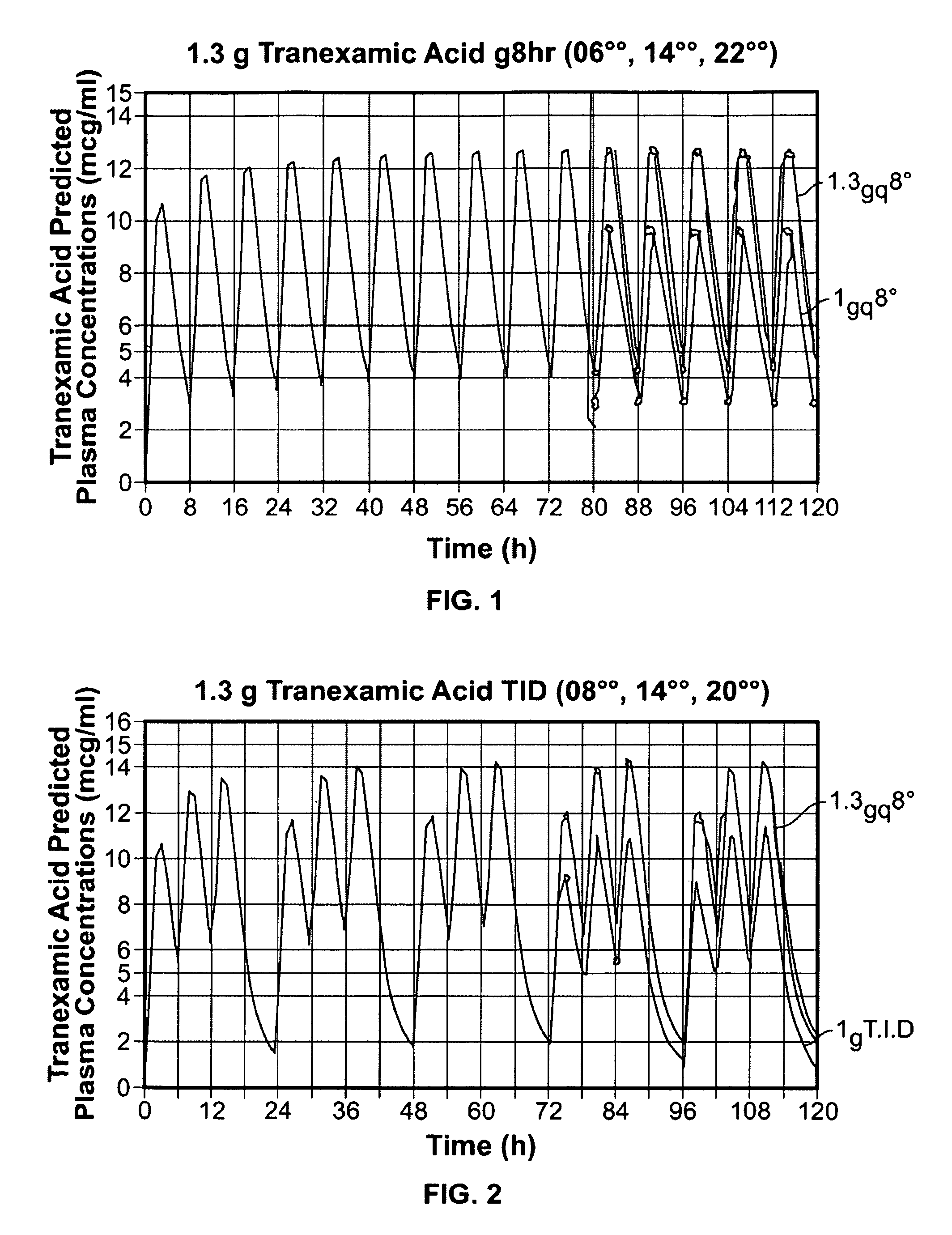

Tranexamic acid formulations with reduced adverse effects

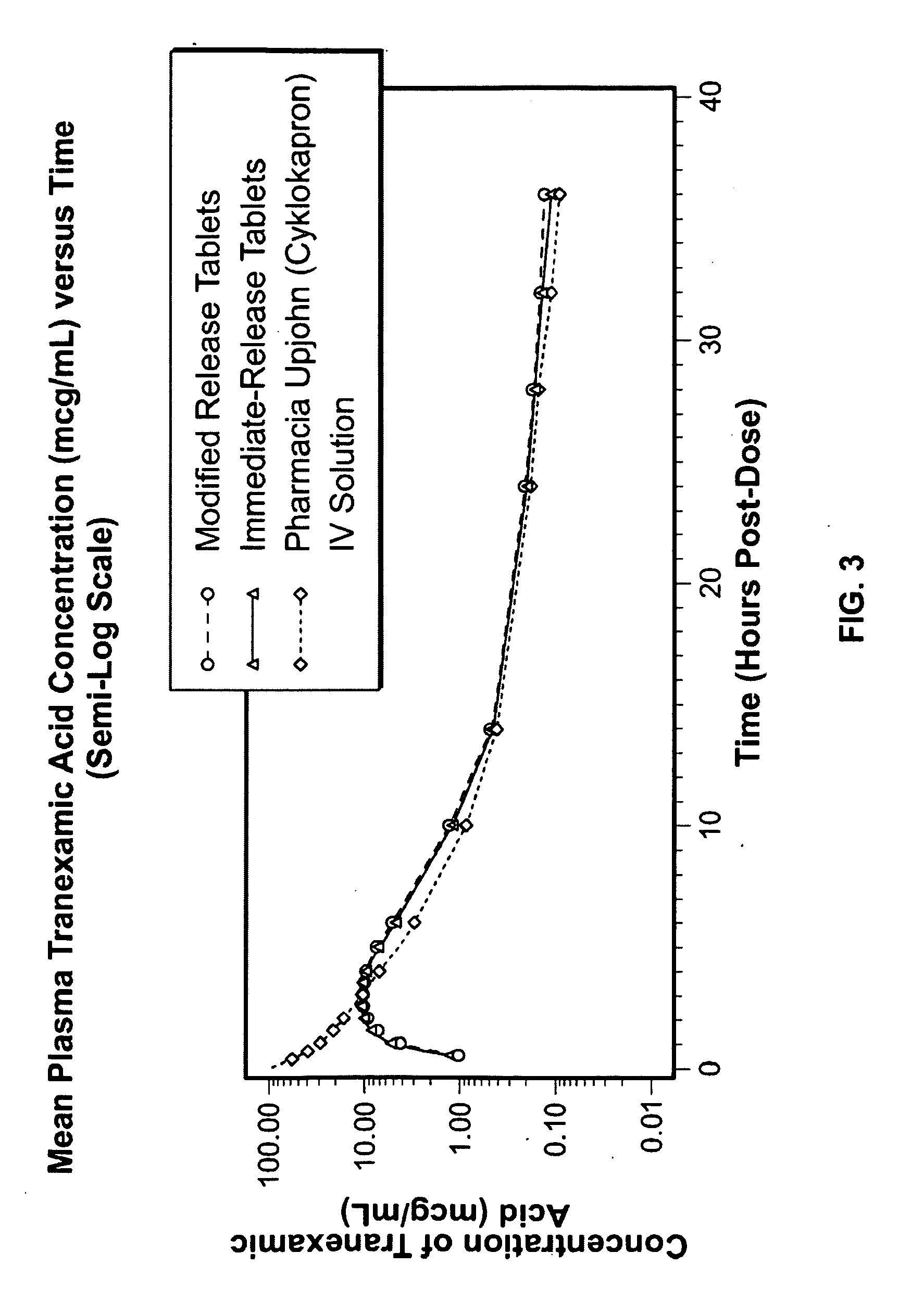

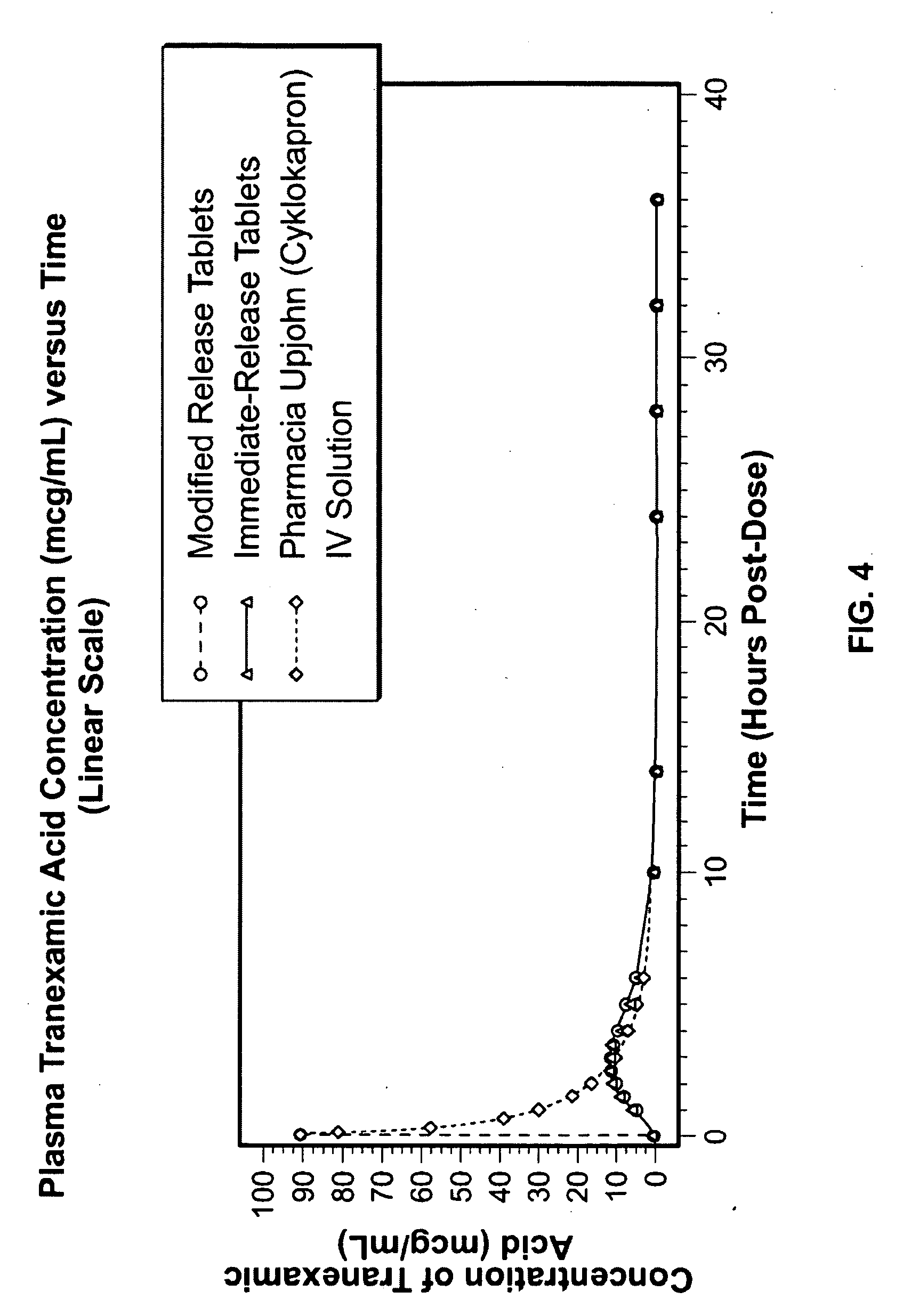

InactiveUS20090017114A1Minimize and eliminate undesirable gastrointestinal side effectMinimize and prevent dissolutionBiocidePowder deliveryIntestinal structureSide effect

