Hot-pressed wood-plastic composite with sandwich structure and manufacturing method thereof

A technology of wood-plastic composite material and sandwich structure, which is applied in the manufacturing field of hot-press sandwich structure wood-plastic composite material and hot-press sandwich structure wood-plastic composite material, which can solve the problem of low impact toughness, insufficient strength and modulus Requirements, easy crushing and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

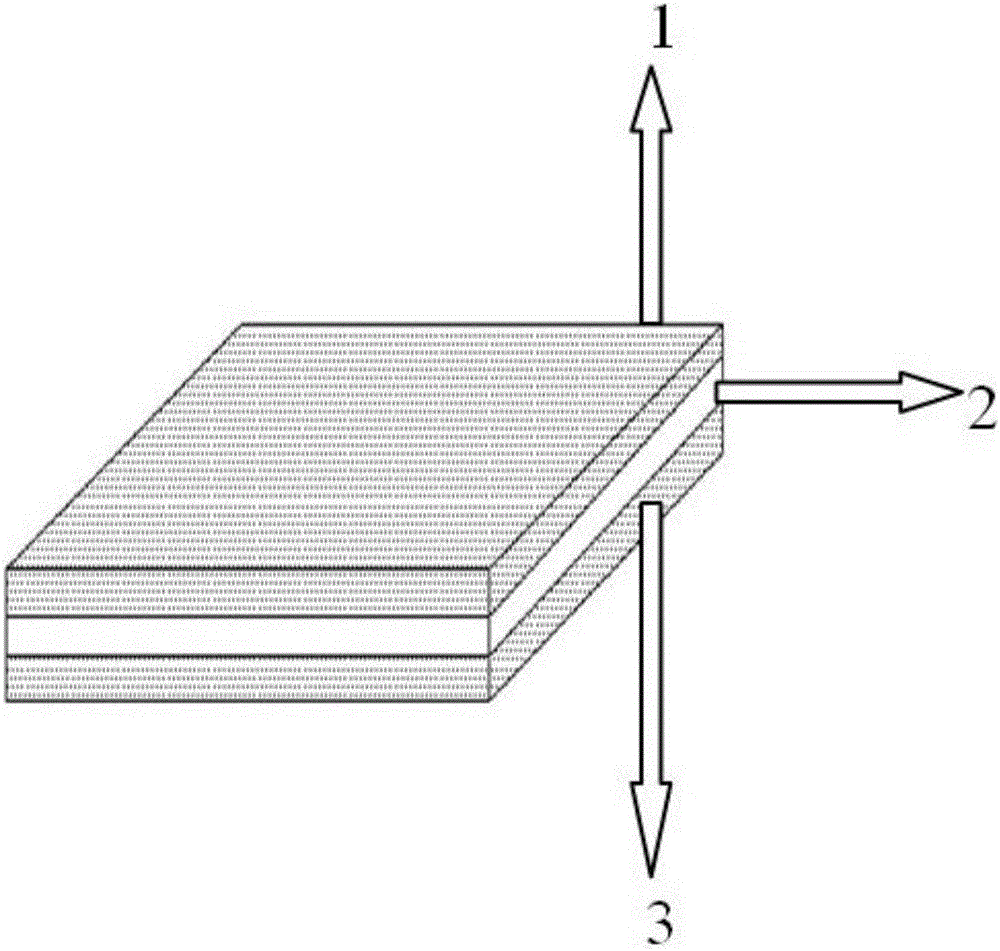

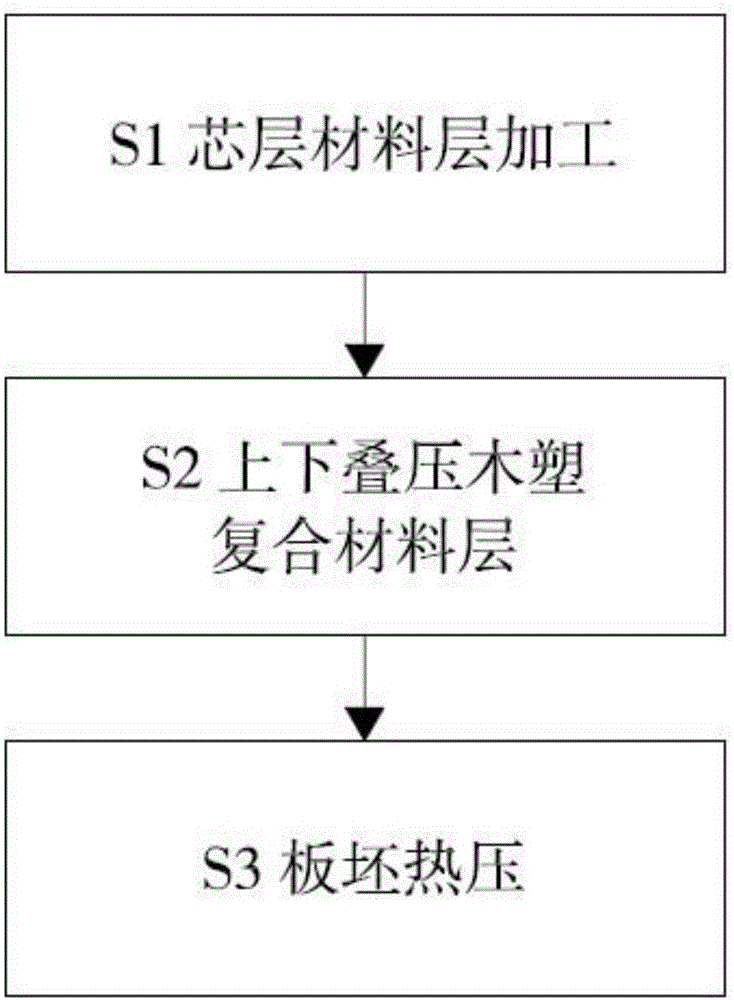

[0025] Specific Embodiment 1: Combining figure 1 Describe this embodiment mode, a wood-plastic composite material with a hot-pressed sandwich structure and its manufacturing method described in this embodiment mode, including a wood-plastic composite material layer, and the wood-plastic composite material layer is at least divided into an upper surface wood-plastic material layer 1 and the lower surface wood-plastic material layer 3, there is also a core material layer 2 between the upper surface wood-plastic material layer 1 and the lower surface wood-plastic material layer 3, and the core material layer 2 Form a hot-pressed sandwich structure with the upper surface wood-plastic material layer 1 and the lower surface wood-plastic material layer 3, the core layer material layer 2 is made of flexible polymer materials, and constitutes the hot-pressed sandwich structure flexible intercalation.

[0026] The technical effect of this embodiment is: glass is a fragile material, but...

specific Embodiment approach 2

