Patents

Literature

65results about How to "Reduce energy consumption for beating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

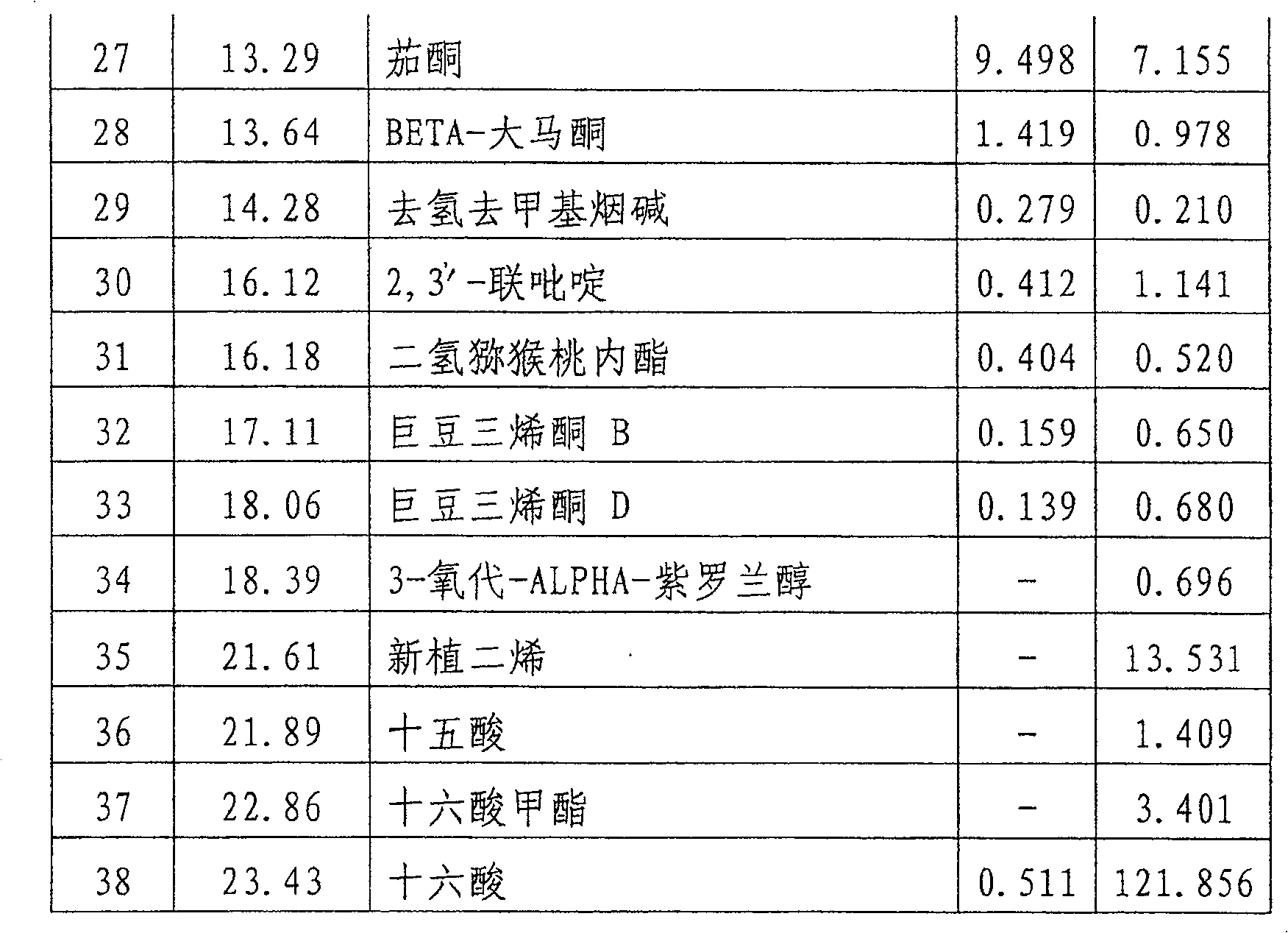

Method for preparing tobacco sheet and application thereof

ActiveCN101637298AGood physical propertiesExtract completelyTobacco preparationTobacco treatmentMaillard reactionFiber

The invention discloses a method for preparing tobacco sheets and an application of the method. In the method, enzymolysis is implemented when the tobacco stalk and the tobacco powder are soaked, solid-liquid separation is implemented after extraction, the solids are made into fiber sheet substrates, liquid is made into concentrated solution by alcohol precipitation and concentration, the concentrated solution is made into coating liquid by maillard reaction and coated on the fiber sheet substrates, and the fiber sheet substrates are dried and cut into tobacco sheets. In the invention, the macromolecular compounds that influence the quality of the tobacco sheets are sufficiently degraded by enzymolysis, the content of the impure taste in the tobacco sheets is decreased, the internal quality of the tobacco sheets is improved, and better aroma is obtained by the technical solution that produces prospective aroma by the maillard reaction to provide a rich aroma for the tobacco sheets so as to obtain tobacco sheet products fitting different types of cigarette products and having better internal quality. The tobacco sheets prepared by the method have excellent compatibility and harmonywith the conventional raw materials of the cigarettes, and have the advantages of good cigarette taste, various and rich aromas and less impure taste.

Owner:CHINA TOBACCO GUANGDONG IND

Method for producing glassine paper

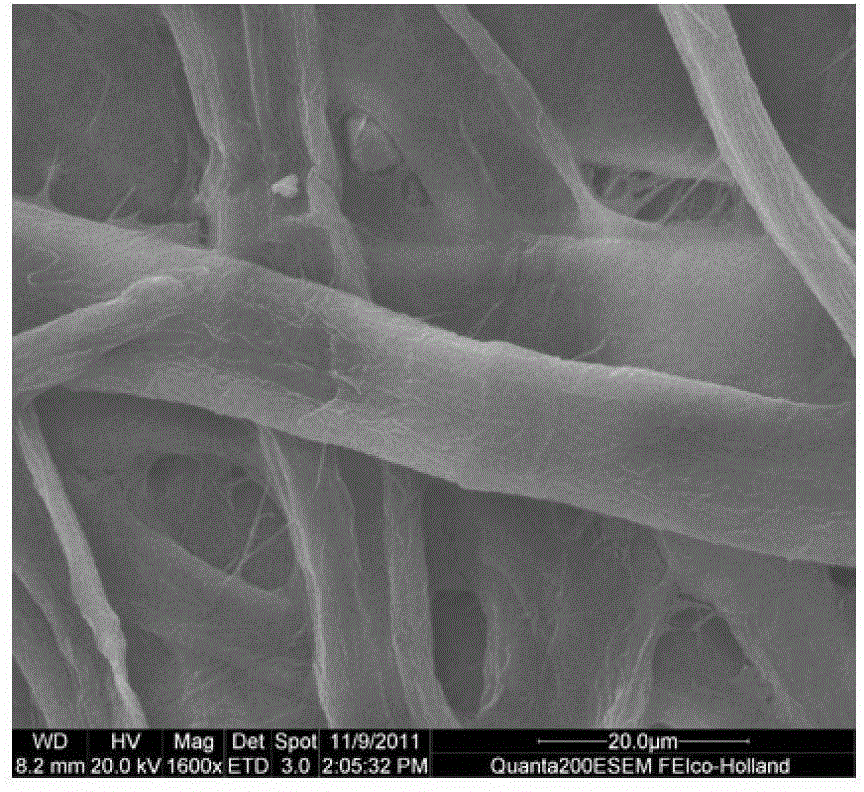

InactiveCN102493284AReduce energy consumption for beatingReduce energy billsSpecial paperWater-repelling agents additionSulfateCellulase

The invention relates to a method for producing glassine paper, which is characterized by comprising the following steps: a. respectively carrying out pulping on bleached sulfate needle wood chemical pulp and bleached sulfate broadleaf wood chemical pulpboard, respectively adding an beater auxiliary agent modified cellulase in the pulp for beating; b. preparing the pulp according to weight ratio, adding a sizing agent for mixing, forming by net part dehydration, carrying out shoe pressing and drying; c. passing the paper through at least 3 pressing areas when superpressing. The method of the present invention saves beating energy consumption by 10-15% and steam consumption by 5%.

Owner:YUEYANG FOREST & PAPER CO LTD

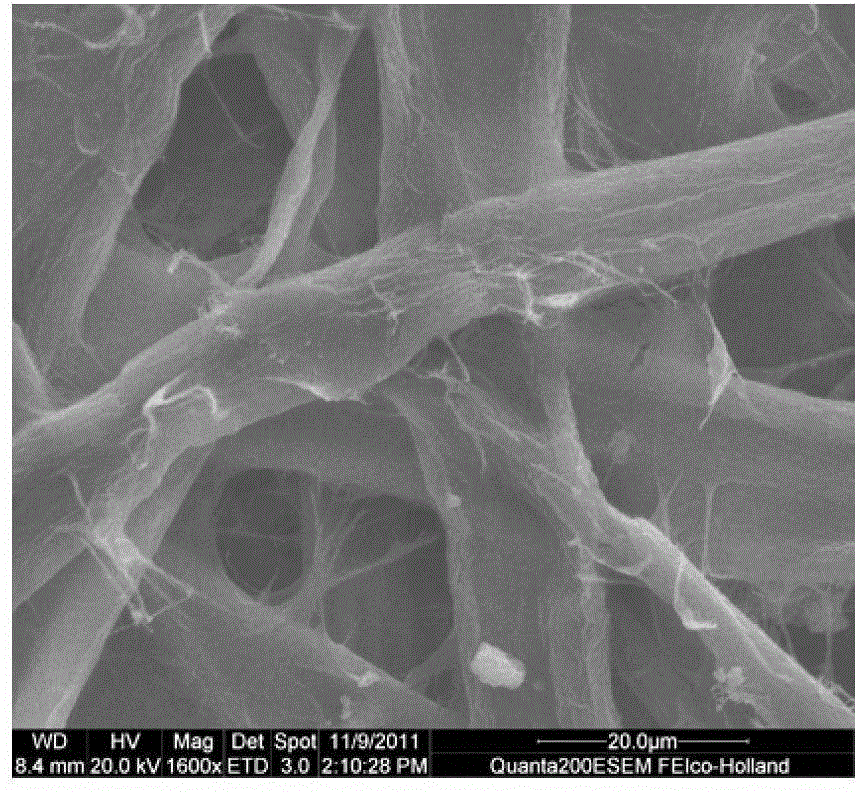

Preparation method for nano-cellulose

ActiveCN104047198APromote swellingFacilitate dissociationPulping with organic solventsPlant fibreWastewater

The invention relates to a preparation method for nano-cellulose. The method comprises the steps of: providing a plant fiber pulp; untwining the plant fiber pulp to separate the plant fiber into single fiber; conducting pre-defiberization treatment on the untwined plant fiber pulp, and simultaneously adding a TEMPO catalytic oxidation system to oxidize the fiber; when the freeness of the plant fiber pulp reaches 150-450ml, separating the oxidized fiber and wastewater; conducting defiberization treatment on the oxidized fiber again to freeness of 50ml and below, thus obtaining defiberized oxidized fiber; and carrying out nanocrystallization treatment on the defiberized oxidized fiber so as to obtain a nano-cellulose solution. The method is easier to realize wastewater separation and recovery of chemicals, at the same time can save pulping energy consumption by 20%-82%, and is easier to obtain nano-cellulose with uniform size and low cost.