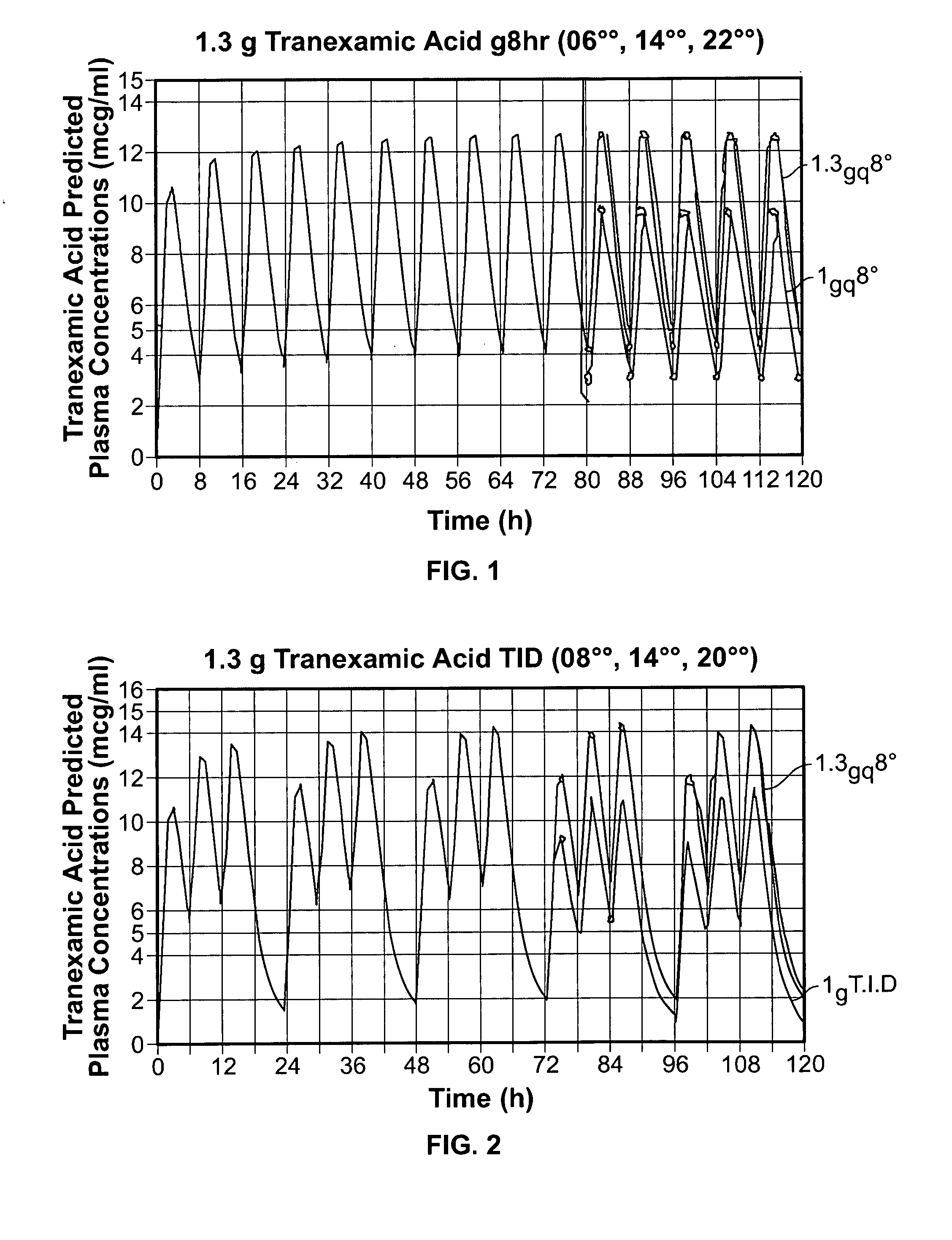

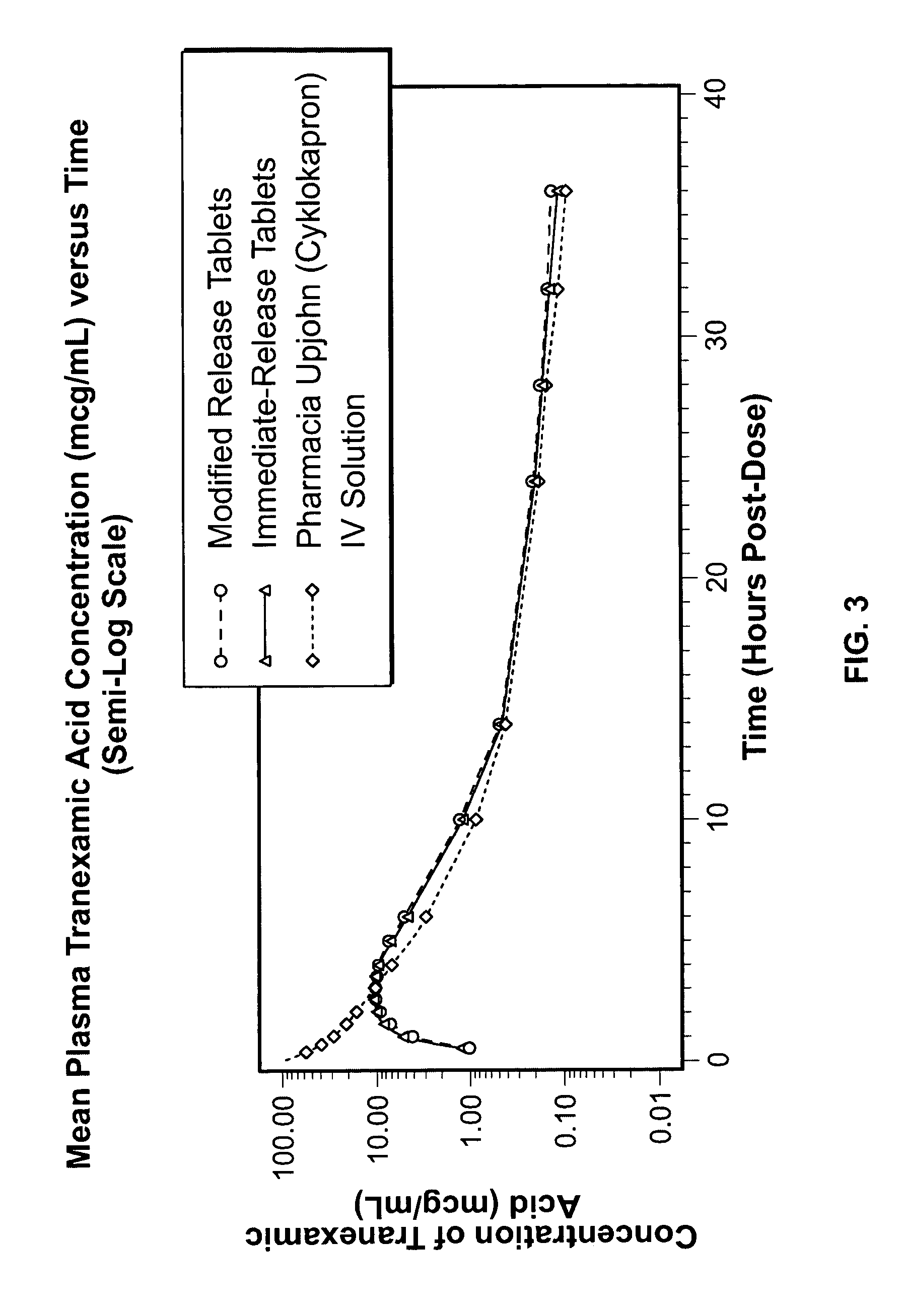

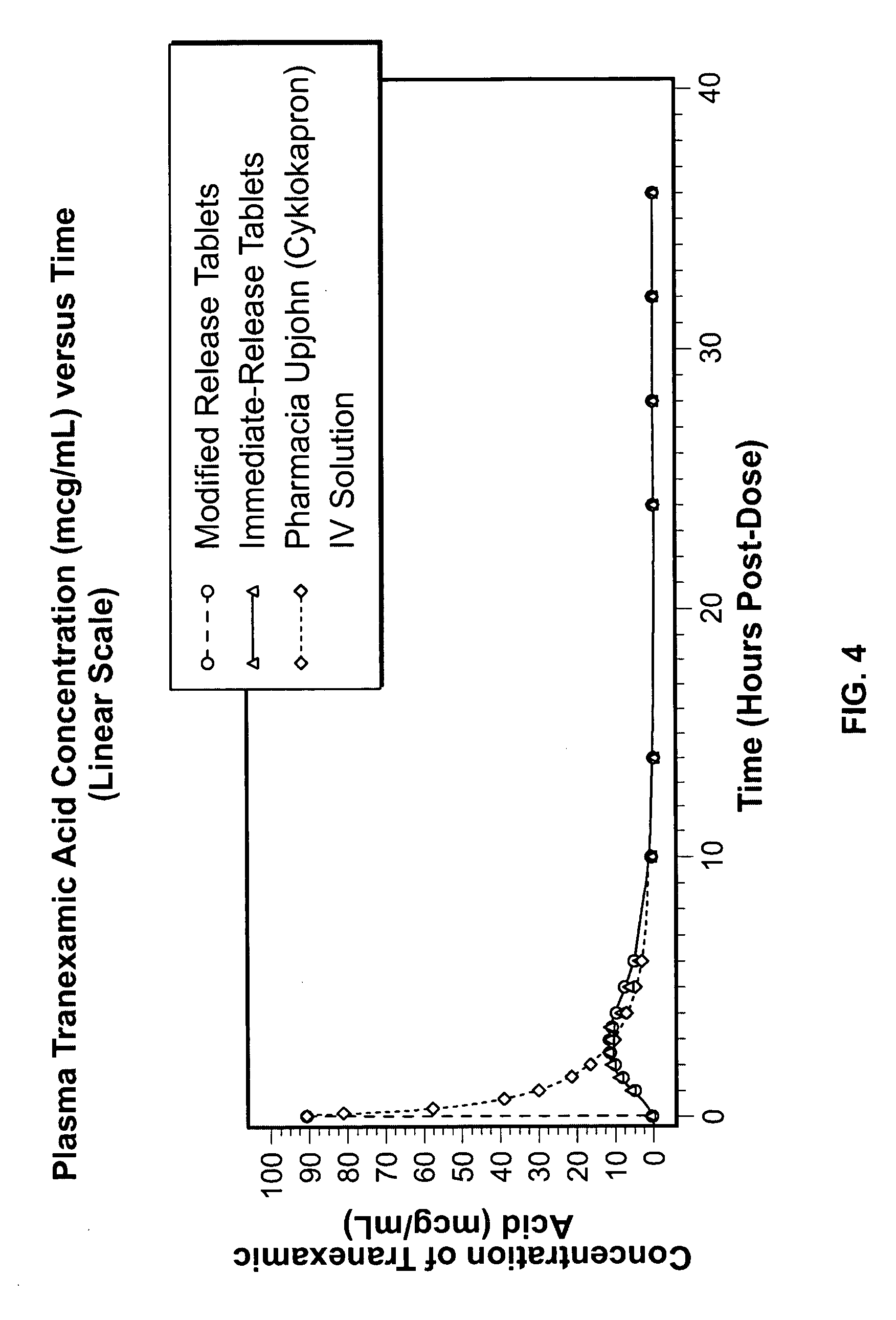

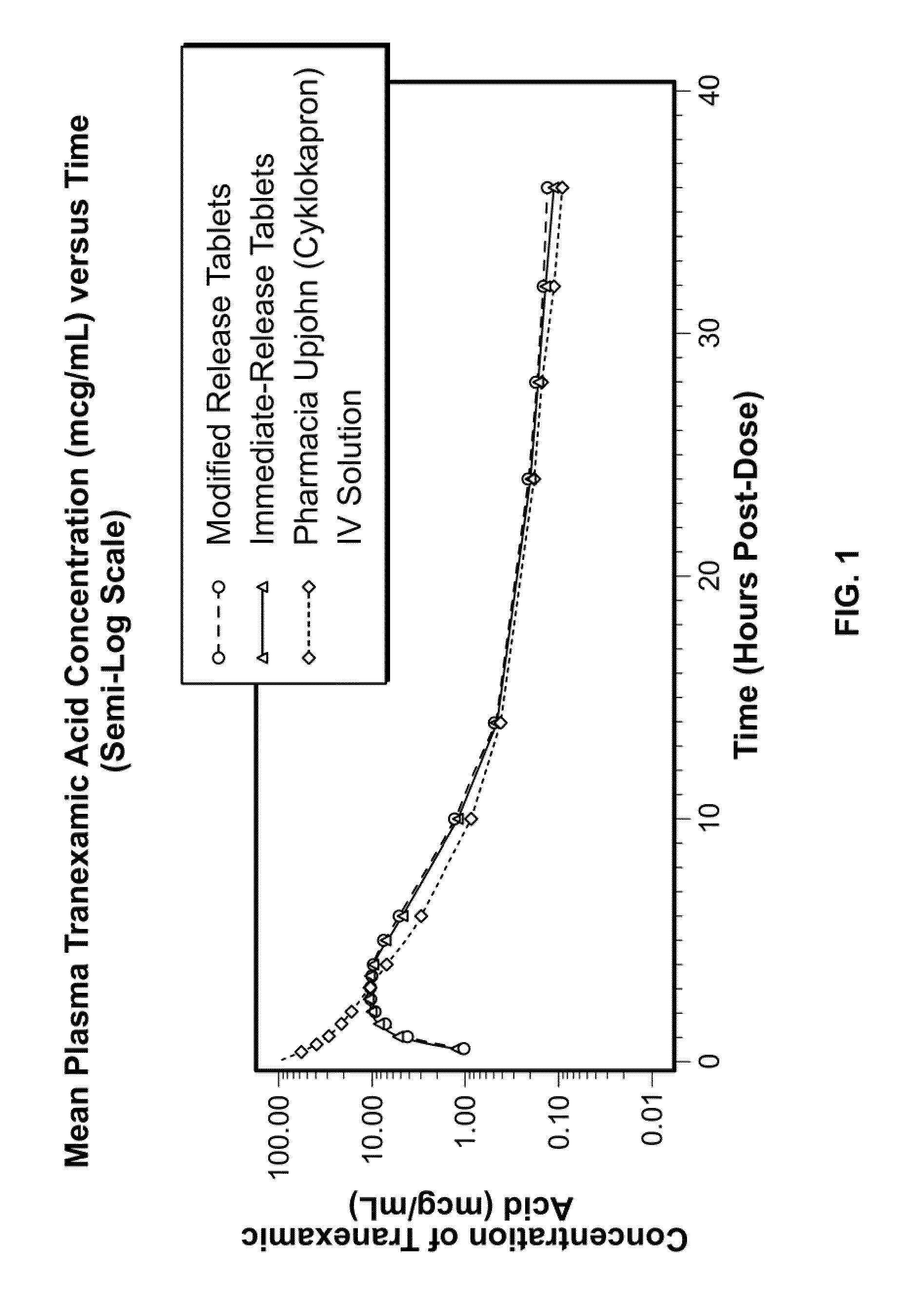

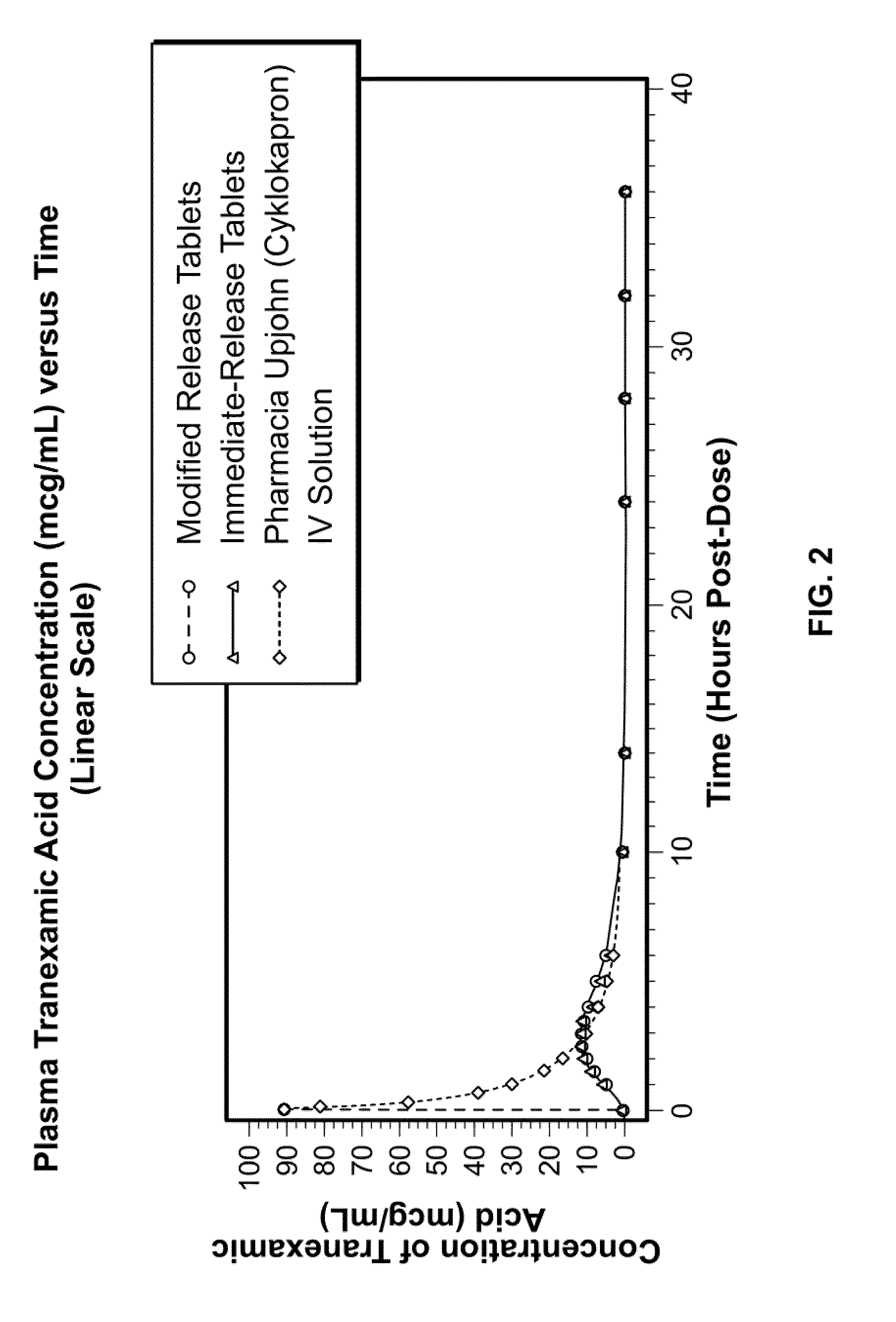

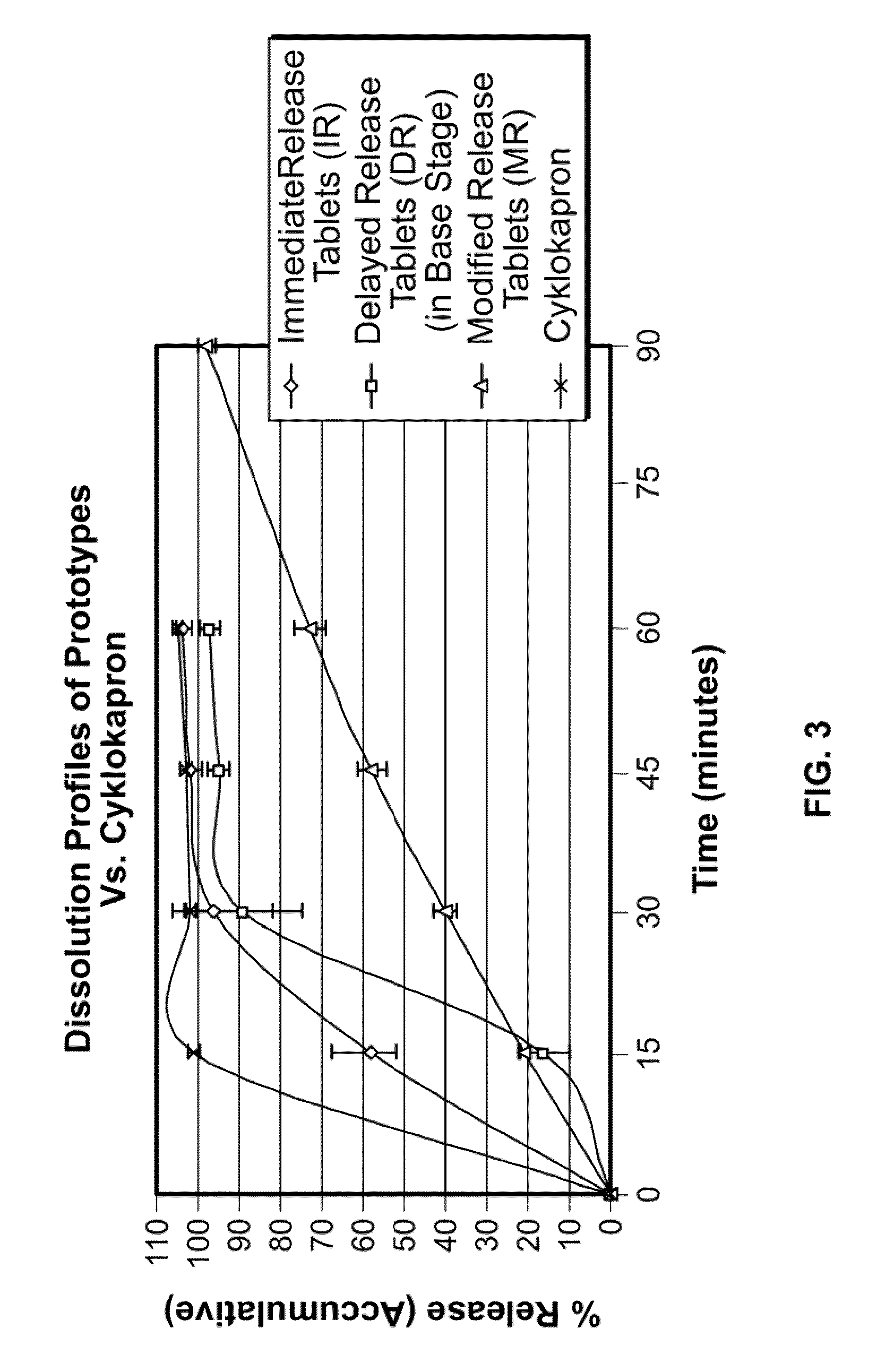

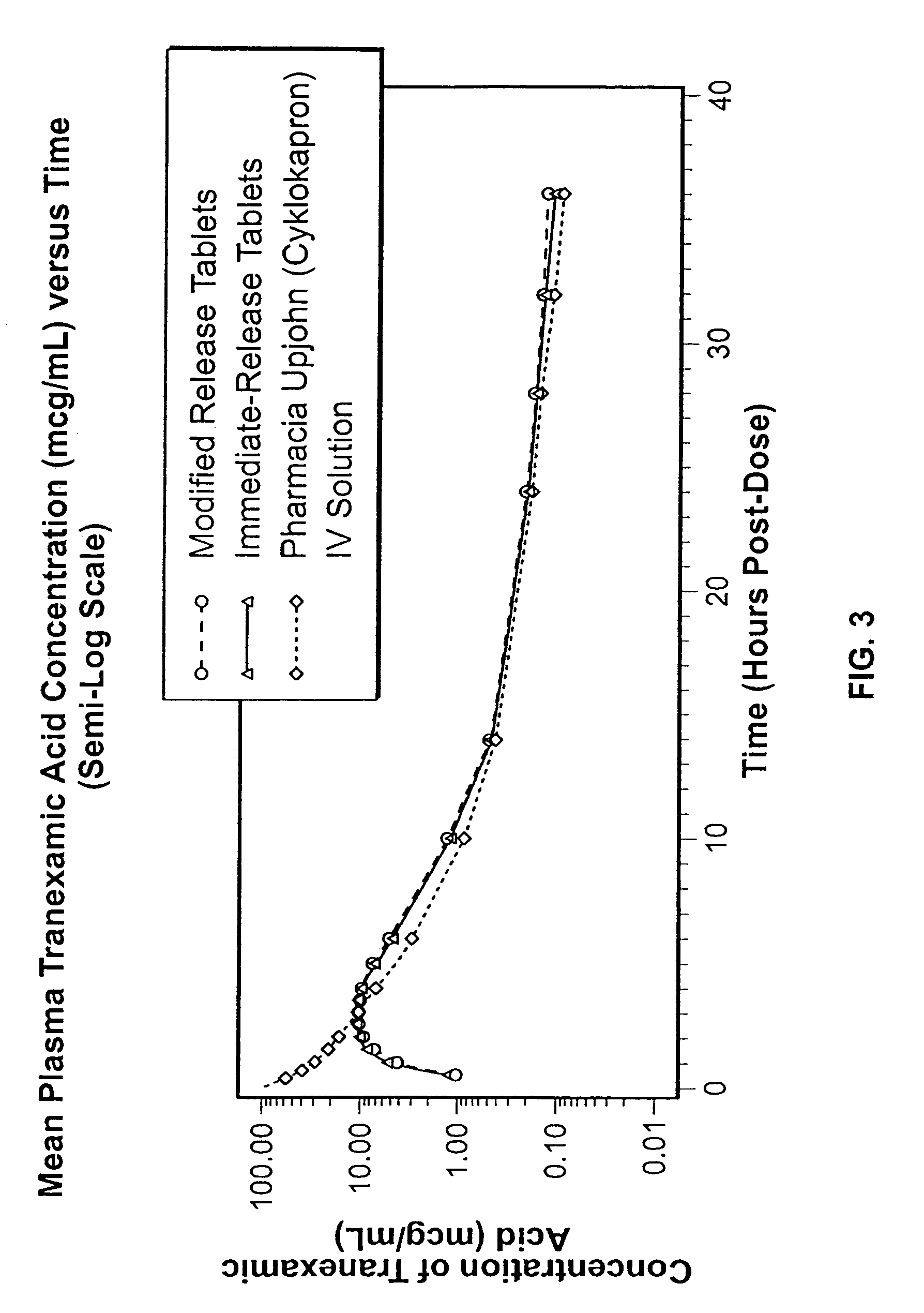

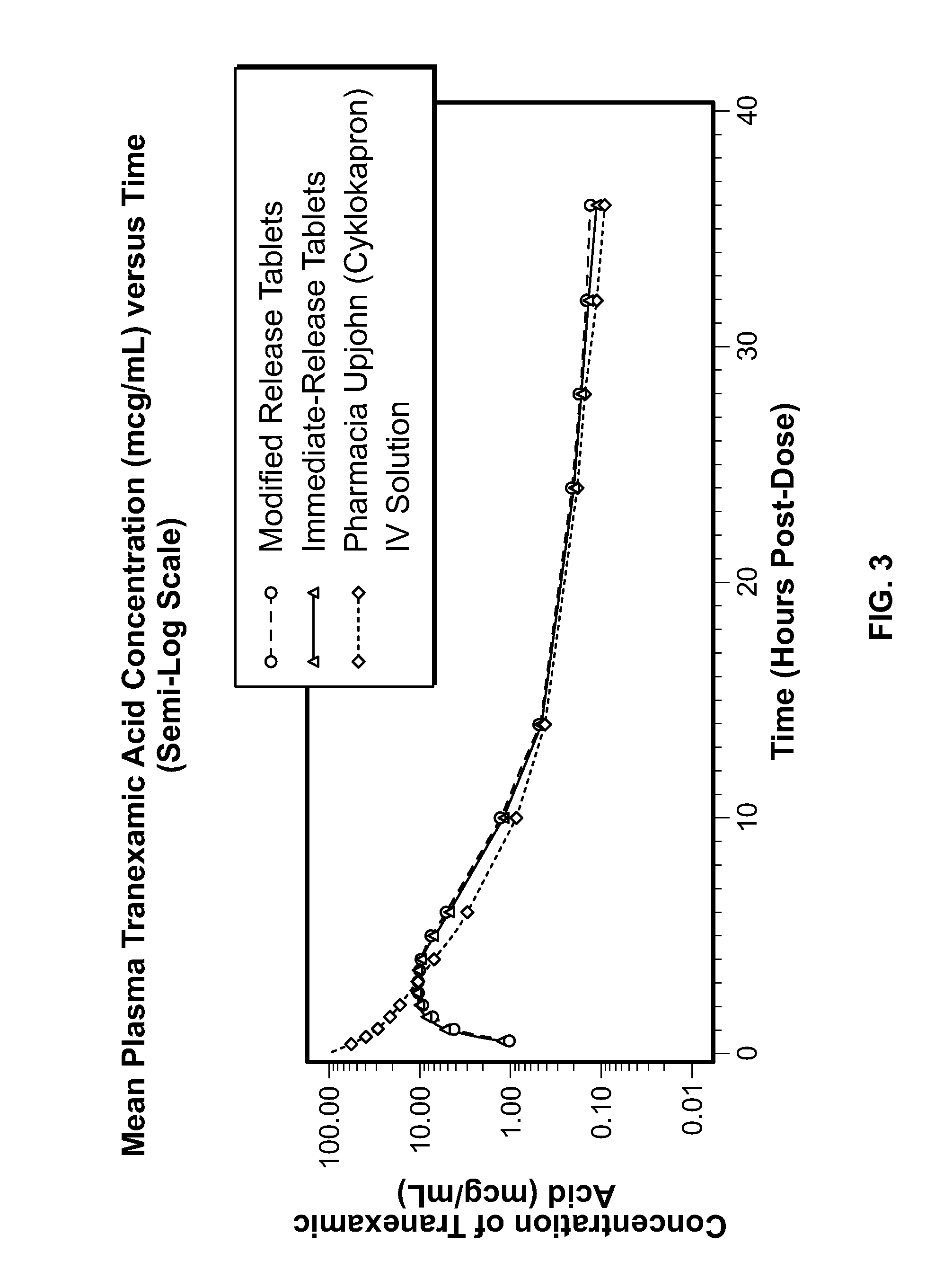

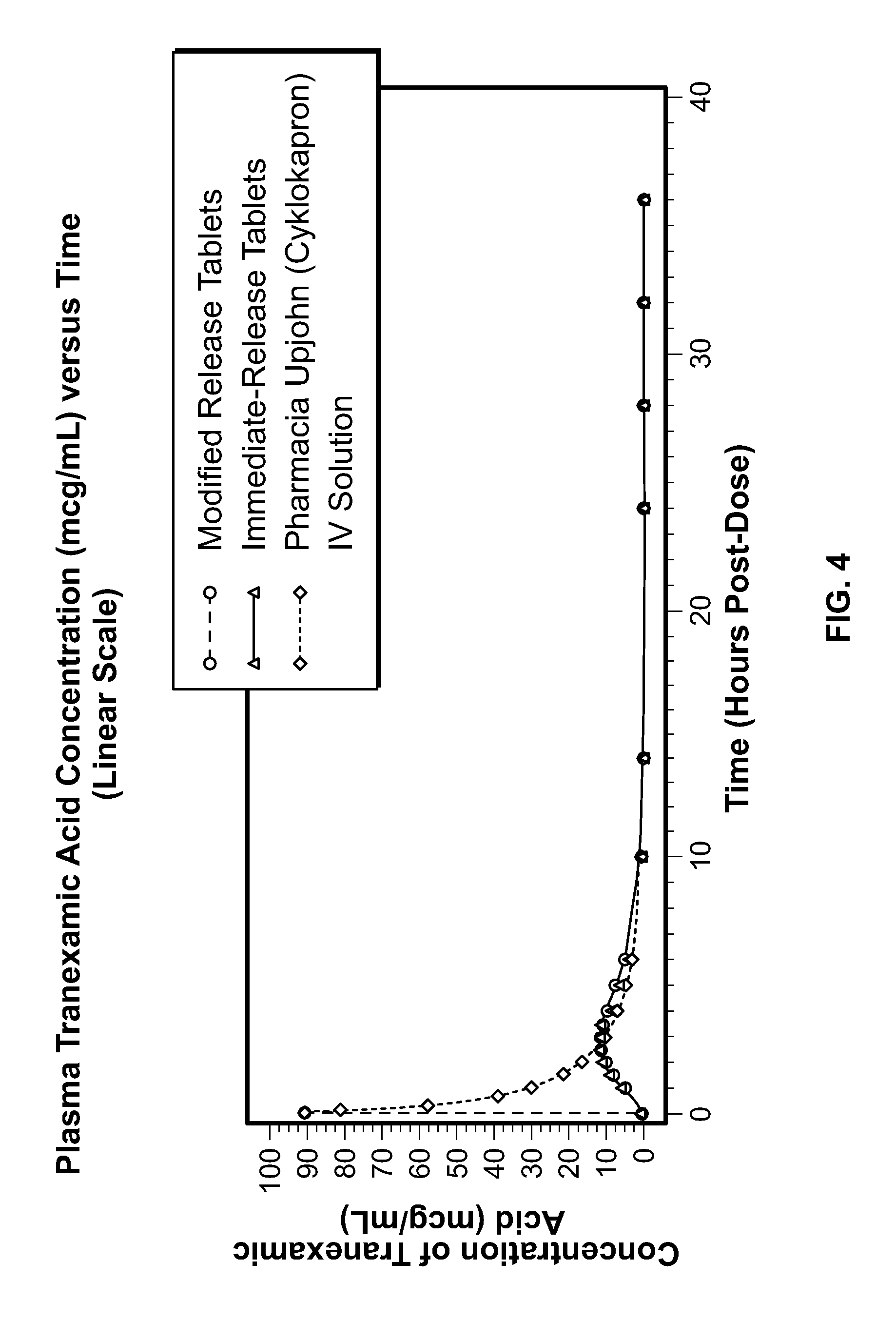

Tranexamic acid formulated in an oral dosage form with at least one agent that decreases tranexamic acid release in the stomach. Such formulations minimize nausea, vomiting, and other adverse gastric effects that may accompany tranexamic acid therapy, for example, to treat heavy menstrual bleeding. One embodiment is an extended release formulation with waxes, polymers, etc. that prevent a bolus release of tranexamic acid in the stomach. An alternative embodiment is a delayed release formulation with polymers that prevent release of tranexamic acid in the acid environment of the stomach and delay its release until the formulation reaches the less acid environment of the intestines. Such formulations enhance patient compliance with therapy because adverse effects of tranexamic acid therapy are reduced.

Owner:FERRING BV

Tranexamic acid formulations with reduced adverse effects

InactiveUS20050025825A1Minimize and eliminate undesirable gastrointestinal side effectMinimize and prevent dissolutionBiocideOrganic active ingredientsIntestinal structureNausea sickness