[0027] Specific Embodiment 2: Combining figure 1 Describe this embodiment, the wood-plastic composite material with a hot-pressed sandwich structure described in this embodiment, the core material layer 2 is a continuum of flexible polymer intercalation made of thermoplastic polymers, the thermoplastic Polymers include polyethylene, polypropylene, polyvinyl chloride and polystyrene, etc., and a mixture of one or more of them, and the thermoplastic polymers are new or recycled materials; others are the same as in Embodiment 1.

[0028]The technical effect of this embodiment is: thermoplastic polymer is a kind of flexible polymer with good toughness, as the core material layer, it can endow the wood-plastic composite material with sandwich structure with good impact toughness, low density and other advantages, and thermoplasticity Polymers are thermoplastic polymers, with low processing temperature and simple process, and can be recycled and reused many times. The elastic contin...

specific Embodiment approach 3

[0029] Specific embodiment 3: The core material layer 2 is made of a mixture of thermoplastic polymers and compatibilizers in a certain proportion, and the thermoplastic polymers include polyethylene, polypropylene, polyvinyl chloride and polystyrene One or more of them, the thermoplastic polymer is new material or recycled material; the compatibilizer is maleic anhydride grafted polyethylene, maleic anhydride grafted polypropylene, titanium One or a mixture of several of esters, isocyanates, and silanes; others are the same as in Embodiment 1.

[0030] The technical effect of this embodiment is: the thermoplastic polymer is melt-mixed with a compatibilizer as the core material layer, which can well improve the interface between the non-polar thermoplastic polymer and the polar wood powder in the upper and lower wood-plastic layers Compatibility, improve the bonding strength between the core material layer and the upper and lower wood-plastic material layers, thereby improving...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com