Improved production technology for mold-pressed wood part coated with melamine impregnated abrasion-resistant paper

A technology of melamine and production process, which is applied in the direction of wood processing appliances, manufacturing tools, and the joint of wooden veneers, which can solve problems such as easy cracking, achieve huge economic and environmental benefits, and optimize product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. These embodiments are only used to illustrate the present invention, and should not be interpreted as limiting the patent protection scope of the present invention.

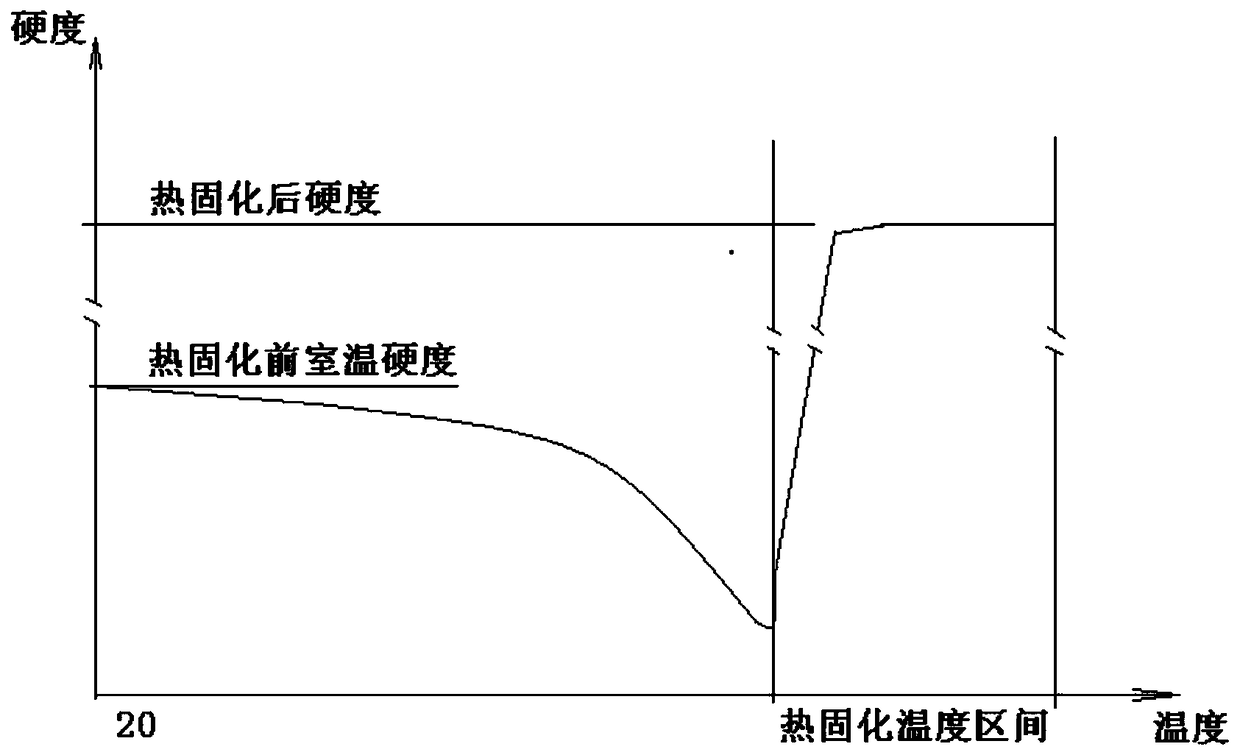

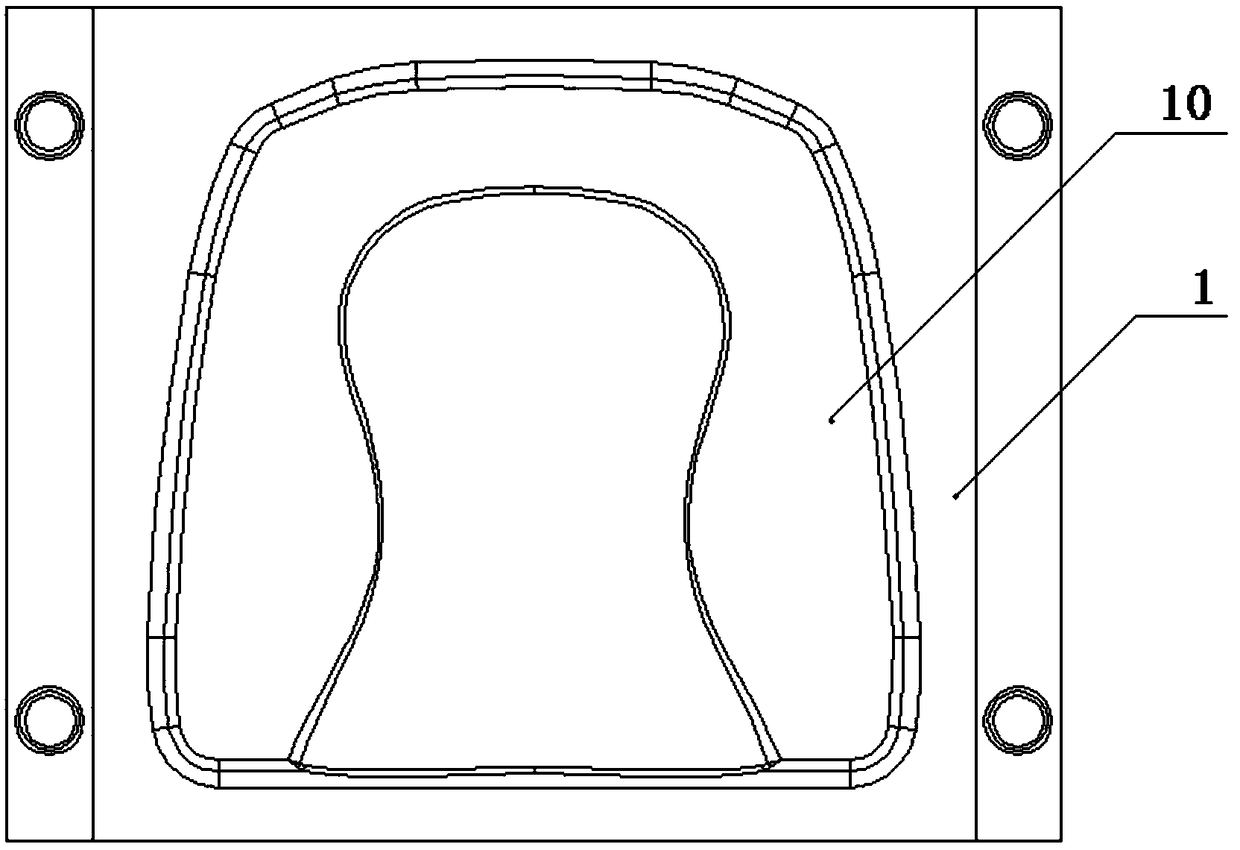

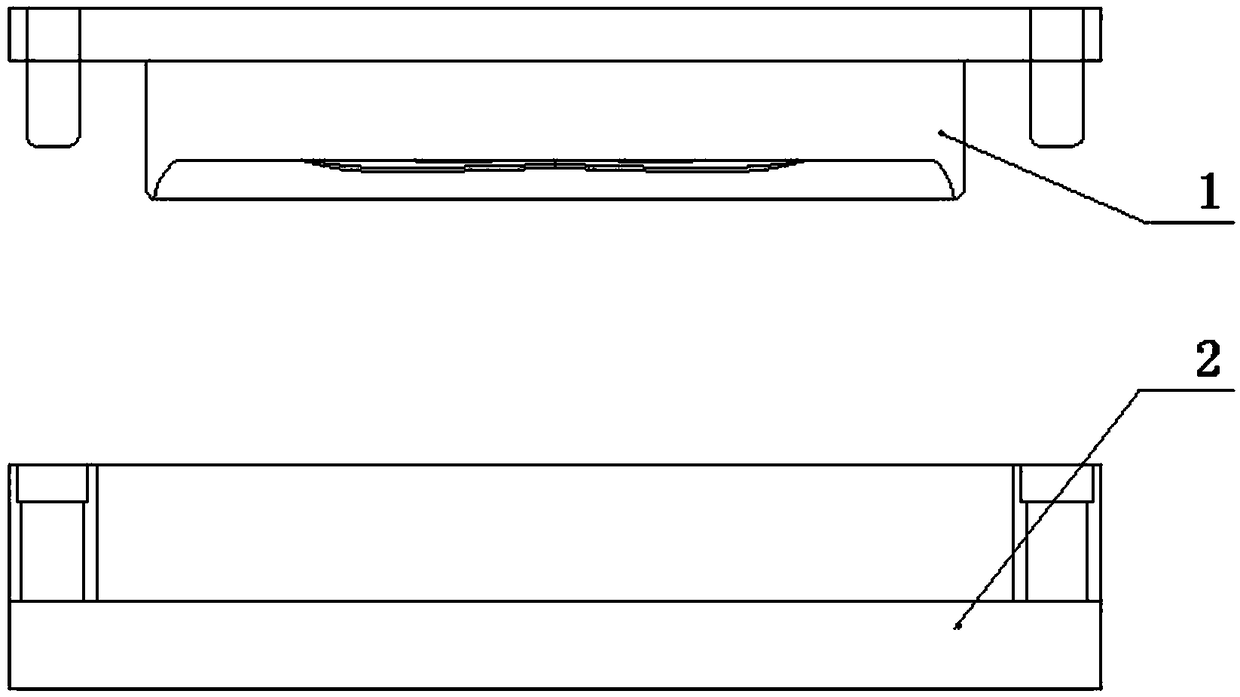

[0026] An improved production process of molded wooden parts coated with melamine-impregnated wear-resistant paper, including covering the surface of the molded wooden part blank with melamine-impregnated wear-resistant paper in a mold, closing the mold, pressurizing and heating to make the melamine The process of attaching the impregnated wear-resistant paper to the surface of the molded wood blank and curing it; its characteristic is: using melamine-impregnated wear-resistant paper that gradually softens at low heat and cured at high heat, in a molding machine that opens and closes the upper and lower molds , place the molded wood blank in the cavity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com