Owner:GOLD EAST PAPER JIANGSU

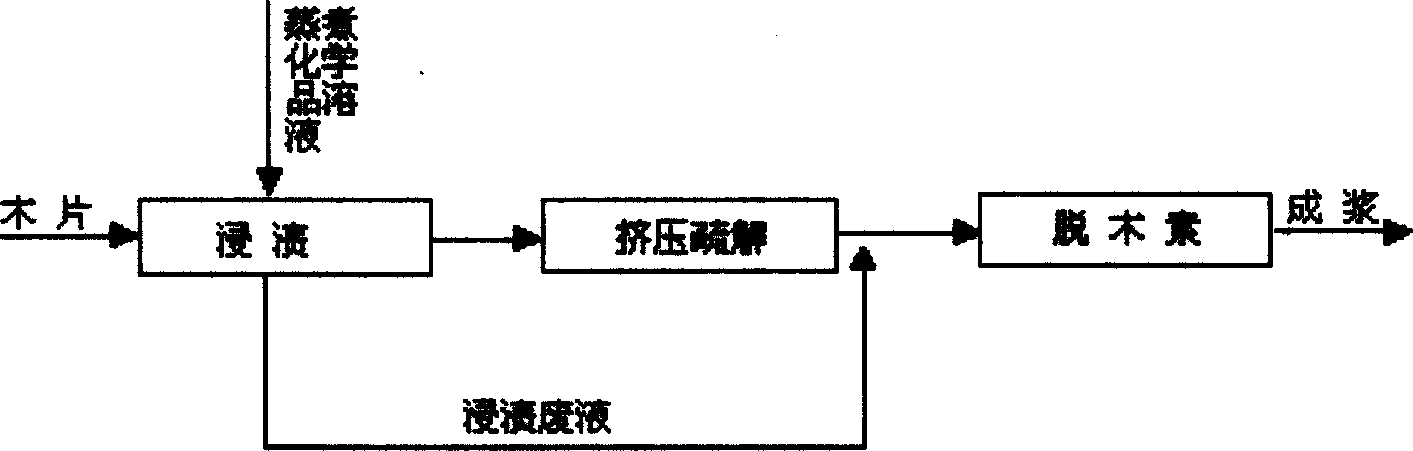

Method for producing chemical wood pulp

InactiveCN1563564AIncrease production capacityTake advantage ofCellulose material pulpingMaterials sciencePressed wood

This invention is a chemical wood pulp productive method. It contains following steps: 1) To soak, Put the thin piece wood plate into the soak liquid container, the soaking temperature is 50-90 deg.C. Soaking time is 15-50 minutes; the soak liquids use part or whole boiling liquid. 2) To relieve squeeze and press; relieve the pressed wood plate, the pressing ratio is 3-6:1. 3) To take-out lignin: put the pressing wood plate and its soak liquid into the boiler, boiling them to do the reaction of take-out lignin.

Owner:QILU UNIV OF TECH

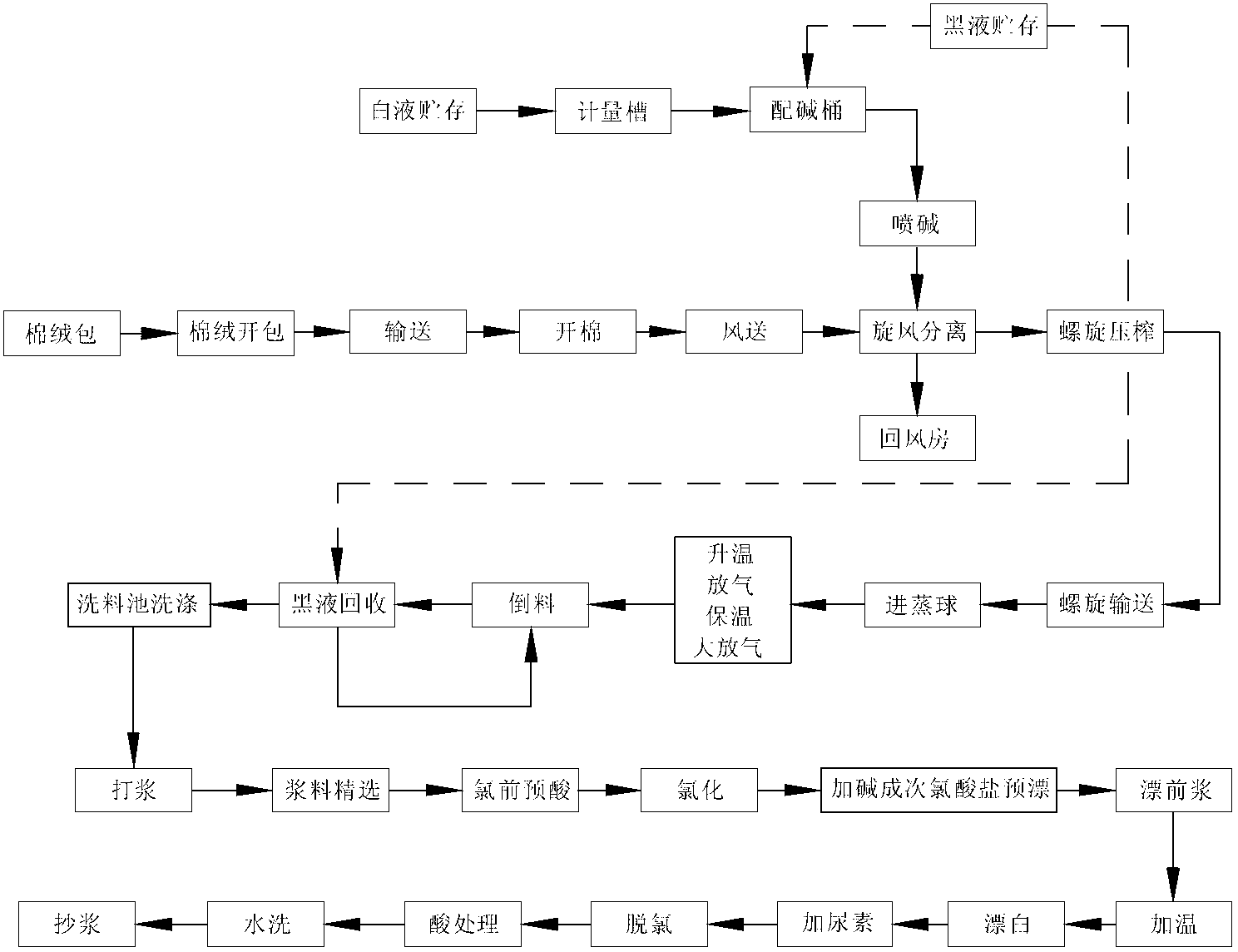

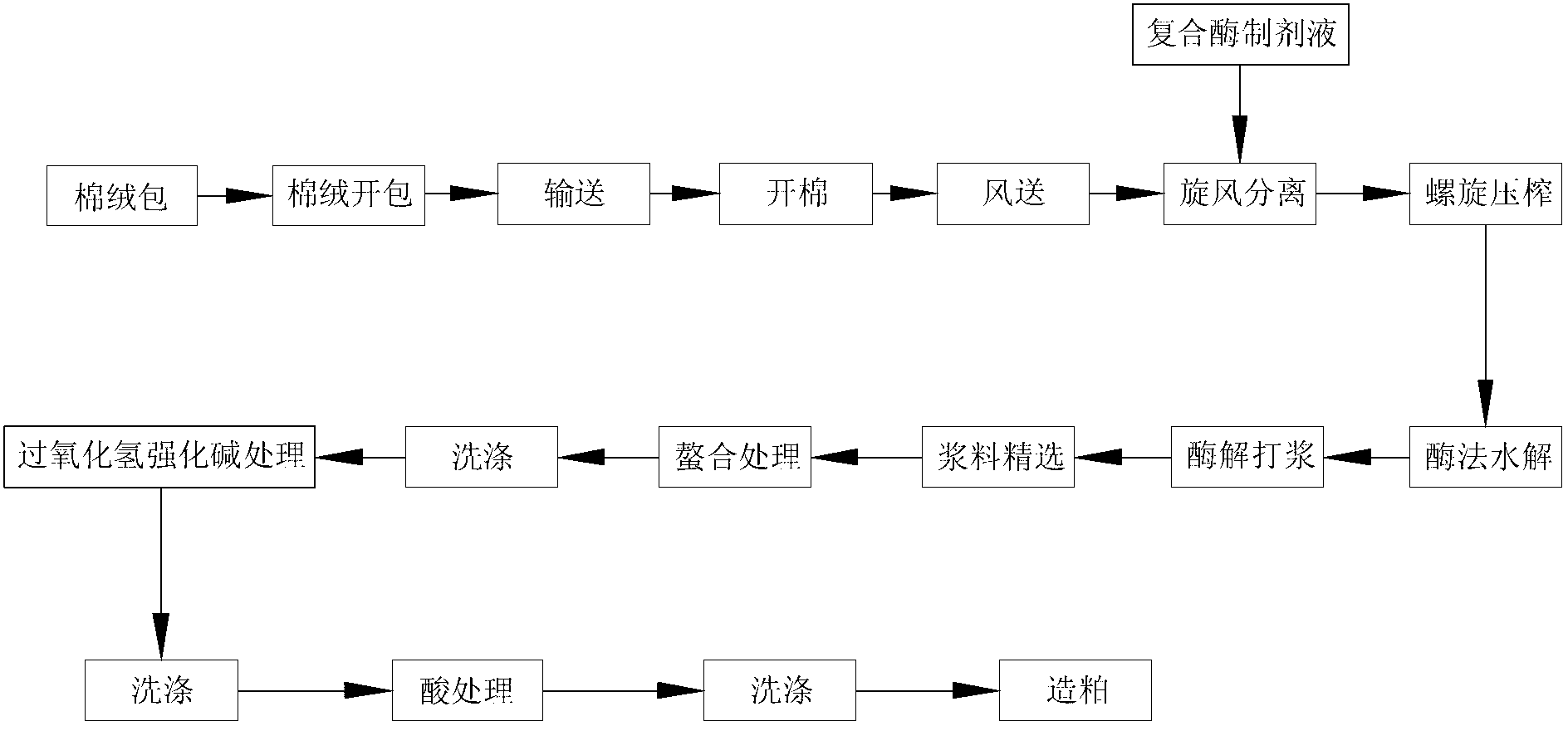

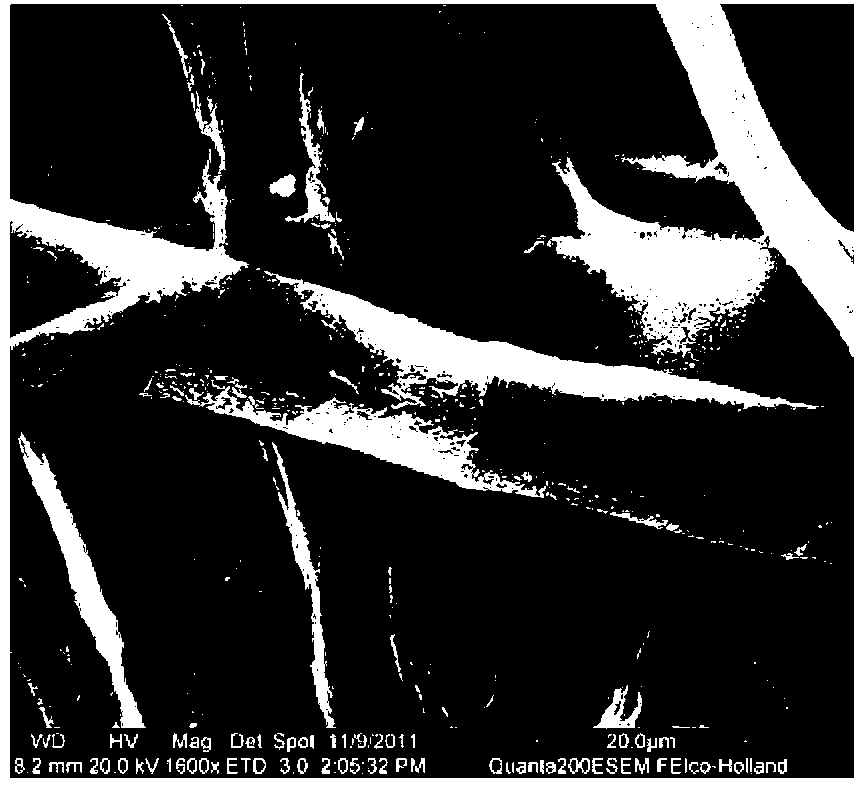

Complex enzyme preparation and technique for preparing dissolving pulp by using same

ActiveCN103061181ALoose structureEnhancement and effectPaper material treatmentChemical oxygen demandCellulose fiber

The invention relates to the technical field of production of regenerated cellulose fiber, in particular discloses a complex enzyme preparation applied in the preparation of dissolving pulp and a technique for preparing the dissolving pulp by using the enzyme preparation. The complex enzyme preparation is divided into a complex enzyme preparation I and a complex enzyme preparation II, wherein the complex enzyme preparation I mainly consists of feruloyl esterase, lipase and the like; and the complex enzyme preparation II mainly consists of xylanase, cellulase and the like. The complex enzyme preparation is applied in the technique for purifying alpha-cellulose and preparing the dissolving pulp; and the technique comprises the following steps of impurity removal for raw materials, enzyme method pretreatment, enzymolysis pulping, chelation treatment, alkali hydroxyl active oxygen cooking, acid treatment, washing, sand removal and pulp mixing. The method has the simple preparation technique, and adopts the complex enzyme preparation to treat the raw material pulp so as to effectively remove lignin, hemicellulose, pectin substance and waxiness and to reduce the degree of polymerization of the alpha-cellulose; the energy consumption is low under the normal pressure condition; the COD (Chemical Oxygen Demand) value of the pulping waste water is low; the yield of the dissolving pulp is high; the alpha-cellulose has high content and uniform degree of polymerization; and the production requirements of viscose can be satisfied.

