Wood board glue smearing and pressing device

A technology of a pressing device and a gluing device is applied in the field of wood board pressing, which can solve the problems of poor effect and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

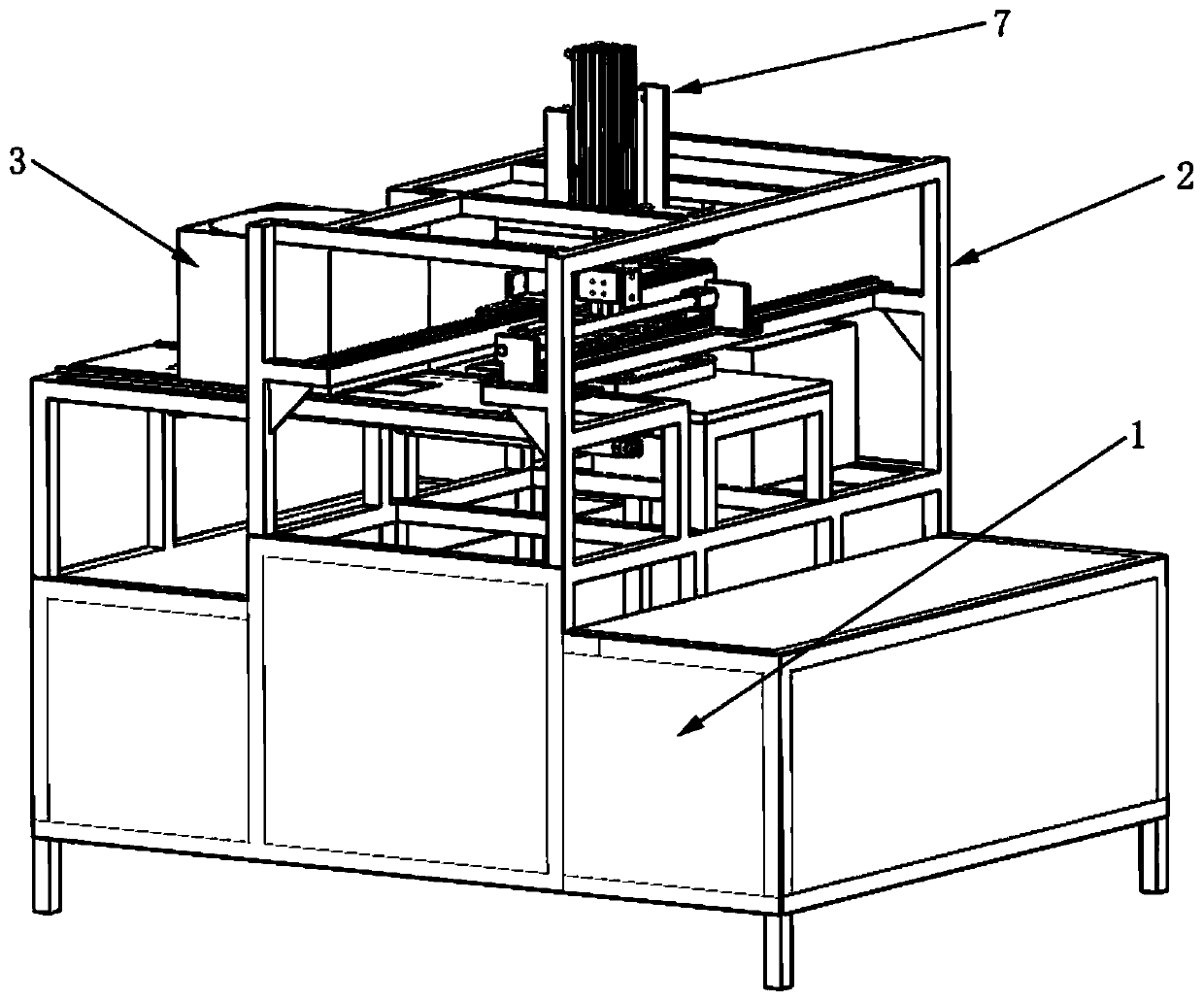

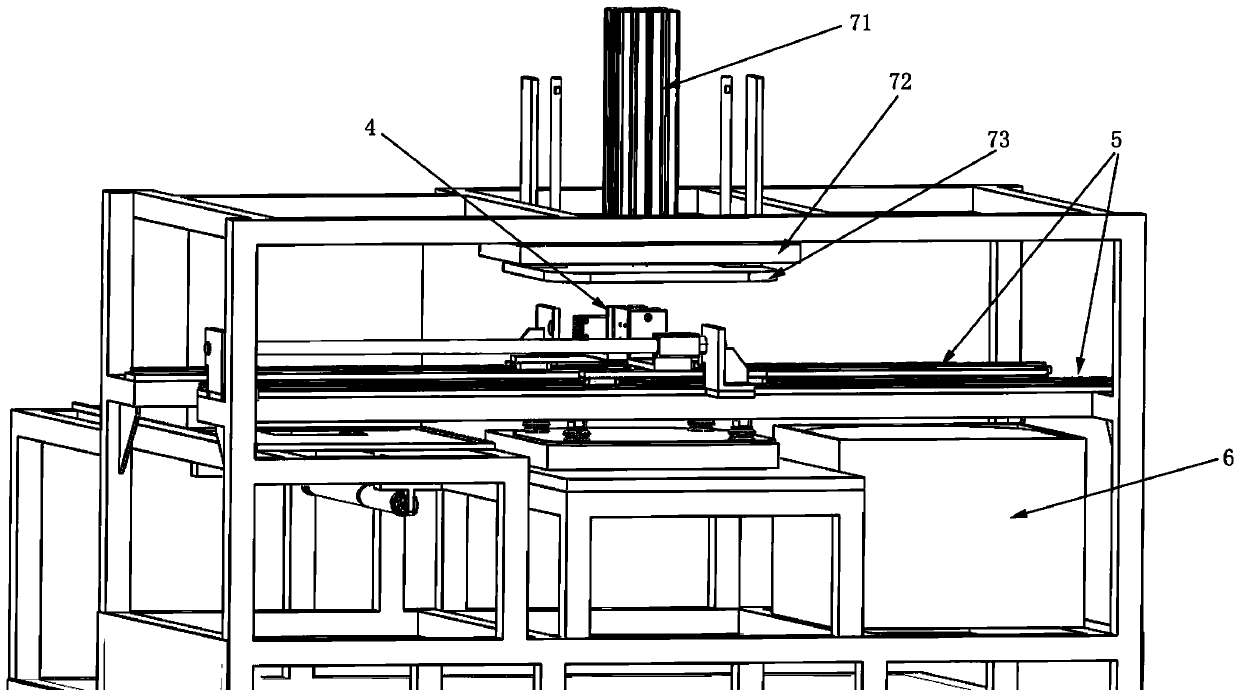

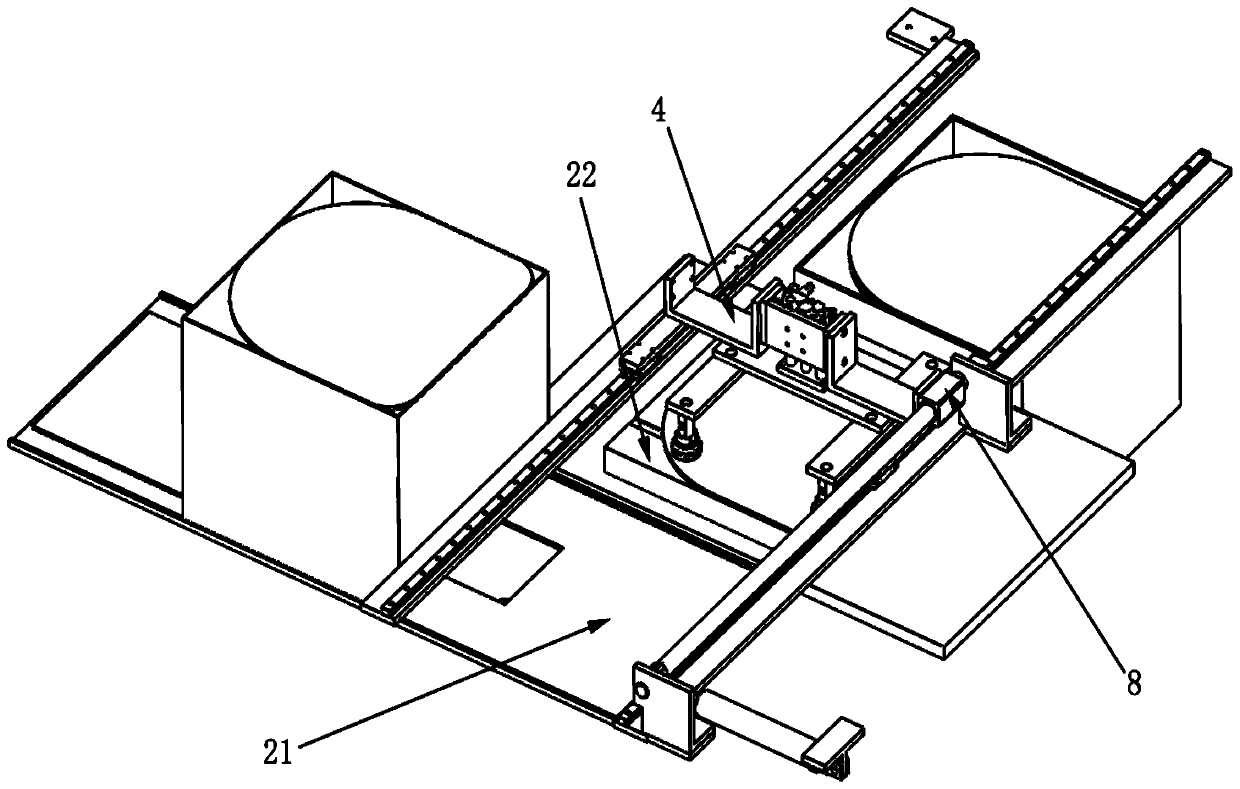

[0037] Such as Figure 1-6 As shown, it includes: base 1, frame body 2, feeding part 3, grabbing part 4, slide rail 5, collecting part 6, pressing part 7, driving device 8, gluing device 9, feeding plate 21, pressing part Closing platform 22, grabbing cylinder 41, connecting plate 42, extending plate 43, suction cup 44, pressing cylinder 71, fixing plate 72, pressing plate 73, pushing cylinder 91, pushing rod 92, rubber storage bottle 93, support rod 94 , rectangular through hole 211, feeding cylinder 222, telescopic rod 223, toggle block 224 and glue outlet 931;

[0038] Such as figure 1 with figure 2 As shown, the frame body 2 is arranged on the base 1; the middle part of the frame body 2 is provided with a slide rail 5, the slide rail 5 is provided with a grasping part 4, and the connection between the grasping part 4 and the slide rail 5 is provided with a driving device 8, The driving device is used to drive the grabbing part 4 to move on the slide rail 5; the grabbin...

Embodiment 2

[0049] Compared with Embodiment 1, Embodiment 2 sets grooves with the same shape as the planks on the pressing platform 22 on the basis of Example 1; by setting the grooves, when the planks are placed on the pressing platform 22, the grooves The wooden board can be limited to improve the accuracy and pressing effect of the subsequent pressing process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com