Tranexamic acid formulated in an oral dosage form with at least one agent that decreases tranexamic acid release in the stomach. Such formulations minimize nausea, vomiting, and other adverse gastric effects that may accompany tranexamic acid therapy, for example, to treat heavy menstrual bleeding. One embodiment is an extended release formulation with waxes, polymers, etc. that prevent a bolus release of tranexamic acid in the stomach. An alternative embodiment is a delayed release formulation with polymers that prevent release of tranexamic acid in the acid environment of the stomach and delay its release until the formulation reaches the less acid environment of the intestines. Such formulations enhance patient compliance with therapy because adverse effects of tranexamic acid therapy are reduced.

Owner:XANODYNE PHARMACEUTICALS INC +1

Bile acid recycling inhibitors for treatment of primary sclerosing cholangitis and inflammatory bowel disease

InactiveUS20140275090A1Reduce erosionExtension of timeBiocideOrganic chemistryApical sodium-dependent bile acid transporterInflammatory bowel disease

Provided herein are methods of treating or ameliorating primary sclerosing cholangitis and inflammatory bowel disease by administering to an individual in need thereof a therapeutically effective amount of an Apical Sodium-dependent Bile Acid Transporter Inhibitor (ASBTI) or a pharmaceutically acceptable salt thereof. Also provided are methods for treating or ameliorating primary sclerosing cholangitis comprising administering to an individual in need thereof a therapeutically effective amount of ASBTI or a pharmaceutically acceptable salt thereof.