Owner:CHAMBROAD CHEM IND RES INST CO LTD

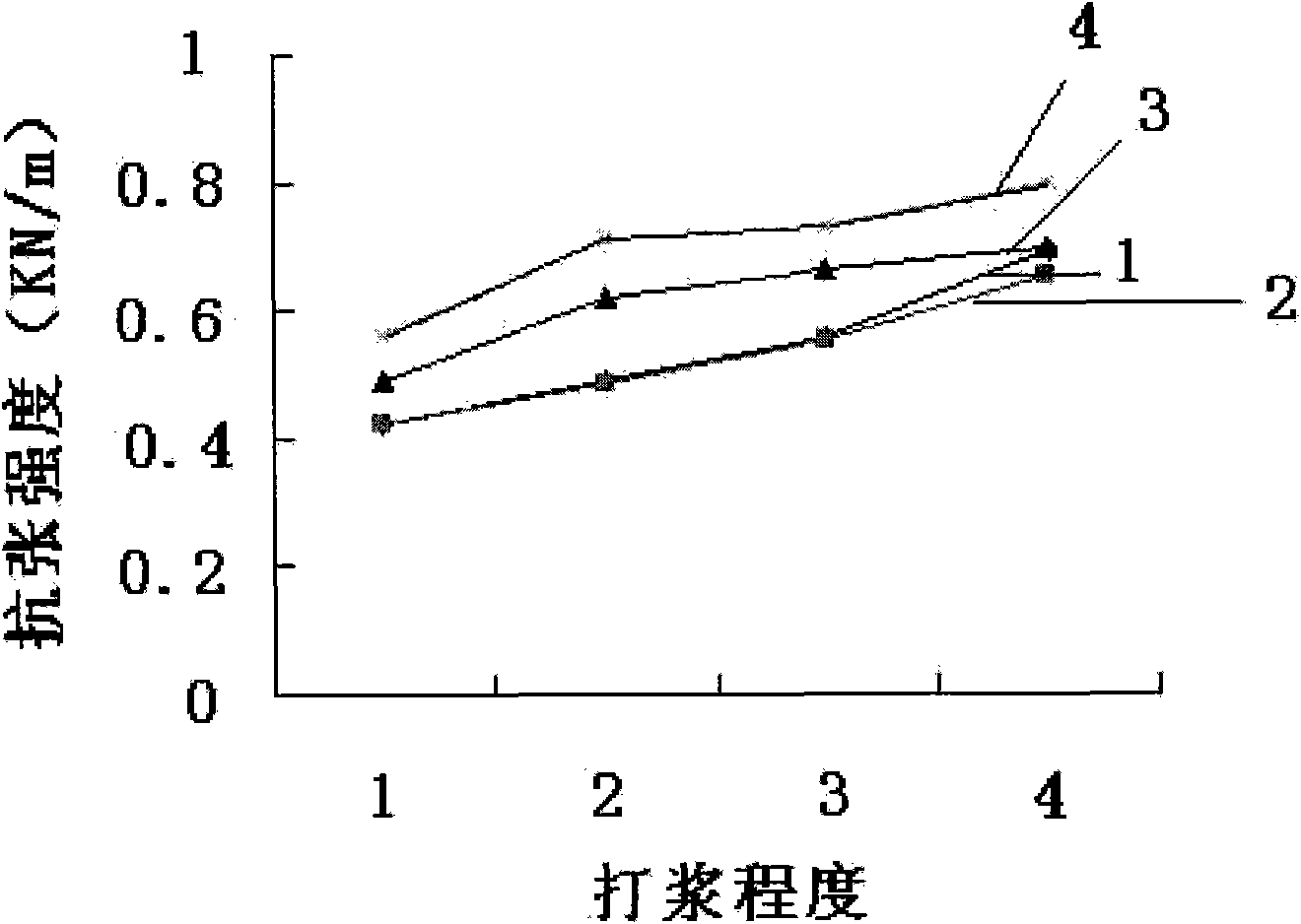

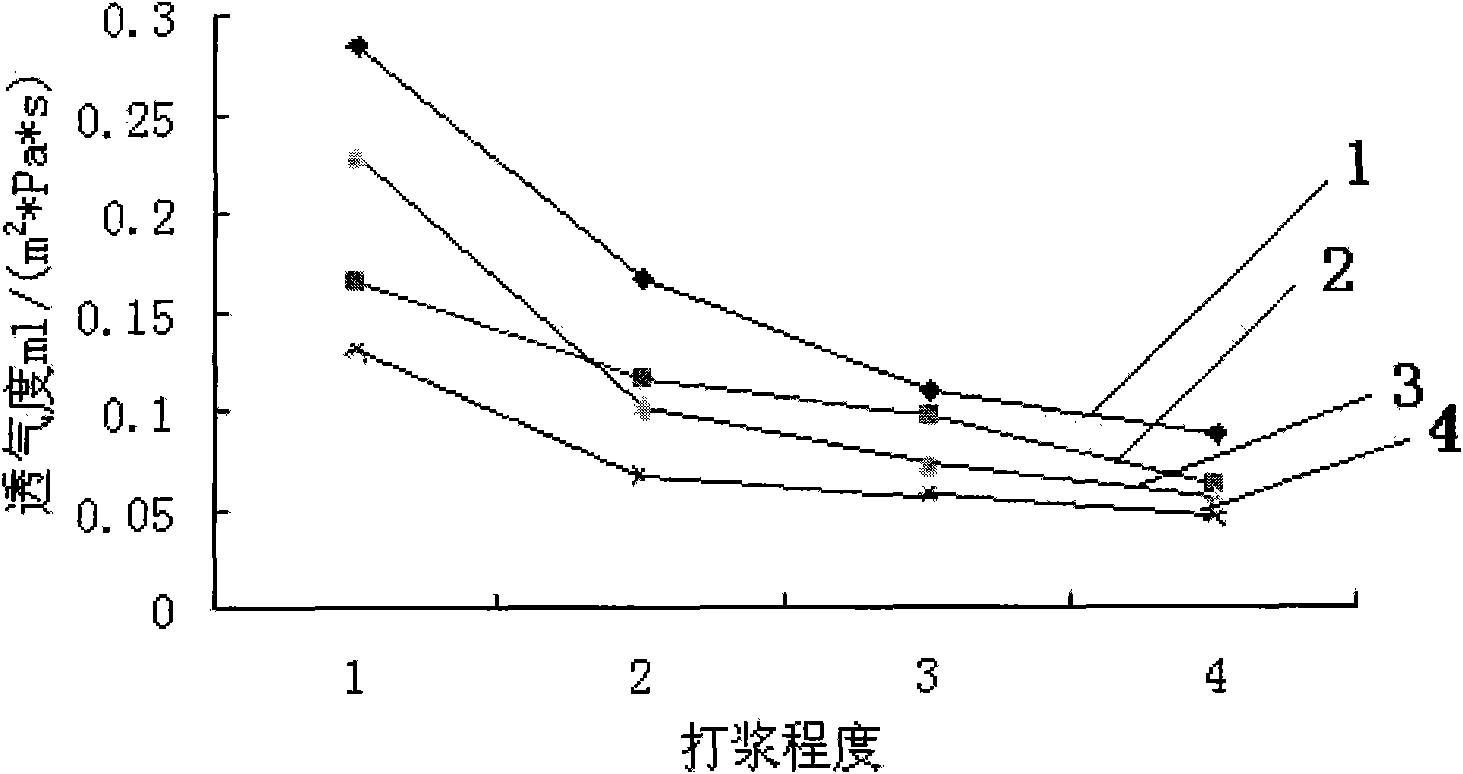

Swlfate wood-pulp enzyme-method modifying process

InactiveCN1814911AGood effectImprove run upChemical/chemomechanical pulpCellulose pulp after-treatment modificationFiberSulfate

