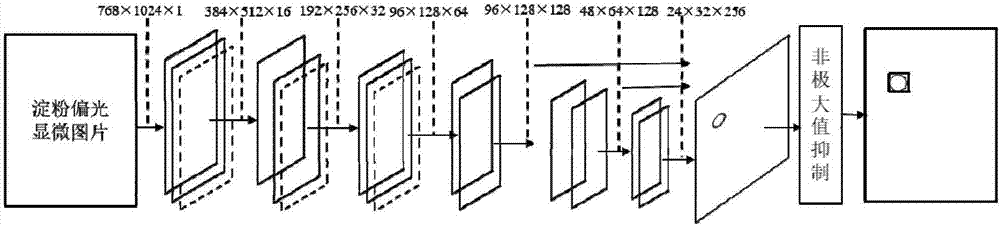

Method for on-line detection of starch gelatinization degree and gelatinization temperature

A technology of starch gelatinization and gelatinization temperature, which is applied in measurement devices, preparation of test samples, material analysis by optical means, etc. The operation is fast and convenient, the parallelism is good, and the effect of eliminating subjective errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

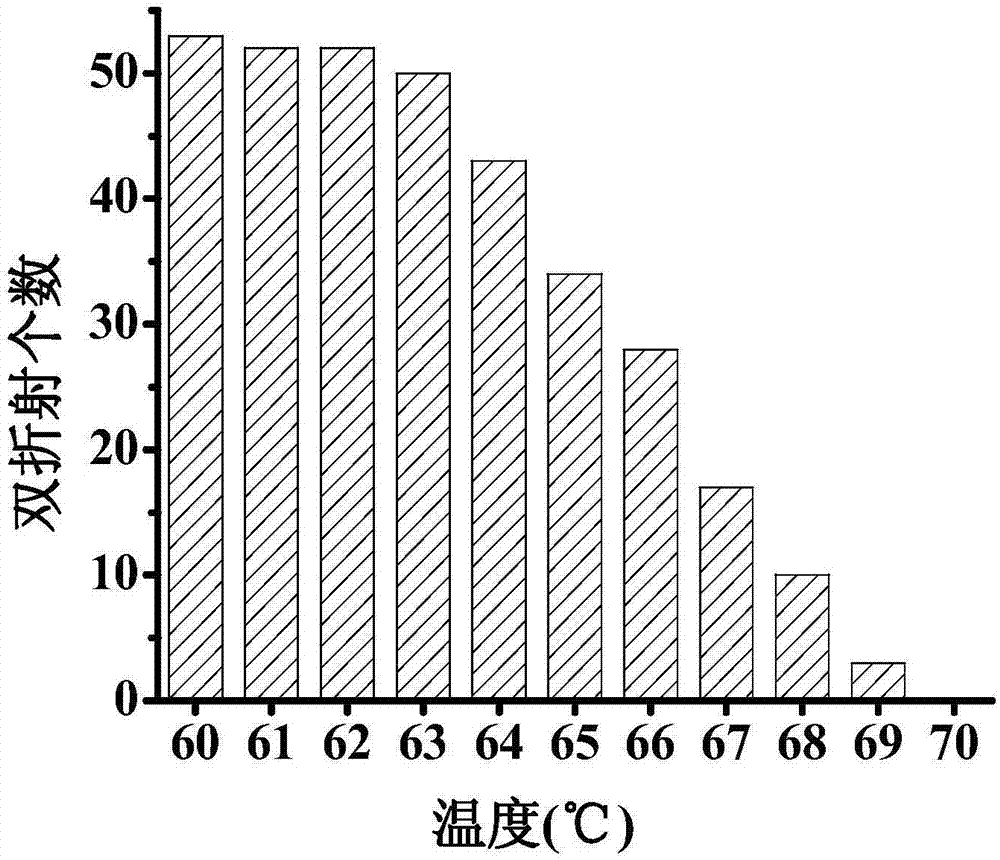

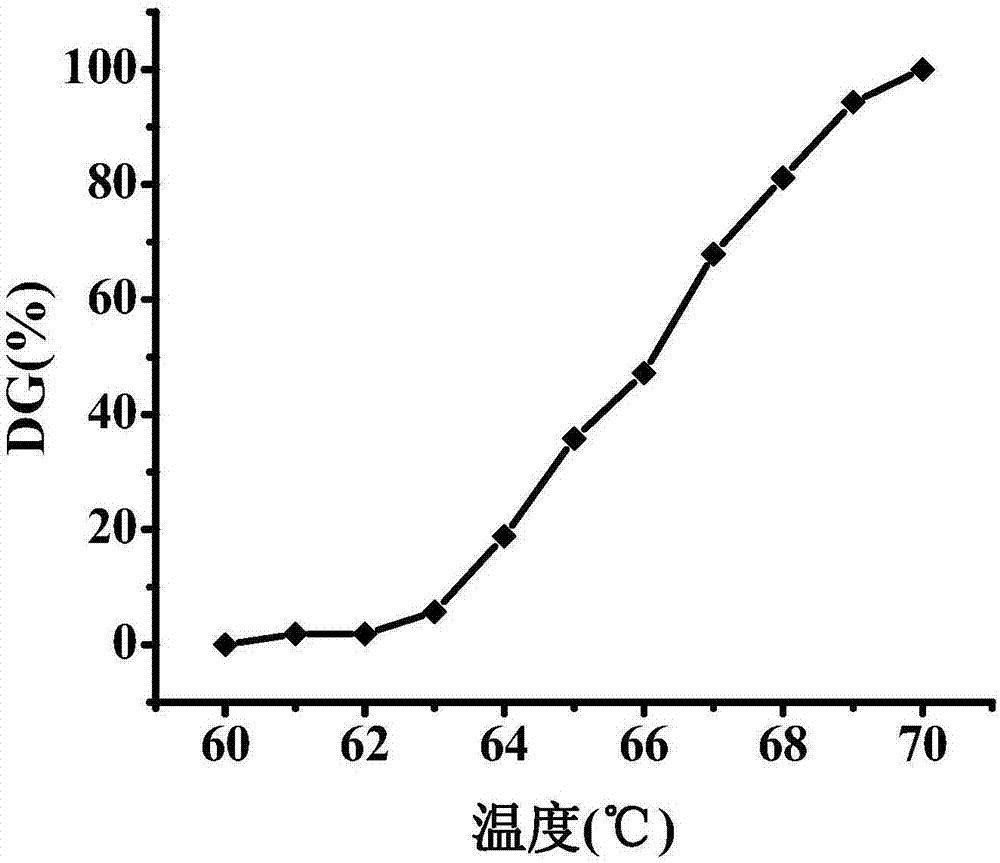

[0079] Measuring the gelatinization properties of common corn starch

[0080] (1) Tablet preparation: prepare ordinary cornstarch suspension with a mass concentration (dry basis) of 0.5%, stir up the sunken starch with a glass rod to make it more evenly dispersed in the system, and quickly absorb the starch milk with a dropper And drop 1 drop to the center of the circular glass slide that has been coated with a circle of glass glue on the edge, disperse the starch solution evenly, cover another glass slide, and seal; the film requires that the starch in the field of view of the optical microscope spread evenly, and the starch Less overlap between particles;

[0081] (2) Shooting: Place the finished film on a hot stage, heat up under a polarizing microscope, and use a digital camera connected to the microscope for continuous data collection; adjust the magnification of the microscope to 50×10, set the aperture of the polarizing microscope and take a picture Exposure time, so t...

Embodiment 2

[0092] Measuring the gelatinization properties of potato starch

[0093] (1) Tablet preparation: configure the potato starch suspension with a mass concentration (dry basis) of 1%, stir up the sunken starch with a glass rod to make it more evenly dispersed in the system, quickly draw the starch milk with a dropper and remove Add 1 drop to the center of a circular glass slide that has been coated with a circle of glass glue on the edge, disperse the starch solution evenly, cover another glass slide, and seal it; the film requires that the starch spread evenly in the field of view of the optical microscope, and the starch granules less overlap between

[0094] (2) Shooting: Place the finished film on a hot stage, heat up under a polarizing microscope, and use a digital camera connected to the microscope for continuous data collection; adjust the magnification of the microscope to 20×10, set the aperture of the polarizing microscope and take a picture Exposure time, so that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com