Preparation method of high-viscosity hydrolysis resistant polybutylene terephthalate

A polybutylene terephthalate and polybutylene phthalate technology, which is applied in the field of polymer material preparation, can solve problems such as low reaction temperature, slow reaction speed, and product quality decline, and achieve high reaction efficiency , Fast response and short response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

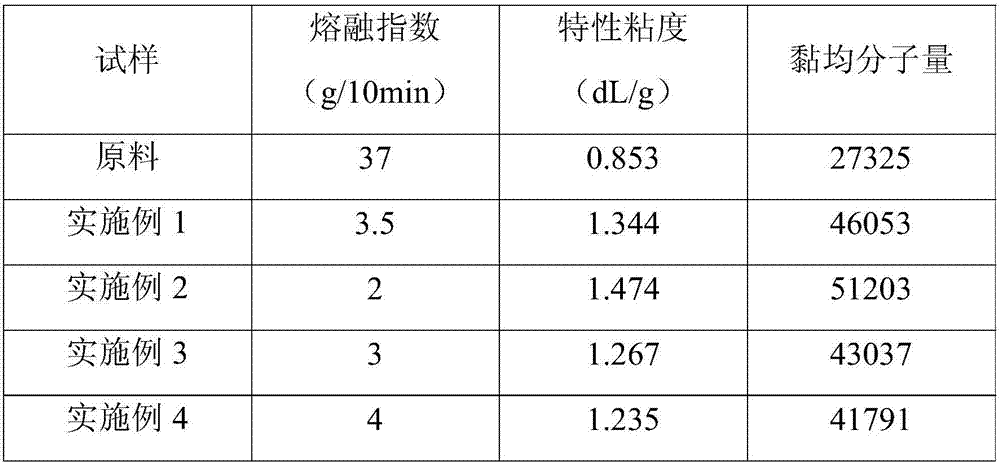

[0023] (1) Counting by weight, weigh 100 parts of polybutylene terephthalate raw material (melt index 37g / 10min, intrinsic viscosity 0.853dL / g, viscosity average molecular weight 27325), 1 part of trimethylolpropane trimethylolpropane Acrylate, 0.5 parts of glycidyl methacrylate are evenly mixed;

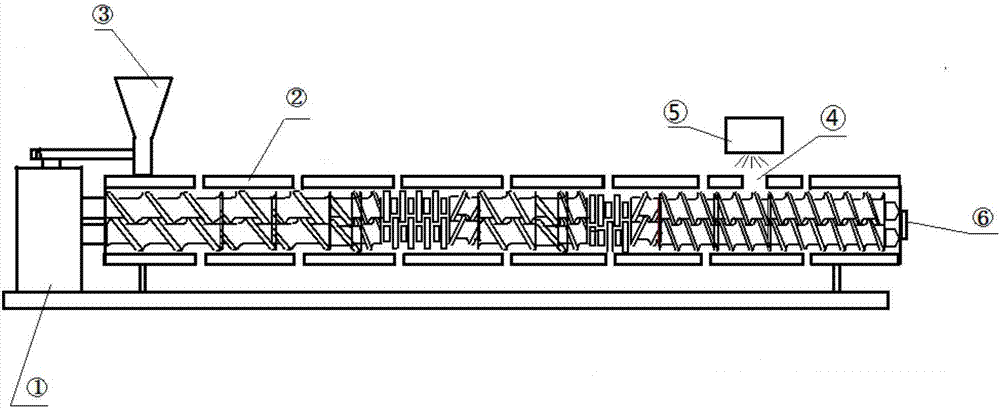

[0024] (2) adopt figure 1 The twin-screw extruder shown is prepared. The length-to-diameter ratio of the twin-screw extruder is 40:1. The rear end homogenization section of the barrel of the extruder is provided with a light port, and a 1kW ultraviolet light port is installed above the light port. Light generator; set the corresponding parameters of the extruder, the screw speed is 160rpm, the feeding speed is 5rpm, the extrusion output is 6.4kg / h, the temperature is set as: feeding section 160-210℃, melting section 220-250℃, homogenization section 250°C.

[0025] (3) When the temperature of the extruder reaches the set value, the reaction extrusion starts. During this process, th...

Embodiment 2

[0027] (1) Counting by parts by weight, weigh 100 parts of polybutylene terephthalate raw materials (melt index 37g / 10min, intrinsic viscosity 0.853dL / g, viscosity average molecular weight 27325), 1 part of pentaerythritol triacrylate, 1.0 Parts of glycidyl methacrylate are evenly mixed;

[0028] (2) adopt figure 1 The twin-screw extruder shown is prepared. The length-to-diameter ratio of the twin-screw extruder is 40:1. The rear end homogenization section of the barrel of the extruder is provided with a light port, and a 1kW ultraviolet light port is installed above the light port. Light generator; set the corresponding parameters of the extruder, the screw speed is 160rpm, the feeding speed is 5rpm, the extrusion output is 6.4kg / h, the temperature is set as: feeding section 160-210℃, melting section 220-250℃, homogenization section 250°C.

[0029] (3) When the temperature of the extruder reaches the set value, the reaction extrusion starts. During this process, the glycidy...

Embodiment 3

[0031] (1) Counting by weight, weigh 100 parts of polybutylene terephthalate raw material (melt index 37g / 10min, intrinsic viscosity 0.853dL / g, viscosity average molecular weight 27325), 1.5 parts of 1,6-hexanedi Alcohol diacrylate, 0.6 parts of allyl glycidyl ether are evenly mixed;

[0032] (2) adopt figure 1 The twin-screw extruder shown is prepared. The length-to-diameter ratio of the twin-screw extruder is 40:1. The rear end homogenization section of the barrel of the extruder is provided with a light port, and a 1kW ultraviolet light port is installed above the light port. Light generator; set the corresponding parameters of the extruder, the screw speed is 160rpm, the feeding speed is 5rpm, the extrusion output is 6.4kg / h, the temperature is set as: feeding section 160-210℃, melting section 220-250℃, homogenization section 250°C.

[0033] (3) When the temperature of the extruder reaches the set value, the reaction extrusion starts. In this process, allyl glycidyl ethe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com