A kind of automatic cut stem softening and continuous production method of tobacco stems

A technology for cut tobacco stems and tobacco stems is applied in the field of automatic cut stem softening and continuous production of tobacco stems. Product suction quality, solving the effect of low extraction efficiency and reduction of irritating components

Active Publication Date: 2022-06-03

CHINA TOBACCO YUNNAN REMFG TOBACCO CO LTD

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] At present, the extraction of tobacco stems in reconstituted tobacco leaves by the papermaking method has been stuck in the solid-liquid separation of twin-screw presses. In order to discharge liquid smoothly, the filter seam is relatively large. During the pressing process, fine fibers are discharged together with the liquid, resulting in a decrease in the yield of raw materials. At the same time, it also brings great pressure to the purification of the extraction liquid. The cost of purification of the extraction liquid also increased

In the current process, there is no continuous washing and steaming of stems, the extraction efficiency is poor, the softness of tobacco stems is not enough, the content of chloride ions in tobacco stems is large, the skin of tobacco stems cannot be removed, and the purity of the extract is poor, etc. Neither can be improved

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

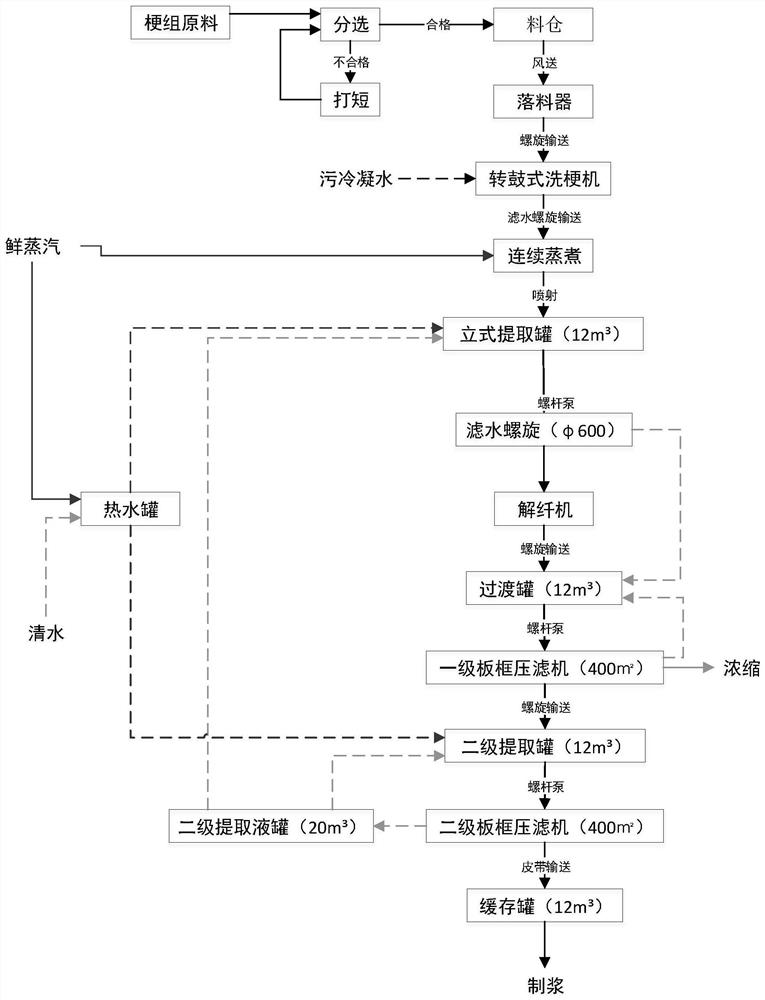

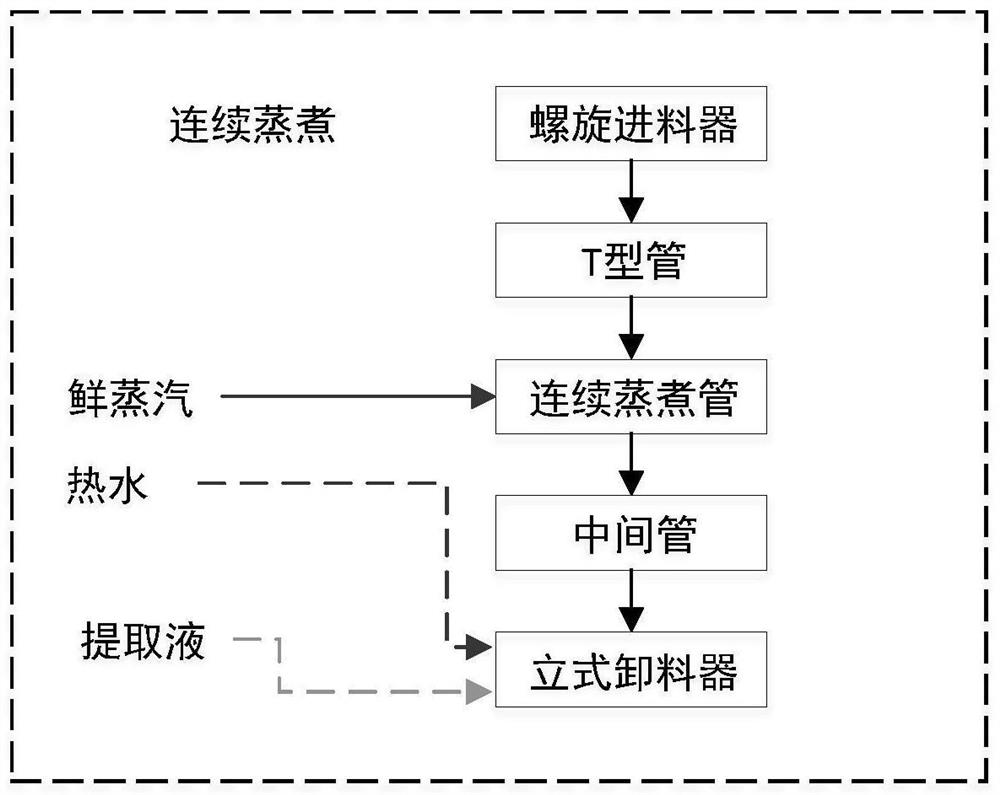

The present invention relates to an automatic and continuous softening method for tobacco stems. The tobacco stems are manually fed and sorted, and then weighed according to the process ratio and sent to the extractor by air in the extracting process section. After that, the tobacco stems are continuously washed and steamed After the stalk process, it enters the vertical extraction tank, and heats water in the vertical extraction tank for stirring and extraction. After the extraction is completed, it is pumped to the water filter screw by the screw pump to remove the surface water and