Adjustable baseboard and molding system

a molding system and adjustable technology, applied in the field of baseboard heaters, can solve the problems of insufficient heat distribution, no suggestion that the baseboard units be used in conjunction with matching, and non-functional molding, and achieve the effect of improving the overall aesthetic appearance or appearance of the system, and enhancing the comfort of the occupants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

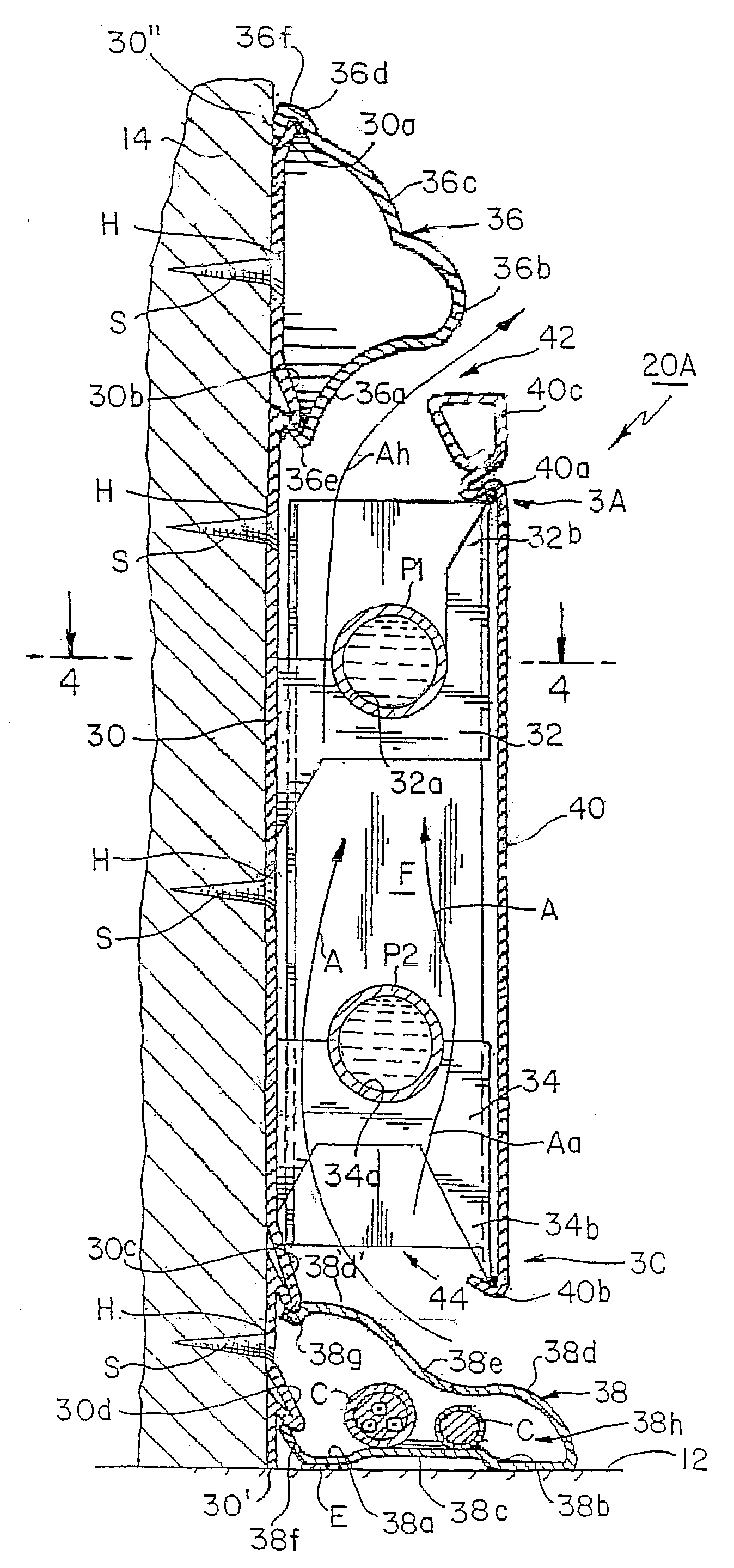

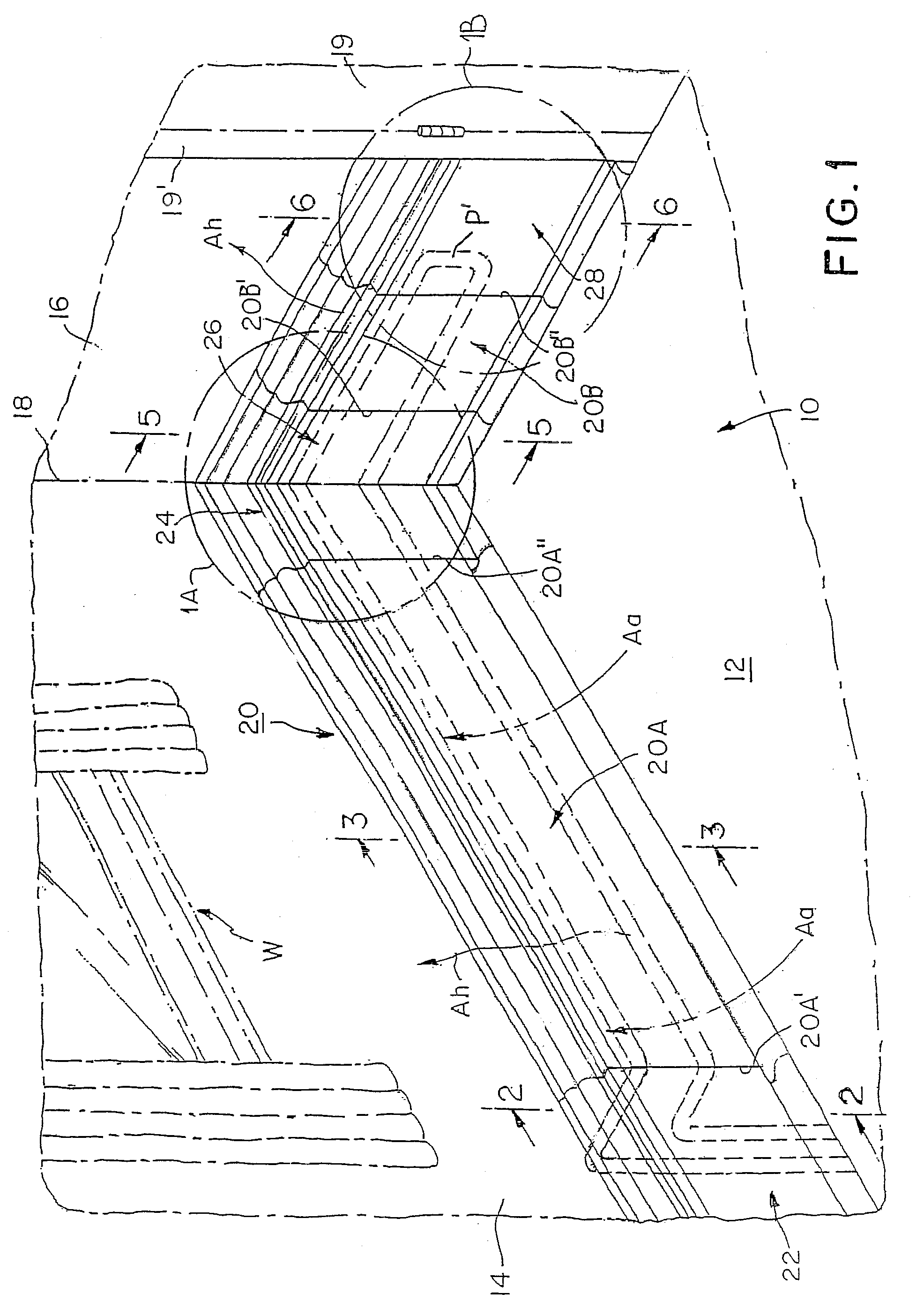

