A tension-compression magnetic shape memory alloy multi-mode smart damper

A memory alloy and damper technology, which is used in building components, building structures, earthquake-proof and other directions, can solve the problems of rare magnetic shape memory alloy dampers and difficult to process, and achieve strong damping capacity, stable performance and high response frequency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

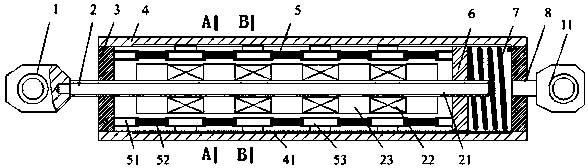

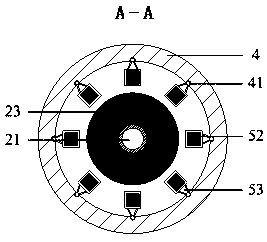

[0030] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

[0031] refer to figure 1 As shown, a tension-compression type magnetic shape memory alloy multi-mode intelligent damper, the damper is composed of a first connecting flange 1, a second connecting flange 11, a core rod 2, a guide nut 3, a cylinder 4, a magnetic shape The memory unit 5, the guide piston 6, the spring 7 and the closing nut 8 are composed, the opening of one end of the cylinder 4 is provided with a guide nut 3, the opening of the other end is provided with a closing nut 8, and a core rod is provided inside the cylinder 4 2. One end of the core rod 2 is movably passed through the guide nut 3 and exposed to a part of the cylinder 4, the part of the core rod 2 exposed to the cylinder 4 is connected to the first connecting flange 1, and the closing nut 8 is connected to the second The connecting flange 11 is connected, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com