Preparation method of PP-g-MAH (Polypropylene grafting Maleic Anhydride) triggered and melt by ultraviolet irradiation

A polypropylene grafting and maleic anhydride technology, which is applied in the field of polymer materials, can solve the problems of lowering the grafting temperature and the grafting rate is not very high, and achieves the effects of avoiding serious degradation, simple equipment and short reaction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A kind of preparation method that ultraviolet radiation triggers molten polypropylene grafted maleic anhydride, comprises the following steps:

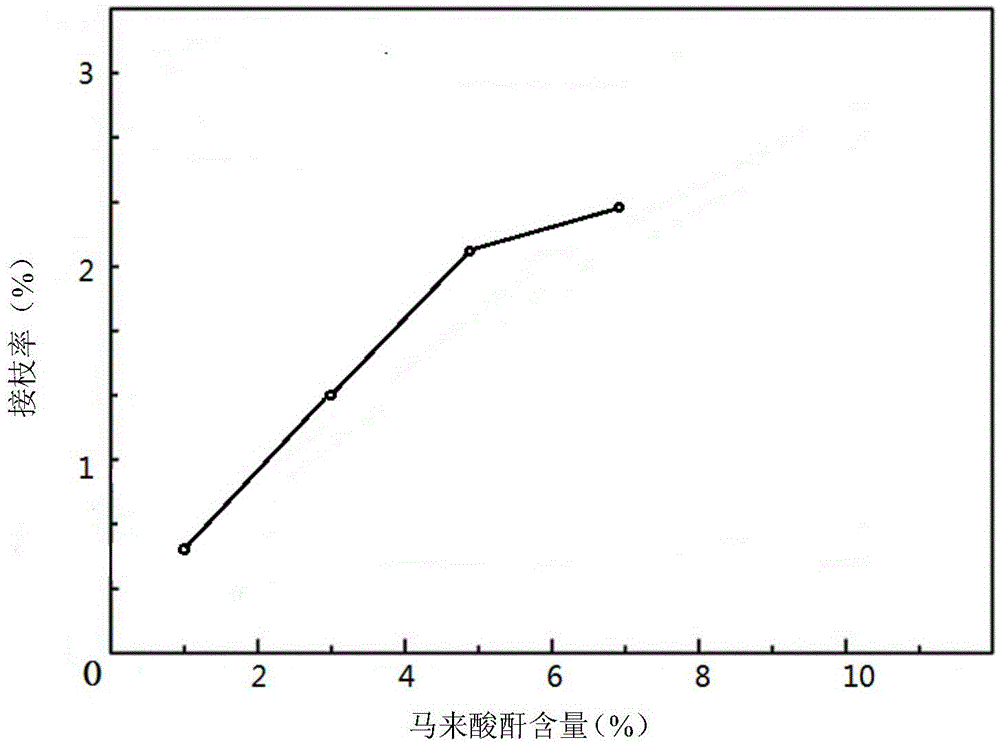

[0041] a. count by weight, take by weighing 100 parts of polypropylene H1030, 2 parts of photosensitizer benzophenone, mix with 1, 3, 5, 7 parts of maleic anhydride respectively;

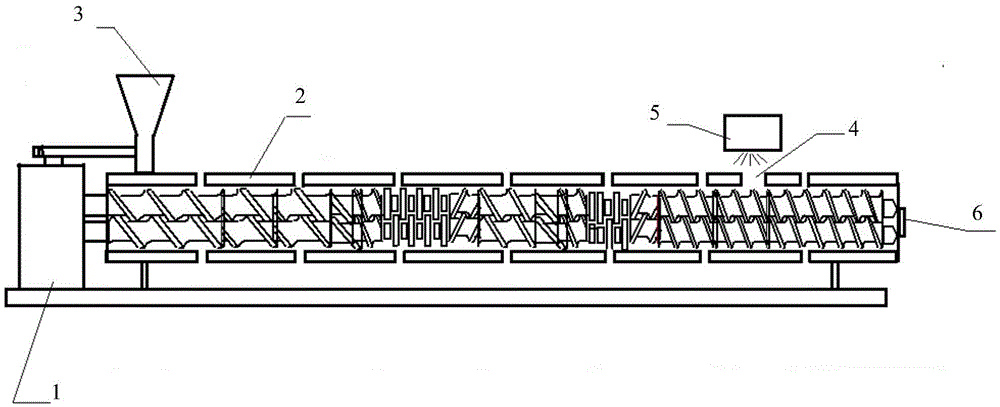

[0042] b. Set the temperature of the extruder; the schematic diagram of the extrusion device is as follows figure 1 Shown; The barrel of the extruder is provided with a light opening;

