Preparation method of spherical antimonous oxide

A technology of antimony trioxide and spherical shape, which is applied in the field of preparation of spherical antimony trioxide, can solve the problems of material mechanical properties decline, failure to meet the use requirements, poor matrix compatibility, etc., and achieve improved compatibility and low oil absorption value , Improve the effect of sphericity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

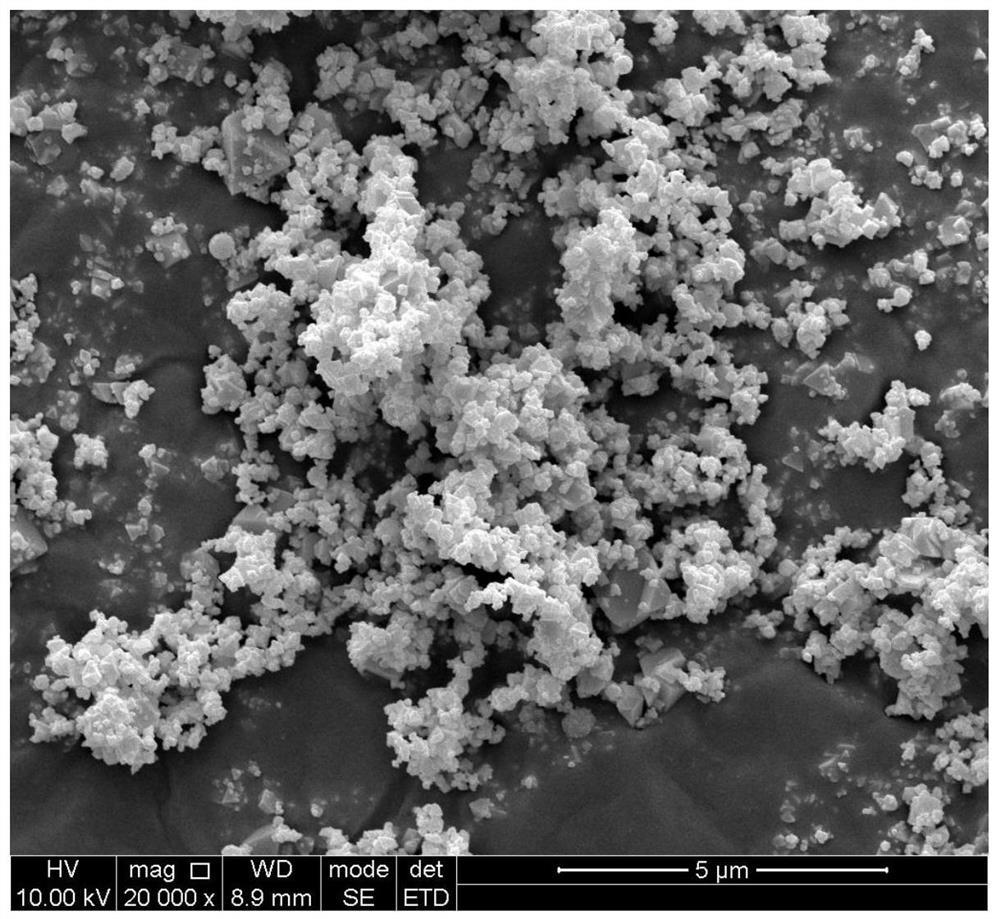

Examples

Embodiment 1

[0024] (1) Preparation of antimony trioxide seed crystals: Weigh an appropriate amount of cubic crystal (purity: 99.8%, D50=1.5 μm, D90=3 μm) and add it to distilled water, the proportion of antimony trioxide is 5%, And add 0.1% sodium hexametaphosphate, and then ultrasonically disperse for 30 minutes to form slurry A; then the slurry A is added to the horizontal sand mill, and the amount of zirconia beads in the horizontal sand mill is adjusted to make it account for the total 65% of the volume, adjust the feed motor speed, control the flow rate to be 34% of the volume of the sand mill, and obtain slurry B after being processed by a horizontal sand mill; filter and dry the slurry B to obtain standby di Antimony seeds, ensure that the particle size distribution is D50≤0.4μm, D90≤1.0μm.

