Preparation process of environment-friendly soft seat toilet lid

A preparation process and toilet cover technology, which is applied to toilet seats or covers, sanitary equipment, wood processing appliances, etc., can solve the problems of non-environmental protection of materials, poor comfort of toilet seats, and environmental protection, and achieve antibacterial performance improvement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

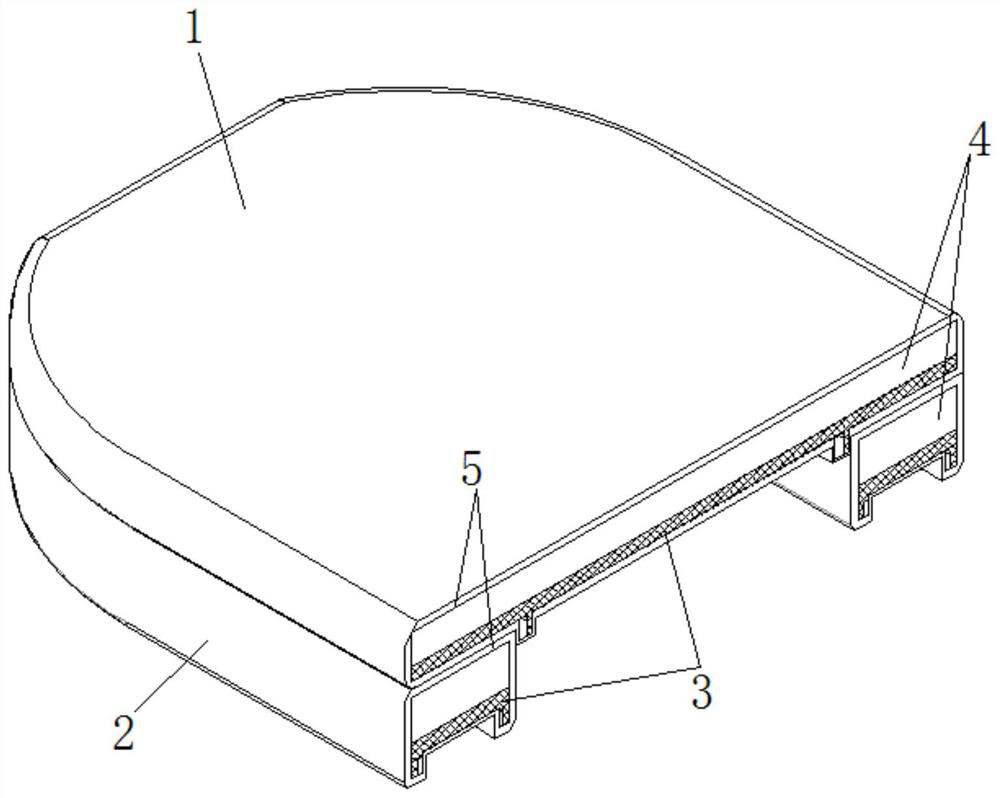

[0026] An environment-friendly soft seat toilet cover, comprising a toilet cover 1 and a toilet seat 2, a plate core 3 is arranged in the middle of the toilet cover 1 and the toilet seat 2, and the outer side of the plate core 3 is covered with a coating material 4, and covered The outside of material 4 is wrapped with wrapping material 5, such as figure 1 shown.

[0027] The covering material 4 is sponge alone or sponge and pearl cotton, and the board core 3 and the covering material 5 are pressed together by a high-frequency machine.

[0028] The wrapping material 5 is TPU, and the wrapping material is wrapped and pressed on the outer side of the wrapping material 4 by a high-frequency machine.

[0029] A preparation process for an environment-friendly soft seat toilet cover, comprising the following steps:

[0030] S1. Select toilet seat and toilet cover core materials: toilet seat and toilet cover are made of core, the core is wood core or PP material core, the thickness...

Embodiment 2

[0036] An environment-friendly soft seat toilet cover, comprising a toilet cover 1 and a toilet seat 2, a plate core 3 is arranged in the middle of the toilet cover 1 and the toilet seat 2, and the outer side of the plate core 3 is covered with a coating material 4, and covered The outside of material 4 is wrapped with wrapping material 5, such as figure 1 shown.

[0037] The covering material 4 is sponge alone or sponge and pearl cotton, and the board core 3 and the covering material 5 are pressed together by a high-frequency machine.

[0038] The wrapping material 5 is TPU, and the wrapping material is wrapped and pressed on the outer side of the wrapping material 4 by a high-frequency machine.

[0039] A preparation process for an environment-friendly soft seat toilet cover, comprising the following steps:

[0040] S1. Selection of toilet seat and toilet cover core material: toilet seat and toilet cover are made of core, the core is wood core or PP material core, the thic...

Embodiment 3

[0046] An environment-friendly soft seat toilet cover, comprising a toilet cover 1 and a toilet seat 2, a plate core 3 is arranged in the middle of the toilet cover 1 and the toilet seat 2, and the outer side of the plate core 3 is covered with a coating material 4, and covered The outside of material 4 is wrapped with wrapping material 5, such as figure 1 shown.

[0047] The covering material 4 is sponge alone or sponge and pearl cotton, and the board core 3 and the covering material 5 are pressed together by a high-frequency machine.

[0048] The wrapping material 5 is TPU, and the wrapping material is wrapped and pressed on the outer side of the wrapping material 4 by a high-frequency machine.

[0049] A preparation process for an environment-friendly soft seat toilet cover, comprising the following steps:

[0050] S1. Select toilet seat and toilet cover core materials: toilet seat and toilet cover are made of core, the core is wood core or PP material core, the thickness...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com