Poplar rod core sulfate pulping process

A sulfate and rod core technology, which is applied in the fields of pulping with inorganic alkali, pulping of cellulose raw materials, pulp bleaching, etc., can solve the problem of particularly serious corrosion of poplar rod cores, affecting pulping quality, pulping and bleaching. and other problems, to achieve the effect of accelerating delignification speed, low pulping cost and reducing lignin content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

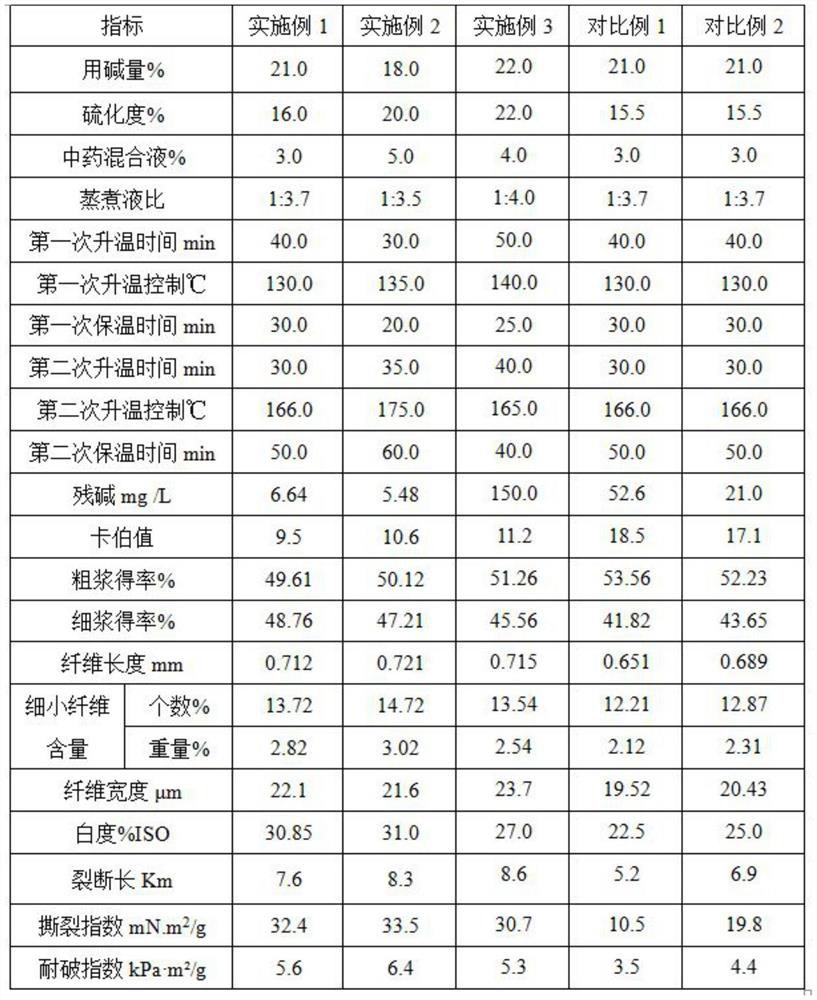

Embodiment 1

[0027] A poplar core kraft pulping process, which comprises the following preparation steps:

[0028] Step A: Take the poplar stick core for chipping and pre-screening. After screening, the length of the wood chips is controlled to be 10-50mm; 12.2%;

[0029] Step B: Put the poplar stick core wood chips prepared in step A into the cooking pot, then add the Chinese medicine mixture, the cooking solid-liquid ratio is controlled to 1:3.7, and the weight of the Chinese medicine extraction mixture accounts for 3% of the wood chip mass; use NaOH Calculated, the mass of alkali used accounted for 21% of the mass of dry wood chips, and the heating rate was controlled during the cooking process. The heating process was divided into two times, the first indirect heating, the second direct heating, and the first heating to 130 ° C. The heating time is controlled at 40 minutes, and when the highest temperature is reached, it is kept for 30 minutes, and then the operation of discharging no...

Embodiment 2

[0035] A poplar core kraft pulping process, which comprises the following preparation steps:

[0036] Step A: Take the poplar stick core for chipping and pre-screening. After screening, the length of the chips is controlled to be 15-45mm; 10%;

[0037] Step B: Put the poplar stick core wood chips prepared in step A into the cooking pot, then add the Chinese medicine mixture, the cooking solid-liquid ratio is controlled to 1:3.5, and the weight of the Chinese medicine extraction mixture accounts for 5% of the wood chip mass; use NaOH Calculated, the mass of alkali used accounts for 18% of the mass of dry wood chips, and the heating rate is controlled during the cooking process. The heating process is divided into two times, the first indirect heating, the second direct heating, and the first heating to 135 ° C. The heating time is controlled at 30 minutes, and when the highest temperature is reached, it is kept for 20 minutes, and then the operation of discharging the non-conden...

Embodiment 3

[0043] A poplar core kraft pulping process, which comprises the following preparation steps:

[0044] Step A: Take the poplar stick core for chipping and pre-screening. After screening, the length of the chips is controlled to be 20-55mm; 50%;

[0045] Step B: Put the poplar stick core wood chips prepared in step A into the cooking pot, then add the Chinese medicine mixture, the cooking solid-liquid ratio is controlled to 1:4.0, and the weight of the Chinese medicine extraction mixture accounts for 4% of the wood chip mass; Calculated, the mass of alkali used accounts for 22% of the mass of dry wood chips, and the heating rate is controlled during the cooking process. The heating process is divided into two times, the first indirect heating, the second direct heating, and the first heating to 140 °C. The heating time is controlled at 50 minutes, and when the highest temperature is reached, it is kept for 25 minutes, and then the non-condensable gas in the cooking pot is disch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com