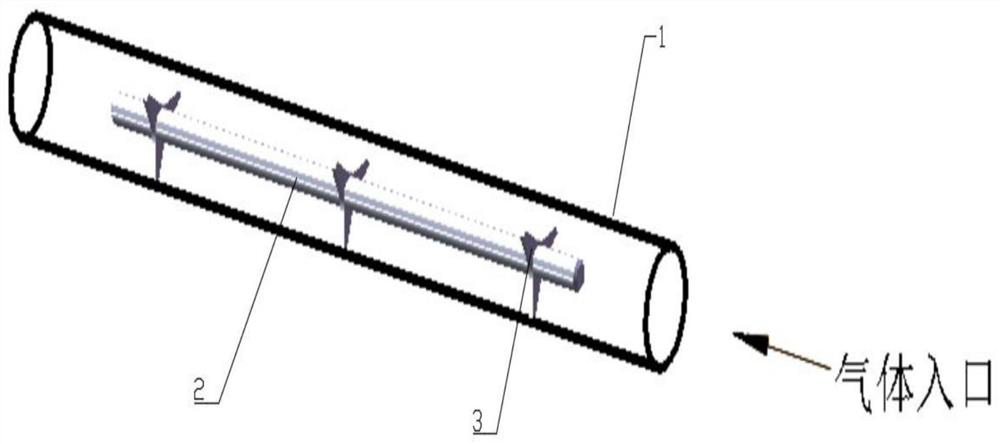

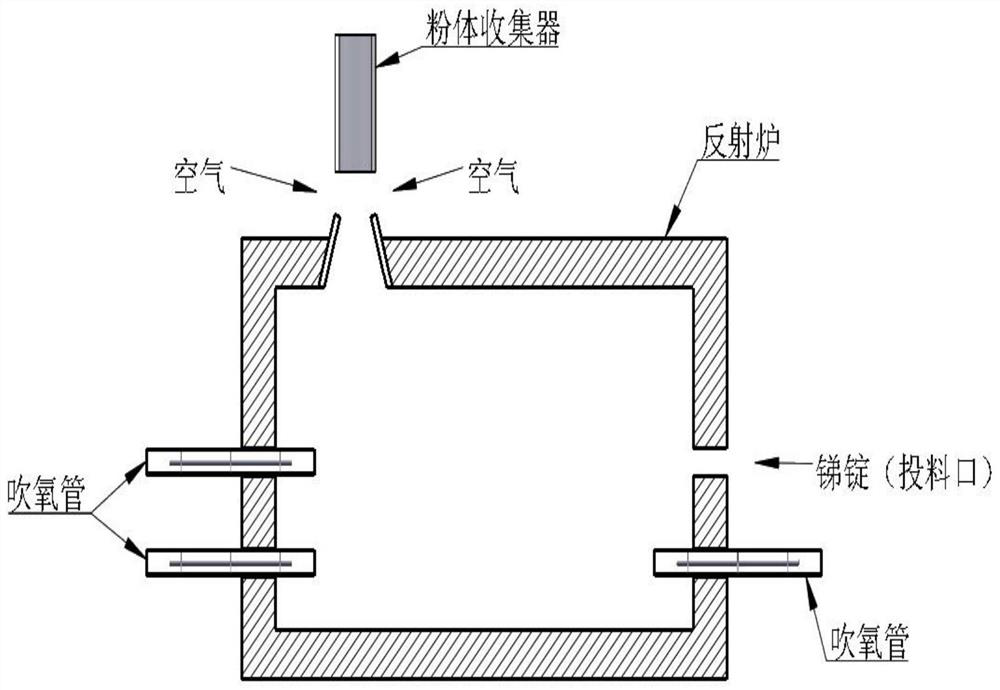

[0025] (2) Prepare a device for preparing spherical antimony trioxide: prepare an oxygen blowing tube, and the oxygen blowing tube (see figure 1 ) comprises a hollow circular outer tube 1 wit...

Embodiment 2

[0028] (1) Preparation of antimony trioxide seed crystals: Weigh an appropriate amount of orthorhombic antimony trioxide (purity: 99.8%, D50=1.5 μm, D90=3 μm) and add it to distilled water. accounted for 15%, and added 0.5% triethylhexanoic acid, and then ultrasonically dispersed for 50 minutes to form slurry A; then the slurry A was added to the horizontal sand mill, and the zirconia beads in the horizontal sand mill were adjusted The amount makes it account for 70% of the total volume, adjust the feed motor speed, the control flow is 26% of the volume of the sand mill, and obtain the slurry B after being processed by the horizontal sand mill; the slurry B is filtered and dried, Obtain spare antimony trioxide seed crystals, and ensure that the particle size distribution thereof is D50≤0.3 μm and D90≤0.7 μm.

[0029] (2) Prepare a device for preparing spherical antimony trioxide: prepare an oxygen blowing tube, and the oxygen blowing tube (see figure 1 ) comprises a hollow ci...

Embodiment 3

[0032](1) Preparation of antimony trioxide seed crystals: Weigh an appropriate amount of antimony trioxide (purity: 99.8%, D50=3.5 μm, D90=6 μm) in the cubic crystal form and add it to distilled water. Ratio of 10%, and adding 0.2% triethylhexanoic acid, and then ultrasonically dispersed for 60 minutes to form slurry A; then the slurry A was added to the horizontal sand mill, and the zirconia beads in the horizontal sand mill were adjusted The amount makes it account for 85% of the total volume, adjust the feed motor speed, control the flow rate to be 14% of the sand mill volume, obtain the slurry B after being processed by the horizontal sand mill; the slurry B is filtered and dried, Obtain spare antimony trioxide seed crystals, and ensure that the particle size distribution thereof is D50≤0.3 μm and D90≤0.6 μm.

[0033] (2) Prepare a device for preparing spherical antimony trioxide: prepare an oxygen blowing tube, and the oxygen blowing tube (see figure 1 ) comprises a holl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com