Owner:LUMENA PHARMA INC

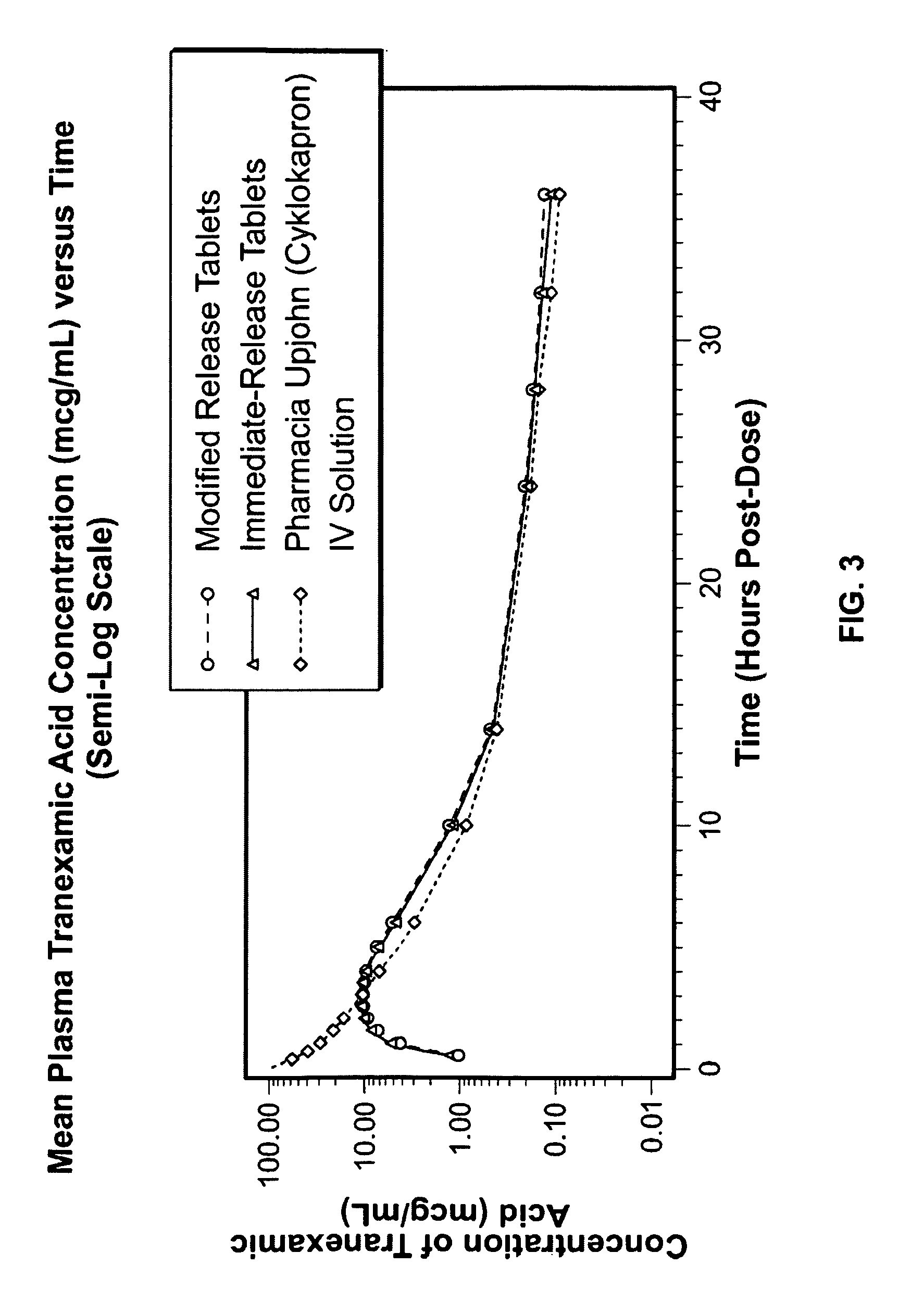

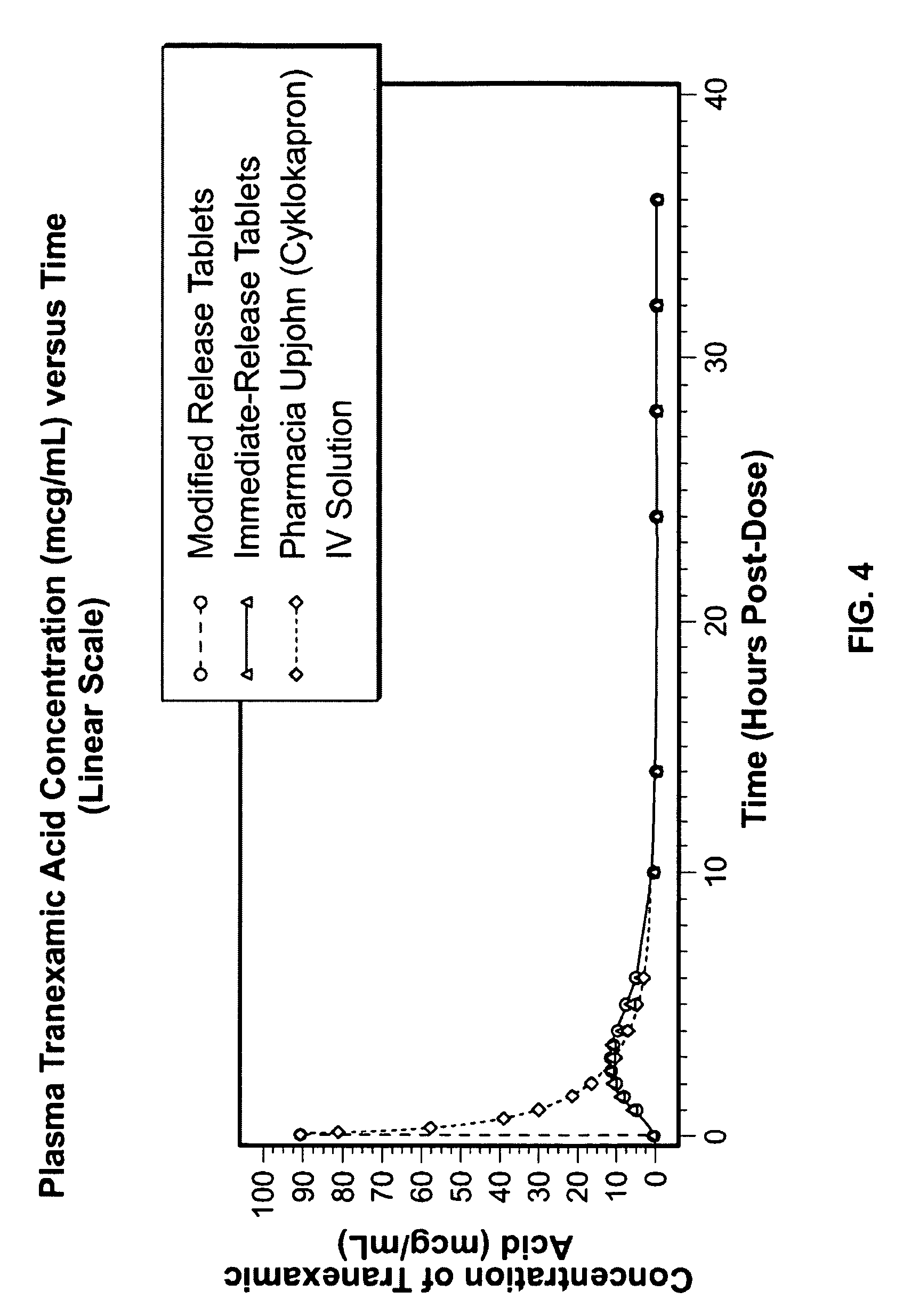

Tranexamic acid formulations

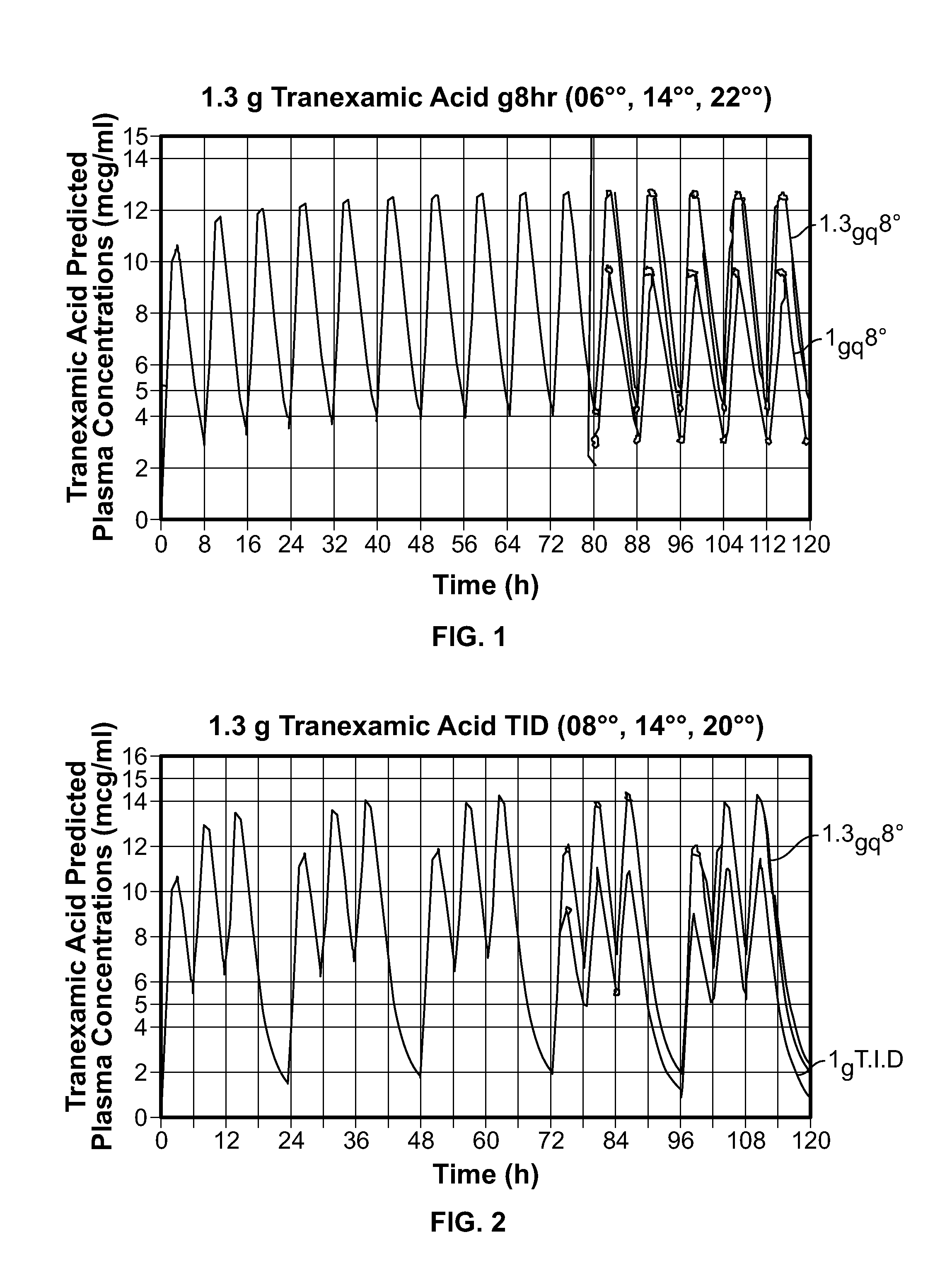

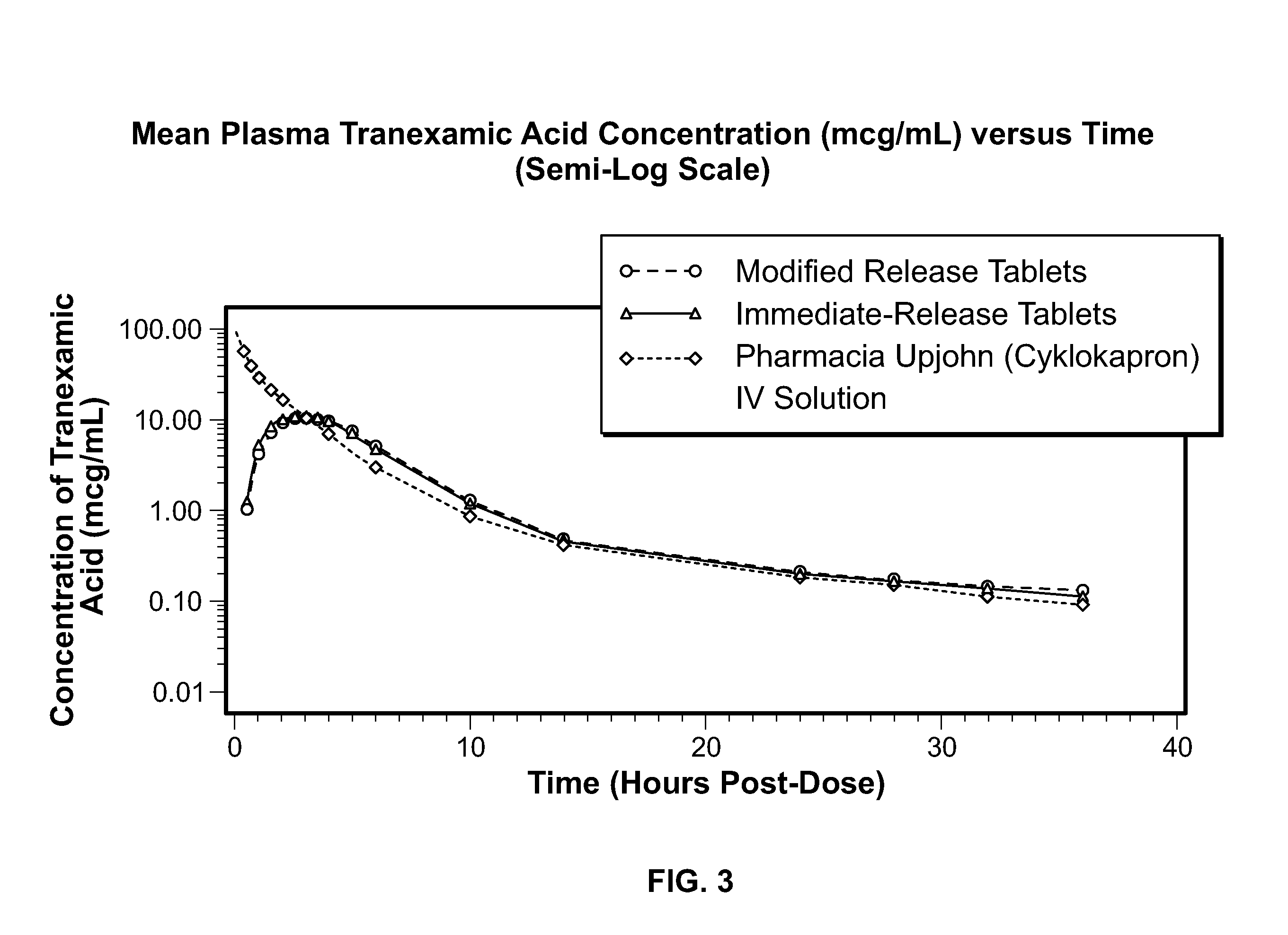

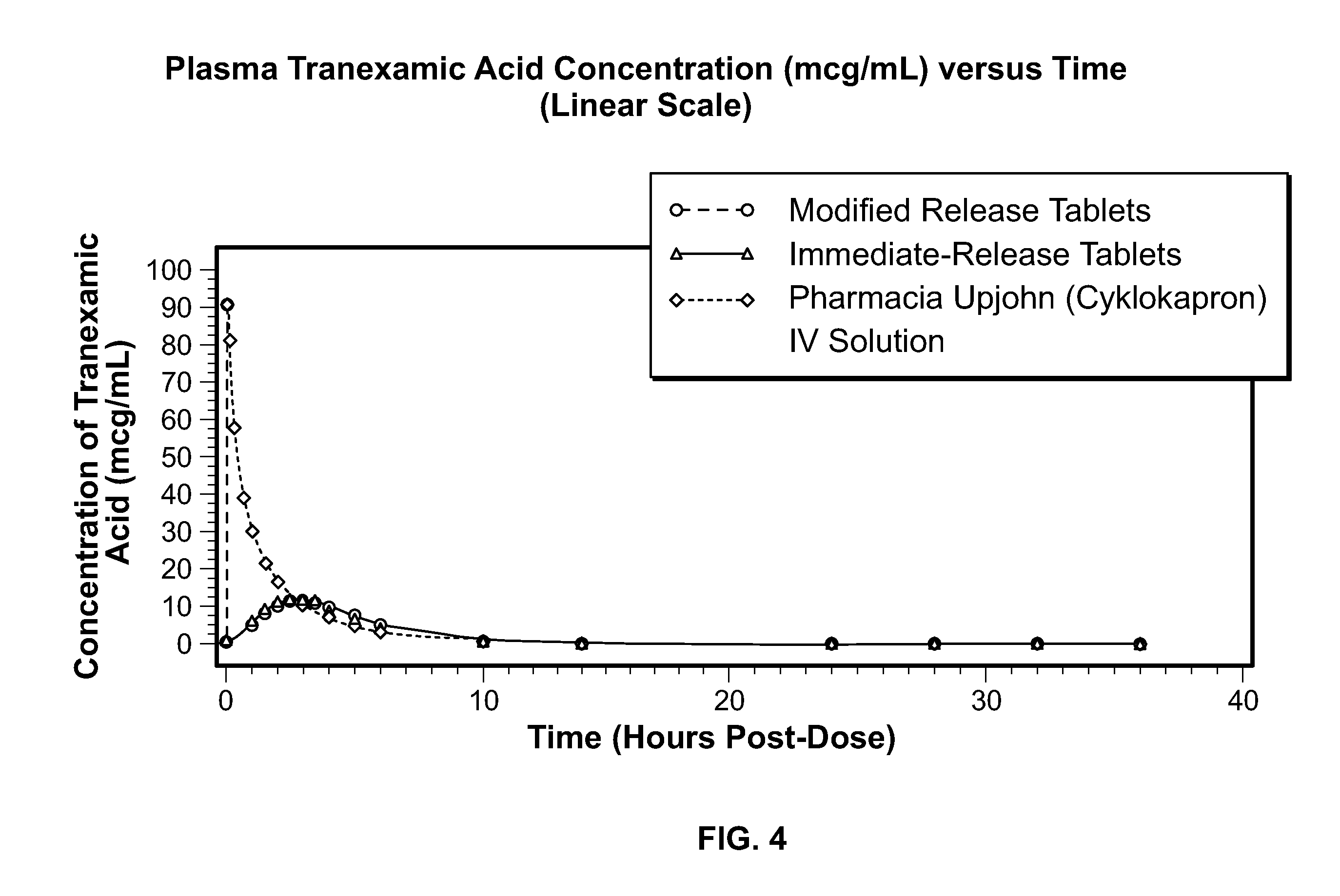

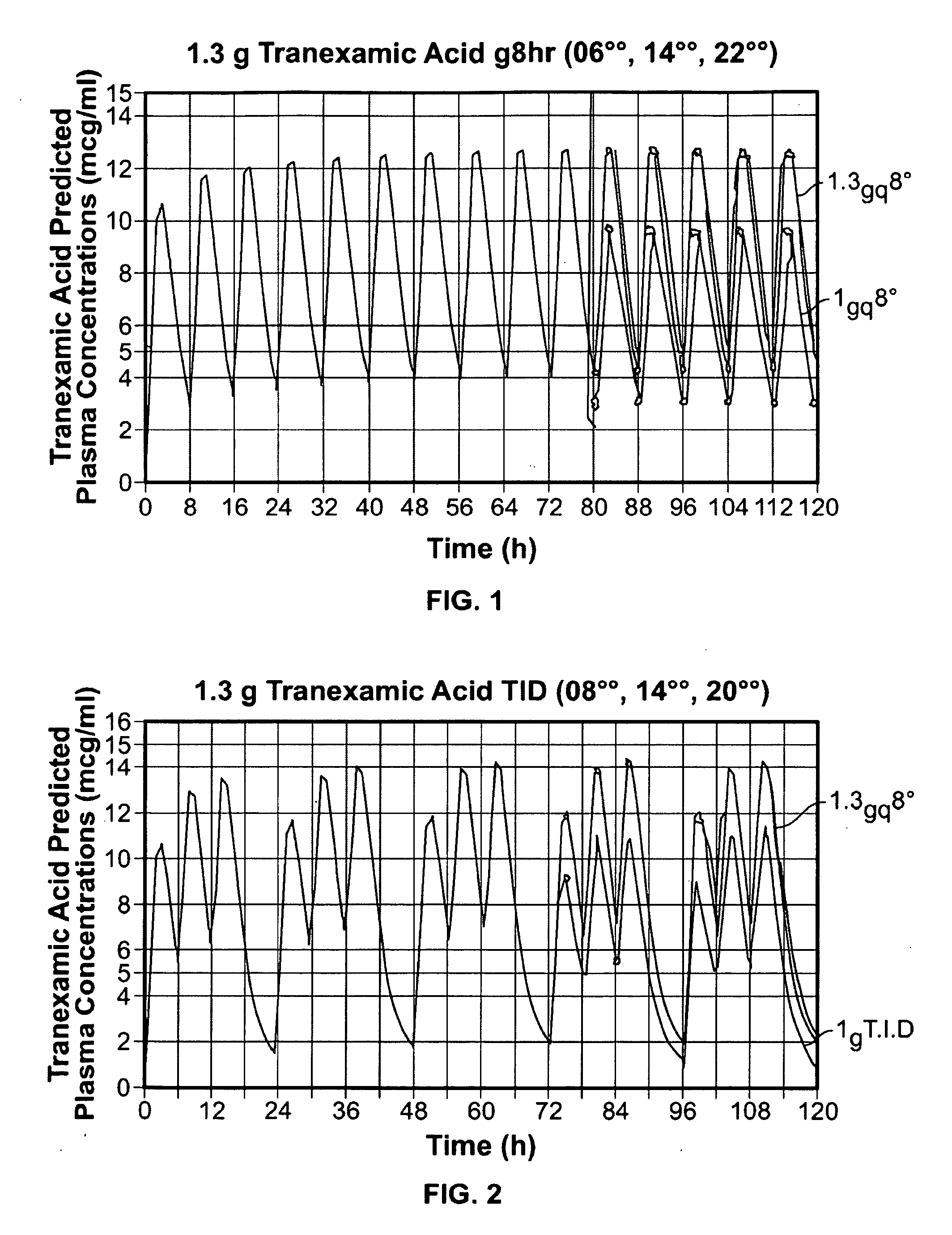

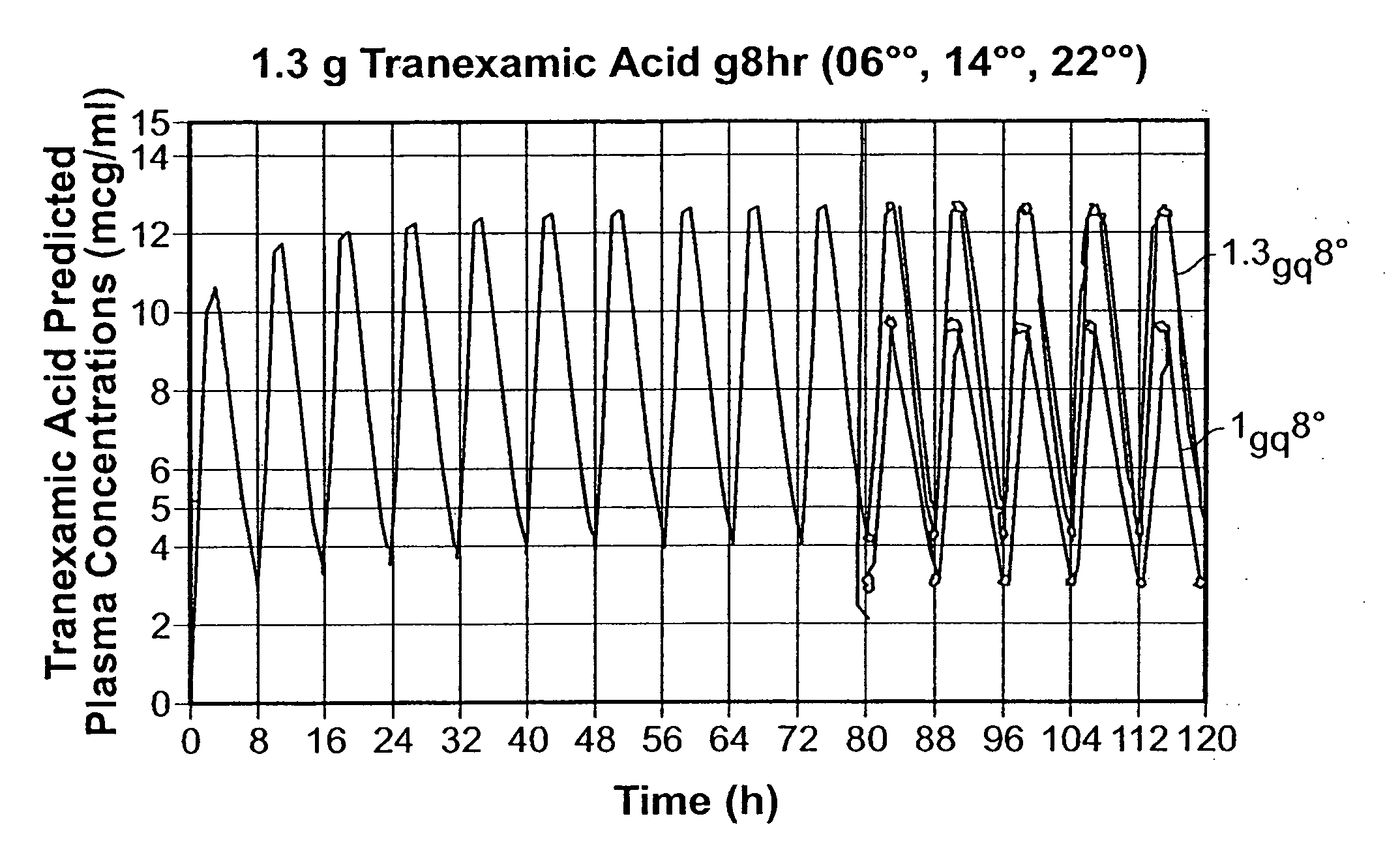

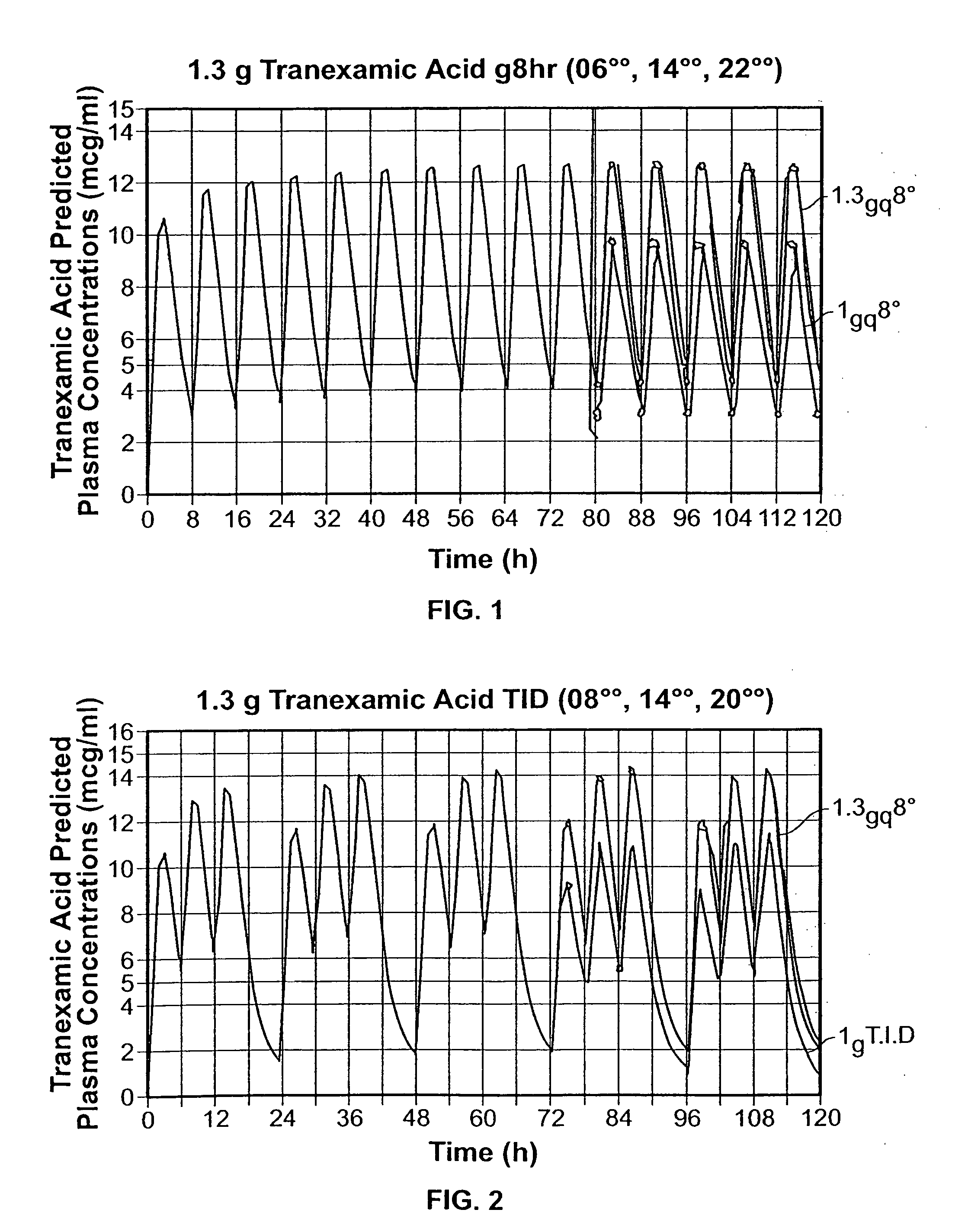

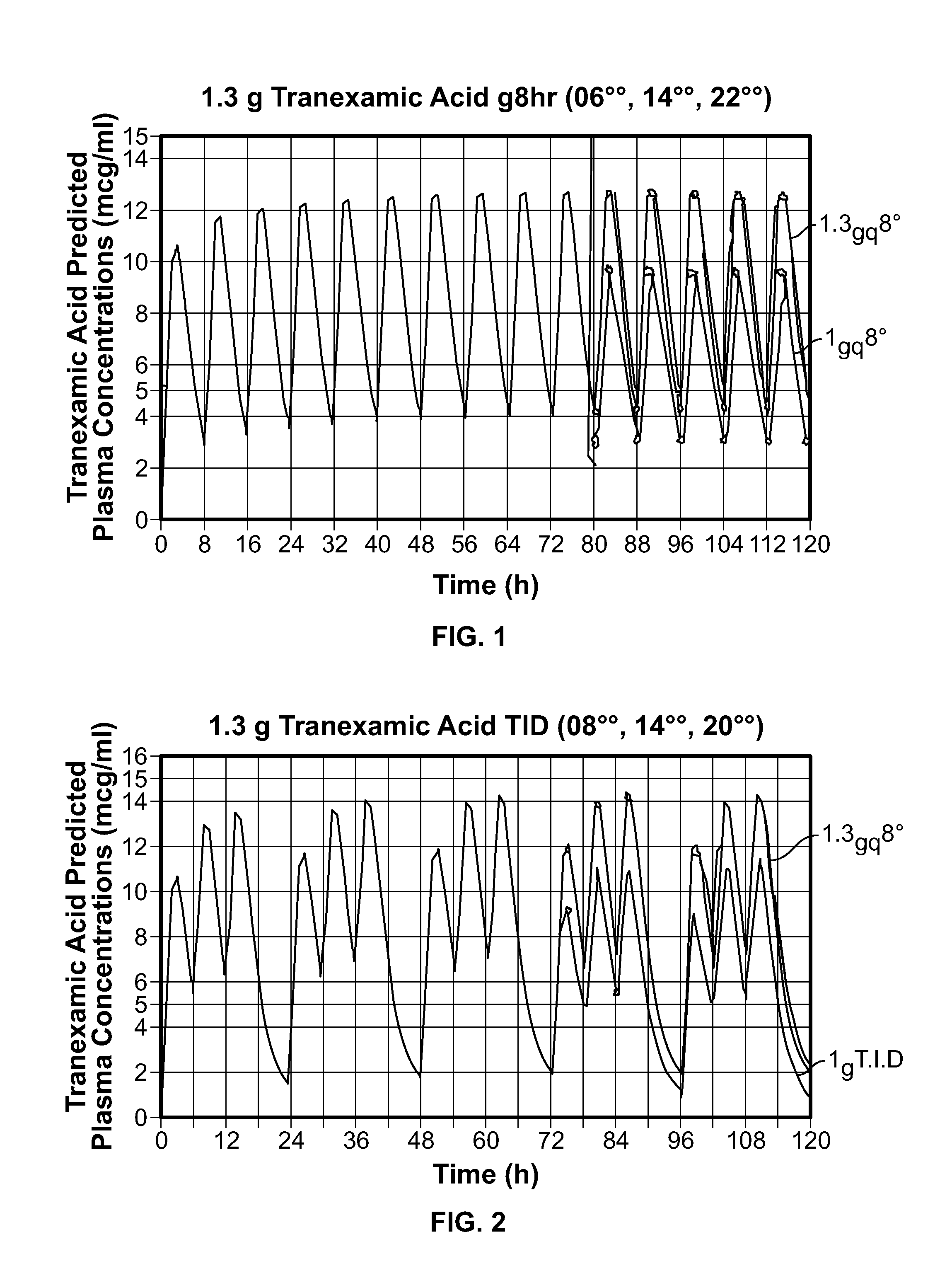

InactiveUS20050244495A1Minimize and eliminate undesirable gastrointestinal side effectReduce concentrationBiocidePill deliveryTranexamic acidPharmacology

Disclosed are modified release oral tranexamic acid formulations and methods of treatment therewith.

Owner:AMRING PHARM INC +1

Tranexamic acid formulations with reduced adverse effects

InactiveUS20090214644A1Minimize and eliminate undesirable gastrointestinal side effectMinimize and prevent dissolutionBiocideOrganic active ingredientsTranexamic acidAdverse effect

Owner:FERRING BV

Tranexamic Acid Formulations

ActiveUS20100143468A1Minimize and eliminate undesirable gastrointestinal side effectReduce concentrationBiocideNervous disorderTranexamic acidPharmacology

Disclosed are modified release oral tranexamic acid formulations and methods of treatment therewith.

