Horizontal hot pressing veneer drier

A drying machine and hot-pressing plate technology, which is applied to veneer presses, plywood presses, wood processing equipment, etc., can solve the problems of high labor intensity, low labor efficiency, and difficult mechanism feeding, so as to reduce labor intensity, Simple structure, effect of improving labor productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

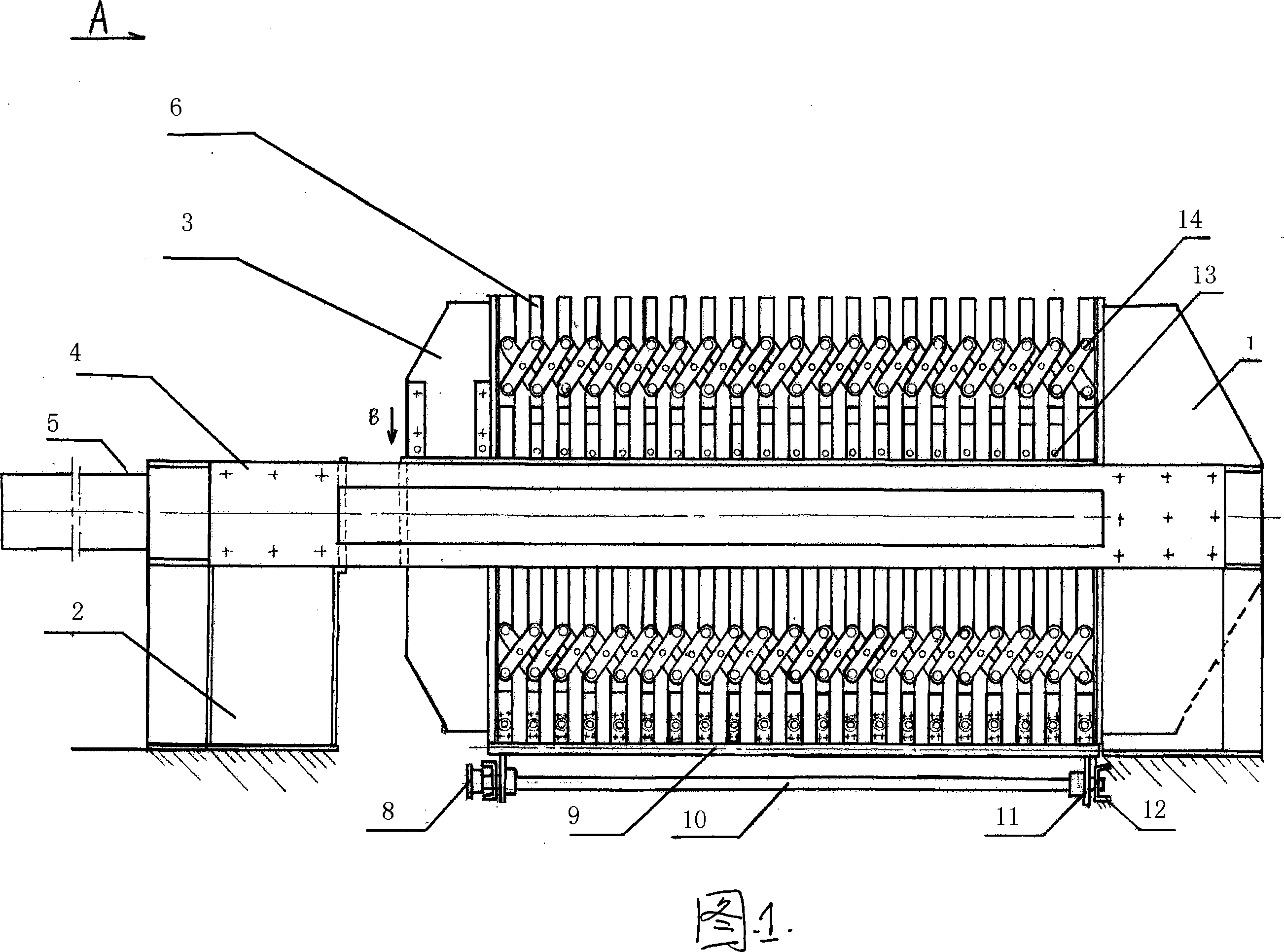

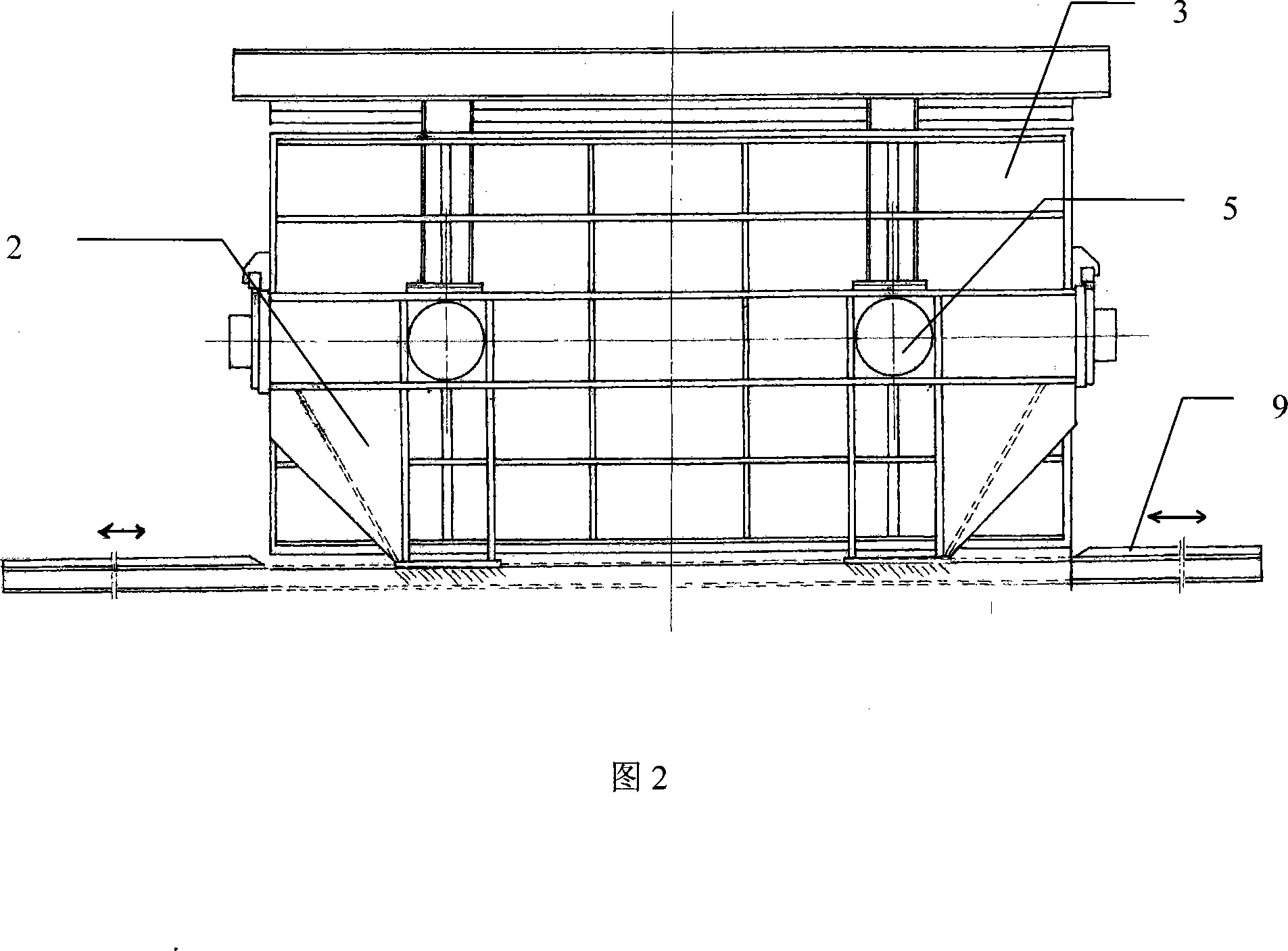

[0021] As shown in Figures 1, 2, and 5, according to the manufacturing and installation procedures of the wood-based panel hot press, each component is manufactured and installed; the heating and pressurization system is the same as that of the ordinary press; the hot pressing plate on the heating system passes through the pipeline and the heat source The pressurization system is connected with the pressurization pump through pipelines; the frame is composed of front beam (1), rear beam (2) and side support beam (4); the pressurization system is composed of oil cylinder (5), movable beam (3), The hot pressing plate (6) and the front beam constitute, the oil cylinder is fixed on the rear beam, and the plunger (18) of the oil cylinder is connected with the movable beam; the hot pressing plates at both ends are respectively fixed on the front beam and the movable beam, and the movable beam, the hot pressing plate Hang on the side support beam through the supporting pulley (13), an...

