Compound enzyme and application thereof

A compound enzyme and pectinase technology, applied in the direction of enzymes, lyases, hydrolytic enzymes, etc., can solve the problems of difficult beating, high electricity costs, and large equipment investment, and achieve easy fiber separation, reduced beating difficulty, and beating The effect of power consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1-10

[0027] Table 1 specific embodiment 1-10 parts by weight selection

[0028]

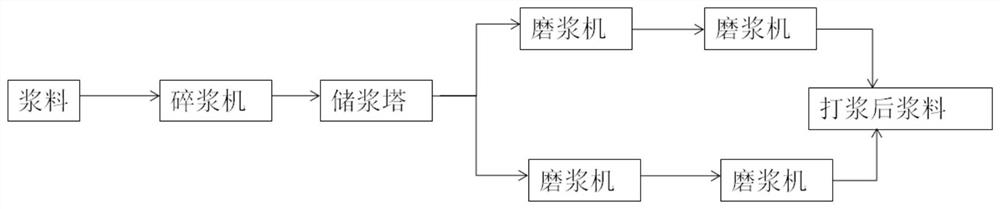

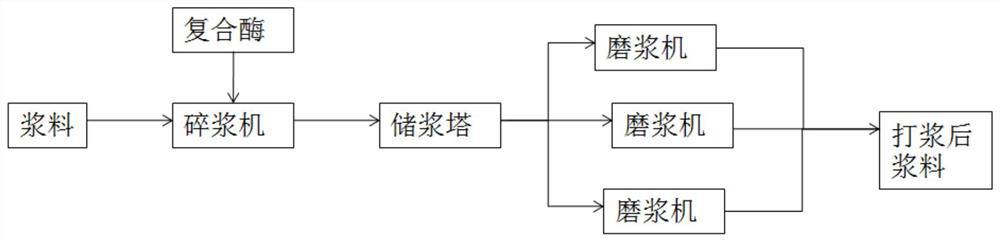

[0029] After weighing the components according to Table 1, the application of the compound enzyme described in the embodiment in the beating process comprises the steps:

[0030] (1) The slurry is transported to a pulper, and a compound enzyme is added in the pulper, and the amount of the compound enzyme is 0.09kg / ton dry pulp to obtain a mixed slurry A;

[0031] (2) Transport the mixed slurry A obtained in step (1) to a slurry storage tower, and react in the slurry storage tower. The reaction time is 3.5 hours, and the reaction temperature is 50° C., and it is transported to a refiner for refining. Obtain the slurry after beating.

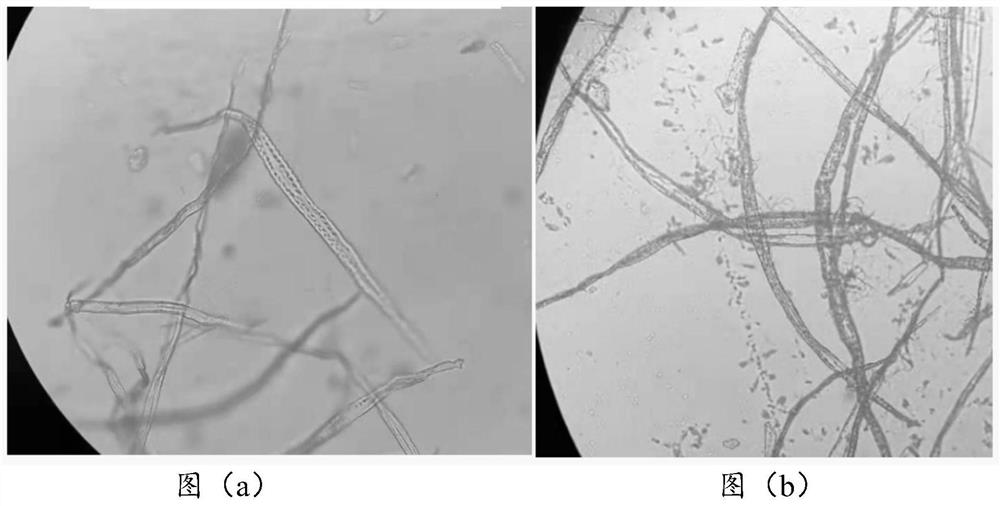

[0032] Simultaneously, the application sets comparative example, and the enzymatic activity etc. of comparative example 1-9 are exactly the same as embodiment 3, and specific comparative example 1-9 is set as follows, comparative example 9 does not adopt compound enzy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com