Owner:AMRING PHARM INC

Tranexamic acid formulations

ActiveUS20090209646A1Minimize and eliminate undesirable gastrointestinal side effectReduce concentrationBiocidePeptide/protein ingredientsTranexamic acidPharmacology

Disclosed are modified release oral tranexamic acid formulations and methods of treatment therewith.

Owner:AMRING PHARM INC

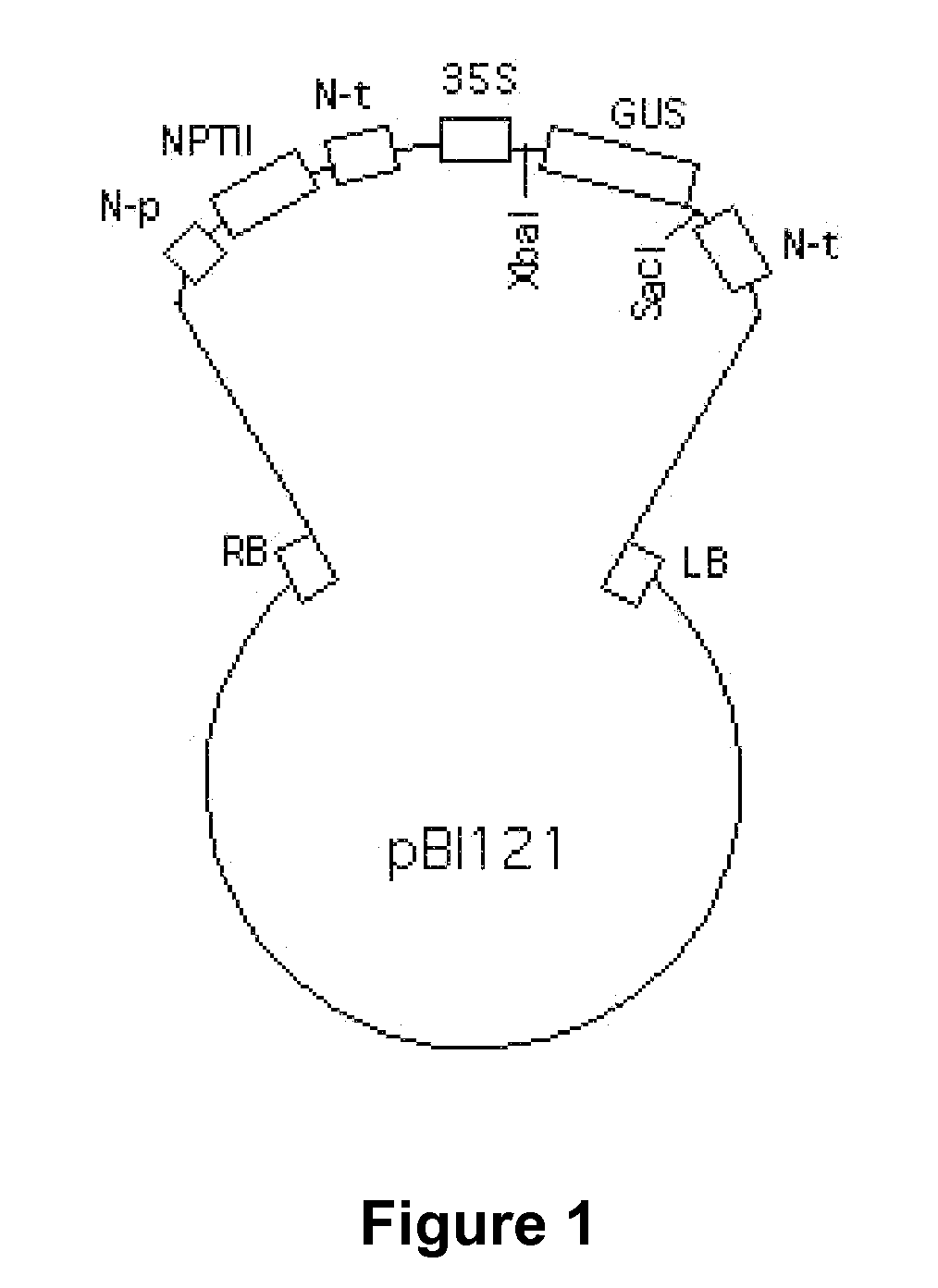

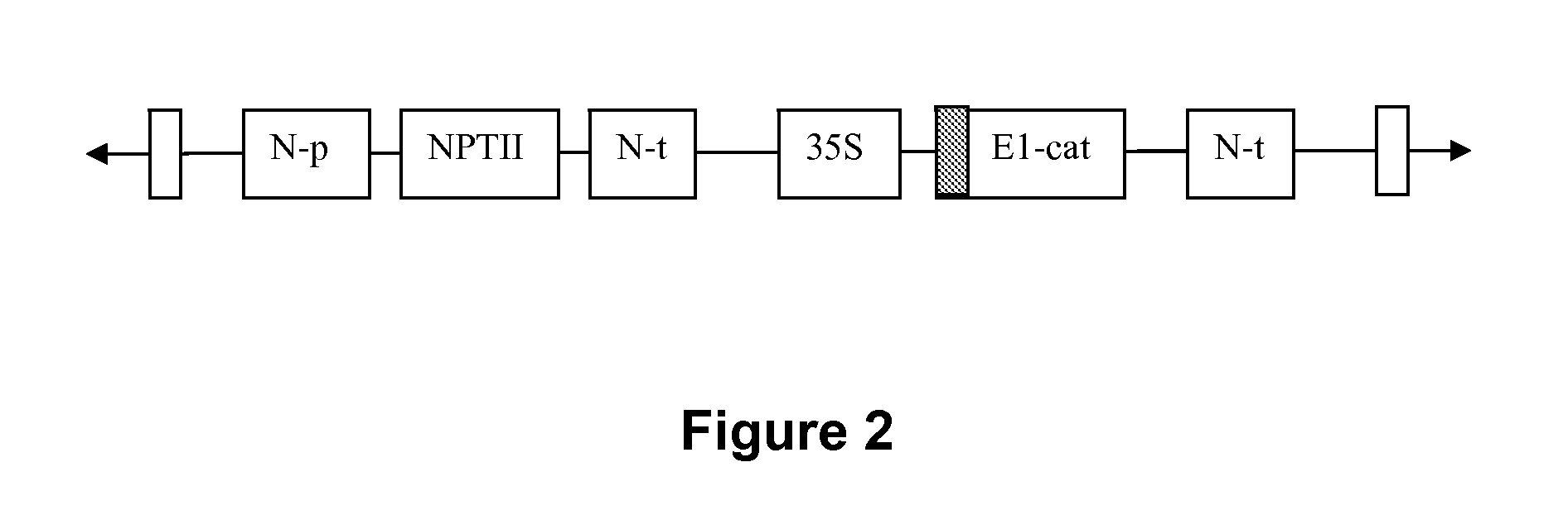

Processing cellulosic biomass

InactiveUS20120040408A1Reduce processShort timeClimate change adaptationBiofuelsDownstream processingLignocellulosic biomass

Improved systems and methods for reducing costs and increasing yields of cellulosic ethanol are disclosed herein, along with plants genetically transformed for increased biomass, expression of lignocellulolytic enzyme polypeptides, and / or simplification of harvesting and downstream processing. Methods for processing biomass from these transgenic plants that involve less severe and / or less expensive pre-treatment protocols than are typically employed are also disclosed.

Owner:EDENSPACE SYST CORP +1

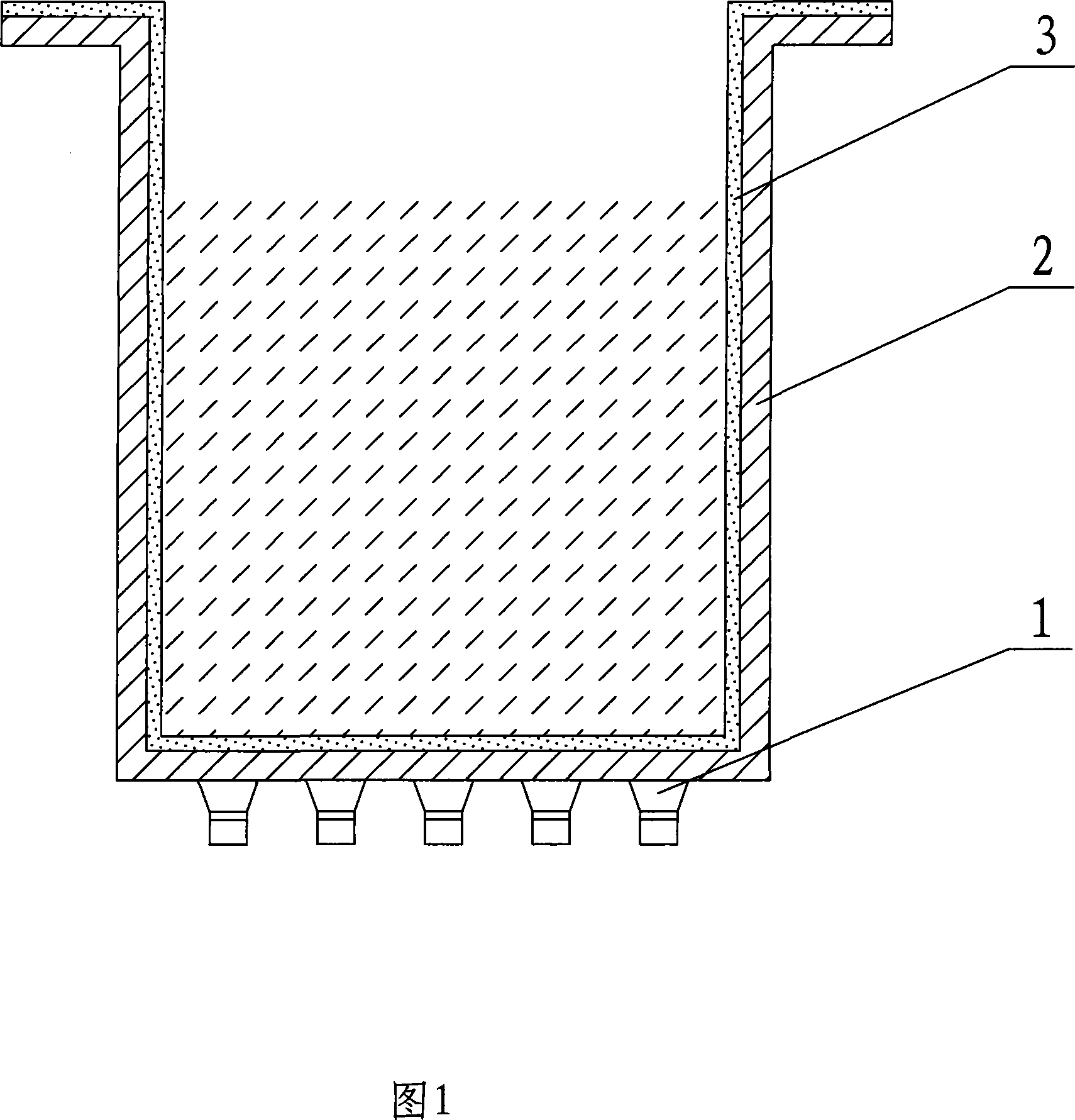

Ultrasonic cleaning groove and its processing method

InactiveCN101121170ALow acid concentrationReduce pollutionLiquid surface applicatorsFouling preventionAbrasive blastingUltrasonic sensor

The present invention discloses an ultrasonic cleaning tank comprising an ultrasonic transducer and a stainless steel reservoir; the reservoir wall thickness is between 1to 3 mm and the internal surface of the reservoir is blasted with grits; the internal surface of the reservoir with certain harshness is sprayed with a polytetrafluoroethylene layer and the polytetrafluoroethylene layer thickness is between 0.1 to 0.4 mm; the processing method is that the internal surface of the stainless steel reservoir is blasted with grits to make the surface harsh; after the internal surface is cleaned, at least twice polytetrafluoroethylene static sprayings are implemented on the internal surface of the reservoir; the coating of the cleaning tank surface is dense and the coating is closely combined with the reservoir to prevent the reservoir from being corroded by strong acid and have excellent abrasion resistant function; the ultrasonic conduction rate is high and the acid concentration of the cleaning liquid can be reduced which reduces the environmental pollution and effectively prolongs the service life of the cleaning device.

Owner:ZHANGJIAGANG ULTRASONIC & ELECTRIC

Tranexamic acid formulations with reduced adverse effects

ActiveUS20060127476A1Minimize and eliminate undesirable gastrointestinal side effectMinimize and prevent dissolutionBiocidePeptide/protein ingredientsNausea sicknessPatient compliance

Tranexamic acid formulated in an oral dosage form with at least one agent that decreases tranexamic acid release in the stomach. Such formulations minimize nausea, vomiting, and other adverse gastric effects that may accompany tranexamic acid therapy, for example, to treat heavy menstrual bleeding. One embodiment is an extended release formulation with waxes, polymers, etc. that prevent a bolus release of tranexamic acid in the stomach. An alternative embodiment is a delayed release formulation with polymers that prevent release of tranexamic acid in the acid environment of the stomach and delay its release until the formulation reaches the less acid environment of the intestines. Such formulations enhance patient compliance with therapy because adverse effects of tranexamic acid therapy are reduced.

Owner:AMRING PHARM INC

Tranexamic acid formulations

ActiveUS20090048341A1Minimize and eliminate undesirable gastrointestinal side effectReduce concentrationBiocidePeptide/protein ingredientsTranexamic acidPharmacology

Disclosed are modified release oral tranexamic acid formulations and methods of treatment therewith.

Owner:AMRING PHARM INC

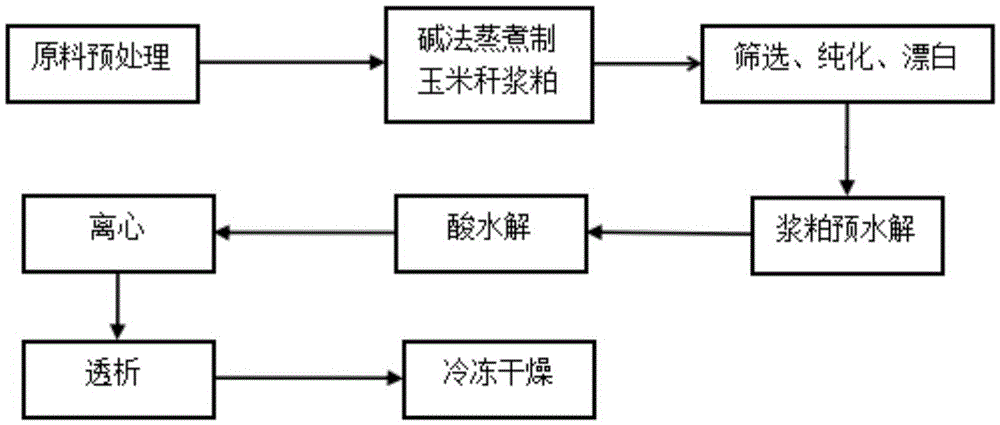

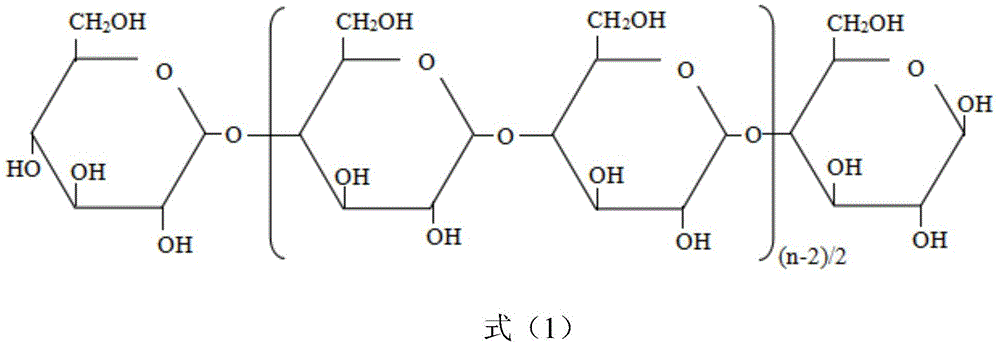

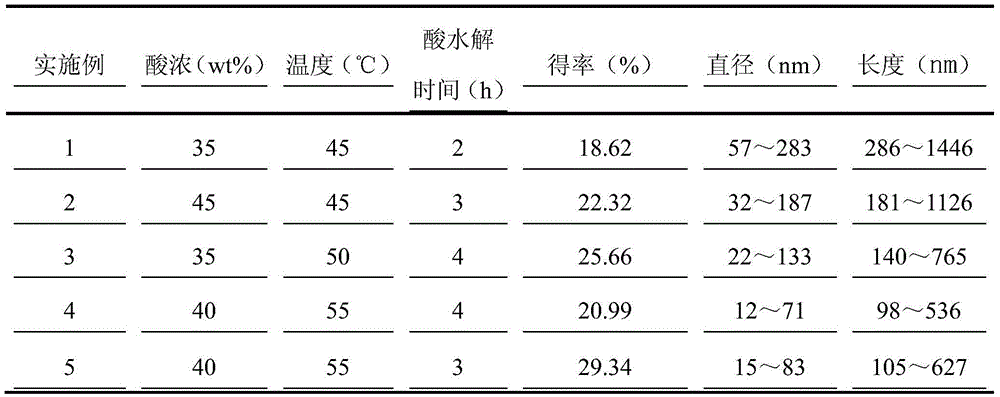

Cornstalk nanocellulose whiskers and preparation method and application thereof

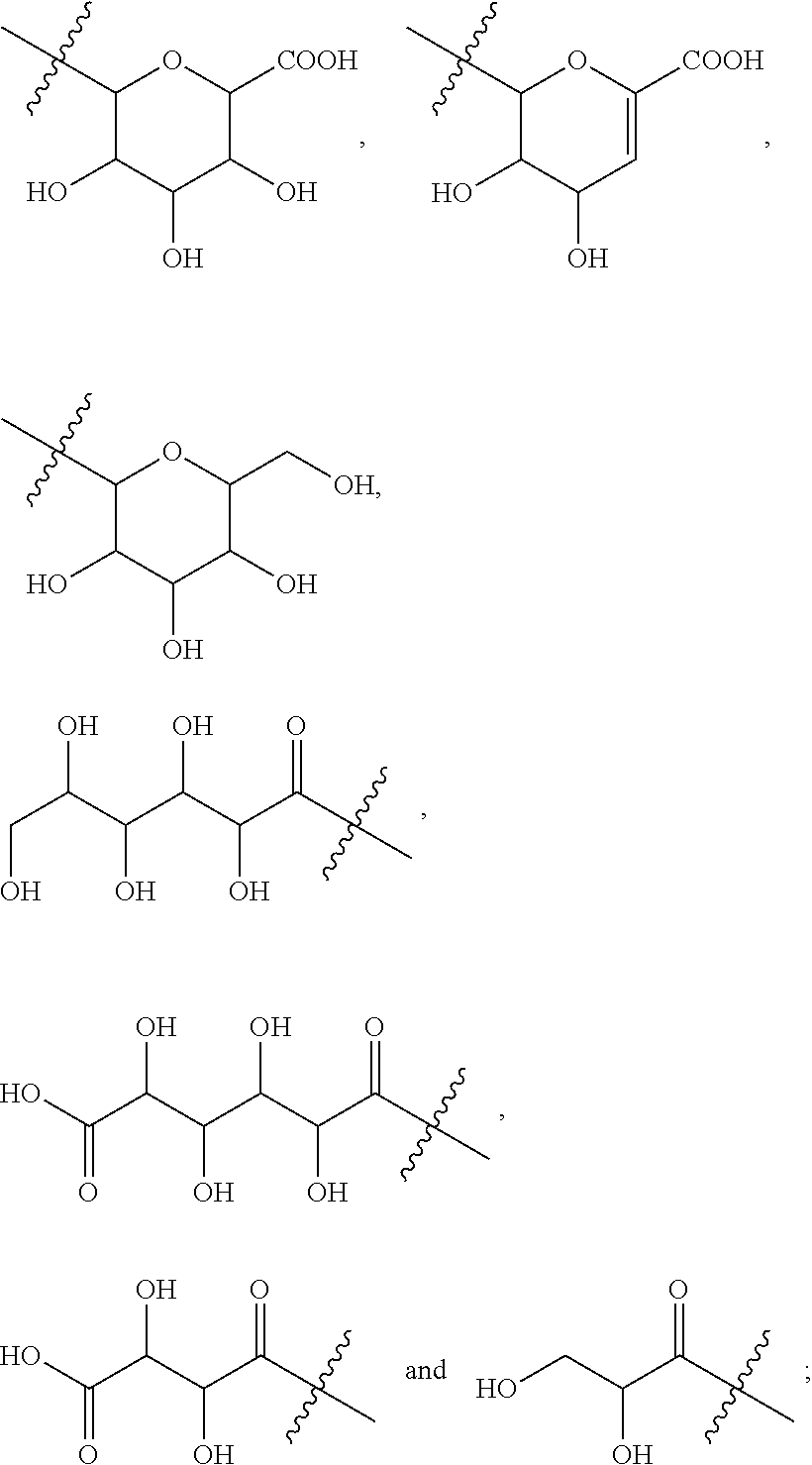

InactiveCN105568744AFully run upReduce the degree of polymerizationNon-woody plant/crop pulpFiberAcid hydrolysis

The invention belongs to the field of high polymer materials and particularly discloses cornstalk nanocellulose whiskers and a preparation method and application thereof. The molecular chain structural formula of the cornstalk nanocellulose whiskers is shown as in the described formula (1), wherein n is a natural number less than 200, and the molecular weight of cornstalk nanocellulose is 10000-30000. The preparation method of the cornstalk nanocellulose whiskers is simple, and high-temperature high-pressure hydrolysis pretreatment is adopted for full fibering; compared with acid or alkaline pretreatment in other nanocellulose preparation methods, the pretreatment method has the advantages that chemicals in the pretreatment process are saved, difficulty in treatment of waste fluid in the pretreatment process is lowered, and further acid concentration of subsequent acid hydrolysis cellulose can be lowered.