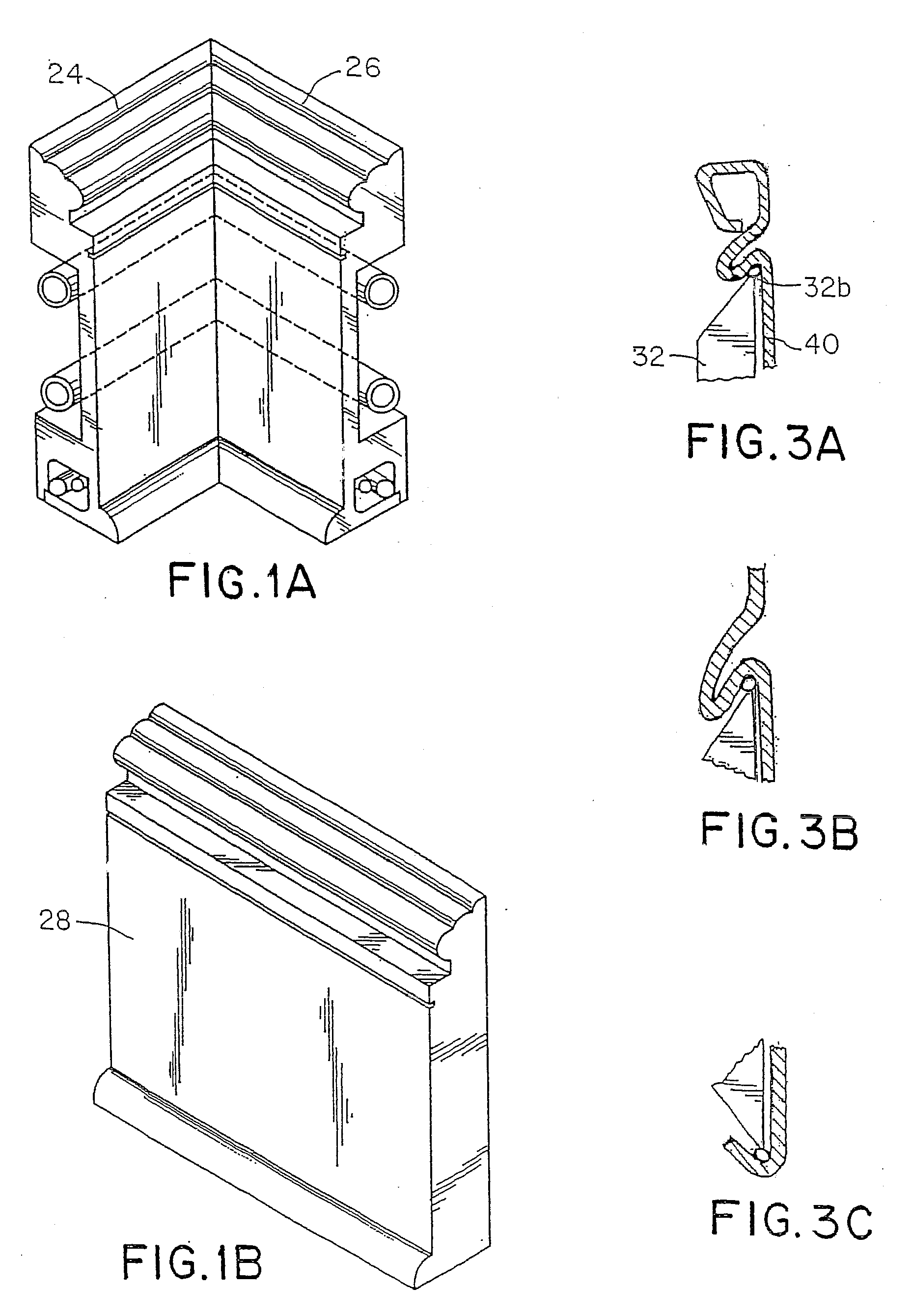

[0051] Referring now more specifically to the drawings, and first referring to FIG. 1, an enclosure or room to be heated is generally designated by the reference numeral 10, a perspective view of only one corner of a typical room being illustrated. It will become evident from the description that follows that the present invention can be used about the entire periphery of a room or only along a portion of a wall of the enclosure.

[0052] The enclosure 10 includes a floor 12 and walls 14 and 16 that meet at a corner 18.

[0053] The baseboard system according to the present invention is generally designated by the reference numeral 20. The system 20 includes, in the example shown in FIG. 1, a baseboard unit 20A on the wall 14, such as below window W, and unit 20B somewhat centered in the middle of wall 16 between the corner 18 of the enclosure, and an opening in the wall, namely, door 19. The baseboard units 20A and 20B are arranged along the walls 14, 16, respectively, proximate to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com