Trichoderma reesei liquid submerged fermentation cellulase and enzymatic beating process thereof

A technology of cellulase and Trichoderma reesei, which is applied in pulping of cellulose raw materials, enzymes, and treatment of fiber raw materials, can solve the problems of weak commercial pulp market competitiveness, difficulty in beating kraft pulp, and shortage of papermaking raw materials. Achieve the effect of reducing energy consumption, low cost and low production cost of beating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

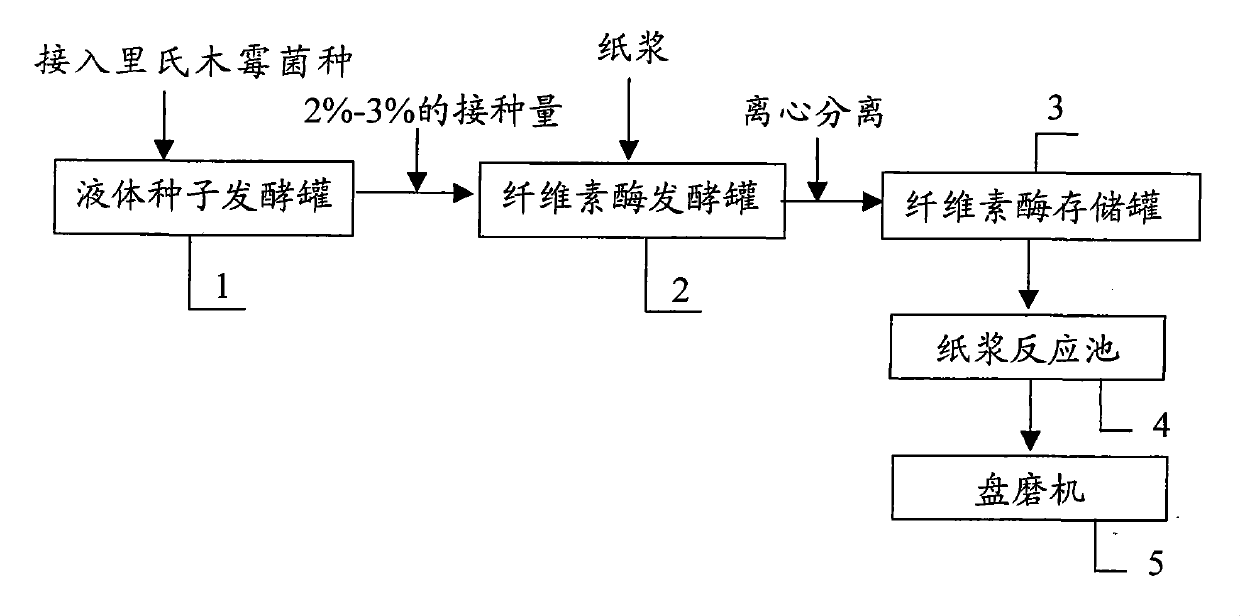

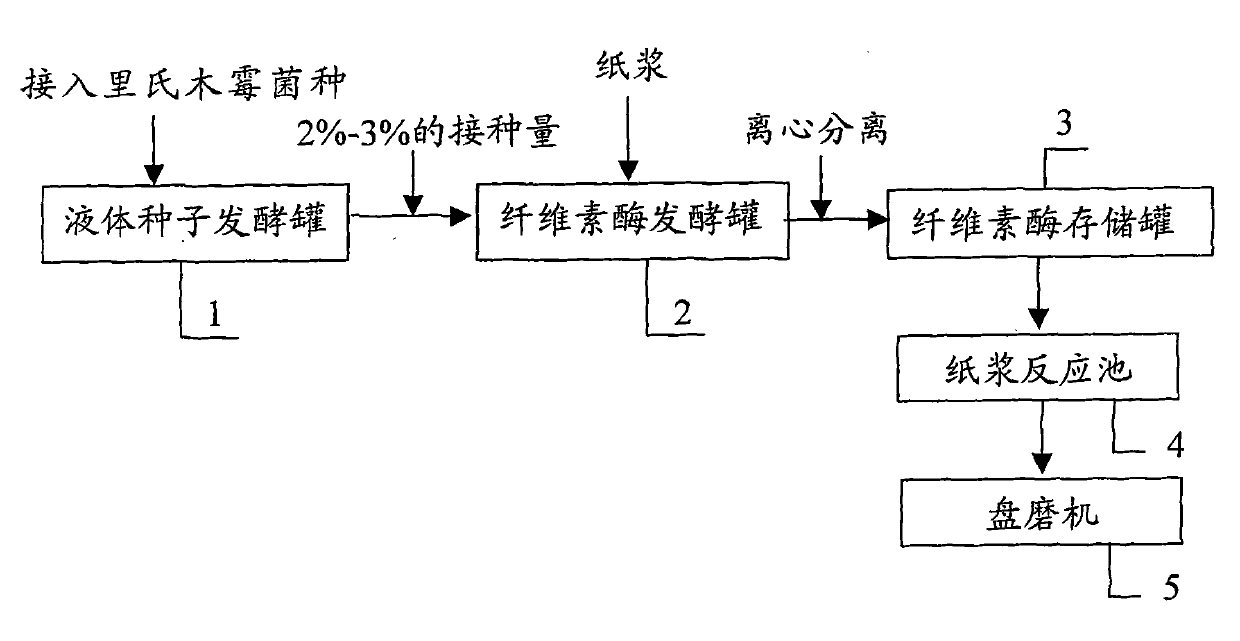

[0037] See figure 1 , A cellulase preparation, the production strain used is Trichoderma reesei. Connect the Trichoderma reesei test tube slant strain to the liquid seed fermentor 1 for seed fermentation to obtain the required liquid seeds; then connect the liquid