Owner:SOUTH CHINA UNIV OF TECH

Foam plug flow diverting acidification technique

InactiveCN101126314AIncrease carrying capacityIncrease in sizeFluid removalCarrying capacityNitrogen

The invention provides a foam plug diversion and acidification technology. The method is that: a high permeable layer is temporality blocked by injecting foam plug and utilizing the diversion ability of the foamed fluid, then the acid liquid is converted to a low permeable layer and then the uniform acidification with different permeability is realized and thus, the acid-soluble blockage of the reservoir is effectively solved; at the same time, the high carrying capacity of the foamed fluid and the expansion of the nitrogen can back-drain the acidified solid particles and the residual acid, which can decrease the secondary injury. The invention is especially suitable for solving the acid-soluble injury of the heterogeneous stratum.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Tranexamic acid formulations

ActiveUS8273795B2Minimize and eliminate undesirable gastrointestinal side effectReduce concentrationBiocidePeptide/protein ingredientsPharmacologyTranhexamic acid

Disclosed are modified release oral tranexamic acid formulations and methods of treatment therewith.

Owner:AMRING PHARM INC

Tranexamic acid formulations

ActiveUS7947739B2Minimize and eliminate undesirable gastrointestinal side effectReduce concentrationBiocideNervous disorderTranexamic acidPharmacology

Disclosed are modified release oral tranexamic acid formulations and methods of treatment therewith.

Owner:AMRING PHARM INC

Aluminum Alloy Hard Anodic Oxidation Film and Its Process Method

InactiveCN102286766AImprove performanceHigh hardnessSurface reaction electrolytic coatingHigh current densityHardness

The invention relates to an aluminum alloy hard anodized film and a process method thereof. After degreasing and degreasing, the surface of the aluminum alloy workpiece is shot peened with clean stainless steel shot, and then hard anodized in an electrolyte with low sulfuric acid concentration, and hard anodized with low current density and then high current density The hard oxide film is obtained after treatment, the thickness of the oxide film is 340-374 μm, and the hardness is high, the film layer is dense, and it is beneficial to environmental protection and cost reduction.

Owner:XIHUA UNIV

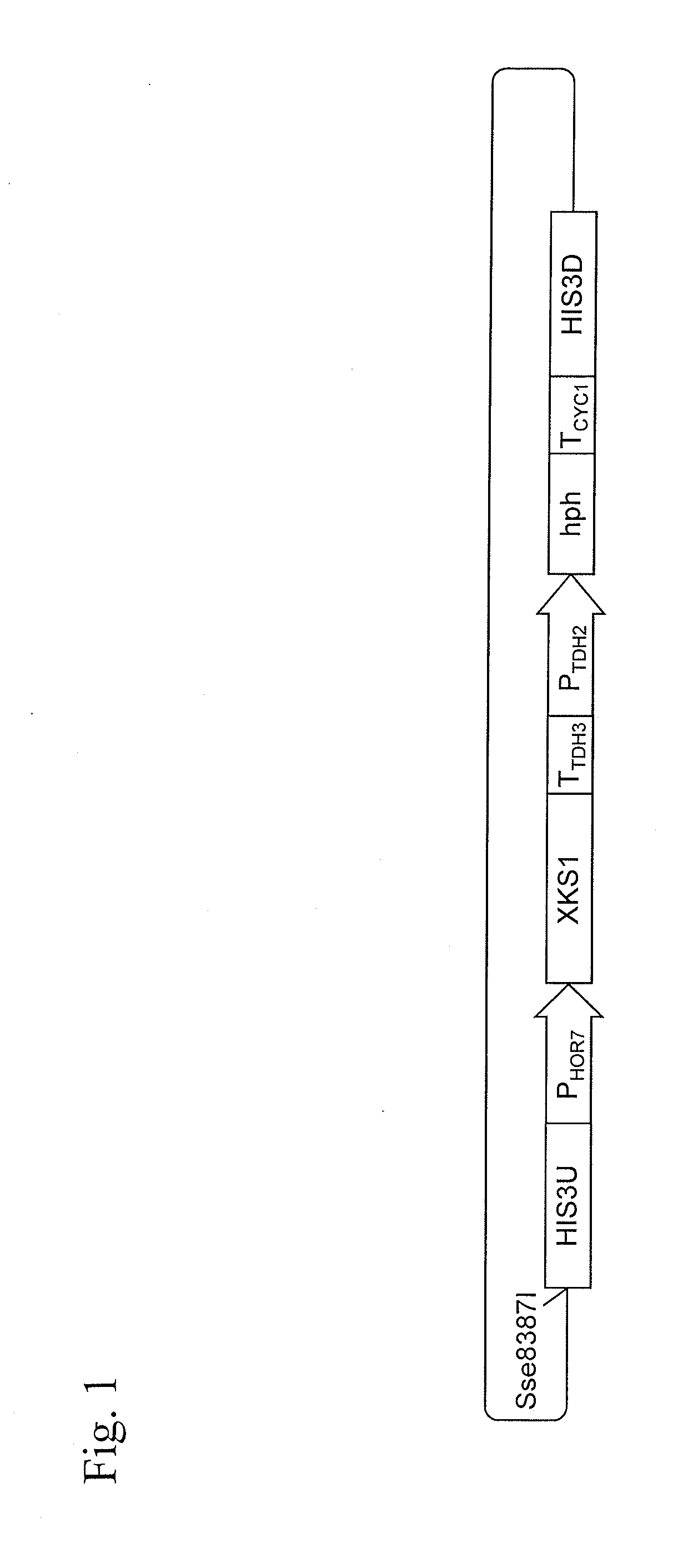

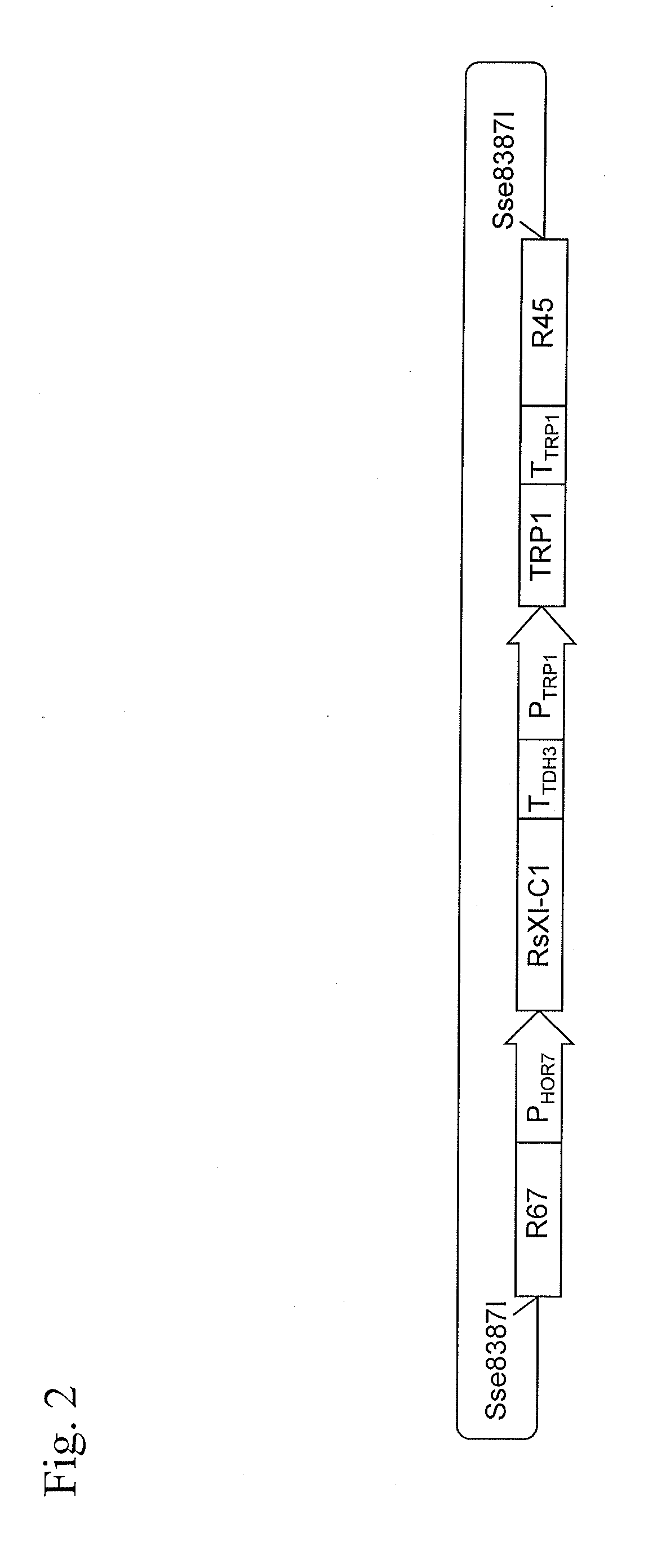

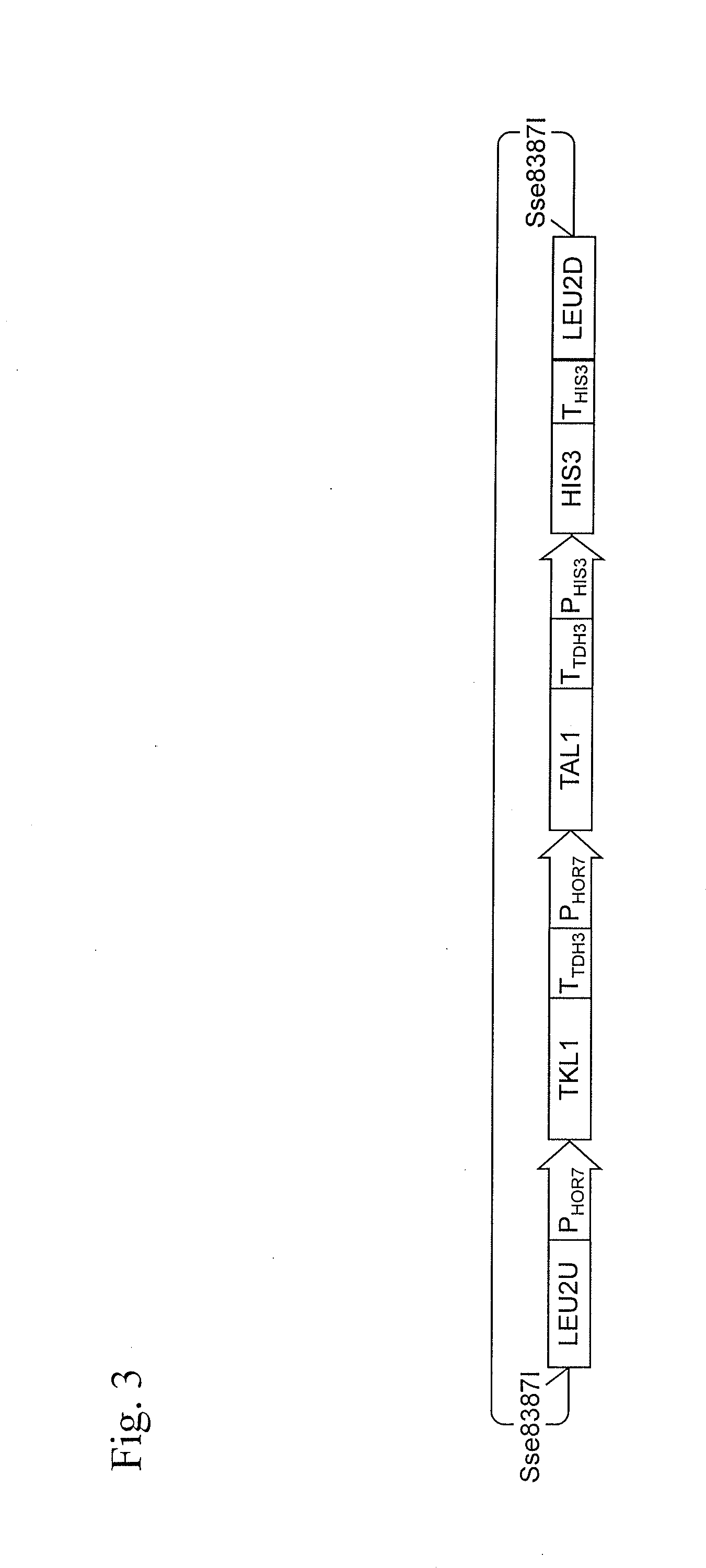

Method for producing ethanol using recombinant yeast

The invention is intended to metabolize acetic acid and to lower acetic acid concentration in a medium at the time of xylose assimilation and ethanol fermentation by a yeast strain having xylose-metabolizing ability. The method for producing ethanol comprises a step of culturing recombinant yeast strains resulting from introduction of a xylose isomerase gene and an acetaldehyde dehydrogenase gene into a medium containing xylose, so as to perform ethanol fermentation.

Owner:TOYOTA JIDOSHA KK

Method for preparation of compound amino acid liquid from cottonseed meal

InactiveCN103937846ALow acid concentrationIncrease profitMicroorganism based processesFermentationBacillus licheniformisFiltration

The invention relates to a method for preparation of a compound amino acid liquid from cottonseed meal. The method includes: firstly carrying out mechanical crushing and cooking pretreatment on cottonseed meal, then inoculating Aspergillus niger, Aspergillus oryzae and Saccharomyces cerevisiae, and conducting culture under an aerobic condition for 15-20h to form a first level enzymolysis system, then inoculating Bacillus subtilis and bacillus licheniformis respectively to further conduct aerobic culture for 18-32h so as to form a fermentation broth, then adding edible grade concentrated hydrochloric acid into the fermentation broth to perform acid hydrolysis, and carrying out filtration and acidity adjustment settlement in order at the end of the hydrolysis to obtain the compound amino acid liquid, then refining the compound amino acid liquid by a complexing affinity extraction technology, mixing the extraction residual water phase generated in the refining process with the compound amino acid liquid to prepare light soy sauce, and taking the raffinate oil phase as an extraction agent for cycle use in refining of next batch compound amino acid liquid. The method provided by the invention not only effectively improves the raw material utilization rate, reduces the production cost, avoids generation of toxic by-products, but also increases the additional value of the product.

Owner:WUHAN POLYTECHNIC UNIVERSITY

Tranexamic acid formulations

ActiveUS8022106B2Minimize and eliminate undesirable gastrointestinal side effectReduce concentrationBiocidePeptide/protein ingredientsMedicineTranexamic acid

Disclosed are modified release oral tranexamic acid formulations and methods of treatment therewith.

