Full-automatic cut stem softening and continuous production method for tobacco stems

A production method and fully automatic technology, which is applied in the fields of tobacco, tobacco preparation, and tobacco treatment, can solve the problems of poor purity of the extract, decreased yield of raw materials, and low dryness of pressed materials, so as to improve the quality of product suction , Reduce the irritating components, and solve the effect of low extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

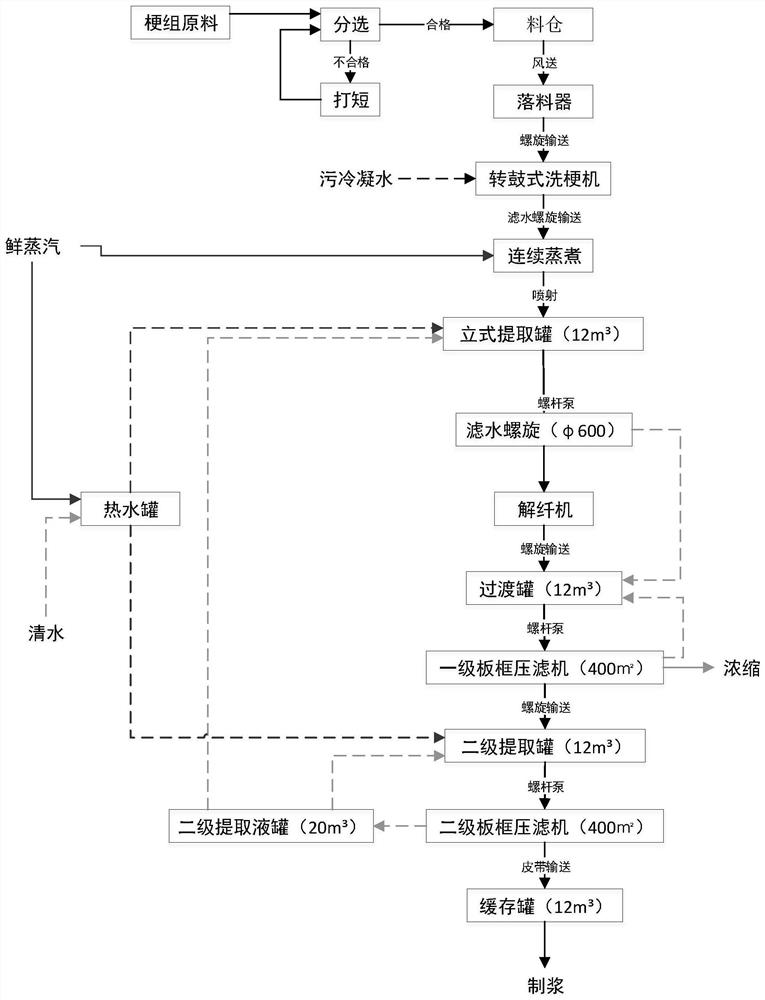

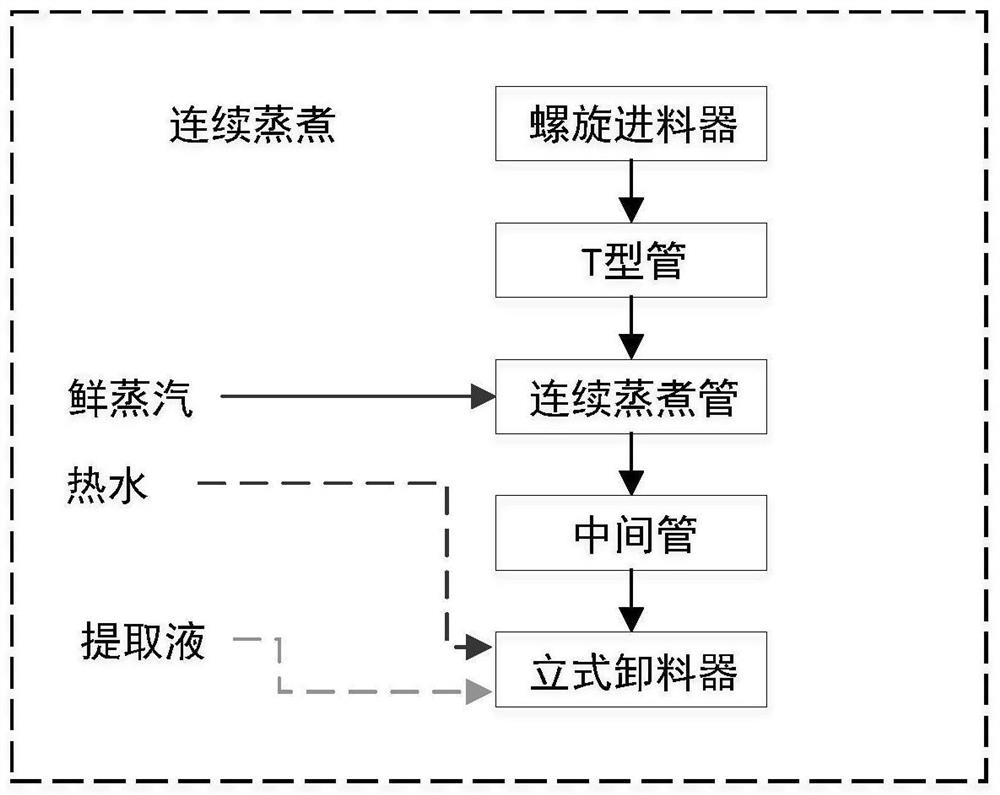

[0035] Such as figure 1 Shown, a kind of tobacco stem automatic shredded stem softening and continuous production method comprises the following steps:

[0036] (1) Tobacco stem pretreatment: the tobacco stems are fed into the sorting system, and the tobacco stems with a length > 20mm are sorted and shortened to make the length less than 20mm, and then the tobacco stem raw materials enter the tobacco stem silo for temporary storage. Weigh and discharge according to the process ratio, and send the measured tobacco stem raw materials into the extractor of the extraction process by air delivery;

[0037](2) Stem washing: After the tobacco stems are discharged from the feeder, they enter the drum type stem washing machine for washing. The temperature of the washing water is 55°C, and the washing time is 6 seconds. The washed tobacco stems enter the filter water The spiral removes the surface water, and the surface water returns to the drum type stem washing machine to continue to...

Embodiment 3

[0043] Such as figure 1 Shown, a kind of tobacco stem automatic shredded stem softening and continuous production method comprises the following steps:

[0044] (1) Tobacco stem pretreatment: the tobacco stems are fed into the sorting system, and the tobacco stems with a length > 20mm are sorted and shortened to make the length less than 20mm, and then the tobacco stem raw materials enter the tobacco stem silo for temporary storage. Weigh and discharge according to the process ratio, and send the measured tobacco stem raw materials into the extractor of the extraction process by air delivery;

[0045] (2) Stem washing: After the tobacco stems are discharged from the feeder, they enter the drum type stem washing machine for washing. The temperature of the washing water is 50°C, and the washing time is 5 seconds. The washed tobacco stems enter the filter water The spiral removes the surface water, and the surface water returns to the drum type stem washing machine to continue t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com