sent to the primary mill for defiberization. The fibered stalks are diluted in the transition tank and sent to the plate and frame filter press for solid-liquid separation through the screw pump, the liquid is sent to the concentration section for concentration, and the solid is spirally transported to the secondary extraction tank through the bottom of the plate and frame filter press. Add hot water to the extraction tank for dilution and stirring extraction, and then pump it to the second-stage plate and frame filter press for solid-liquid separation through a screw pump, and the solid enters the pulping process section for pulping. After being treated by the method of the invention, the extract has a suspension content less than or equal to 0.2%, and can directly enter the concentration process section for concentration.

Description

A kind of automatic cut stem softening and continuous production method of tobacco stem technical field The invention belongs to the technical field of tobacco processing, specifically a kind of automatic cut stem softening of tobacco stems and continuous chemical regeneration. production method. Background technique At present, the extraction of tobacco stems in the paper-making reconstituted tobacco leaves has always been carried out using a twin-screw press to carry out solid-liquid separation. The solid-liquid separation method not only has a low dryness of the pressed material, but cannot reach 35% of the dryness of the pressed material, but also due to the twin-screw press In order to drain the liquid smoothly, the filter gap is large. During the pressing process, the fine fibers are discharged together with the liquid, resulting in a lower yield of raw materials. At the same time, it also brings great pressure on the purification of the extract, and the cost o...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): A24B3/18A24B15/24A24B5/16

CPCA24B3/185A24B3/182A24B3/18A24B15/24A24B5/16

Inventor 况志敏王茜茜刘建平王忠泽吕正峰郭维平杨旭

Owner CHINA TOBACCO YUNNAN REMFG TOBACCO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com