Owner:AMRING PHARM INC

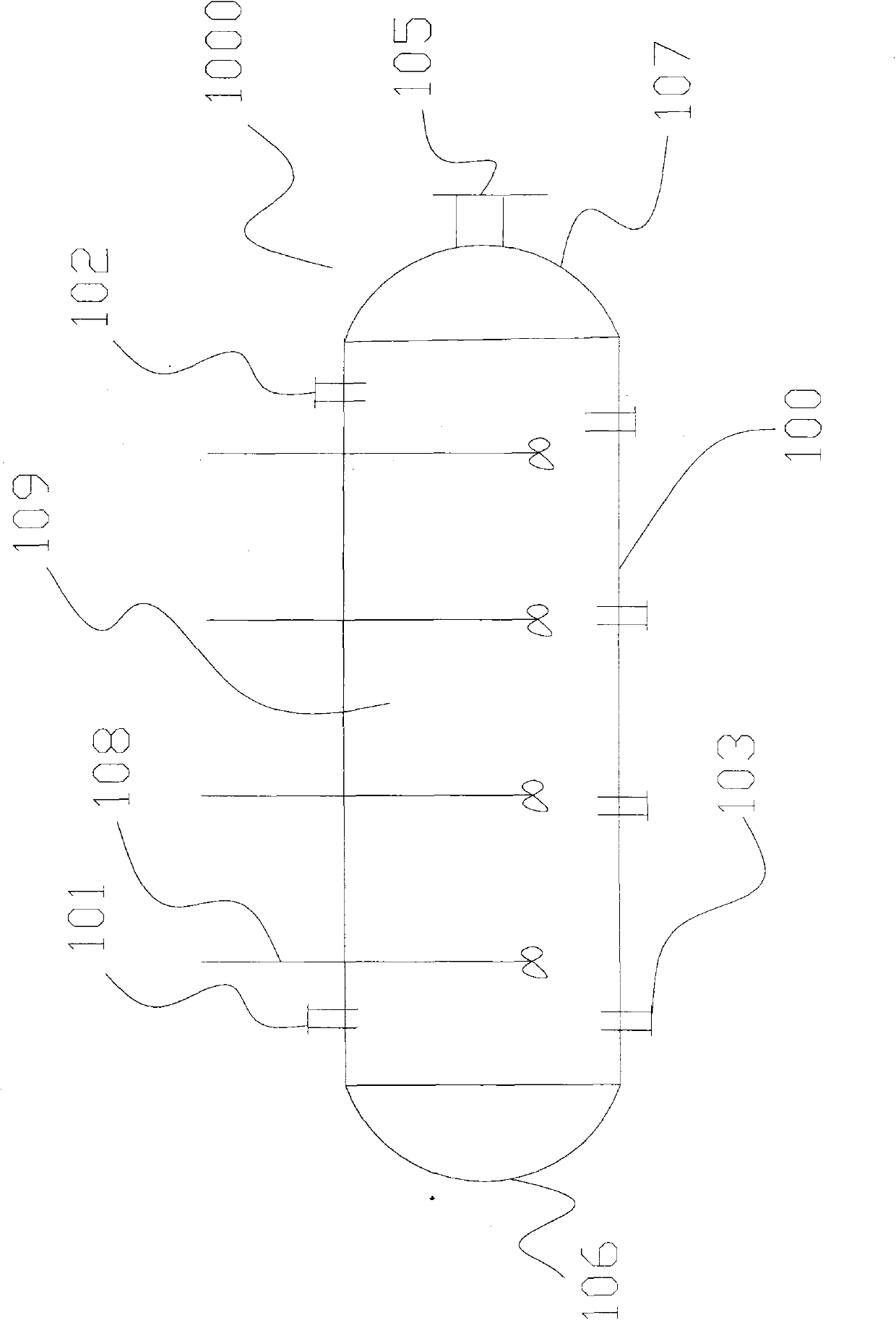

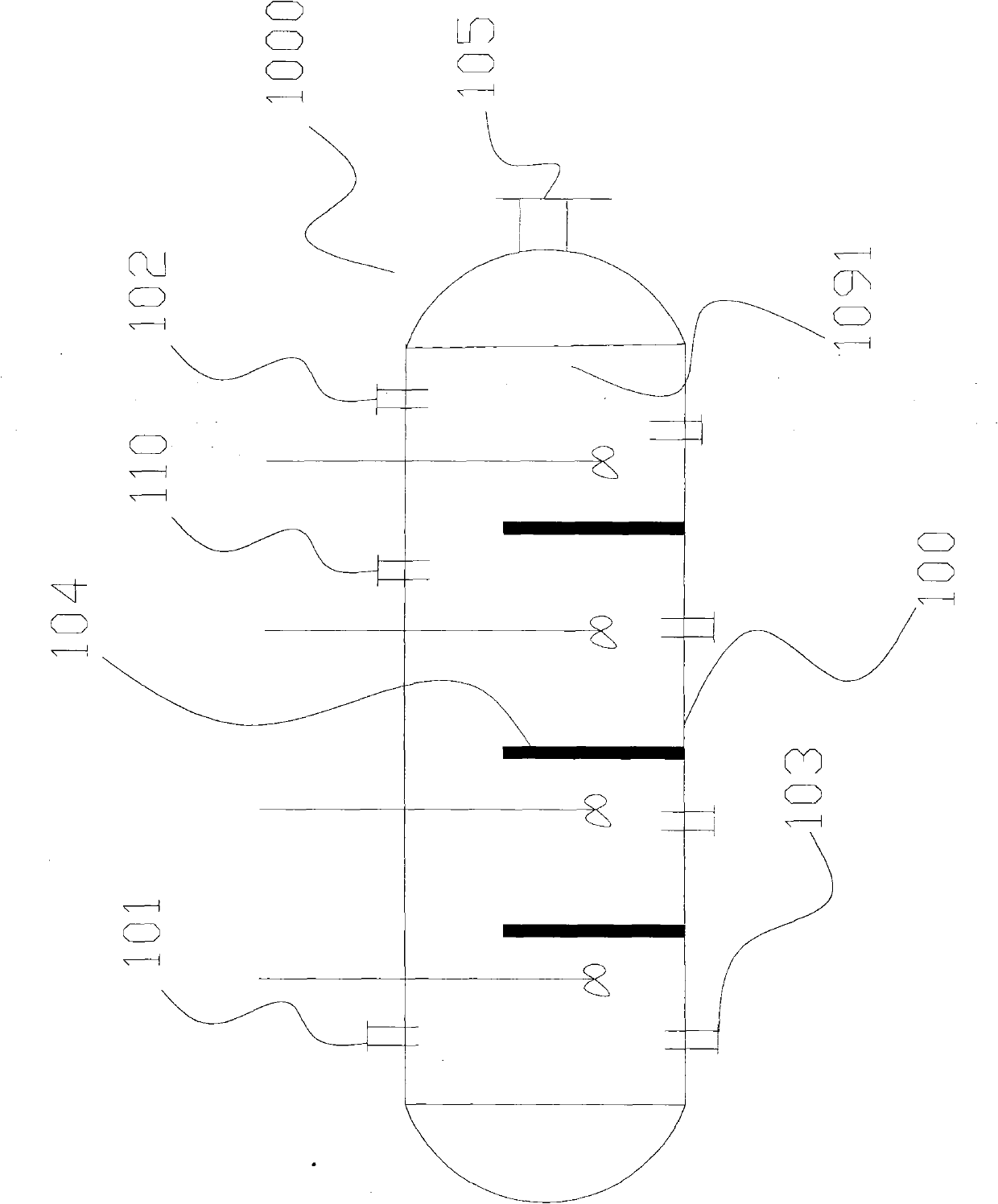

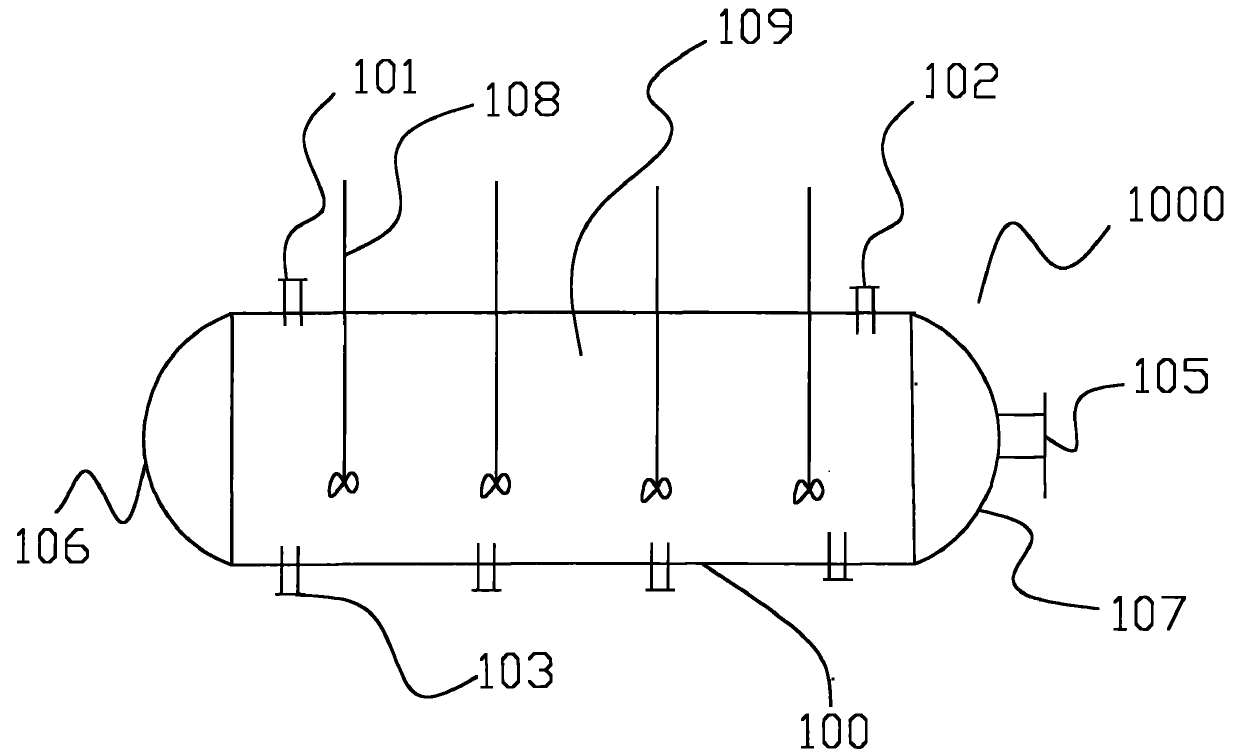

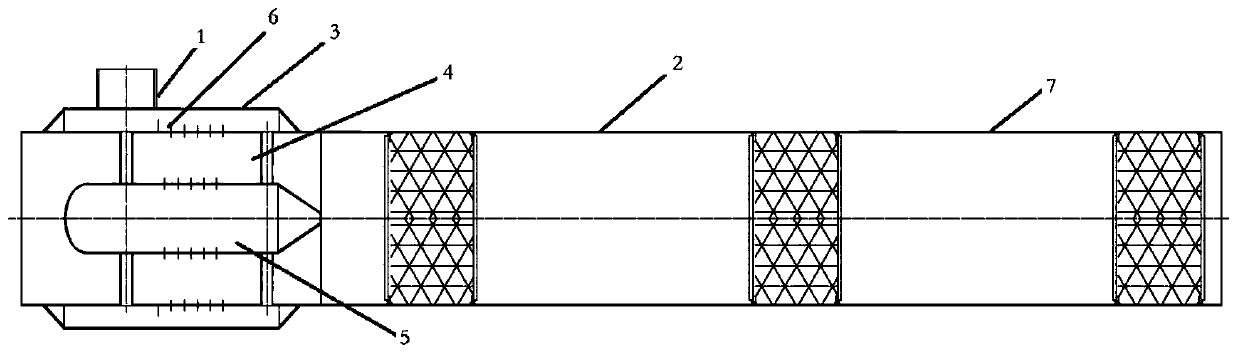

Horizontal type pressure leaching kettle and zinc sulfide concentrate leaching method using same

ActiveCN102168181AEasy to moveReduce manufacturing costProcess efficiency improvementPregnant leach solutionAcid concentration

The invention discloses a horizontal type pressure leaching kettle comprising a kettle body, a first feed port, oxygen inlets, a second feed port and a discharge port, wherein the kettle body is provided with a first end and a second end, and a leaching space is defined in the kettle body; the first feed port is arranged at the part, adjacent to the first end, of the top of the kettle body; the oxygen inlets are arranged at the bottom and lateral part of the kettle body; the second feed port is arranged at the part, adjacent to the second end, of the top of the kettle body; and the discharge port is arranged at the second end. In addition, the invention further provides a leaching method using the horizontal type pressure leaching kettle. The horizontal type pressure leaching kettle can be used for conducting zinc sulfide concentrate leaching reaction in the pressure kettle, and simultaneously realizing reduction of acid concentration and iron content of the discharged leachate.

Owner:云南永昌铅锌股份有限公司

Food composition and pharmaceutical composition with strains of lactic acid bacteria for reducing blood uric acid concentration

InactiveUS20200214328A1Low acid concentrationBacteriaLactobacillusBiotechnologyLactic acid bacterium

A food composition and pharmaceutical composition with strains of lactic acid bacteria for reducing blood uric acid concentration are provided, comprising at least one or two isolated lactic acid bacteria strains selected from the following two: TSF331 (Lactobacillus fermentum) and TSR332 (Lactobacillus reuteri).

Owner:GLACT BIOTECH

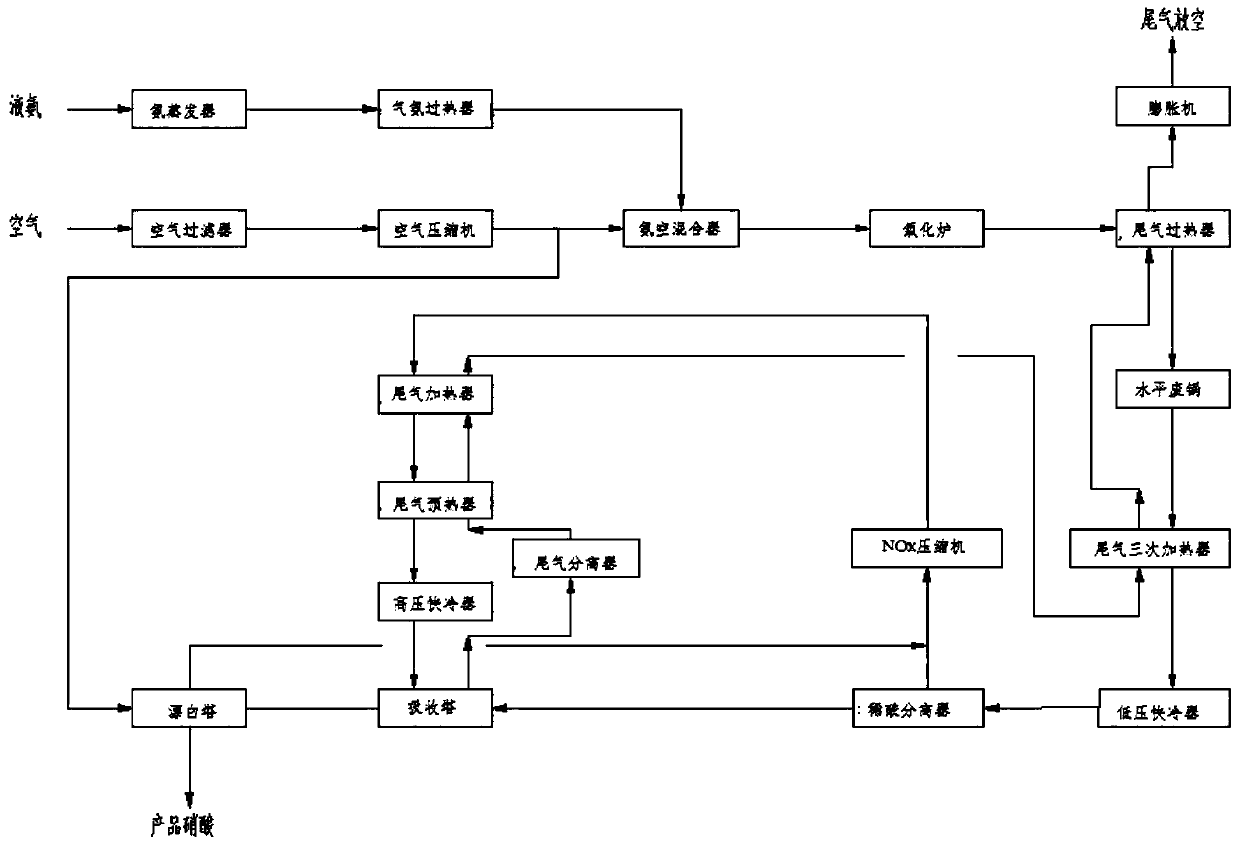

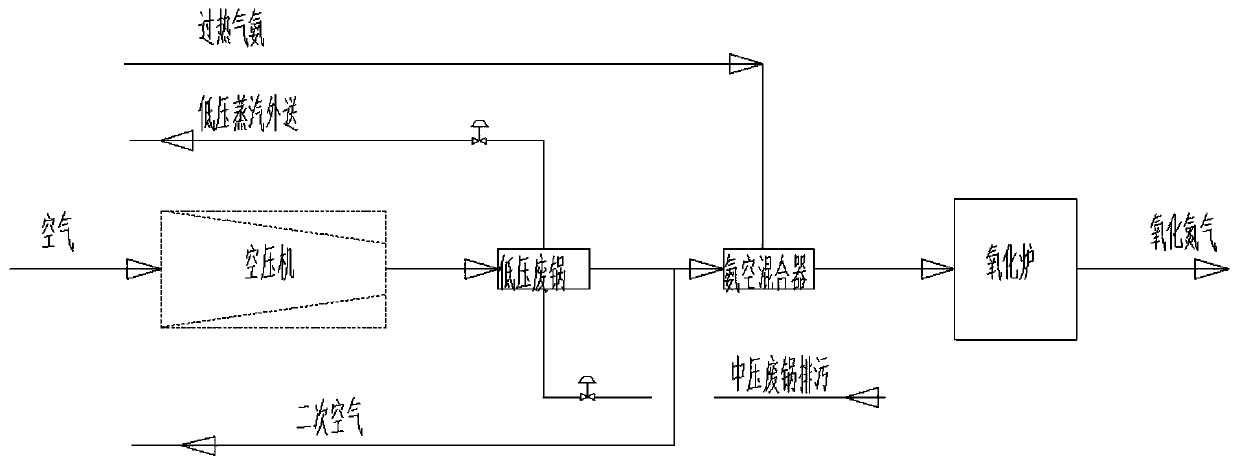

Dilute nitric acid production process

ActiveCN110550614AReduce emission concentrationImprove absorption rateEnergy inputNitric oxideChemical industryEvaporation

The invention belongs to the field of chemical industry, and in particular, relates to a dilute nitric acid production process. The process includes the following steps: after ammonia evaporation andheating, adjusting the flow quantity, allowing gas ammonia to enter an ammonia-air mixer and uniformly mixing the gas ammonia with compressed air; allowing the ammonia-air mixture after mixing to enter an oxidation furnace, carrying out catalytic oxidation reaction on a platinum mesh surface, oxidizing ammonia into nitric oxide, recycling waste heat from process gas leaving the catalyst through awaste heat boiler and tail gas respectively, and then condensing by a low-pressure quick cooler, after separation of dilute acid, mixing the process gas with air from a bleaching tower, and then allowing the mixed gas to enter an oxidation nitrogen compressor; further increasing the temperature of gas through the compressed process gas; recycling waste heat of the compressed process gas, cooling,and then allowing the cooled process gas to enter an absorption tower; and carrying out a reaction of oxide of nitrogen in the absorption tower after absorption with water to generate nitric acid. Theprocess has the advantages of high nitrogen oxide absorption rate, low ammonia consumption, high acid concentration and low tail gas emission concentration, and can reach the standard without furthertreatment.

Owner:SICHUAN GOLDEN ELEPHANT SINCERITY CHEM CO LTD

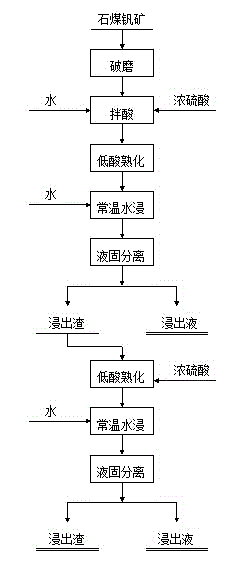

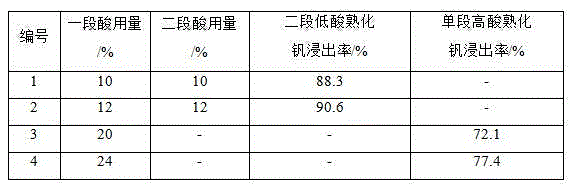

Two-stage curing vanadium extraction method of stone coal vanadium ores

ActiveCN104451202AImprove leaching rateInhibit side effectsProcess efficiency improvementSlagPhysical chemistry

The invention provides a two-stage curing vanadium extraction method of stone coal vanadium ores. The two-stage curing vanadium extraction method comprises the following steps: (1) firstly, breaking and grinding the stone coal vanadium ores, and then adding water and concentrated sulfuric acid to the obtained ore powder and mixing evenly to obtain a mixture, wherein the mass of the concentrated sulfuric acid added accounts for 10%-15% of the mass of the stone coal vanadium ores; (2) curing the mixture, next, leaching the obtained mixture by use of water, and performing liquid-solid separation to obtain a vanadium-containing leaching solution and leaching slag; (3) adding concentrated sulfuric acid to the leaching slag and mixing evenly, next, curing, leaching the obtained mixture by use of water, and performing liquid-solid separation to obtain a vanadium-containing leaching solution and leaching slag, wherein the mass of the concentrated sulfuric acid added accounts for 10%-15% of the mass of the stone coal vanadium ores; and (4) blending the vanadium-containing leaching solution of the step (2) and the vanadium-containing leaching solution of the step (3). The two-stage curing vanadium extraction method of the stone coal vanadium ores has the advantages that side reactions in curing are effectively inhibited and the vanadium leaching rate is greatly increased. A two-stage low-acid curing method is adopted, the acid concentration is relatively low, and the curing process is clean and environment-friendly; and as a result, the two-stage low-acid curing method has a great industrial application prospect.

Owner:肃北蒙古族自治县西矿钒科技有限公司

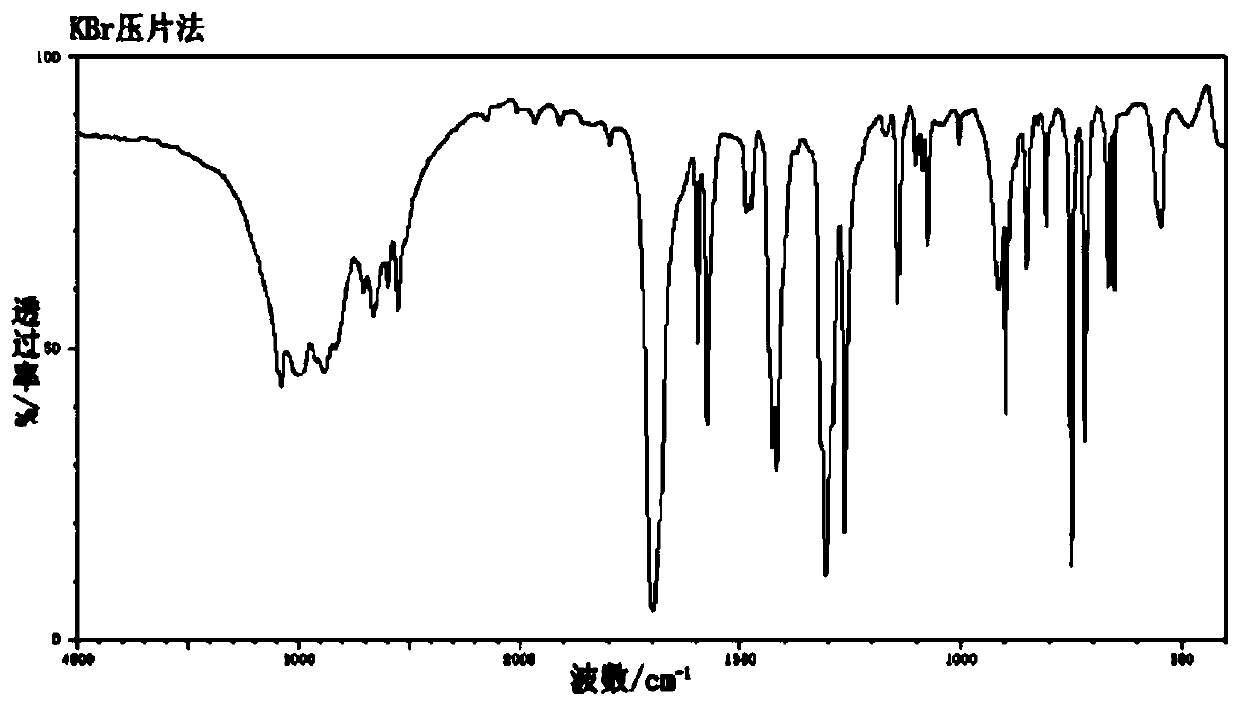

Low-cost environment-friendly method for preparing epoxidized silicone rubber

The invention discloses a low-cost and environment-friendly method for preparing epoxidized silicone rubber. The method comprises the following steps: taking 1-10 parts of high vinyl silicone rubber,100 parts of an organic peroxy acid poor solvent and 0.5-12 parts of an epoxidation reagent; mixing the high vinyl silicone rubber with the organic peroxy acid poor solvent; after complete dissolution, adding the epoxidation reagent for reaction to obtain epoxidized silicone rubber solution; storing the obtained solution at low temperature to separate out a deoxidation product of the epoxidation reagent and an unreacted epoxidation reagent, then precipitating epoxidized silicone rubber; and performing washing and drying to obtain the epoxidized silicone rubber. The preparation method is more scientific and reasonable, the produced epoxidized silicone rubber has the molecular weight of original high vinyl silicone rubber and is free of gel, the performance of the epoxidized silicone rubberis more stable, the strength of the epoxidized silicone rubber is higher, meanwhile, the production cost is reduced, and the method is more suitable for mass production.

