A method for preparing foam material based on ozone-modified bagasse thermomechanical pulp

A technology for thermally refining mechanical pulp and foam materials, which is applied in pulp beating methods, pulp bleaching, fiber raw material processing, etc., can solve the problems of high cost of bleached pulp, limited application fields of foam materials, etc. , the effect of easy to separate silk broom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

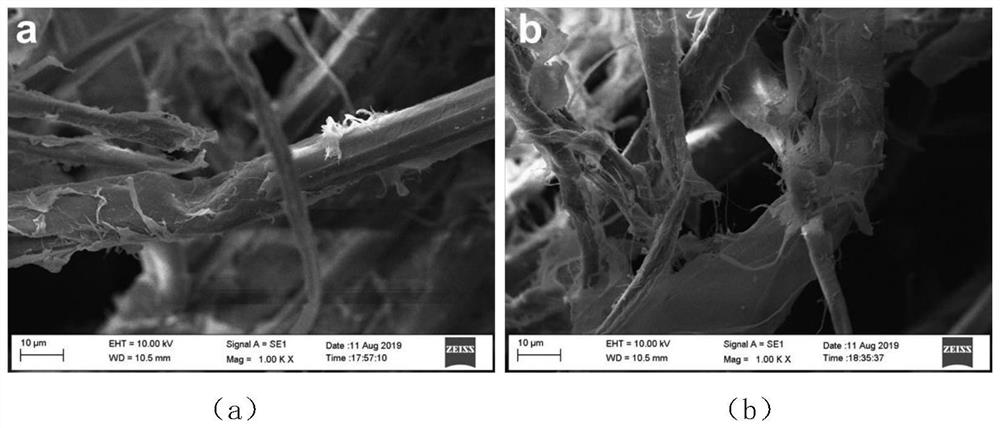

Image

Examples

Embodiment 1

[0021] A method for preparing foam material based on ozone-modified bagasse thermomechanical pulp, specifically comprising the following steps:

[0022] Step 1: take 50g of dry bagasse thermo-mechanical pulp and adjust it with distilled water to a pulp concentration of 30%, place the adjusted pulp in a stainless steel reaction tank and disperse it evenly, inject 5% ozone until the reaction is complete and then take it out;

[0023] Step 2: take the ozone-modified thermomechanical pulp with distilled water to prepare a 2% pulp consistency, place them in a PFI beater respectively, and beat the pulp to 9000r to stop;

[0024] Step 3: Take 20g of the beaten raw material and configure it into a pulp suspension with a concentration of 2%, add 4% of foaming agent A and 25% of foaming agent B, mix them evenly, and then add them to the decomposing machine. Under high-speed stirring, foam is generated.

[0025] After the wet foam is injected into the mold, it is dried at a constant temp...

Embodiment 2

[0027] A preparation method of ozone-modified bagasse thermo-mechanical pulp and foam material, which specifically comprises the following steps:

[0028] Step 1: take 50g of dry bagasse thermo-mechanical pulp and adjust it with distilled water to a pulp concentration of 30%, place the adjusted pulp in a stainless steel reaction tank and disperse it evenly, inject 5% ozone until the reaction is complete and then take it out;

[0029] Step 2: take the ozone-modified thermomechanical pulp to prepare a certain pulp consistency with distilled water, place it in a PFI beater, and beat to 9000r;

[0030] Step 3: Take 20g of the beaten raw material and configure it into a pulp suspension with a concentration of 3%, add 4% of foaming agent A and 25% of foaming agent B, mix evenly, and then add it to the decomposing machine. Under high-speed stirring, foam is generated.

[0031] After the wet foam is injected into the mold, it is dried at a constant temperature and tested after demoldi...

Embodiment 3

[0033] A preparation method of ozone-modified bagasse thermo-mechanical pulp and foam material, which specifically comprises the following steps:

[0034] Step 1: take 50g of dry bagasse thermo-mechanical pulp and adjust it with distilled water to a pulp concentration of 30%, place the adjusted pulp in a stainless steel reaction tank and disperse it evenly, inject 5% ozone until the reaction is complete and then take it out;

[0035] (2) Take the ozone-modified thermomechanical pulp to prepare a certain pulp consistency with distilled water, place it in a PFI beater, and beat to 9000r;

[0036] (3) Take 20g of the raw material after beating and configure it into a pulp suspension with a concentration of 4%, add 4% of foaming agent A and 25% of foaming agent B and mix it evenly, then add it to the decomposing machine, and under high-speed stirring, foam is generated.

[0037] After the wet foam is injected into the mold, it is dried at a constant temperature and tested after de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com