seeds to the cellulase fermentor 2 according to a certain amount of inoculum, and ferment at a certain amount Fermented under conditions, and finally centrifuged to obtain the required cellulase enzyme solution, and store it in the cellulase storage tank 3 for use.

[0038] Preparation of enzyme solution: insert Trichoderma reesei test-tube slant strain into liquid seed fermentation tank 1. Seed fermentation medium adopts: 1% glucose, 4% nutrient element solution, 1% bran and 0.1% trace element solution, At a temperature of 30°C, pH 5.76, stirring speed 250r / min, ventilation volume 0.2m 3 Fermented for 48h under the condition of 48h to obtain the required liquid seeds; then the seeds were connected to the cellulase fer...

Embodiment 2

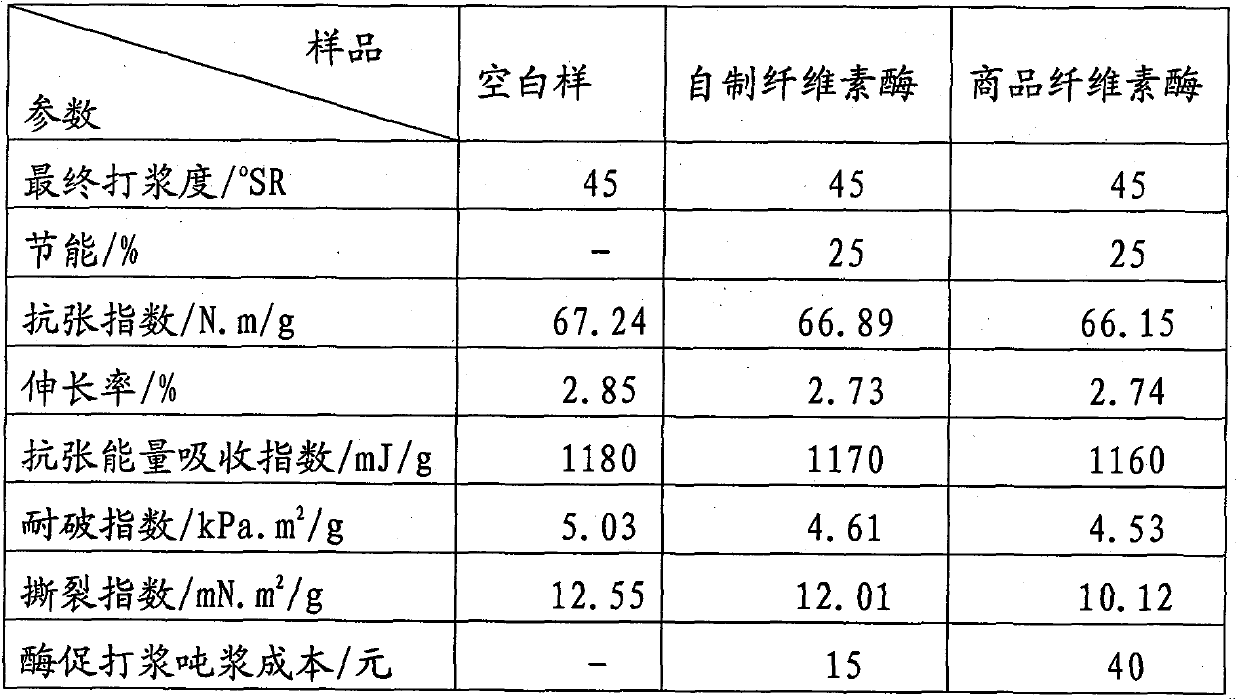

[0042] Contrast slurry sample: blank slurry sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com