Owner:QILU UNIV OF TECH

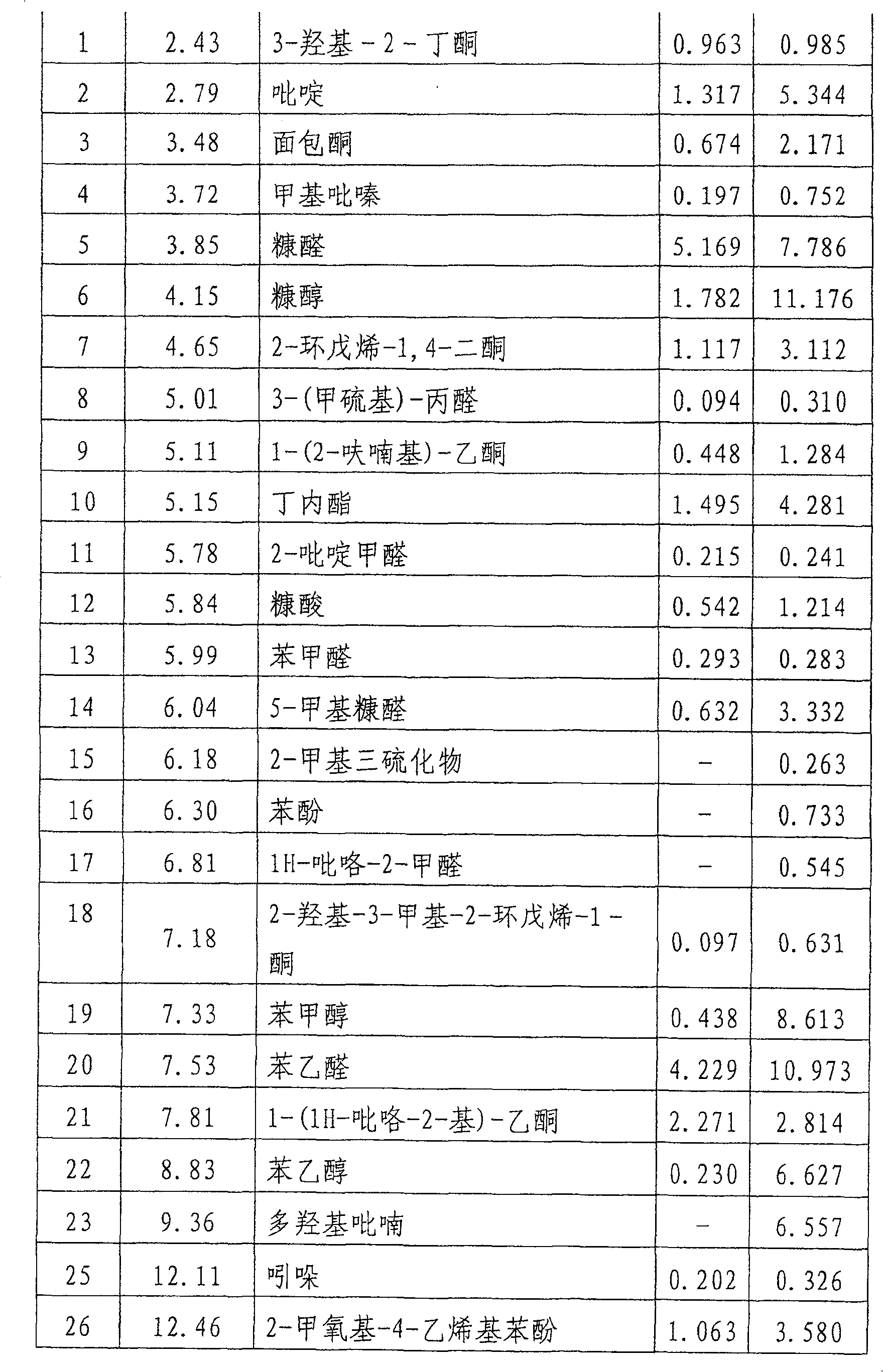

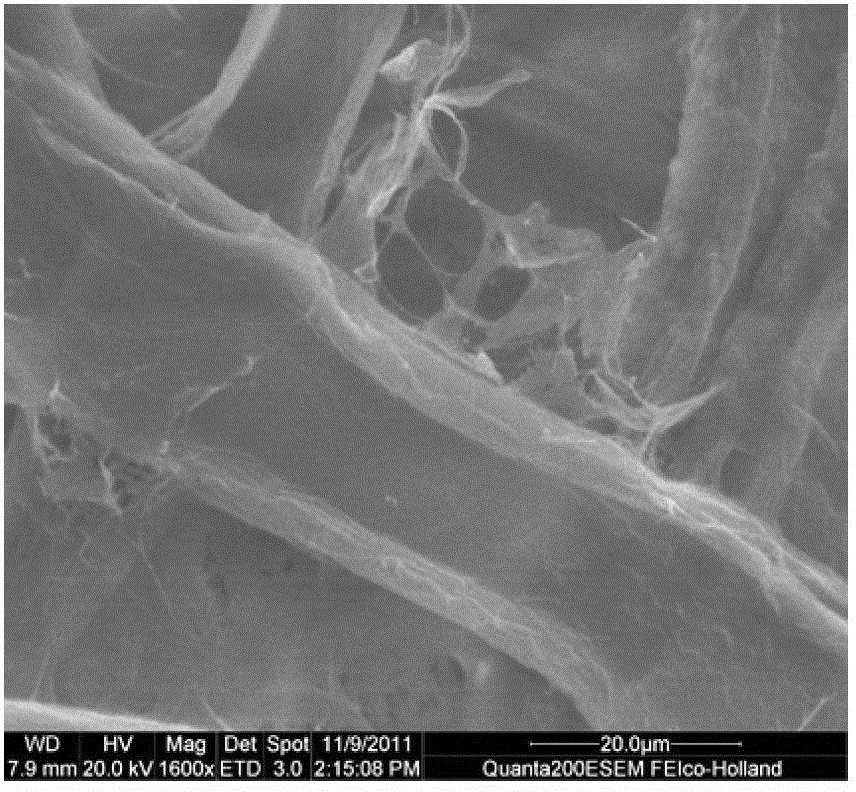

Additives for modifying reproduced tobacco leaves, prepn. method and use thereof

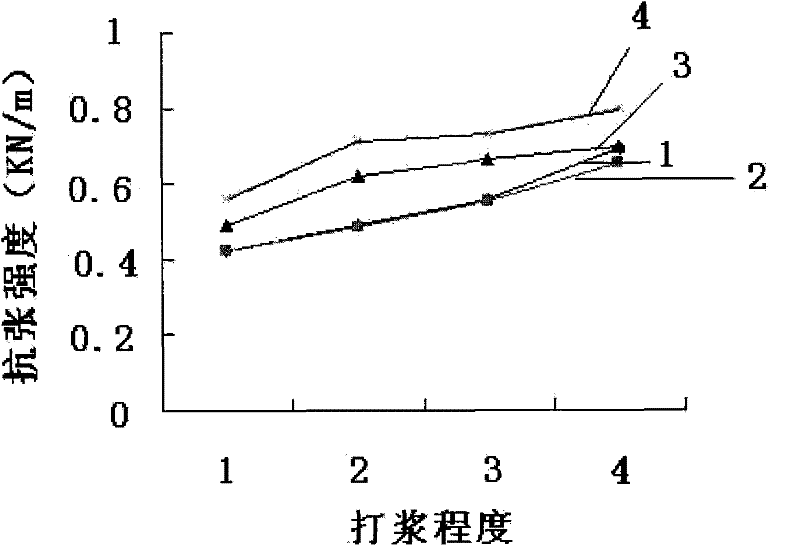

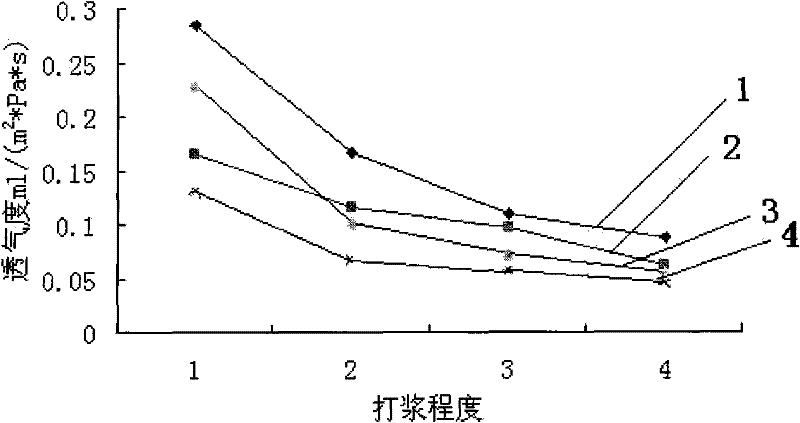

ActiveCN1947606AReduce energy consumption for beatingImprove drainageTobacco treatmentMacromolecular SubstancesChemistry

A modifying additive for preparing the tobacco leaf sheet by paper-making method is prepared through proportionally adding acidic proteinase, composite pectase, composite neutral cellulase and neutral lipase in water, stirring, filtering and taking clear liquid. It can be used to treat tobacco stems for improving the flavouring component in liquid extract and the physical properties of tobacco stem and the looseness of tobacco leaf sheet.

Owner:YUNNAN REASCEND TOBACCO TECH GRP

Biological treatment method of non-wood pulp

InactiveCN1924188AImprove water filtration performanceImprove bindingNon-fibrous pulp additionPaper/cardboardFiberCellulase

This invention relates to non-wood paper pastry biological process method, which comprises the following steps: adding enzyme into paper pastry before beating pastry with enzyme as 10-500g / ton, pastry concentration for 3-20 percentage, temperature for 20 to 60 degrees, time for 0.5 to 4 hours, pH 5.0 to 8.5, wherein, the said enzyme is of fiber enzyme or semi-fiber enzyme. This invention adopts fiber enzyme or semi-fiber enzyme to process non-wood pastry to add brooming in beating pastry process.

Owner:QILU UNIV OF TECH

ECF bleaching technology of fast growing poplar by sulfate pulp bio-chemical method

The invention discloses an ECF bleaching technology of fast growing poplar by a sulfate pulp bio-chemical method. The technology provided by the invention is characterized by comprising the following steps: (1) boiling: taking fast growing poplar chips, stewing the fast growing poplar chips in a digester to obtain virgin pulp, washing, and screening to obtain paper pulp; (2) xylanase pretreatment; and (3) ECF bleaching: bleaching the above paper pulp which has undergone enzyme treatment, wherein the bleaching process is one of three bleaching processes, namely ODQP, OPDQP or O1O2PDQP. According to the invention, xylanase is used to pretreat the paper pulp, and one of the three bleaching processes, namely ODQP, OPDQP or O1O2PDQP, is carried out for bleaching so as to obtain the paper pulp with higher whiteness and viscosity. In comparison with paper pulp which is directed bleached without xylanase pretreatment, the paper pulp produced by the ECF bleaching technology has the following advantages: beating whiteness loss is less, folding strength is averagely higher by 40 times, burst index is averagely higher by 0.45N.m.g<-1>, breaking length is averagely higher by 0.35KM, and tear index difference is very little.

