Method for producing chemical wood pulp

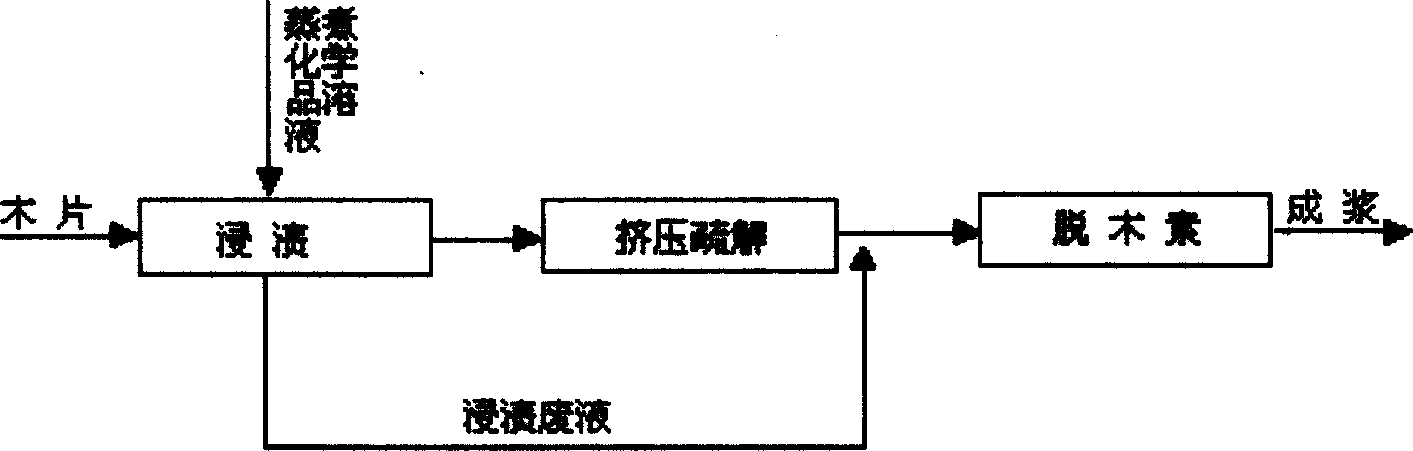

A production method and technology for chemical wood pulp, which are applied in the fields of cellulose raw material pulping, textiles and papermaking, papermaking, etc., can solve the problems of difficulty in dissolution, long cooking time, waste of fiber raw materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0101] The conventional Soda-AQ method pulping process condition of poplar is: use alkali amount 20% (as Na 2 O weight, with respect to dry raw material, the same below), liquid ratio 1: 4, anthraquinone 0.05%, maximum temperature 165 ℃, heating time 90 minutes, holding time 120 minutes. The pulping properties are: fine pulp yield 48.11%, reject rate 1.51%, kappa value 20.35. After beating by PFI beater for 22000 rpm, the beating degree is 43.9°SR, and it is copied into paper. Its strength index is as follows: breaking length is 7.45km, folding resistance is 930 times, and tear index is 7.52mN m 2 g -1 .

[0102] Poplar Soda-AQ pulp was produced by IED pulping process. The composition of the cooking liquid is: the amount of alkali used is 14%, the liquid ratio is 1:4, and anthraquinone is 0.05%. The soaking section uses the cooking solution at 90°C for 30 minutes. After impregnation, it is extruded by a screw extruder, and the compression ratio is 4:1. After extruding an...

Embodiment 2

[0105] The conventional KP pulping process conditions for poplar wood are: the amount of alkali used is 20%, the degree of vulcanization is 25%, the liquid ratio is 1:4, the highest temperature is 165°C, the heating time is 90 minutes, and the holding time is 120 minutes. The pulping performance is as follows: the yield of fine pulp is 48.64%, the reject rate is 0.94%, and the Kappa value is 17.67. The beating degree is 44.2°SR after 22,000 revolutions of PFI beater, and the paper is copied into paper. The strength index is as follows: breaking length is 7.79km, folding resistance is 970 times, and tear index is 7.48mN m 2 g -1 .

[0106] Yangshu KP pulp was produced by IED pulping process. The composition of the cooking liquid is as follows: the amount of alkali used is 20%, the degree of sulfidation is 25%, and the liquid ratio is 1:2, which is the same as the amount of cooking chemicals used in conventional pulping. The impregnation section uses the cooking solution at 7...

Embodiment 3

[0108] The conventional NS-AQ pulping process conditions of poplar are: alkali amount 20%, alkali ratio 0.85, liquid ratio 1:4, anthraquinone 0.1%, maximum temperature 170°C, heating time 90 minutes, holding time 330 minutes. The pulping performance is: the yield of fine pulp is 64.21%, the reject rate is 2.04%, and the Kappa value is 29.12. The beating degree is 44.8°SR after 18,000 revolutions of PFI beater, and the paper is copied into paper. The strength index is as follows: breaking length 8.21km, folding resistance 921 times, tear index 7.68mN m 2 g -1 .

[0109] Poplar NS-AQ pulp was produced by IED pulping process. The composition of the cooking liquid is as follows: the amount of alkali used is 20%, the alkali ratio is 0.85, the liquid ratio is 1:4.5, and anthraquinone is 0.1%, which is the same as that of conventional pulping and cooking chemicals. The impregnation section uses the cooking solution at 85°C for 30 minutes. After impregnation, it is squeezed and lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tear index | aaaaa | aaaaa |

| Tear index | aaaaa | aaaaa |

| Tear index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com