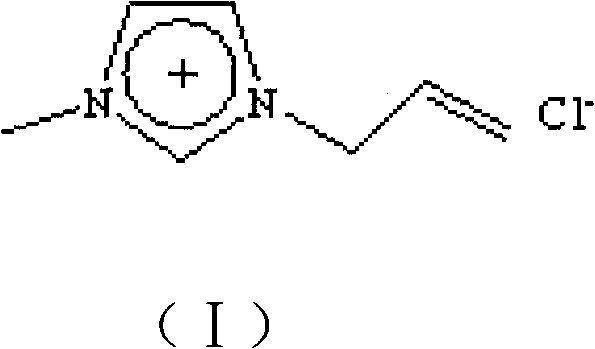

Method for treating paper pulp by using 1-allyl-3-methylimidazole chloride

The technology of methyl imidazole and allyl group is applied in the field of pulp processing, which can solve the problems of high energy consumption for beating, and achieve the effects of improving physical indicators, reducing damage and improving physical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Pine radiata chemical pulp is routinely beaten to a beating degree of 50.0°SR, the beating energy consumption is 520kW·h / t pulp, the fiber length is 2.28mm, and the fine component content is 8.5%. Use this slurry to make quantitative 70g / m 2 Cultural paper, the bulk thickness of the finished paper is 1.87cm 3 g -1 , burst index 2.64KPa m 2 g -1 , Tensile index 47.8N m / g, folding number 572 times, tear index 6.12mN m / g 2 g -1 , the napping speed (representing the surface strength of the paper) is 1.12m / s, and the K&N value (representing the printing ink absorption, the lower the K&N value, the higher the printing gloss, the lower the ink consumption, and the better the printing performance) is 21.4.

[0015] The method of the invention is used to treat the radiata pine chemical pulp. Steps: Before beating, the pulp is concentrated, dried and dehydrated to a moisture content of 1.5%, and then the pulp is treated with 1-allyl-3-methylimidazolium chloride, and the tre...

Embodiment 2

[0018] Wheat straw chemical pulp is routinely beaten to a beating degree of 36.5°SR, the beating energy consumption is 365kW·h / t pulp, the fiber length is 1.15mm, and the fine component content is 15.3%. Use this slurry to make quantitative 70g / m 2 Cultural paper, the bulk thickness of the finished paper is 1.82cm 3 g -1 , burst index 1.54KPa m 2 g -1 , Tensile index 41.6N·m / g, folding number 378 times, tear index 4.65mN·m 2 g -1 , the pulling speed is 1.01m / s, and the K&N value is 21.8.

[0019] The method of the invention is used to treat the wheat straw chemical pulp. Steps: Before beating, the pulp is concentrated, dried and dehydrated to a moisture content of 1.8%, and then the pulp is treated with 1-allyl-3-methylimidazolium chloride, and the treatment condition is 1-allyl-3-methylimidazolium chloride Chemical dosage 12L / kg pulp, steam indirect heating, temperature 70°C, time 120min, wash pulp after treatment to remove 1-allyl-3-methylimidazolium chloride, recover...

Embodiment 3

[0022] The poplar high-yield pulp is beaten to a beating degree of 52.0°SR, the energy consumption of beating (fine refining) is 1050kW·h / t pulp, the fiber length is 0.92mm, and the fine component content is 22.8%. Using this slurry to make paper with a basis weight of 75g / m 2 , the bulk thickness of the paper is 3.15cm 3 g -1 , burst resistance index 2.25KPa·m 2 g -1 , tensile index 32.5N m / g, tear index 3.27mN m / g 2 g -1 , the pulling speed is 0.85m / s, and the K&N value is 25.6.

[0023] The method of the invention is used to treat the poplar high-yield pulp. Steps: after a period of rough refining, the poplar high-yield pulp is treated, the pulp is first concentrated, dried and dehydrated to a moisture content of 2.0%, and then the pulp is treated with 1-allyl-3-methylimidazolium chloride. The conditions are 1-allyl-3-methylimidazolium chloride dosage 8L / kg pulp, steam indirect heating, temperature 120°C, time 20min, pulp is washed after treatment, and 1-allyl-3-meth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com