Owner:QILU UNIV OF TECH

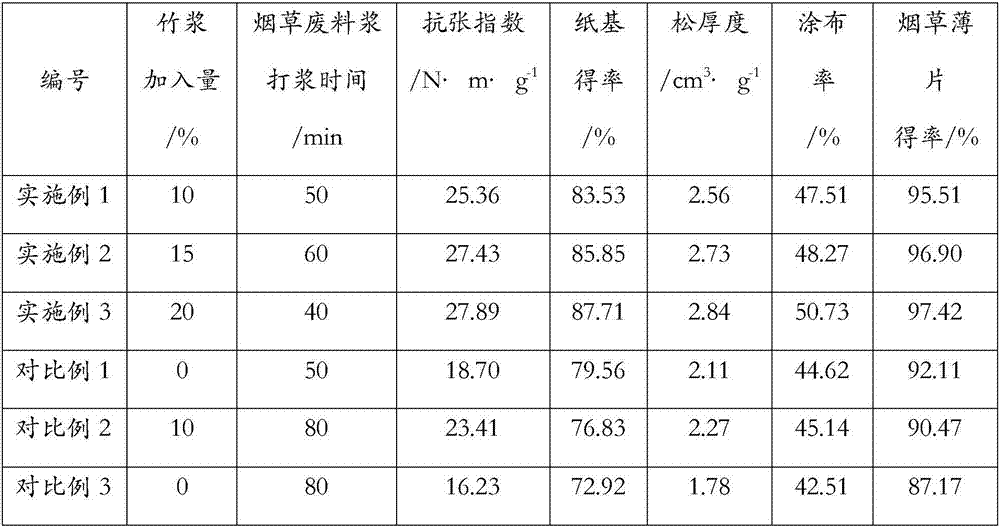

Preparation method of tobacco sheet

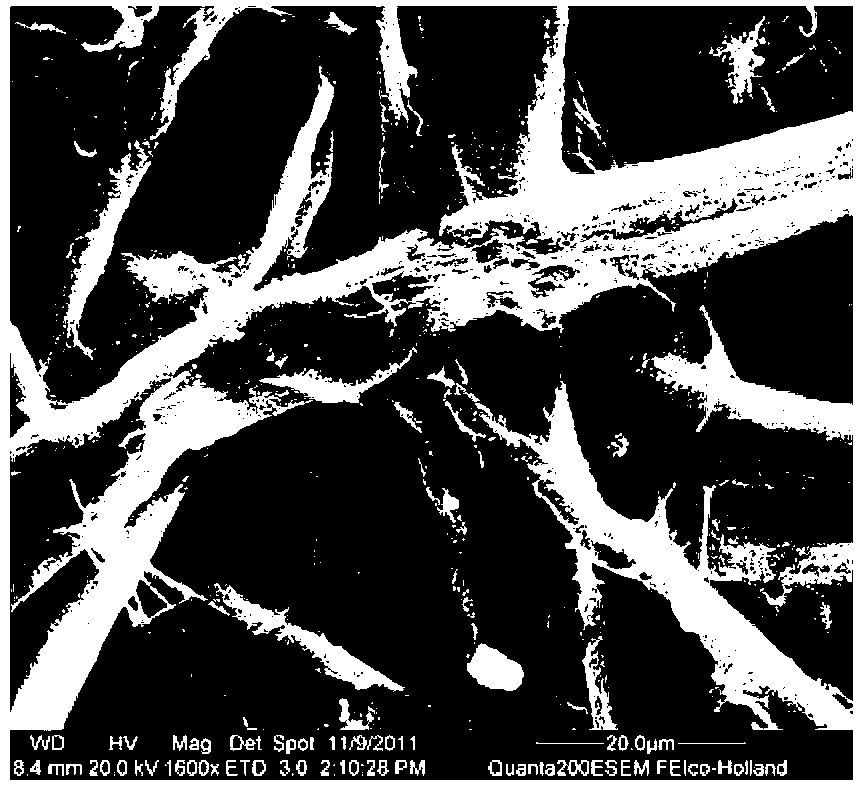

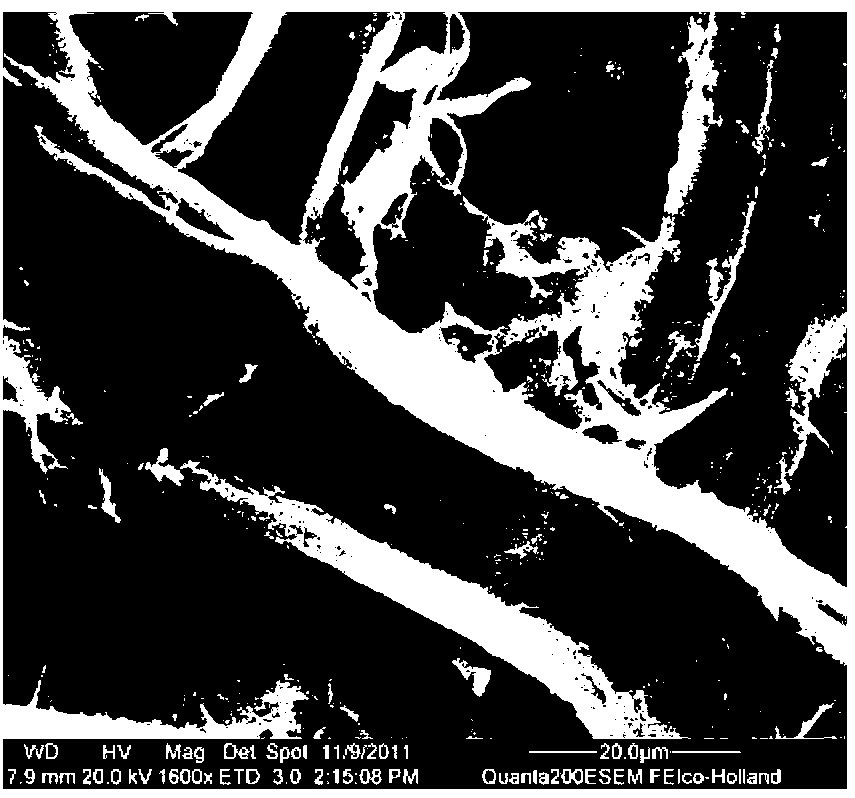

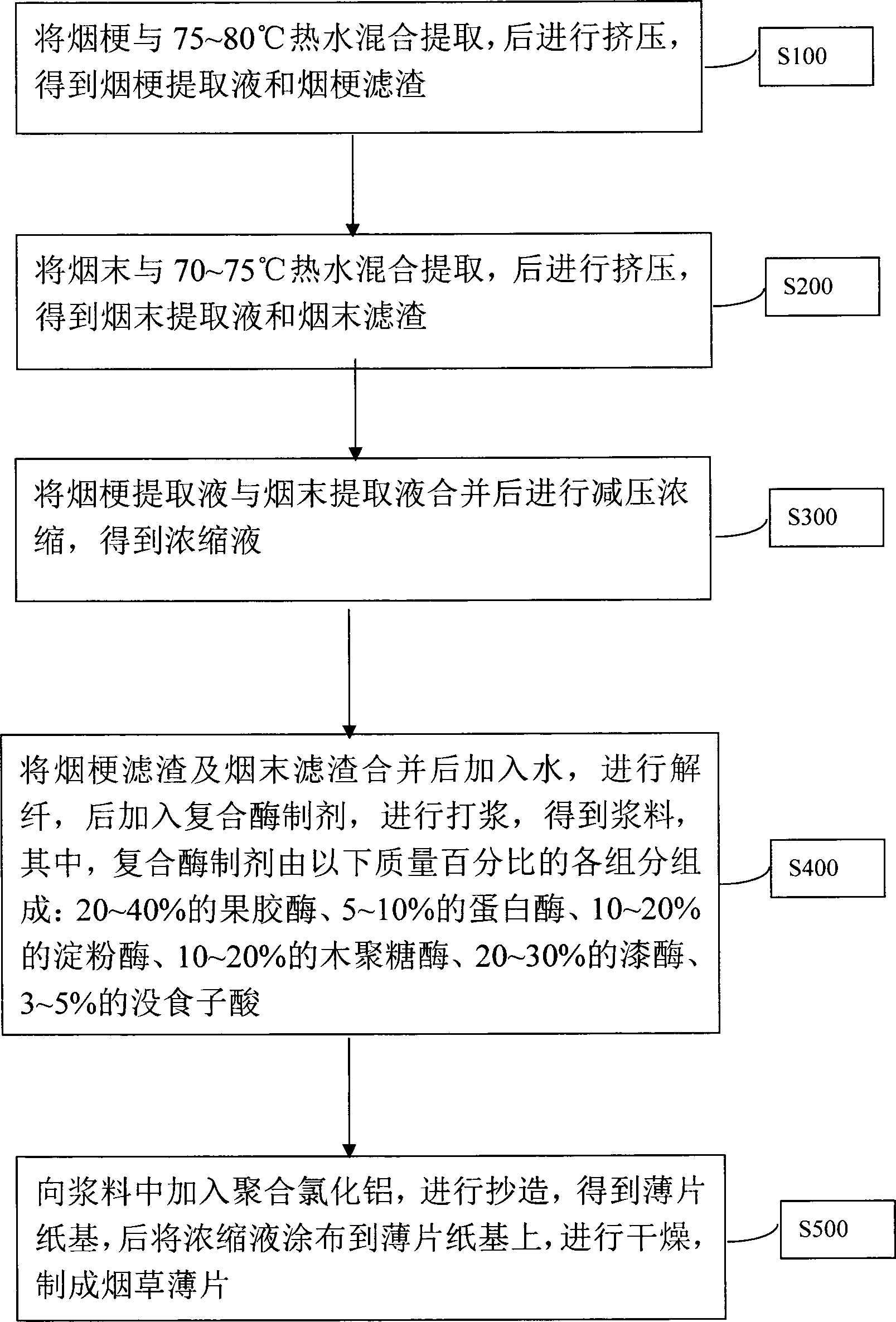

The invention provides a preparation method of a tobacco sheet. The preparation method of the tobacco sheet includes the following steps: 1) mixing tobacco stems with hot water of 75-80 DEG C for extraction, and then squeezing to obtain tobacco stem extracting solution and tobacco stem filter residues; 2) mixing tobacco powder with hot water of 70-75 DEG C for extraction, and then squeezing to obtain tobacco powder extracting solution and tobacco powder filter residues; 3) mixing the tobacco stem extracting solution with the tobacco powder extracting solution for decompression concentration so as to obtain concentrated solution; 4) adding water into a mixture of the tobacco stem filter residues and the tobacco powder filter residues for fiber decomposition, and then adding complex enzyme preparations for pulping so as to obtain pulp materials; and 5) adding polymeric aluminum into the pulp materials for manufacturing paper with pulp so as to obtain a sheet paper base, then coating the sheet paper base with the concentrated solution, and drying to obtain the tobacco sheet. According to the preparation method of the tobacco sheet, the complex enzyme preparations are added after fibers of the tobacco stem filter residues and the tobacco powder filter residues are decomposed, and performance of the pulp materials is improved, pulping energy consumption is reduced, and the sheet yield is improved through synergistic effects among a variety of enzymes.

Owner:SUZHOU KUNLAN BIOTECH

ECF bleaching technology of fast growing poplar by NaOH-AQ pulp biochemical method

The invention discloses an ECF bleaching technology of fast growing poplar by a NaOH-AQ pulp biochemical method. The technology provided by the invention is characterized by comprising the following steps: (1) steaming: taking fast growing poplar chips, stewing the fast growing poplar chips in a digester to obtain virgin pulp, washing and screening to obtain paper pulp; (2) xylanase pretreatment; and (3) ECF bleaching: bleaching the above paper pulp which has undergone enzyme treatment, wherein the bleaching process is ODED and comprises steps of: oxygen delignification or reinforced oxygen delignification is firstly carried out on the paper pulp which has undergone enzyme treatment; after oxygen delignification, the paper pulp is washed and D-stage chlorine dioxide bleaching is then carried out; after D-stage chlorine dioxide bleaching, the paper pulp is washed and then E stage is performed; and after E stage, the paper pulp is washed and secondary D stage is carried out. According to the invention, xylanase is used to pretreat the paper pulp, and then bleaching is performed by the ODED bleaching process so as to obtain the paper pulp with higher whiteness and viscosity. Under the condition that the total dosage of ClO2 is 1%, the whiteness of bleached pulp reaches up to 88.6% ISO as the highest level and to 88.1% ISO as the lowest level.

