Natural-color bamboo pulp for reconstituted tobacco additive and preparation method thereof

A technology of natural bamboo pulp and reconstituted tobacco

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

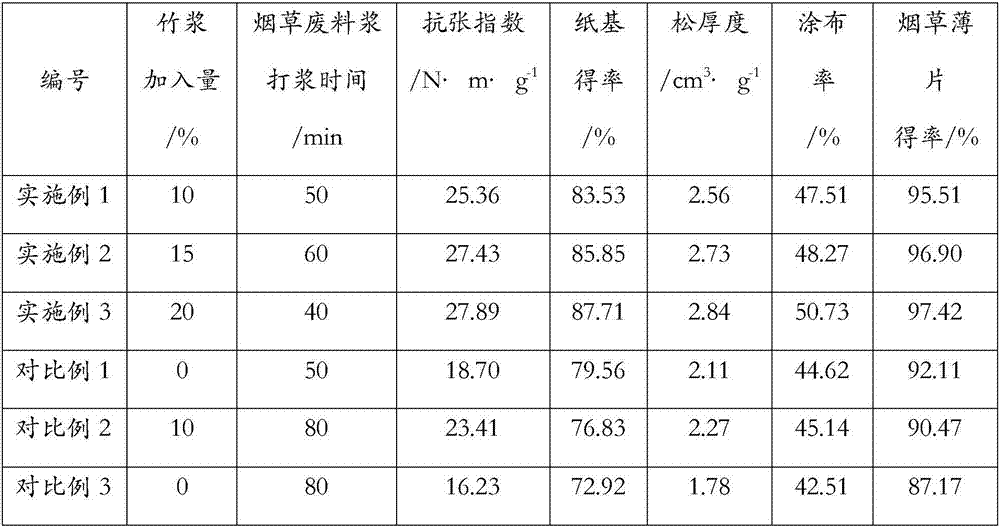

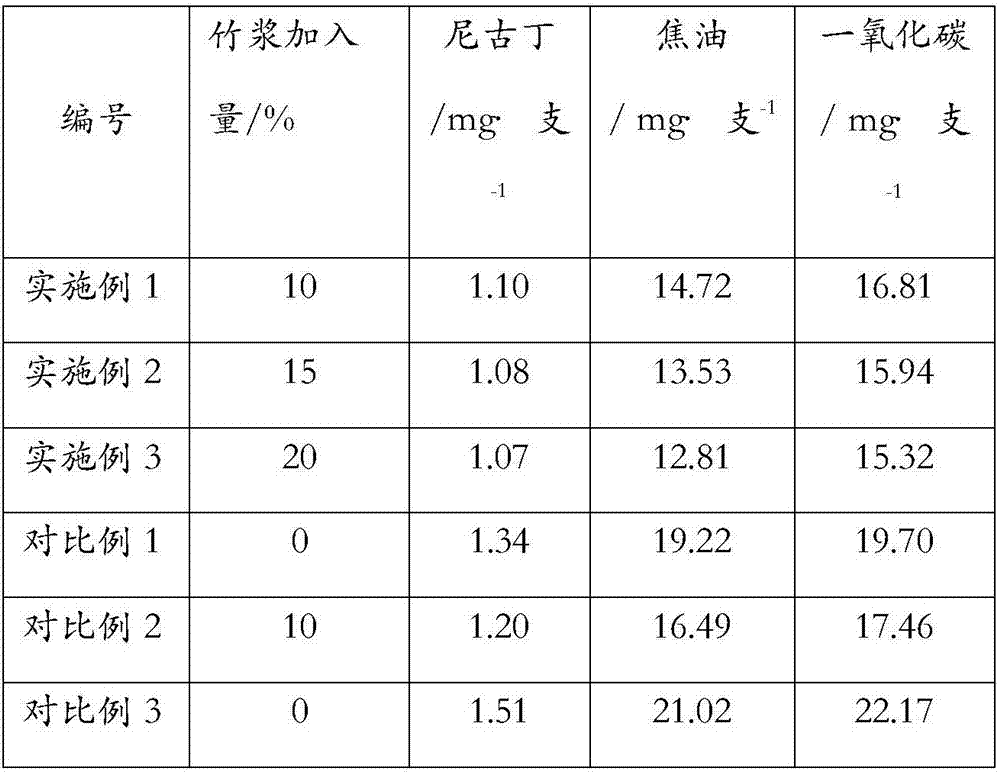

Examples

Embodiment 1

[0045] (1) Cut the bamboo directly into lengths of 10-50mm and widths of 5-20mm, and use a dry method to remove impurities such as mud, sand, knots, and chips through a dust collector. After dust removal, send them to a cooking pot for alkaline cooking. The liquid ratio is 1 : 6, relative to the dry raw material quality, 30% (Na 2 O meter), 0.5% of dihydroanthraquinone, 0.1% of sodium dodecylbenzenesulfonate, 15% of sulfidation degree.

[0046] The cooking curve is: heat up to 150°C within 90 minutes, corresponding to a pressure in the pot of about 0.48MPa, then put the pot until the pressure in the pot is 0MPa, then raise the temperature to the highest temperature of 150°C, and keep it at this temperature for 80 minutes until the end of cooking.

[0047] (2) concentration: the slurry obtained in step (1) is put into the spray pot, and concentrated through waste liquid extraction, screening and concentrator, and the mass concentration of the slurry after concentration is 20%; ...

Embodiment 2

[0062] (1) Cut the bamboo directly into 10-50mm long and 5-20mm wide, adopt wet method, wash away surface impurities and remove excess water after the grass washer, enter the digester for alkaline cooking, the liquid ratio is 1: 3. Relative to the quality of the dry raw material, the amount of alkali used is 15% (calculated as Na2O), tetrahydroanthraquinone is 0.6%, xylenesulfonic acid is 0.2%, and the degree of sulfidation is 30%.

[0063] The cooking curve is: heat up to 148°C within 90 minutes, corresponding to a pressure of about 0.45MPa in the pot, then put the pot until the pressure in the pot is 0MPa, then raise the temperature to the highest temperature of 148°C, and keep it at this temperature for 80 minutes until the end of cooking.

[0064] (2) Concentration: the slurry obtained in step (1) is entered into the spray pot, and concentrated through waste liquid extraction, screening and concentrator, and the mass concentration of the slurry after concentration is 30%; ...

Embodiment 3

[0075] (1) Cut the bamboo directly into lengths of 10-50mm and widths of 5-20mm, and use a dry method to remove impurities such as mud, sand, knots, and chips through a dust collector. After dust removal, send them to a cooking pot for alkaline cooking. The liquid ratio is 1 : 4, relative to the dry raw material quality, 20% (Na 2 O meter), dihydrodihydroxyanthraquinone 1.0%, alkylphenol polyoxyethylene ether sodium sulfate 0.1%, degree of vulcanization 20%.

[0076] The cooking curve is: the temperature is raised to 152°C within 90 minutes, corresponding to a pressure in the pot of about 0.50 MPa, then the pot is placed until the pressure in the pot is 0 MPa, and then the temperature is raised to the highest temperature of 152°C, and kept at this temperature for 80 minutes until the end of cooking.

[0077] (2) Concentrate: the slurry that step (1) is obtained enters spray pot, is concentrated through waste liquid extraction, screening and concentrator, and the mass concentra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile index | aaaaa | aaaaa |

| Burst index | aaaaa | aaaaa |

| Tear index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com