Ultrasonic cleaning groove and its processing method

A processing method, ultrasonic technology, applied in cleaning methods and utensils, cleaning methods using liquids, pollution prevention methods, etc., can solve the problems of affecting the cleaning effect of ultrasonic cleaning devices, poor ultrasonic conductivity, poor acid corrosion resistance, etc., Achieve the effect of high ultrasonic transmission efficiency, good wear resistance and dense coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

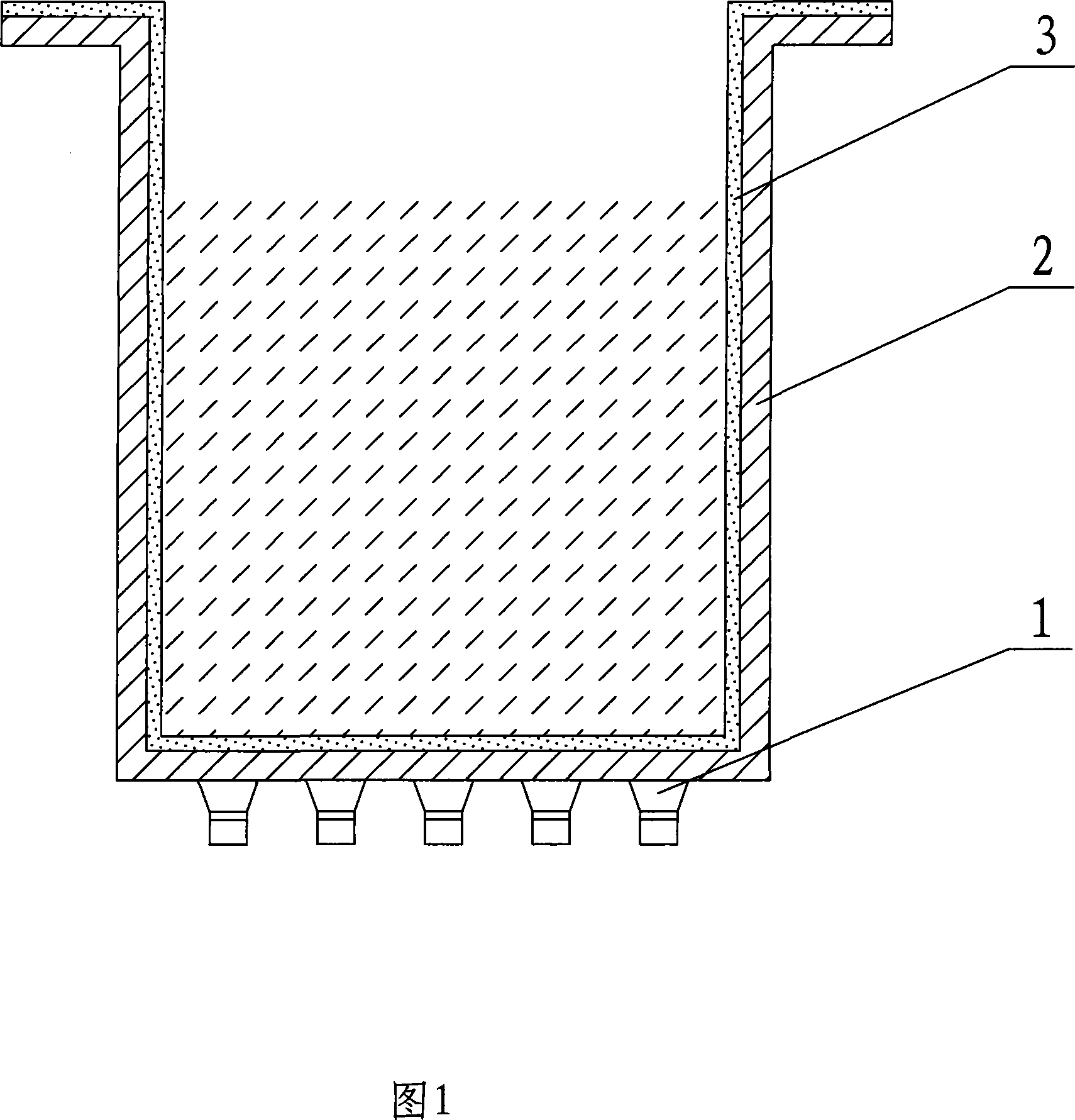

[0011] Below in conjunction with accompanying drawing, ultrasonic cleaning tank of the present invention and processing method thereof are described in further detail:

[0012] As shown in Figure 1, an ultrasonic cleaning tank includes an ultrasonic transducer 1, a stainless steel tank body 2 arranged on the ultrasonic transducer 1, the wall thickness of the tank body 2 is between 1-3 millimeters, and the thickness of the tank body 2 The inner wall is sandblasted to make the inner surface of the tank body 2 have a certain roughness, and then the inner surface of the tank body 2 is sprayed with polytetrafluoroethylene layer 3. Polytetrafluoroethylene is also called Teflon, polytetrafluoroethylene The thickness of the fluoroethylene layer 3 is between 0.1-0.4 mm. Since the inner surface of the tank body 2 is relatively rough, it is very conducive to the combination between the polytetrafluoroethylene layer 3 and the inner surface of the tank body 2, preventing , peeling occurs b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com