Owner:QILU UNIV OF TECH

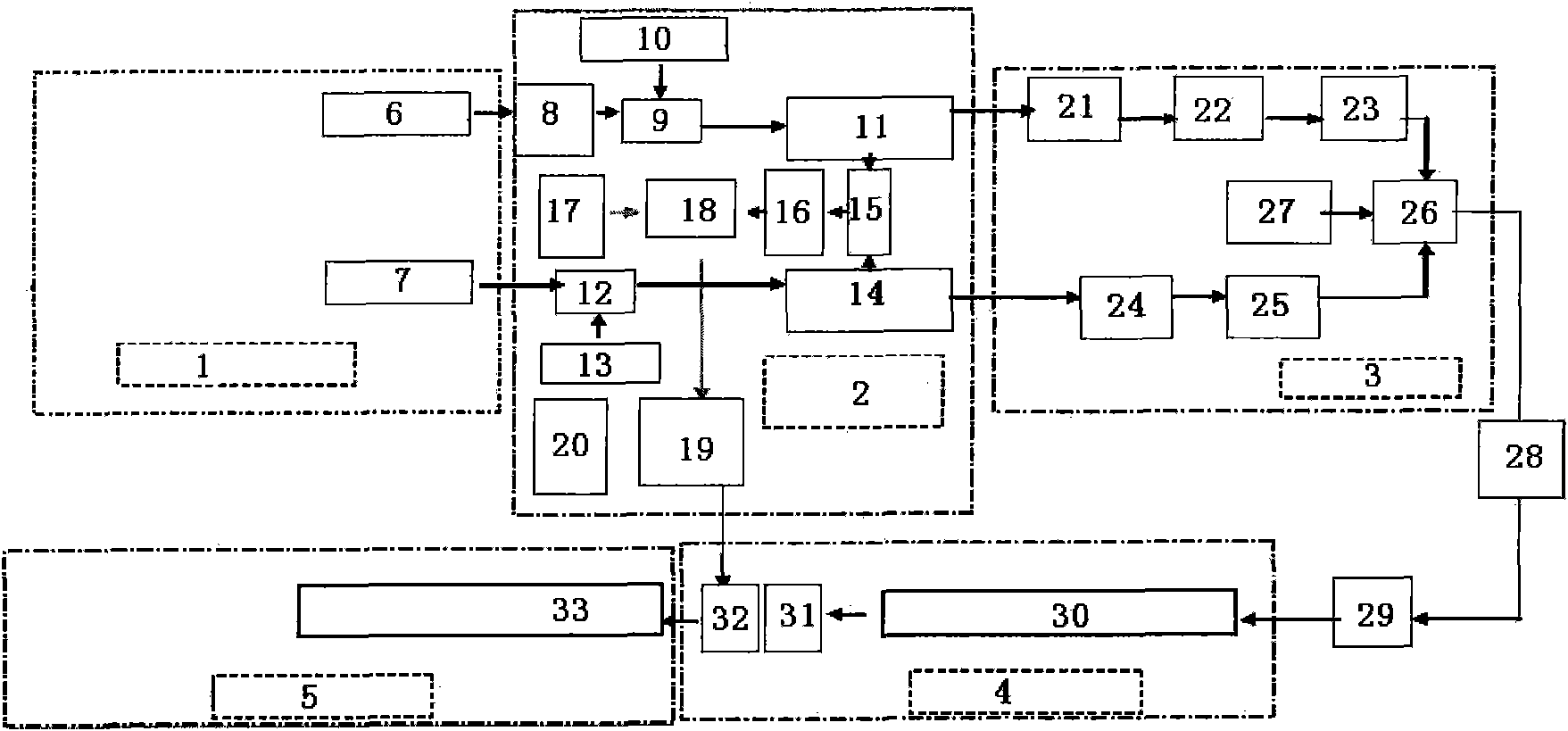

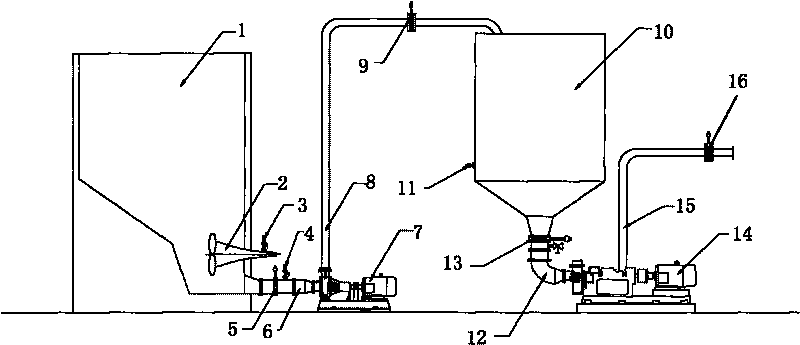

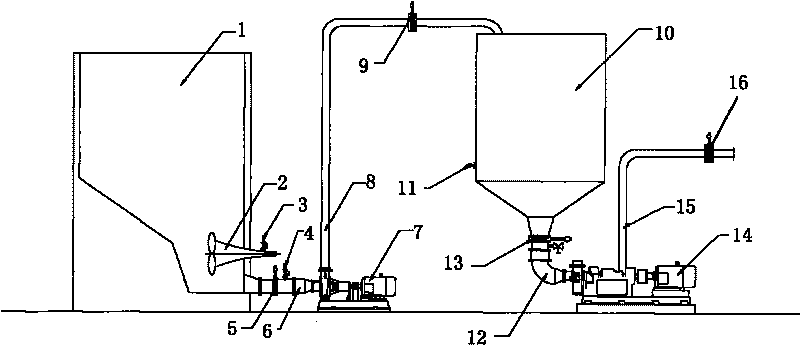

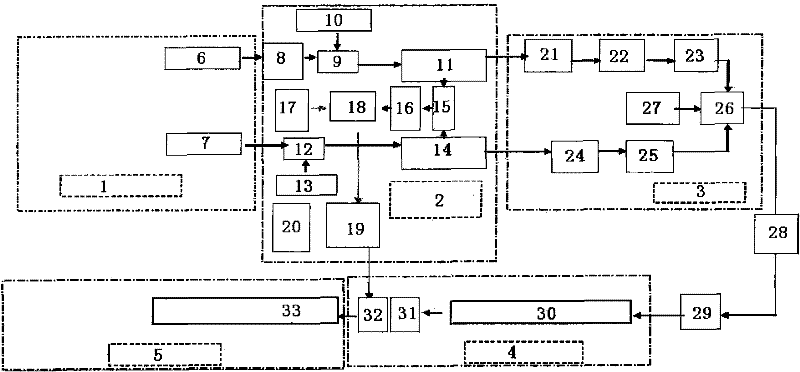

Device for controlling pulping process and control method thereof

InactiveCN101705633AQuality improvementImprove stabilityPulp beating methodsPulp and paper industryEnergy consumption

The invention discloses a device for controlling a pulping process and a control method thereof. The device comprises a first pulp tank, a pulp pump, a second pulp tank and a pulping machine sequentially connected with each other, wherein the first pulp tank is internally provided with a stirrer with dilution water, a pulp inlet tube of the pulp pump is provided with a dilution water tube, a pulp outlet tube of the pulp pump is provided with a paper pulp concentration meter, the second pulp tank is provided with a liquid level meter, and a pulp outlet tube of the pulping machine is provided with a flow meter. The method realizes the control of the pulping process through constant paper pulp concentration, constant paper pulp flux and constant pulping power. In the invention, the device and the method realize the pulping process under the set conditions of paper pulp concentration, flux, pressure and pulping power, thereby being beneficial to the stability of the pulping quality and the paper quality, reducing the energy consumption of the pulping process and improving the physical performance of papers.

Owner:SOUTH CHINA UNIV OF TECH

Method for pre-treating wood chips by hot water before preparing chemi-mechanical pulp and pulping method by using same

ActiveCN103790057AReduce consumption costReduce manufacturing costPretreatment with water/steamPre treatmentWoodchips

The invention relates to a method for pre-treating wood chips by hot water before preparing chemi-mechanical pulp. The method comprises the following steps: after soaking the wood chips, spirally extruding the wood chips; adding water into the wood chips which are spirally extruded, carrying out self-hydrolyzing pre-treatment on a mixture of the wood chips and water, and obtaining a pre-hydrolysate and the wood chips after self-hydrolyzing pre-treatment; and collecting the extruded wood chips as a raw material of chemi-mechanical pulp to obtain the wood chips after pre-treatment by hot water. The pre-treatment method provided by the invention fully uses existing part of equipment in the pulping industry without external complex equipment, and only water, small amount of dilute acids and ethanol are used without purchasing other chemicals, so that the pre-treatment process can be realized, thereby greatly saving the comprehensive production cost. Meanwhile, the method is beneficial for effectively combining pulping and papermaking with bio-refinery by existing enterprises.

Owner:TIANJIN UNIV OF SCI & TECH

Biochemical-method ECF (Extracellular Fluid) bleaching process for KP (Kraft Pulp) of fast growing poplars

The invention discloses a biochemical-method ECF (Extracellular Fluid) bleaching process for KP (Kraft Pulp) of fast growing poplars. The process is characterized by comprising the following steps of: (1) cooking: putting fast growing poplar wood chips into a cooking pot for cooking so as to obtain primary pulp, then, washing and screening so as to obtain paper pulp; (2) carrying out pretreatment by using xylanase; and (3) bleaching ECF: the bleaching of the paper pulp subjected to enzyme treatment comprises the steps of: firstly, carrying out oxygen delignification or intensified oxygen delignification on the paper pulp subjected to enzyme treatment; washing the paper pulp after the oxygen delignification is ended, and then, carrying out D-section chlorine dioxide bleaching; washing the paper pulp after the D-section chlorine dioxide bleaching is ended, and then, carrying out E-section treatment; and washing the paper pulp after the E-section treatment is ended, and then, carrying out second D-section treatment. According to the process, an ODED bleaching sequence is adopted to carry out bleaching, the paper pulp with higher whiteness and viscosity is obtained, and the whiteness of the bleached pulp reaches 88.1% ISO to the maximum and reaches 87.6% ISO to the minimum in the case that the total consumption of ClO2 is 1%; and the whiteness of the ODED-bleached pulp is 85.1% ISO.