Owner:BEIJING UNIV OF CHEM TECH

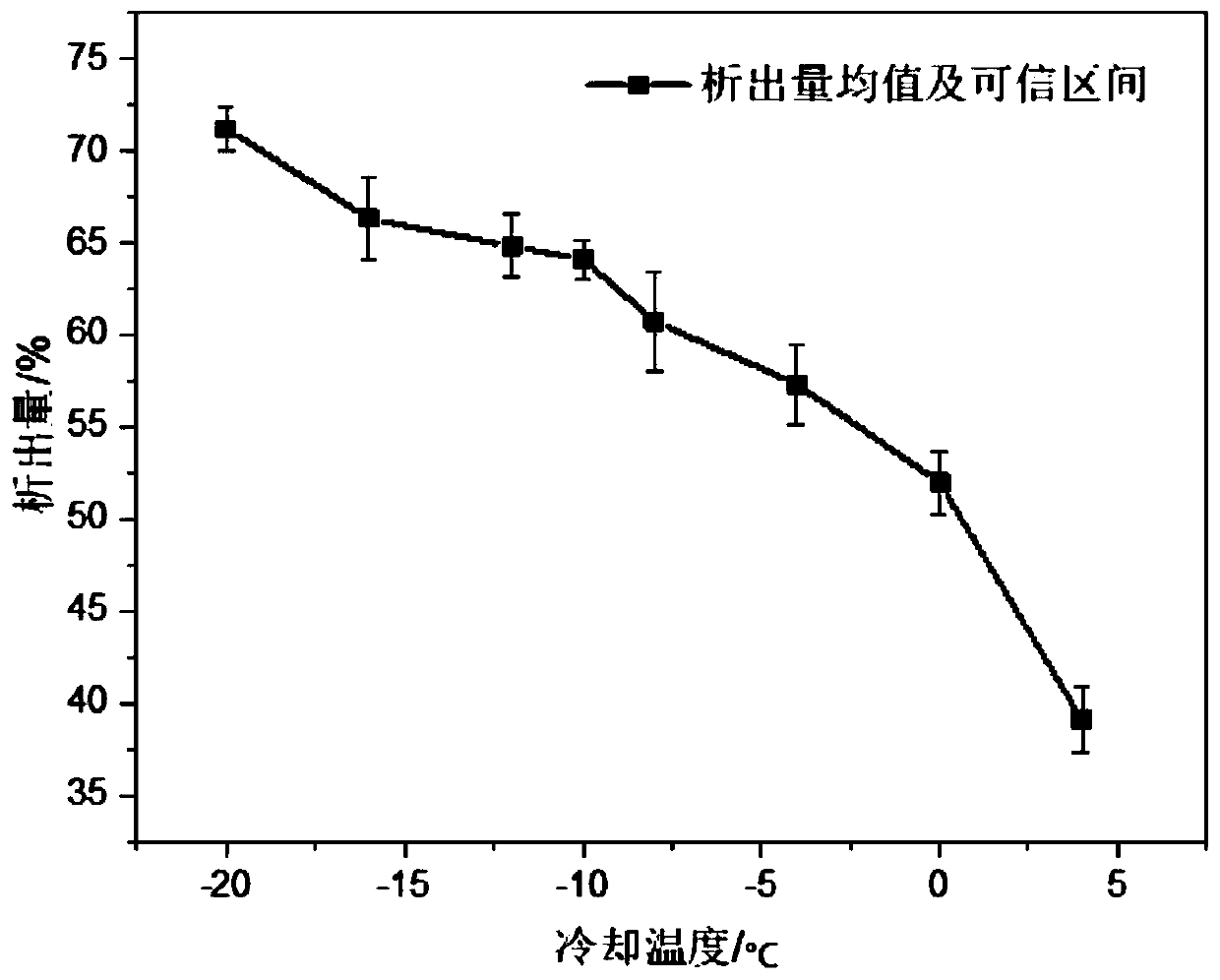

Method for processing raw fruit to produce enhanced fruit products and the fruit products produced by the method

InactiveUS20100009060A1Low brix levelSpecific beneficial nutraceutical qualityFruit and vegetables preservationAnimal feeding stuffFruit juiceAmerican cranberry

A method for processing a fruit, such as a cranberry, includes cutting open a fruit and partially removing a highly concentrated juice fraction from the fruit when pressed while maintained within a sub-freezing temperature range. The skin of the frozen fruit is penetrated by being sliced or punctured facilitating juice extraction and subsequently infusion, such as by vacuum. Before extraction, the sliced fruit is uniformly tempered to a temperature below 32° F., more specifically to between 26° F. and 32° F. To extract juice, the fruit is pressed, removing from about 40% to 65% by weight of the liquid, yielding a concentrated fruit juice, with significantly enhanced brix, acid, and color, and a partially dehydrated fruit piece, with significantly reduced brix, acid, and color, and still within the given sub-freezing temperature range. The fruit piece may then be infused, such as under vacuum while being rotated, with a variety of ingredients.

Owner:SMITH JONATHAN D

Low-energy-consumption preparation method for synthesizing high-purity folic acid

The invention discloses a low-energy-consumption preparation method for synthesizing high-purity folic acid. The method comprises adding 2,4,5-triamino-6-hydroxypyrimidine sulfate, p-aminobenzamide glutamic acid, trichloroacetone, sodium acetate and sodium pyrosulfite into water, performing docking reaction, adjusting pH by adding solid sodium acetate before the reaction is started and separately adding a sodium hydroxide solution during reaction and after the reaction is finished, and filtering; performing acid-washing and filtering in hydrochloric acid solution; adding a magnesium oxide solution into water for reaction, adding active carbon for decoloring, and filtering; adjusting pH value by using hydrochloric acid, cooling and filtering; and washing with purified water and filtering, drying the filter cake, so as to obtain the final product. By using the method for producing folic acid, energy consumption is reduced, also yield and product purity are improved, and also cost is substantially saved.

Owner:北京斯利安药业有限公司

Method for processing raw fruit to produce enhanced fruit products and the fruit products produced by the method

InactiveUS20100009049A1Low brix levelLow TAcyFruit and vegetables preservationFood shapingFruit juiceAmerican cranberry

A method for processing a fruit, such as a cranberry, includes cutting open a fruit and partially removing a highly concentrated juice fraction from the fruit when pressed while maintained within a sub-freezing temperature range. The frozen fruit is cut open by being sliced or punctured facilitating juice extraction and subsequently infusion, such as by vacuum. Before extraction, the sliced fruit is uniformly tempered to a temperature below 32° F., more specifically to between 26° F. and 32° F. To extract juice, the fruit is pressed, removing from about 40% to 65% by weight of the liquid, yielding a concentrated fruit juice, with significantly enhanced brix, acid, and color, and a partially dehydrated fruit piece, with significantly reduced brix, acid, and color, and still within the given sub-freezing temperature range. The fruit piece may then be infused, such as under vacuum while being rotated, with a variety of ingredients.

Owner:SMITH JONATHAN D

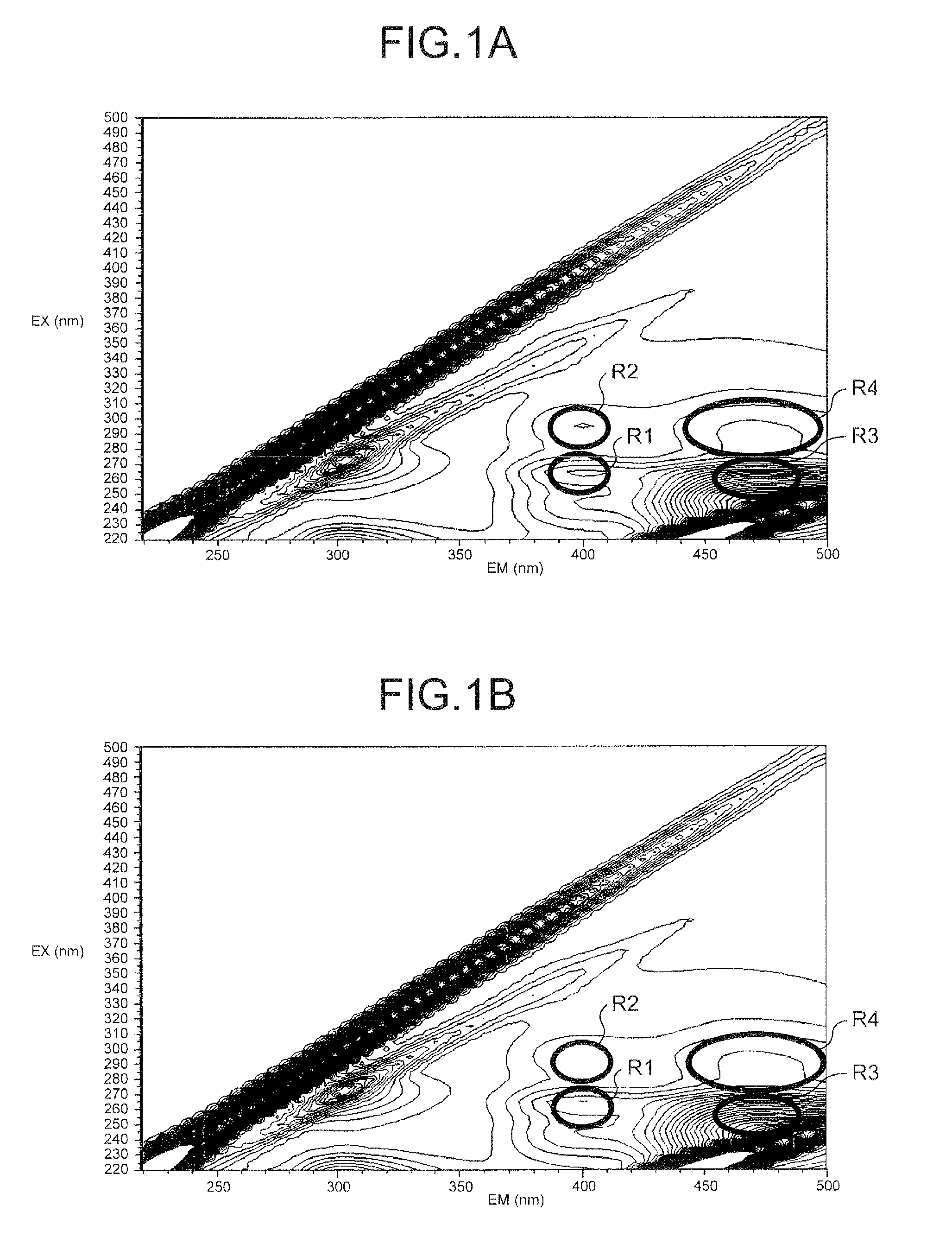

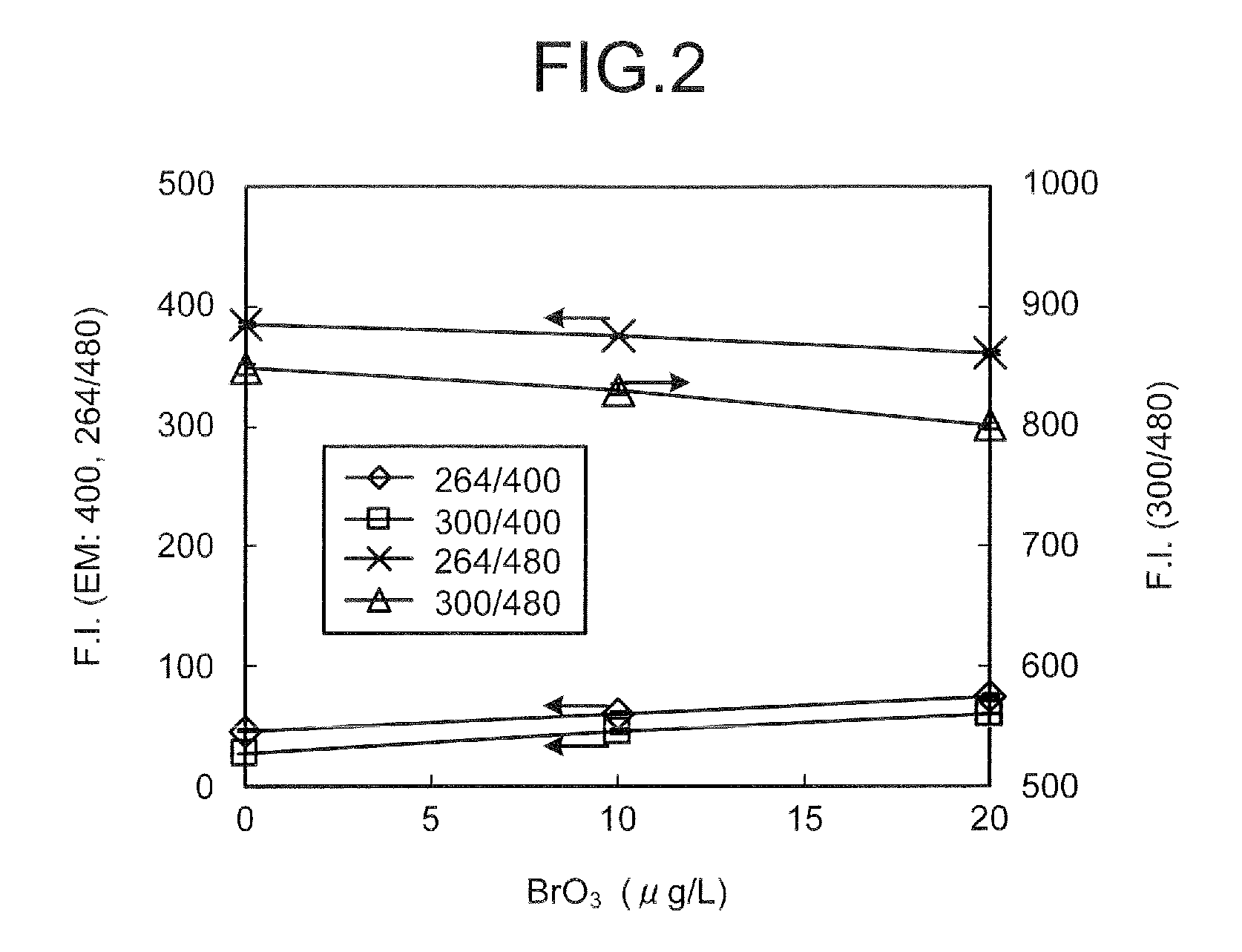

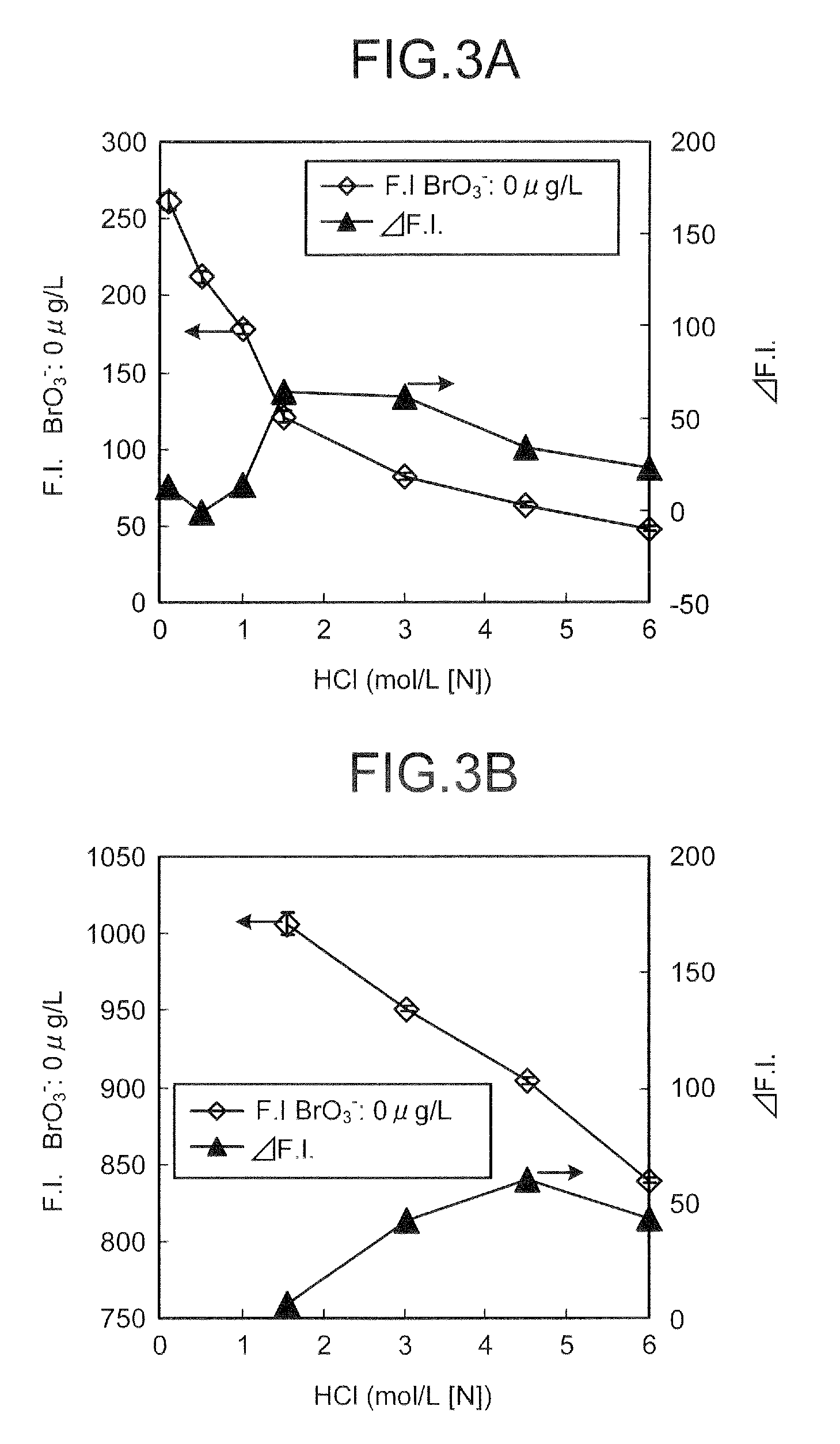

Method and apparatus for measuring bromate ions

ActiveUS9023654B2Improve accuracyLow acid concentrationAnalysis using chemical indicatorsMaterial analysis by observing effect on chemical indicatorReference sampleSample water

A method for measuring bromate ions includes: an adding step of adding a fluorescent substance whose fluorescence intensity changes by the coexistence of bromate ions to sample water; a measuring step of measuring the fluorescence intensity of the fluorescent substance; a difference calculating step of calculating a difference between the fluorescence intensity measured and a reference fluorescence intensity of reference sample water that contains no bromate ion; and a concentration calculating step of calculating bromate ion concentration from the calculated fluorescence intensity difference. The measuring step includes a step of measuring the fluorescence intensity at any one of a case where an excitation wavelength is 264 nm and an emission wavelength is 400 nm, a case where the excitation wavelength is 264 nm and the emission wavelength is 480 nm, and a case where the excitation wavelength is 300 nm and the emission wavelength is 400 nm.

Owner:METAWATER CO LTD

Process for producing garden furniture from locust wood

InactiveUS20050283992A1Attractive surfaceLow acid concentrationDrying using combination processesWood treatment detailsEngineeringLocust

Owner:HEINZ KETTLER GMBH & CO KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com