Preparation method of tobacco sheet

A technology for tobacco sheets and tobacco stems, applied in the field of tobacco sheet preparation, can solve the problems of low bulk of paper base, low total yield of sheet, decreased yield of paper base and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

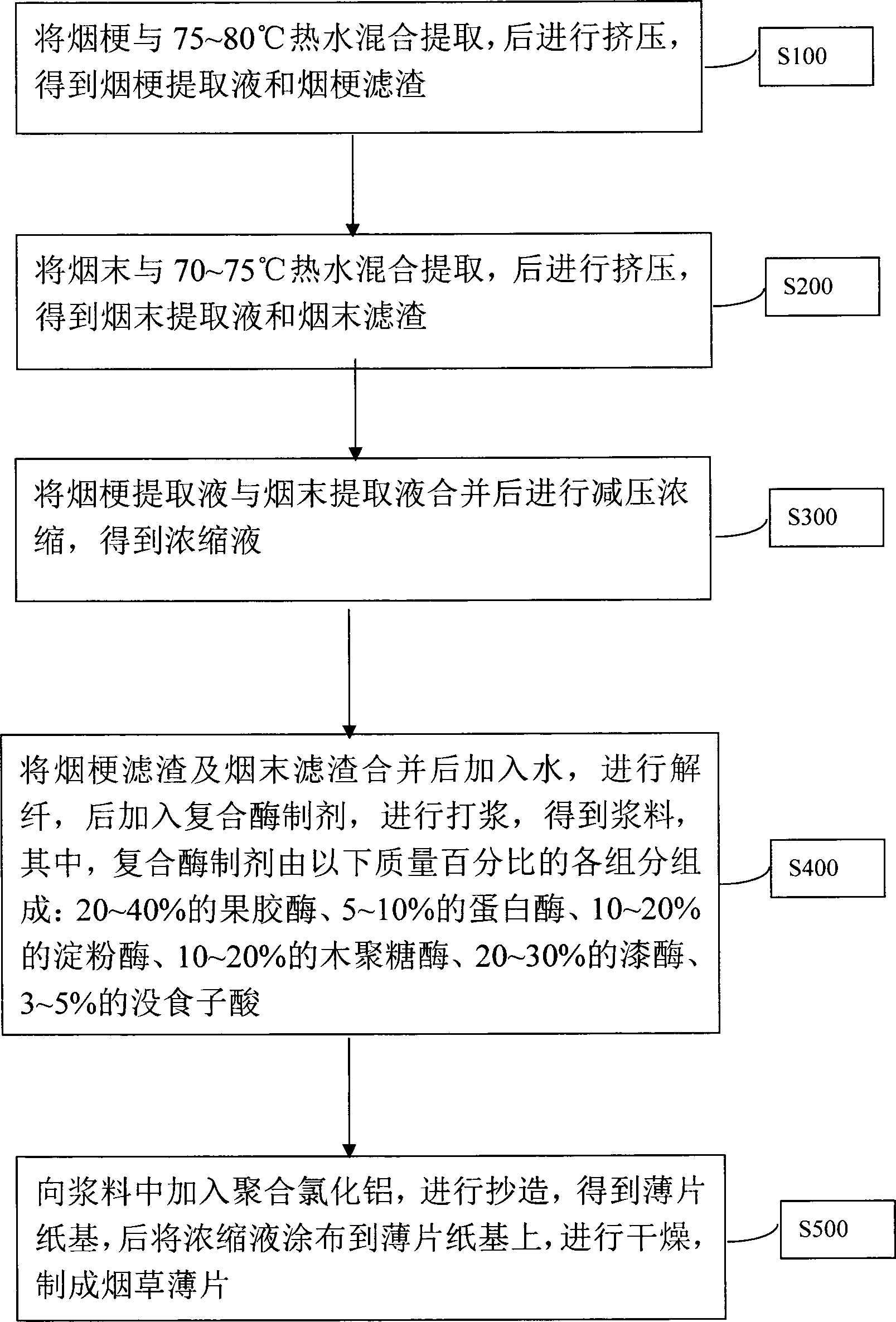

[0018] see figure 1 , the preparation method of the tobacco sheet of an embodiment, comprises the following steps:

[0019] Step S100 , mixing and extracting tobacco stems with hot water at 75-80°C, and then extruding to obtain tobacco stem extracts and tobacco stem filter residues.

[0020] Wherein, the times of mixing and extracting tobacco stems and water are two times, during each extraction process, the mass ratio of tobacco stems and water is 1:5-1:7, and each extraction time is 30 minutes.

[0021] Step S200, mixing and extracting the tobacco powder with hot water at 70-75°C, and then extruding to obtain a tobacco powder extract and a tobacco powder filter residue.

[0022] Wherein, the times of mixing and extracting tobacco powder and water are two times, and in each extraction process, the mass ratio of tobacco powder and water is 1:5-1:7, and the extraction time is 30 minutes each time.

[0023] The mass ratio of the tobacco stems to the tobacco powder is 1:1.2˜1:1...

Embodiment 1

[0042] A method for preparing tobacco sheets, comprising the following steps:

[0043] (1) Mix and extract 1 kg of tobacco stems with 5 kg of 80°C hot water twice, and then extrude to obtain tobacco stem extracts and tobacco stem filter residues, wherein the extraction time for each extraction is 30 minutes.

[0044] (2) 1.5 kg of tobacco powder and 7.5 kg of 75°C hot water were mixed and extracted twice, and then extruded to obtain tobacco powder extract and tobacco powder filter residue, wherein the extraction time for each time was 30 minutes.

[0045] (3) The tobacco stem extract and the tobacco powder extract were combined and then concentrated under reduced pressure to obtain a concentrated solution with a density of 1.2 g / mL.

[0046] (4) Combine the tobacco stem filter residue and the tobacco powder filter residue, add water, and use a defibrator to defibrate. When the defibrate is completed, the degree of beating is 20°SR. Add compound enzyme preparation afterward, car...

Embodiment 2

[0050] A method for preparing tobacco sheets, comprising the following steps:

[0051] (1) Mix and extract 1 kg of tobacco stems with 7 kg of hot water at 75° C. for 2 times, and then extrude to obtain tobacco stem extracts and tobacco stem filter residues, wherein the extraction time for each extraction is 30 minutes.

[0052] (2) 1.2 kg of tobacco powder and 8.4 kg of 75°C hot water were mixed and extracted twice, and then extruded to obtain tobacco powder extract and tobacco powder filter residue, wherein the extraction time for each time was 30 minutes.

[0053] (3) The tobacco stem extract and the tobacco dust extract were combined and then concentrated to obtain a concentrated solution with a density of 1.22 g / mL.

[0054] (4) Combine the tobacco stem filter residue and the tobacco powder filter residue, add water, and use a defibrator to defibrate. When the defibrate is completed, the degree of beating is 15°SR. Add compound enzyme preparation afterward, carry out beat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com