Owner:QILU UNIV OF TECH

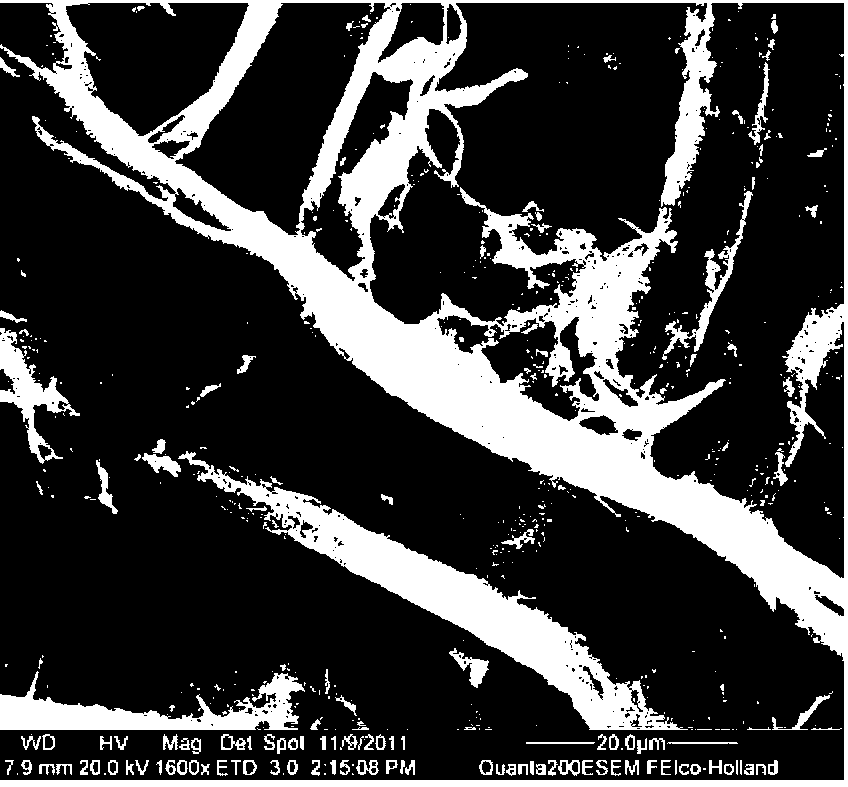

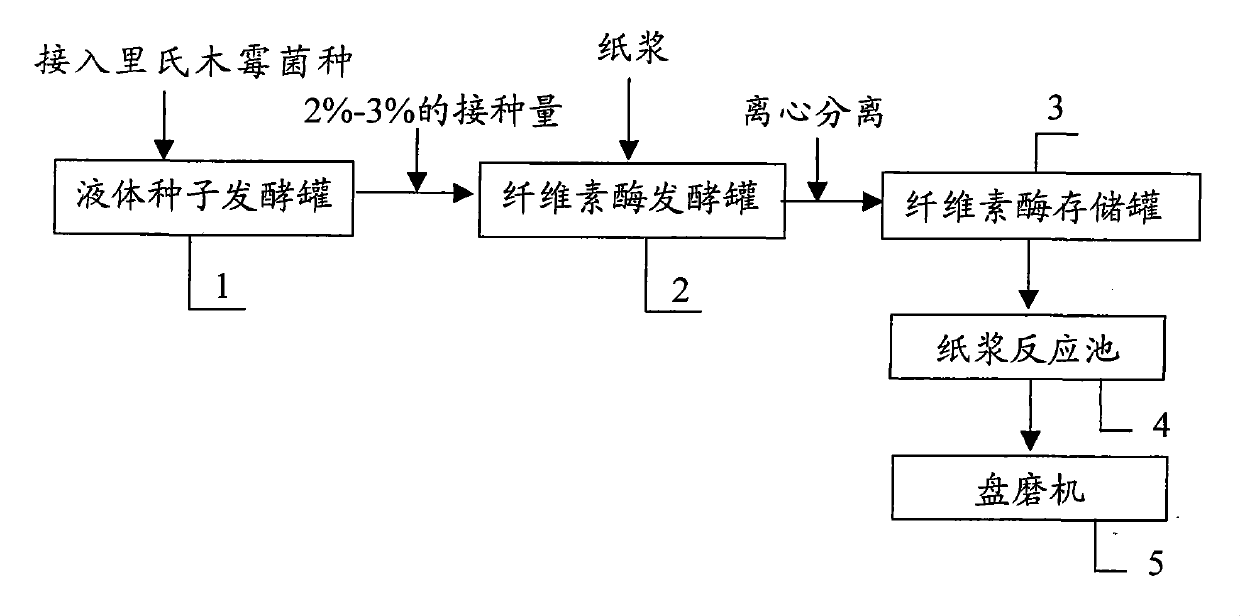

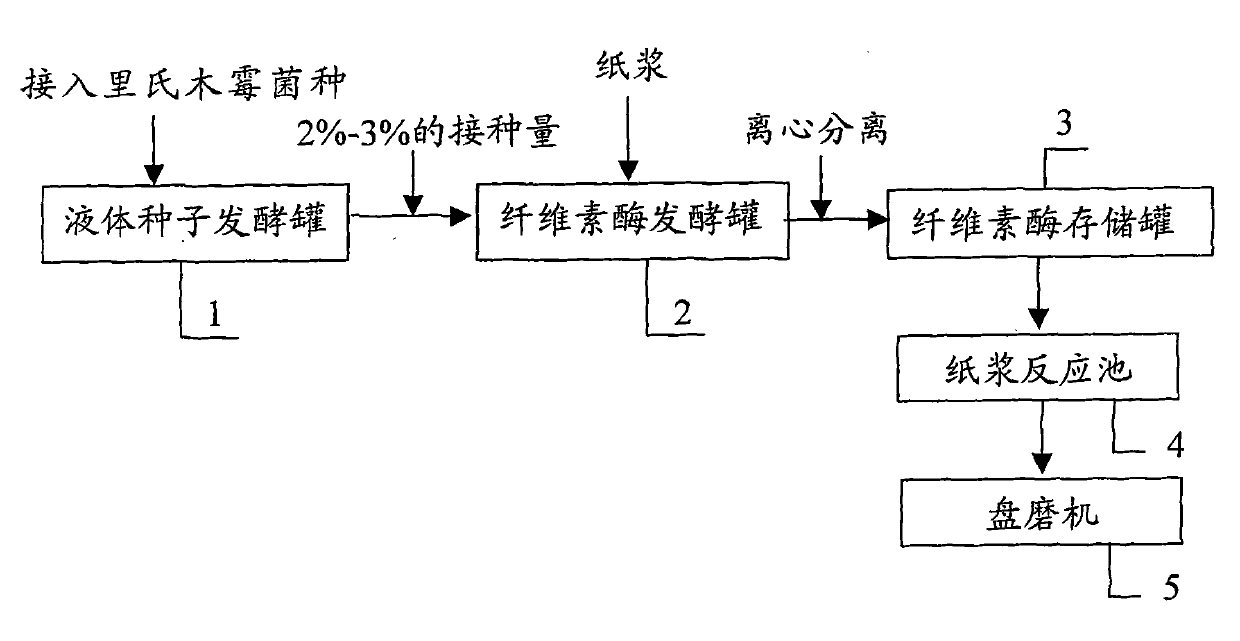

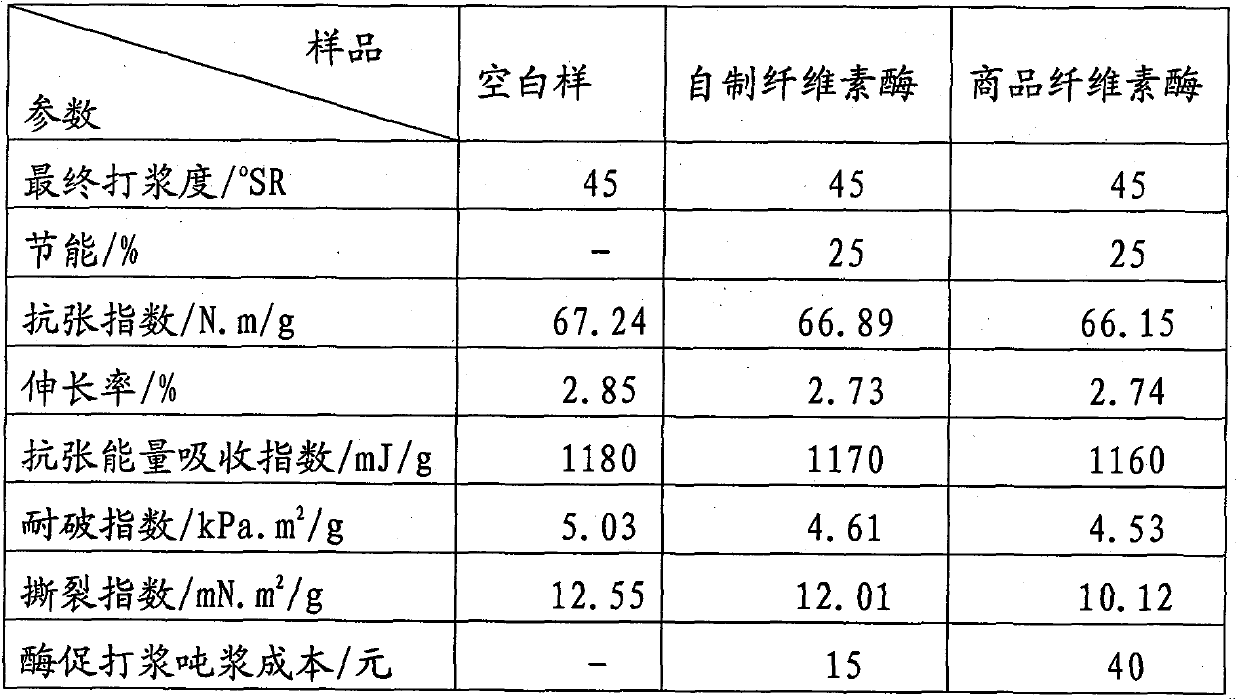

Trichoderma reesei liquid submerged fermentation cellulase and enzymatic beating process thereof

InactiveCN101418289BImprove adaptabilityIncrease enzyme activityMicroorganism based processesEnzymesSubmerged fermentationEngineering

Owner:TIANJIN UNIV OF SCI & TECH

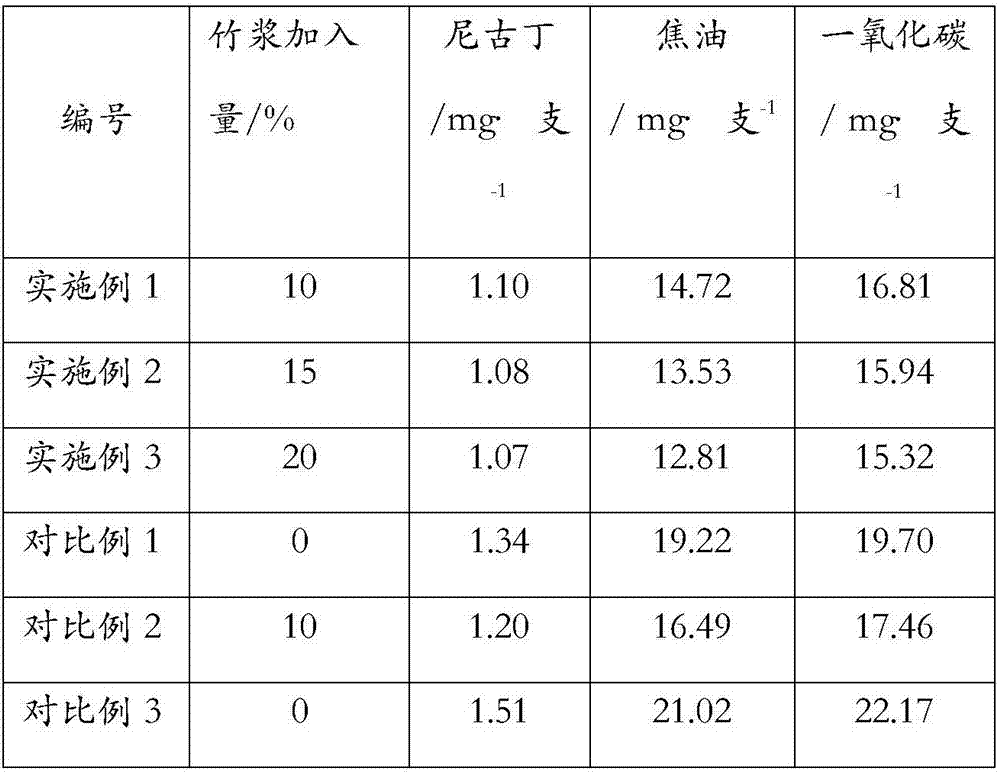

Natural-color bamboo pulp for reconstituted tobacco additive and preparation method thereof

The invention belongs to the technical field of reconstituted tobacco, and specifically relates to natural-color bamboo pulp for a reconstituted tobacco additive and a preparation method thereof. The method is characterized in that bamboo is used as the raw material and subjected to preparing, stewing, squeezing extrusion, dipping, pulping and papermaking to obtain a high-purity product. The physical performance indexes of the natural-color bamboo pulp are that the tensile index is 35-45N-m / g; the burst index is 2.5-3.5kPa-m<2> / g; the tearing index is 6.5-9.5mN-m<2> / g; the intrinsic viscosity is 800-1000mL / g; the whiteness is 30-40% ISO; the pentosane is less than 8%; the ash content is less than 1.0%; the bulk is 5.0-8.5cm<3> / g. The prepared tobacco slices are added to finished cut tobacco based on ratio; the prepared cigarette is capable of supplying more air intake quantity while smoking, so that the cigarette can be promoted to completely burn, and the quantity of pyrolysis products under oxygen-poor condition can be effectively decreased, and as a result, the releasing quantity of harmful components such as tar and nicotine can be decreased.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

Method for producing noodle packing paper

InactiveCN102505572AImprove paper surface friction coefficientReduce energy consumption for beatingNatural cellulose pulp/paperFlexible coversHardwoodAmyris

The invention relates to a method for producing noodle packing paper, which is mainly characterized by comprising the following steps of: blending poplar chemical mechanical pulp, bleached sulfate softwood pulp and bleached sulfate hardwood pulp serving as fiber raw materials, treating by using a thick pulp sieve, seasoning, slushing, desanding and degassing, sizing, performing fine screening, dewatering and forming a mesh part, squeezing, before-drying, performing surface sizing, after-drying, calendering, reeling, and packing, wherein the weight percent ratio of the poplar chemical mechanical pulp to the bleached sulfate softwood pulp to the bleached sulfate hardwood pulp is (16-25):(25-35):(45-55); during surface sizing, a lubricant and enzyme converted starch are mainly involved and compounded in a weight ratio of (1-5):20; and the glue concentration of the surface of the starch is 6 to 8 percent, and sizing amount is 1 to 4g / cm<2>. The food grade lubricant is used for surface sizing to improve the friction coefficient of a paper surface, the high-yield chemical mechanical pulp is used for making the noodle packing paper by optimizing the process, and the smoothness of the paper surface still can be ensured under the condition that pulping energy consumption is greatly reduced.

Owner:YUEYANG FOREST & PAPER CO LTD

Preparation method for paper pulp containing multiple functional groups

ActiveCN104098704AImprove wet strengthHigh strengthWashing/displacing pulp-treating liquorsPulp bleachingCelluloseCatalytic oxidation

A preparation method for paper pulp containing multiple functional groups comprises the following steps: providing vegetable fiber raw material; boiling the vegetable fiber raw material to prepare paper pulp; and after boiling is finished, adding an oxidation system into the paper pulp to perform oxidation modification on the fiber raw material. The oxidation system employs one of TEMPO catalytic oxidation system, a periodate, a nitrite, sodium chlorite and sodium hypochlorite. By adding the oxidation system for oxidizing fiber after the boiling step, paper pulp rich in aldehyde group and carboxyl functional group is obtained, aldehyde group is beneficial for improving the wet strength of paper, and carboxyl is beneficial for reducing energy consumption of beating and increasing the strength of paper. Additionally, the paper pulp rich in multiple functional groups is relatively easy for preparation of cellulose ether and ester derivatives.

Owner:GOLD EAST PAPER JIANGSU

ECF bleaching technology of fast growing poplar by sodium hydroxide anthraquinone pulp bio-chemical method

The invention discloses an ECF bleaching technology of fast growing poplar by a sodium hydroxide anthraquinone pulp bio-chemical method. The ECF bleaching technology is characterized by comprising the following steps: (1) boiling: taking fast growing poplar chips, stewing the fast growing poplar chips in a digester to obtain virgin pulp, washing, and screening to obtain paper pulp; (2) xylanase pretreatment; and (3) ECF bleaching: bleaching the above paper pulp which has undergone enzyme treatment, wherein the bleaching process is one of three bleaching processes, namely ODQP, OPDQP or O1O2PDQP. According to the invention, xylanase is used to pretreat the paper pulp, and one of the three bleaching processes, namely ODQP, OPDQP or O1O2PDQP, is carried out for bleaching so as to obtain the paper pulp with higher whiteness and viscosity. In comparison with paper pulp which is directed bleached without xylanase pretreatment, the paper pulp produced by the ECF bleaching technology has the following advantages: beating whiteness loss is less, folding strength is averagely higher by 30 times, burst index is averagely higher by 0.35N.m.g<-1>, breaking length is averagely higher by 0.25KM, and tear index difference is basically unchanged or slightly reduced by a very small magnitude.

Owner:QILU UNIV OF TECH

Rapid-growth poplar sodium hydroxide anthraquinone pulp biochemical method TCF bleaching process

ActiveCN103362009AHigh viscosityHigh folding resistancePulp bleachingCellulose material pulpingXylanasePre treatment

The invention discloses a rapid-growth poplar sodium hydroxide anthraquinone pulp biochemical method TCF bleaching process. The process is characterized in that the process comprises the steps that: (1) steaming is carried out, wherein rapid-growth poplar wood sheets are steamed in a steaming pot, such that an original pulp is obtained; washing and screening are carried out, such that paper pulp is obtained; (2) xylanase pretreatment is carried out; (3) TCF bleaching is carried out, wherein the treated paper pulp is bleached with one of the bleaching sequence selected from OP-Q-P, O1-O2P-Q-P and O1P-O2P-Q-P. According to the invention, paper pulp is pretreated by using xylanase, and bleaching is carried out with one of the three bleaching sequences of XOPQP, XO1O2PQP and XO1PO2PQP, such that paper pulp with higher whiteness and viscosity are obtained. Compared with paper pulp obtained by direct bleaching without xylanase pretreatment, the paper pulp provided by the invention has lower beating whiteness loss. A folding resistance is higher by 30-49 times, a burst index is higher by 0.3-0.6N.m.g<-1>, a breaking length is higher by 0.15-0.36KM, and a tearing index is not significantly changed. When a same or similar beating degree is reached, needed beating revolutions are less, and beating energy consumption can be saved by approximately 17.8%.

