High-fluidity degradable polyester melt-blown material, and preparation method and application thereof

A technology of degrading polyester and high fluidity is applied in the field of polymer preparation, which can solve the problems of waste mask pollution and short supply of polypropylene meltblown materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

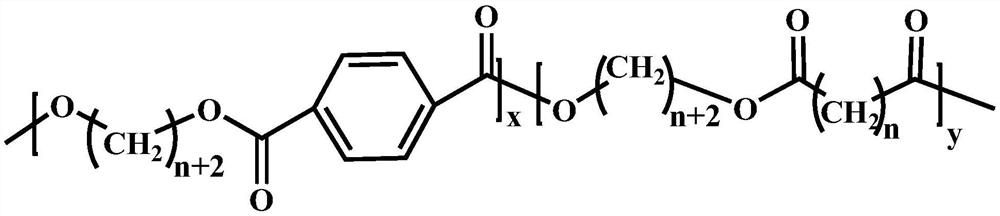

[0059] Take ethylene glycol 100, terephthalic acid 20, oxalic acid 60, trimethyl phosphate 0.015, hydroquinone 0.072, then heat up to 180 ° C, in N 2 React under the atmosphere for 3 hours, then raise the temperature to 200°C, add 0.5% antimony acetate / ethylene glycol mixed solution (concentration: 20g / L), vacuumize to 4kPa, and react for 0.5h; raise the temperature to 220°C, and vacuum until the system pressure is 300Pa , react for 1h, discharge, cool, draw, granulate, and dry to obtain the high-fluidity degradable polyester melt-blown material, whose molecular structure is as follows:

[0060]

[0061] X=12 y=66 n=0 x:y=0.182 Total alkyd ratio=2 Terephthalic acid / total acid mole fraction=15%.

Embodiment 2

[0063] Take ethylene glycol 100, terephthalic acid 30, oxalic acid 65, trimethyl phosphate 0.02, hydroquinone 0.079, then heat up to 190 ° C, in N 2 React under atmosphere for 4 hours, then raise the temperature to 220°C, add antimony acetate / ethylene glycol 0.6 (concentration: 20g / L), evacuate to 4kPa, react for 1h; heat up to 240°C, evacuate to a system pressure of 300Pa, and react for 2h , discharging, cooling, wire drawing, granulation, and drying to obtain the high-fluidity degradable polyester melt-blown material, whose molecular structure is as follows:

[0064]

[0065] X=18 y=72 n=0 x:y=0.25 Total alkyd ratio=1.8 Terephthalic acid / total acid mole fraction=20%.

Embodiment 3

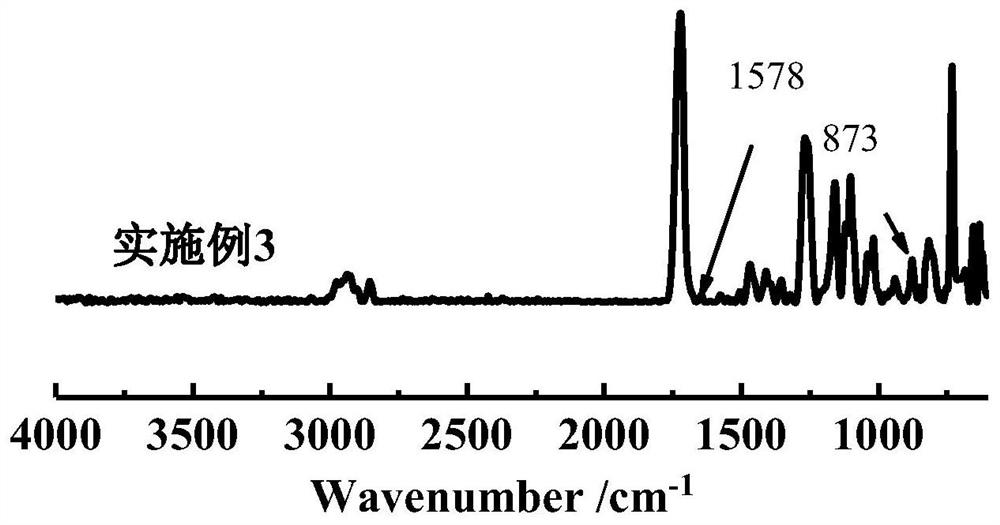

[0067] Take 1,4-butanediol 100, terephthalic acid 40, succinic acid 72, triphenyl phosphite 0.025, antioxidant I-10100.085, and then heat up to 200 ° C, in N 2 React under atmosphere for 3h, then add tetrabutyl titanate / 1,4-butanediol mixed solution 0.45 (concentration: 20g / L), heat up to 230°C, vacuumize to 4kPa, react for 0.5h; after cooling to room temperature, Raise the temperature to 250°C, evacuate to a system pressure of 300Pa, react for 0.5h, discharge, cool, draw, granulate, and dry to obtain the high-fluidity degradable polyester melt-blown material, its molecular structure as follows:

[0068]

[0069] X=24 y=61 n=2 x:y=0.39 Total alkyd ratio=1.4 Terephthalic acid / total acid mole fraction=28%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com