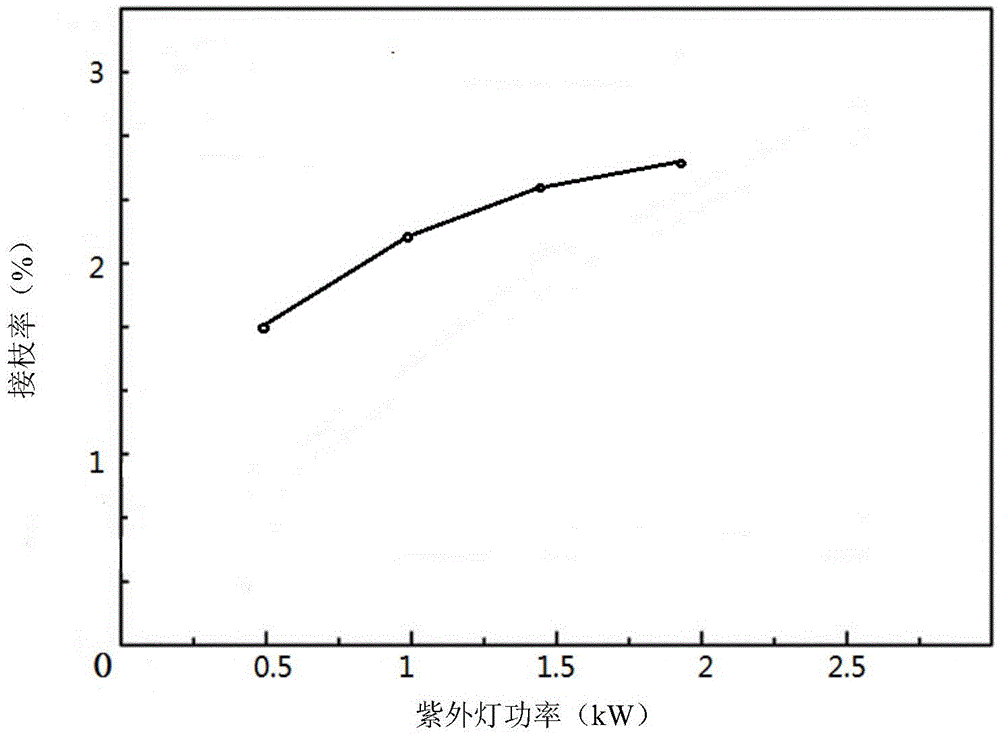

[0043] c. Place a UV lamp with a power of 1kW 10cm above the light port of the extruder, and turn on the UV lamp;

[0044] d. adding the obtained mixture of step a in the extruder hopper;

[0045] e. After the extruder reaches the set temperature, open the extruder for melt blending and extrusion to obtain maleic anhydride grafted polypropylene; the extruder is a twin-screw extruder, and the length of the twin-screw extruder is The diameter ratio is 40:1, the main ...

Embodiment 2

[0049] A kind of preparation method that ultraviolet radiation triggers molten polypropylene grafted maleic anhydride, comprises the following steps:

[0050] a. Counting by weight, take 100 parts of polypropylene H1030, 5 parts of maleic anhydride, 2 parts of photosensitizer 1-hydroxy-cyclohexyl phenyl ketone 184, and mix well;

[0051] b. Set the temperature of the extruder; the schematic diagram of the extrusion device is as follows figure 1 Shown; The barrel of the extruder is provided with a light opening;

[0052] c. Place a UV lamp with a power of 1kW 10cm above the light port of the extruder, and turn on the UV lamp;

[0053] d. adding the obtained mixture of step a in the extruder hopper;

[0054] e. After the extruder reaches the set temperature, open the extruder for melt blending and extrusion to obtain maleic anhydride grafted polypropylene; the extruder is a twin-screw extruder, and the length of the twin-screw extruder is The diameter ratio is 40:1, the main ...

Embodiment 3

[0057] A kind of preparation method that ultraviolet radiation triggers molten polypropylene grafted maleic anhydride, comprises the following steps:

[0058] a. Counting by weight, take 100 parts of polypropylene H1030, 5 parts of maleic anhydride, 2 parts of photosensitizer benzophenone, 1 part of monofunctional monomer grafting aid styrene, and mix uniformly;

[0059] b. Set the temperature of the extruder; the schematic diagram of the extrusion device is as follows figure 1 Shown; The barrel of the extruder is provided with a light opening;

[0060] c. Place a UV lamp with a power of 1kW 10cm above the light port of the extruder, and turn on the UV lamp;

[0061] d. adding the obtained mixture of step a in the extruder hopper;

[0062] e. After the extruder reaches the set temperature, open the extruder for melt blending and extrusion to obtain maleic anhydride grafted polypropylene; the extruder is a twin-screw extruder, and the length of the twin-screw extruder is The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com