Owner:QILU UNIV OF TECH

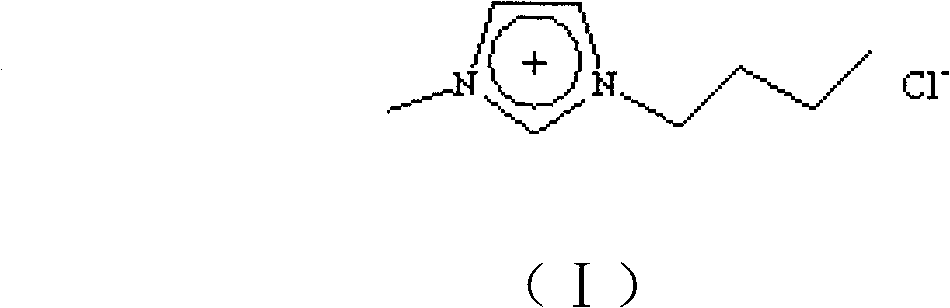

Method for treating paper pulp by using 1-butyl-3-methylimidazole chloride

InactiveCN101806006AReduce energy consumption for beatingImprove fiber qualityPulping with halogen compoundsFiberAfter treatment

The invention discloses a method for treating paper pulp by using 1-butyl-3-methylimidazole chloride, comprising the steps of: carrying out concentration drying dehydration on the paper pulp, and then filling the 1-butyl-3-methylimidazole chloride to treat the paper pulp; after treatment, washing the paper pulp by water for removing the 1-butyl-3-methylimidazole chloride; and then, entering the pulping work section for pulping. The 1-butyl-3-methylimidazole chloride removed by water washing can be recycled by simple dehydration. The method has simple operation and uses the ionic liquid which can be recycled, thus being environment-friendly. The paper pulp treated by the method reduces the pulping energy consumption, improves the fiber quality of the paper pulp, and enhances the physical indexes such as strength, white degree, surface performance, printing performance and the like of paper.

Owner:QILU UNIV OF TECH

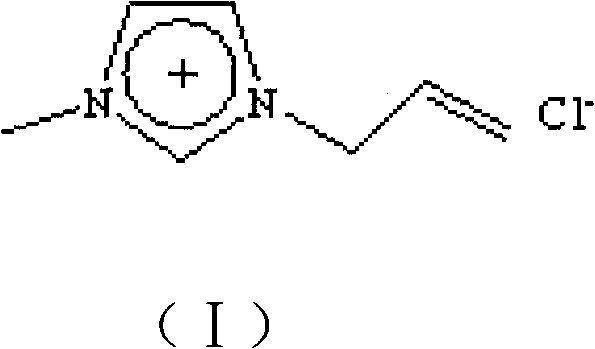

Method for treating paper pulp by using 1-allyl-3-methylimidazole chloride

InactiveCN101806007AImprove physical performanceReduce energy consumption for beatingPulping with halogen compoundsFiberAfter treatment

The invention discloses a method for treating paper pulp by using 1-allyl-3-methylimidazole chloride, comprising the steps of: carrying out concentration drying dehydration on the paper pulp, and then filling the 1-allyl-3-methylimidazole chloride to treat the paper pulp; after treatment, washing the paper pulp by water for removing the 1-allyl-3-methylimidazole chloride; and then, entering the pulping work section for pulping. The 1-allyl-3-methylimidazole chloride removed by water washing can be recycled by simple dehydration. The method has simple operation, reduces the damage for fiber due to pulping and improves the physical performance of paper. The paper pulp treated by the method reduces the pulping energy consumption, improves the fiber quality of the paper pulp, and enhances the physical indexes such as strength, surface performance, printing performance and the like of paper. In addition, the used 1-allyl-3-methylimidazole chloride can be recycled, thus being environment-friendly.

Owner:QILU UNIV OF TECH

Additives for modifying reproduced tobacco leaves, prepn. method and use thereof

A modifying additive for preparing the tobacco leaf sheet by paper-making method is prepared through proportionally adding acidic proteinase, composite pectase, composite neutral cellulase and neutral lipase in water, stirring, filtering and taking clear liquid. It can be used to treat tobacco stems for improving the flavouring component in liquid extract and the physical properties of tobacco stem and the looseness of tobacco leaf sheet.

Owner:YUNNAN REASCEND TOBACCO TECH GRP

Fiber oxidase composition for changing and improving fiber property, and papermaking method and application

ActiveCN104342424AChange and improve surface propertiesHigh reactivityMicroorganism/enzyme additionLuminescent/fluorescent substance additionFiberWAS PROTEIN

The invention discloses a fiber oxidase composition for changing and improving fiber property, and a papermaking method and an application. The composition mainly comprises the following components: a bio-enzyme component with an oxidation function on fibers, and an auxiliary component for increasing catalytic activity on the fiber oxidase, wherein the bio-enzyme component is fiber oxidase for changing the surface property of the fiber by redox reaction; the auxiliary component is protein with catalytic action on the fiber oxidase; and the weight ratio of the bio-enzyme component to the auxiliary component is 1 to (0.4-50). When the composition is used for processing paper pulp, the strength of the prepared paper is significantly enhanced, and the drainage performance of the paper pulp is greatly improved.

Owner:RISINGSTAR BIOTECH GUANGZHOU

Preparation method for two-color oil-proof antibacterial food packaging paper

ActiveCN108130818AImprove aestheticsGood oil resistanceFlexible coversWrappersSlurryPulp and paper industry

The invention discloses a preparation method for two-color oil-proof antibacterial food packaging paper. Components of a slurry are optimized, a filler is pretreated and modified, a multilayer headboxis adopted to adjust and control the components and ratio of the slurry in each layer, and therefore the two-color oil-proof antibacterial food packaging paper is prepared. The food packaging paper provided by the invention is beautiful, can play a dual antibacterial effect, does not fall hairs or powder, and has the characteristics of health and environmental protection.

Owner:浙江恒川新材料有限公司

TCE bleaching technology for sulfate pulp of growing poplar by biological chemical method

The invention discloses a TCE (Total Chlorine-Free) bleaching technology for sulfate pulp of growing poplar by biological chemical method. The technology comprises the following steps: (1), cooking: getting fast-growing polar pieces; putting the fast-growing polar pieces into a distilling pan for cooking, so as to obtain primary pulp, and then washing and screening the primary pulp to obtain paper pulp; (2), pre-treating the paper pulp with xylanase; (3), TCE bleaching: bleaching the paper pulp pre-treated with the xylanase, wherein the bleaching process is one of OP-Q-P, O1-O2P-Q-P or O1P-O2P-Q-P. According to the TCE (Total Chlorine-Free) bleaching technology for sulfate pulp of growing poplar by biological chemical method, the xylanase is adopted to pre-treat the paper pulp, then one of the bleaching processes OP-Q-P, O1-O2P-Q-P or O1P-O2P-Q-P is adopted for bleaching, so that the paper pulp with higher whiteness and viscosity is obtained; compared with the paper pulp obtained through directly bleaching without xylanase pre-treatment, the paper pulp provided by the invention has the advantages that the loss value of whiteness is lesser, the folding strength is higher 45 times averagely, the bursting index is higher 0.45 N*m*g <-1> averagely, the breaking length is higher 0.35 KM, and the tearing index is quite. The beating revolution number is lesser when the paper pulp reaches the same or similar beating degree, and the 20% of beating energy consumption can be saved approximately.

Owner:QILU UNIV OF TECH

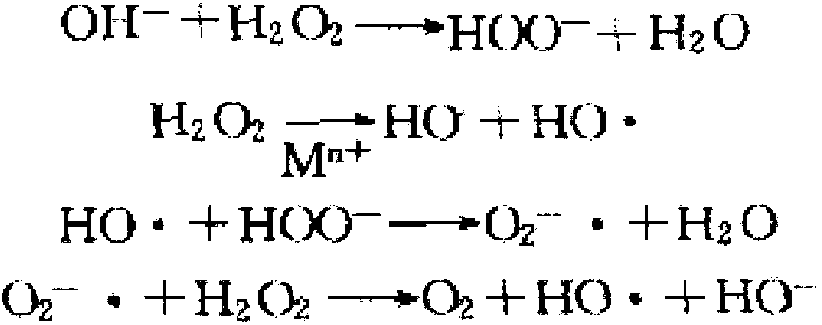

Method for oxidizing surface of pulp fiber with carboxymethylcellulose loaded with Fe2+

InactiveCN109898321AReduce energy consumption for beatingHigh tensile strengthVegetal fibresCelluloseFenton reagent

The invention discloses a method for oxidizing and modifying the surface of pulp fiber with carboxymethylcellulose (CMC) loaded with Fe2+ and belongs to the field of plant fiber modification. The method is basically characterized in that the CMC serves as the carrier of Fe2+ catalysts to form a Fe2+-CMC compound which is adsorbed and immobilized on the surface of plant fiber. During the process ofoxidizing the fiber, Fenton reagents only oxidize and degrade the cellulose on the surface of the fiber to achieve the aim of surface modification of the fiber, reduce the energy consumption of fiberpulping and further improve the tensile strength of paper.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for preparing tobacco sheet and application thereof

ActiveCN101637298BGood physical propertiesExtract completelyTobacco preparationTobacco treatmentMaillard reactionFiber

The invention discloses a method for preparing tobacco sheets and an application of the method. In the method, enzymolysis is implemented when the tobacco stalk and the tobacco powder are soaked, solid-liquid separation is implemented after extraction, the solids are made into fiber sheet substrates, liquid is made into concentrated solution by alcohol precipitation and concentration, the concentrated solution is made into coating liquid by maillard reaction and coated on the fiber sheet substrates, and the fiber sheet substrates are dried and cut into tobacco sheets. In the invention, the macromolecular compounds that influence the quality of the tobacco sheets are sufficiently degraded by enzymolysis, the content of the impure taste in the tobacco sheets is decreased, the internal quality of the tobacco sheets is improved, and better aroma is obtained by the technical solution that produces prospective aroma by the maillard reaction to provide a rich aroma for the tobacco sheets so as to obtain tobacco sheet products fitting different types of cigarette products and having better internal quality. The tobacco sheets prepared by the method have excellent compatibility and harmonywith the conventional raw materials of the cigarettes, and have the advantages of good cigarette taste, various and rich aromas and less impure taste.

Owner:CHINA TOBACCO GUANGDONG IND

Special paper for paper diapers and production process thereof

ActiveCN108914679AGood fiber lengthWith fiber strengthNatural cellulose pulp/paperSpecial paperPerformance indexPulp and paper industry

The invention discloses special paper for paper diapers and a production process thereof, the special paper is prepared from native coniferous wood pulp. The fix quantify of the special paper for thepaper diapers is 50g / m<2>, the beating degree is 28 to 38-degree SR; the transverse tensile index of the finished paper is equal to or greater than 50N-m / g, the longitudinal tensile index of the finished paper is equal to or greater than 100N.m / g, and the longitudinal wet tensile strength of the finished paper is equal to or greater than 150N / m, the tear index of the finished paper is equal to orgreater than 8mN.m<2> / g, the burst index of the finished paper is equal to or greater than 5kPa.m<2> / g and folding resistance of the finished paper is equal to or greater than 1000 times. The specialpaper for the paper diaper is close to non-woven fabric used by current paper diapers manufacturers in performance indexes, and can replace a surface coating layer of the paper diapers. In addition, the special paper for the paper diapers can absorb and remove odor and harmful gases in the paper diapers so as to make the paper diapers safer, sanitary and comfortable.

Owner:山东爱舒乐卫生用品有限责任公司

Swlfate wood-pulp enzyme-method modifying process

InactiveCN100390354CImprove run upIncreased fibrillationChemical/chemomechanical pulpCellulose pulp after-treatment modificationFiberSulfate

Owner:QILU UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com