Cornstalk nanocellulose whiskers and preparation method and application thereof

A technology of nano-cellulose and corn stalks, which is applied in fiber raw material processing, textiles and papermaking, non-woody plants/crop pulp, etc., can solve the problems of complex waste liquid components, environmental pollution, and increased production costs, and achieve chemical conservation The drug and the preparation method are simple and easy, and the effect of reducing the difficulty of handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

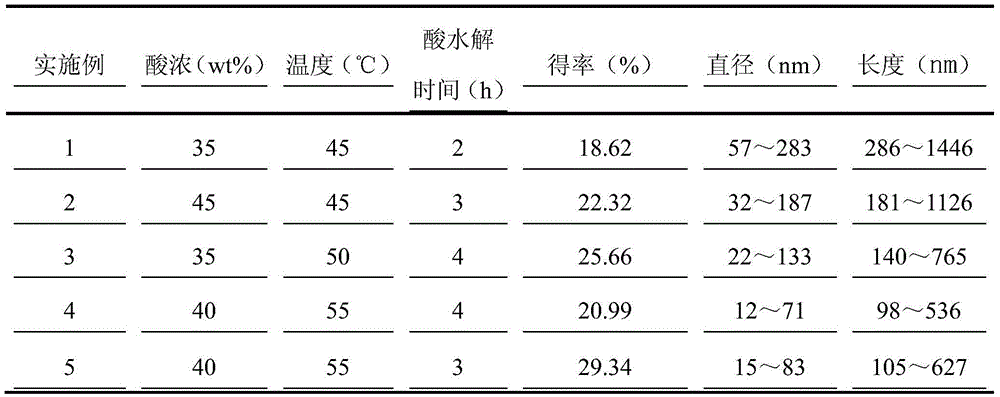

Embodiment 1

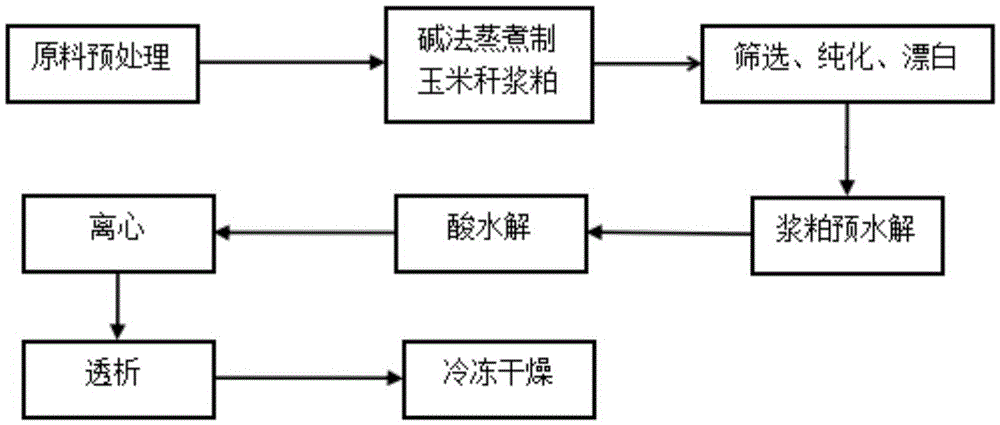

[0040] A kind of preparation method of corn stalk nano cellulose whisker, such as figure 1 As shown, the steps are as follows:

[0041] (1) Cut the corn stalks into 2-3cm sections after removing pith and knots, and balance the moisture for 1 week after screening.

[0042] The treated corn stalks are cooked by alkaline method, and the amount of alkali used is 14% (for absolute dry raw materials, take Na 2 O meter), degree of sulfide 13% (for absolute dry raw materials, in Na 2 O meter), the maximum temperature is 155 ° C, the temperature is raised for 1.5 h, and the heat preservation is 2 h to obtain corn stalk pulp.

[0043]The obtained cornstalk pulp is screened, and the aperture of the screen is 60 mesh. After the pulp was extracted for 6 hours with a phenylethanol mixture with a volume ratio of 2:1 in a Soxhlet extractor, it was treated with an acidified sodium chlorite solution at 75°C for 1 hour to purify the fibers. Then bleach with a hydrogen peroxide solution, the ...

Embodiment 2

[0048] A preparation method of corn stalk nanocellulose whiskers, the steps are as follows:

[0049] (1) Cut the corn stalks into 2-3cm sections after removing pith and knots, and balance the moisture for 1 week after screening.

[0050] The treated corn stalks are cooked by alkaline method, and the amount of alkali used is 14% (for absolute dry raw materials, take Na 2 O meter), degree of sulfide 13% (for absolute dry raw materials, in Na 2 O meter), the maximum temperature is 155 ° C, the temperature is raised for 1.5 h, and the heat preservation is 2 h to obtain corn stalk pulp.

[0051] The obtained cornstalk pulp is screened, and the aperture of the screen is 60 mesh. After the pulp was extracted for 6 hours with a phenylethanol mixture with a volume ratio of 2:1 in a Soxhlet extractor, it was treated with an acidified sodium chlorite solution at 75°C for 1 hour to purify the fibers. Then bleach with a hydrogen peroxide solution, the concentration is 3%, the temperatur...

Embodiment 3

[0056] A preparation method of corn stalk nanocellulose whiskers, the steps are as follows:

[0057] (1) Cut the corn stalks into 2-3cm sections after removing pith and knots, and balance the moisture for 1 week after screening.

[0058] The treated corn stalks are cooked by alkaline method, and the amount of alkali used is 14% (for absolute dry raw materials, take Na 2 O meter), degree of sulfide 13% (for absolute dry raw materials, in Na 2 O meter), the maximum temperature is 155 ° C, the temperature is raised for 1.5 h, and the heat preservation is 2 h to obtain corn stalk pulp.

[0059] The obtained cornstalk pulp is screened, and the aperture of the screen is 60 mesh. After the pulp was extracted for 6 hours with a phenylethanol mixture with a volume ratio of 2:1 in a Soxhlet extractor, it was treated with an acidified sodium chlorite solution at 75°C for 1 hour to purify the fibers. Then bleach with a hydrogen peroxide solution, the concentration is 3%, the temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com