Biological compound enzyme preparation for softening wood fibers and preparation method thereof

A biocomposite enzyme and wood fiber technology, applied in the field of papermaking, can solve the problems of decreased wet weight of pulp, increased number of paper machine breaks, and weakened pulp binding force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The invention also discloses a preparation method of a biocomposite enzyme preparation for promoting fiber modification in the papermaking beating process, comprising the following steps:

[0038] S1: pre-treating neutral pectate lyase, neutral xylanase, neutral cellulase, D-mannanase, and laccase in the raw material enzyme preparation;

[0039] S2: Neutral endo-pectate lyase, 20% to 30% neutral cellulase, 10% to 15% D-mannanase, 5% ~15% of laccase and 10%~20% of neutral xylanase are mixed evenly in the special "multi-enzyme coupling enzyme non-aqueous phase catalysis technology" reactor;

[0040] S3: adding an appropriate amount of preservatives and sterilizing through a diatomaceous earth filter, and then measuring the enzyme activity to prepare a biological compound enzyme preparation for softening wood fibers.

[0041] In step S1, the pretreatment is to dissolve each component of the biological complex enzyme preparation in water.

[0042] The invention also discl...

Embodiment 1

[0057] Kaiping Yidafeng Paper Co., Ltd. (hereinafter referred to as "Yidafeng") has used wood fiber softening enzyme products, and achieved phased results through continuous industrial use.

[0058] 1. Use effect analysis

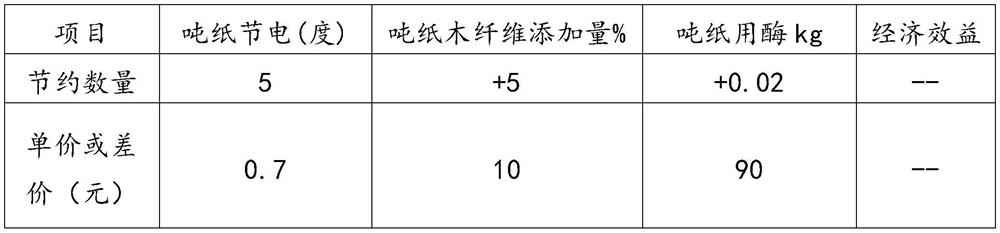

[0059] Table 1 Comparison of the effects of wood fiber percussion

[0060] Before grinding After grinding Knocking degree difference Raise the ratio No enzyme 6 8 2 33% Add enzyme 6 11 5 83% Compared 0 +3 +3 +50%

[0061] Note: Knocking degree, that is, beating degree, which indicates the degree of slurry drainage speed when paper is made on copper wire mesh, is one of the indicators to measure the quality of pulp.

[0062] The data of table 1 shows: 1) after adding described compound enzyme preparation, the degree of knocking after pulping improves obviously;

[0063] 2) After the compound enzyme preparation is added, the wood fiber feels soft and fine, and the fiber is obviously separated.

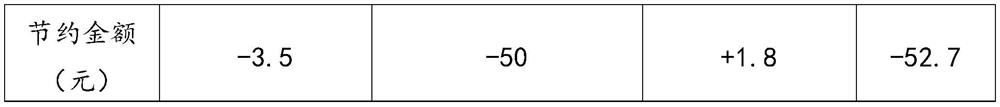

[0064] 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com