Embodiment 2

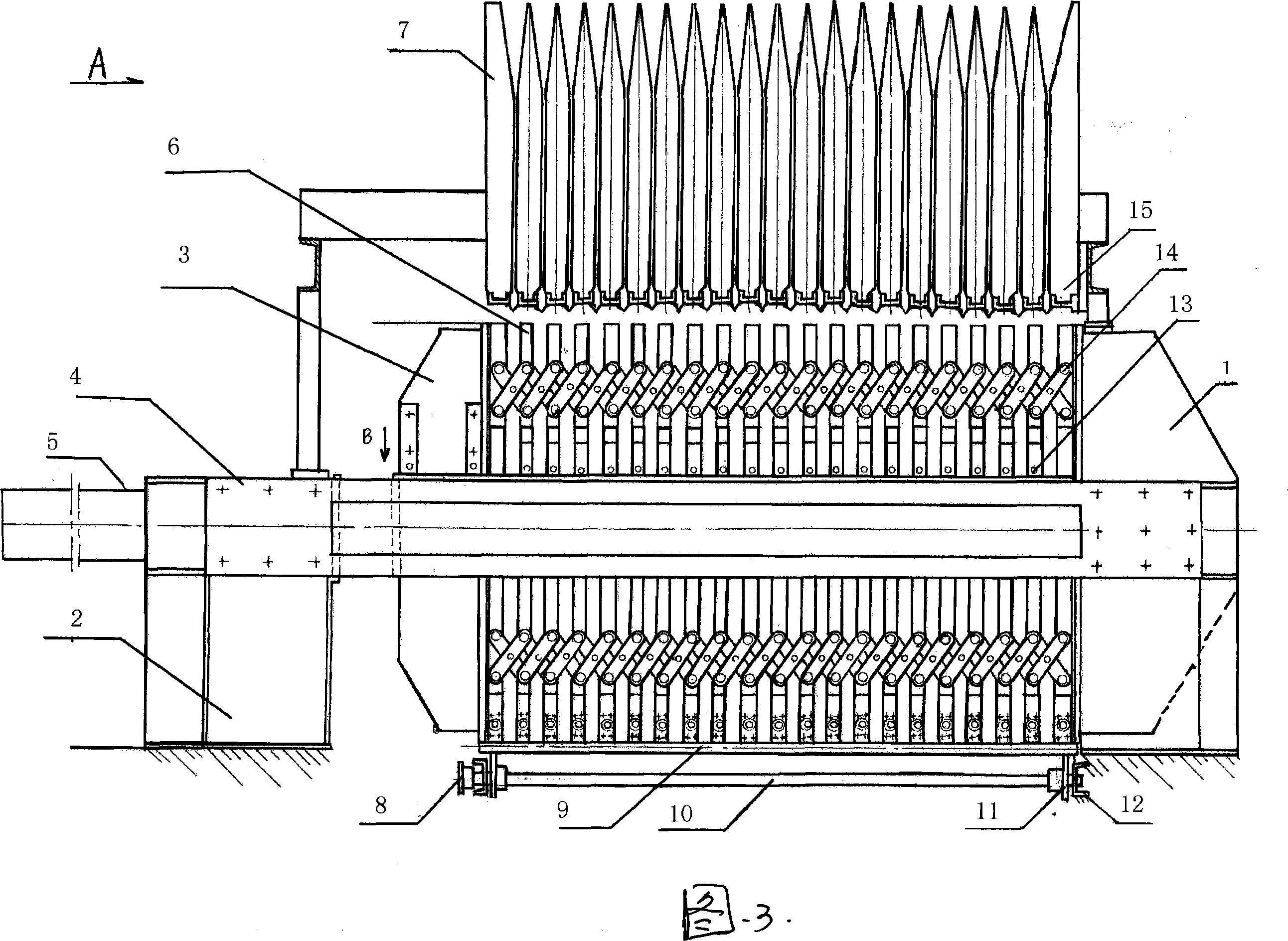

[0024] As shown in Figures 2, 3, 5, and 6, according to the manufacturing and installation procedures of the wood-based panel hot press, each component is manufactured and installed; the heating and pressurization system is the same as that of the ordinary press; the hot pressing plate on the heating system passes through the pipeline It is connected with the heat source, and the pressurization system is connected with the pressurization pump through pipelines; the frame is composed of front beam (1), rear beam (2) and side support beam (4); the pressurization system is composed of oil cylinder (5), movable beam (3 ), hot pressing plate (6), the oil cylinder is fixed on the rear beam, and the plunger (18) of the oil cylinder is connected with the movable beam; the hot pressing plates at both ends are respectively fixed on the front beam and the rear beam, and the movable beam and the hot pressing plate are supported The small pulley (13) is hung on the side support beam, and th...

Embodiment 3

[0027] According to embodiment 1, one is set up below it to be a plate-connecting car, which becomes a kind of horizontal hot-pressed veneer dryer with a plate-connecting car provided by the present invention.

[0028] When the drying work is completed and the board needs to be unloaded, move the receiving car to the bottom of the horizontal hot-pressed veneer dryer, and then open the movable baffle, and the veneer will fall freely in the receiving car under the dryer, and then move out out of the dryer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com