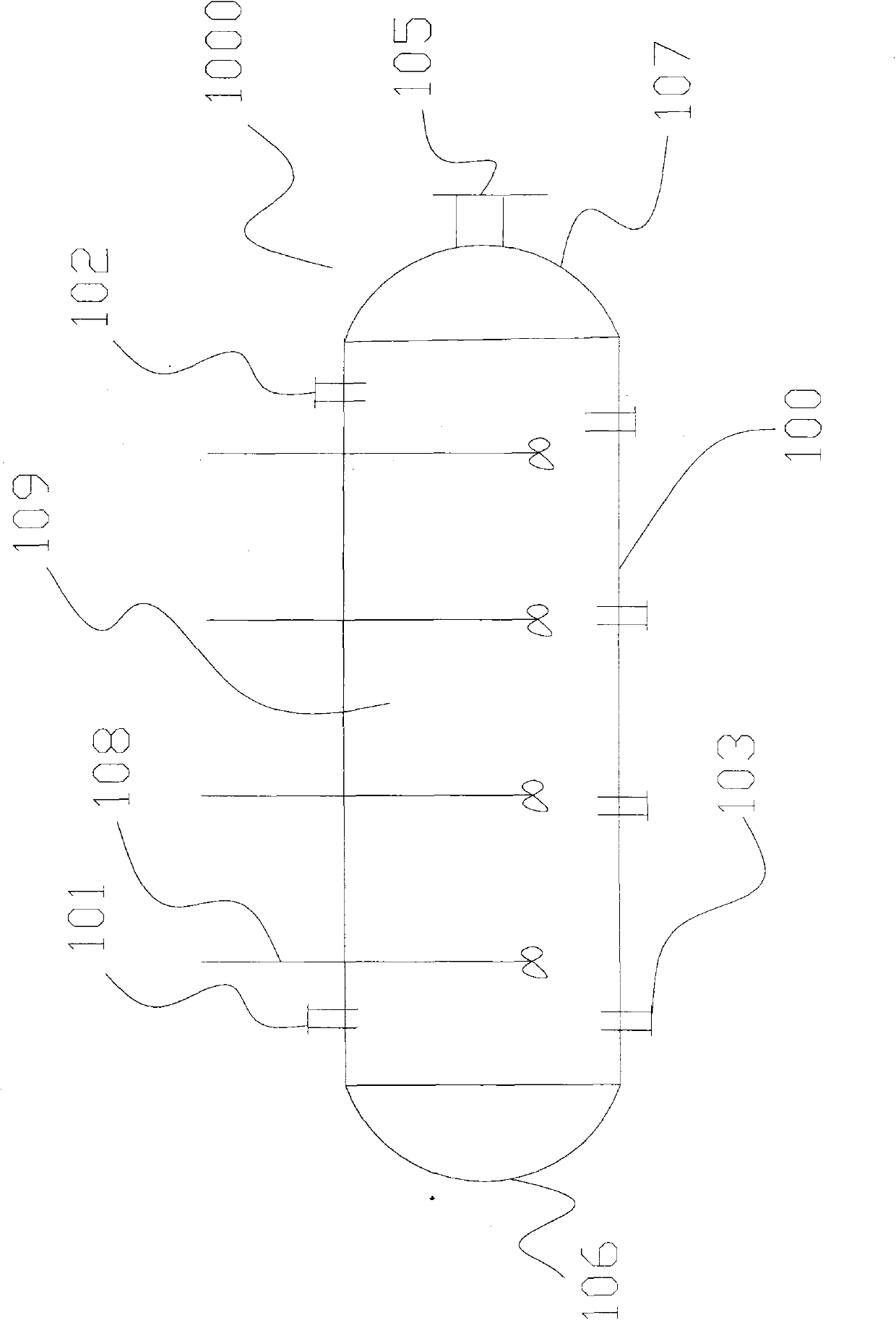

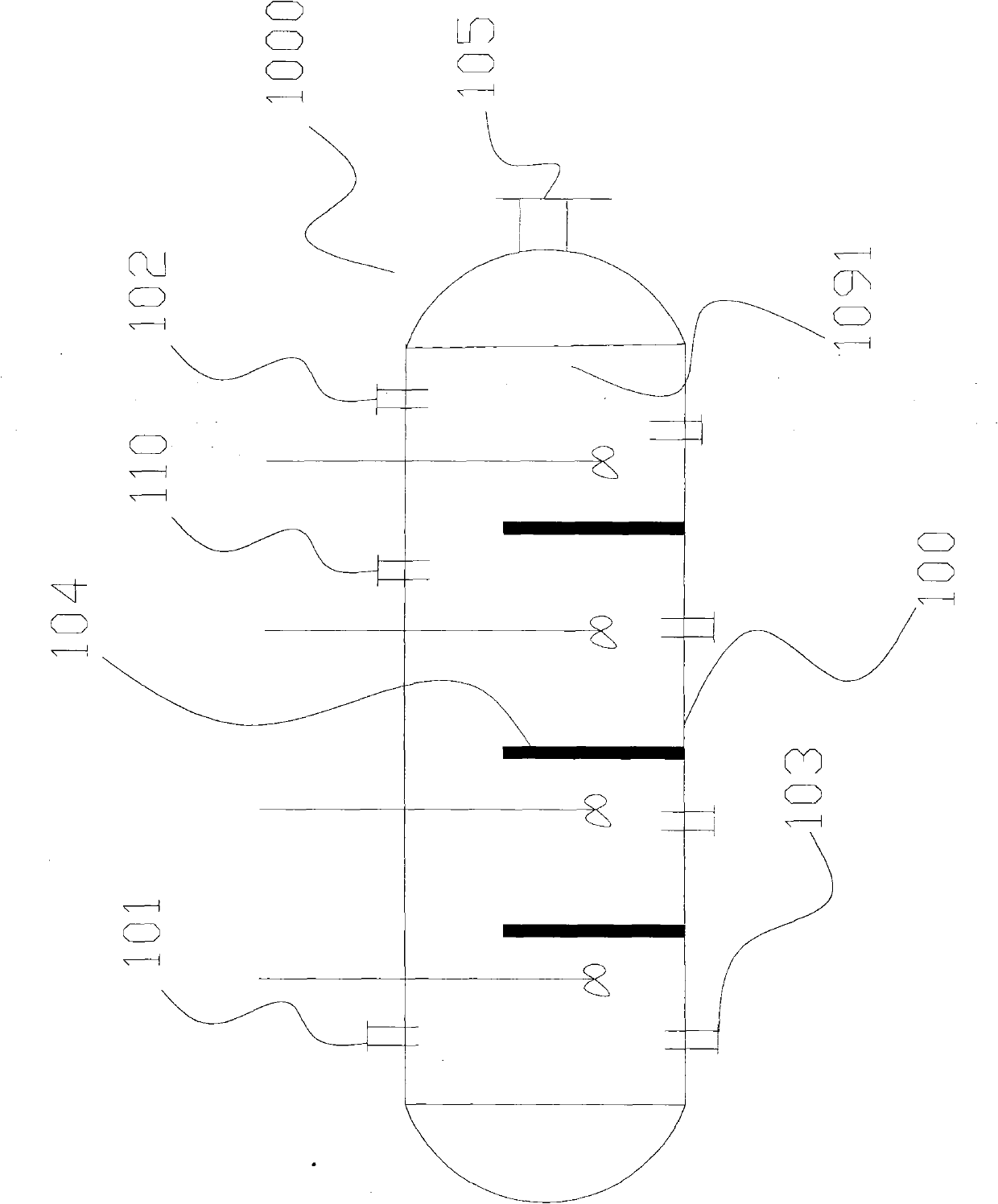

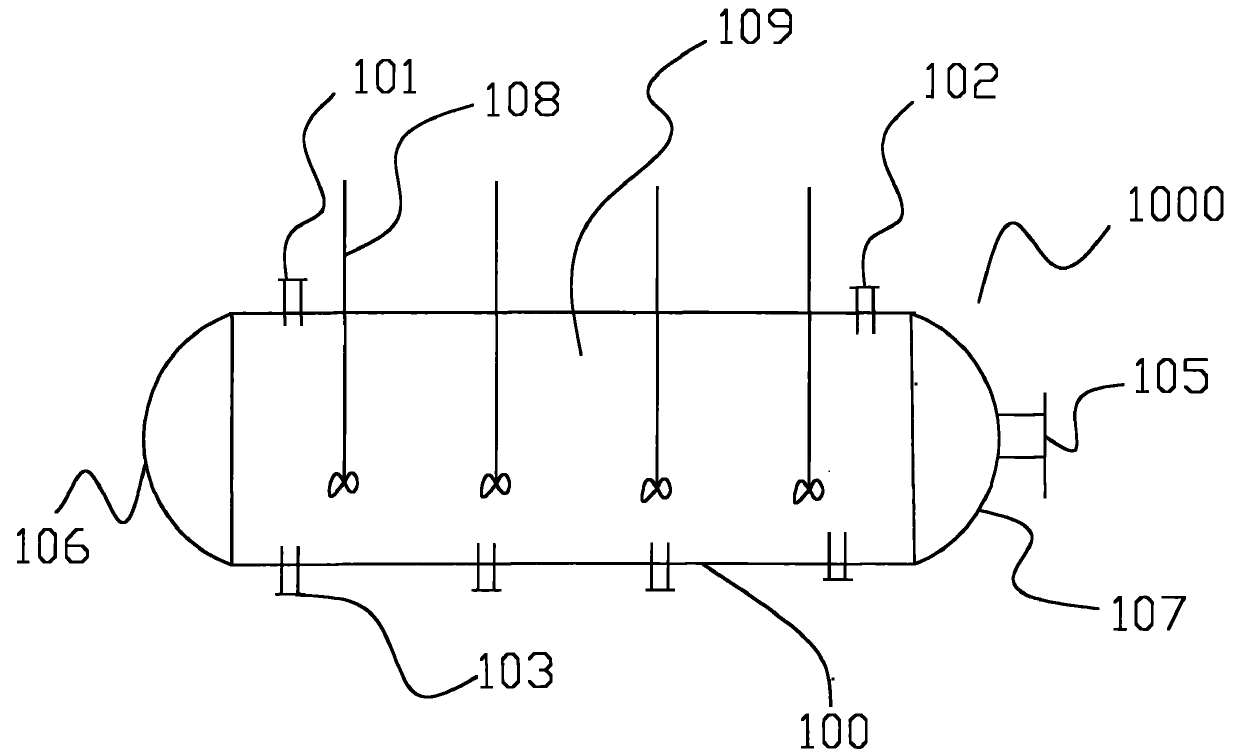

Horizontal type pressure leaching kettle and zinc sulfide concentrate leaching method using same

A technology for zinc sulfide concentrate and pressure leaching, applied in the field of metallurgy, can solve problems to be improved, etc., and achieve the effects of improving leaching efficiency and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0051] The raw material is zinc sulfide concentrate from a factory, and its composition (percentage by weight) is: Zn41.2%, Fe15.67%, S28.29%.

[0052]The zinc sulfide concentrate is subjected to sulfuric acid leaching by adopting the steps of the general method, wherein a total of 240 g of the zinc sulfide concentrate is leached with sulfuric acid having a concentration of 1.5 mol / L. The leaching conditions are: temperature 150±5°C, stirring speed 200-250r / min, leaching time about 120min, internal pressure 1.2Mpa, liquid-solid ratio 5:1. The amount of lignin added is 0.2% by weight of the ore amount, the leaching rate of zinc is 98.23%, and the final acid of the leachate is 0.2mol / L; 300 grams of zinc oxide ore and 1.5% zinc by weight are added to the last chamber of the autoclave. Gram basic sodium carbonate, pH of neutralization end point of leachate: 5.4, at the same time, iron in leachate is transferred to slag phase, liquid and solid are separated by pressure filtration,...

example 2

[0054] The raw material is zinc sulfide concentrate from a factory, and its composition (percentage by weight) is: Zn42.5%, Fe9.7%, S27.36%.

[0055] The zinc sulfide concentrate is subjected to sulfuric acid leaching by adopting the steps of the general method, wherein a total of 240 g of the zinc sulfide concentrate is leached with dilute sulfuric acid with a concentration of 1.4 mol / L. The leaching conditions are: temperature 150±5°C, stirring speed about 200-250r / min, leaching time about 120min, pressure inside the kettle 1.2Mpa, liquid-solid ratio 5:1. The addition of lignin is 0.2% by weight of the ore amount, the leaching rate of zinc is 98.23%, and the final acid of the leachate is 0.18mol / L; 310 grams of zinc oxide ore and 1.1 grams of zinc oxide ore and 1.1 grams of zinc are added in the last chamber of the autoclave. Alkali salt, leaching solution neutralization endpoint pH: 5.4, so that the iron in the leaching solution is transferred to the slag phase, and the liq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com