High-starch-content thermosetting artificial board starch adhesive and preparation method thereof

A starch adhesive and wood-based panel technology, which is applied in adhesives, grafted polymer adhesives, manufacturing tools, etc., can solve the problem of high proportion of starch in starch adhesives, achieve the effect of reducing costs and broadening the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

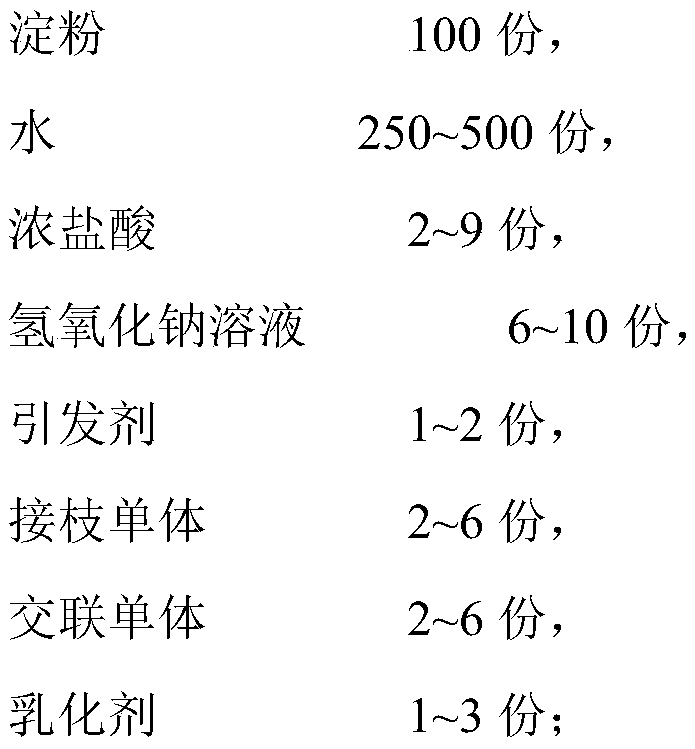

[0046] Formula (mass / g):

[0047]

[0048]

[0049] Process flow:

[0050] (1) Starch and water are made into starch milk with a mass ratio of 35% on a dry basis of starch, and stirred evenly;

[0051] (2) Heat up the starch milk in step (1) at a rate of 2°C / min, keep it warm for 10min when the temperature reaches 50°C, then continue to heat up to 70°C, dilute 8.6g 12mol / L concentrated hydrochloric acid solution to 0.5mol / L L, added to starch milk for acid hydrolysis, acid hydrolysis for 2.5h, then adding 10mol / L sodium hydroxide solution to adjust the pH to 4; adjust the temperature of the acid hydrolyzed starch milk to 80 °C at a rate of 1 °C / min, pre- Gelatinization for 30min;

[0052] (3) get 0.51g initiator and be dissolved in 40g water and make initiator solution, get and account for initiator solution total mass 15% initiator solution and emulsifier and grafting monomer mix, make seed emulsion, step (2) After cooling the system at a rate of 1°C / min to 70°C, dro...

Embodiment 2

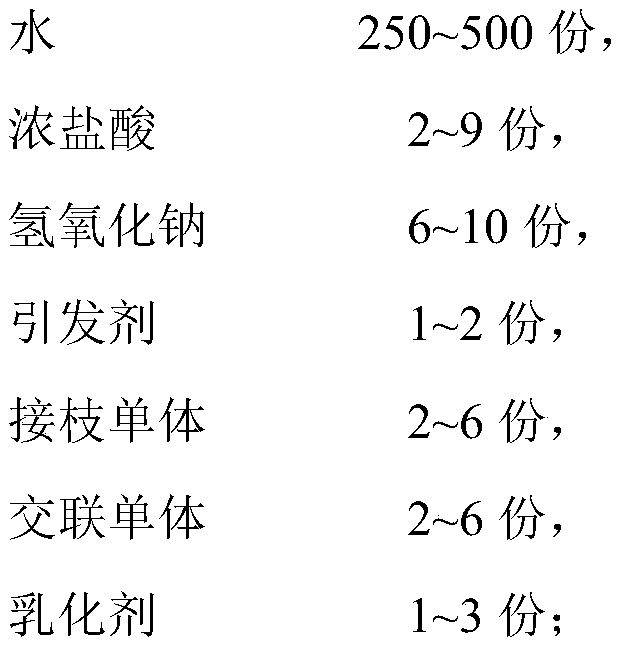

[0058] Formula (mass / g):

[0059]

[0060]

[0061] Process flow:

[0062] (1) Starch and water are made into starch milk with a mass ratio of 35% on a dry basis of starch, and stirred evenly;

[0063] (2) Heat up the starch milk in step (1) at a rate of 2°C / min. When the temperature reaches 50°C, keep it warm for 10 minutes, then continue to heat up to 70°C, keep it warm for 2.5h, and dilute 8.6g of 12mol / L concentrated hydrochloric acid solution 0.5mol / L, add it to starch milk for acid hydrolysis, then add 10mol / L sodium hydroxide solution to adjust pH to 4; adjust the temperature of acid hydrolyzed starch milk to 80℃ at a rate of 1℃ / min, 30min;

[0064] (3) get 0.51g initiator and be dissolved in 40g water and make initiator solution, get and account for initiator solution total mass 15% initiator solution and emulsifier and grafting monomer mix, make seed emulsion, step (2) After cooling the system at a rate of 1°C / min to 70°C, drop the seed emulsion into the reac...

Embodiment 3

[0070] Formula (mass / g):

[0071]

[0072]

[0073] Process flow:

[0074] (1) Starch and water are made into starch milk with a mass ratio of 35% on a dry basis of starch, and stirred evenly;

[0075] (2) Heat up the starch milk in step (1) at a rate of 2°C / min. When the temperature reaches 50°C, keep it warm for 10 minutes, then continue to heat up to 70°C, keep it warm for 2.5h, and dilute 8.6g of 12mol / L concentrated hydrochloric acid solution 0.5mol / L, add it to starch milk for acid hydrolysis, then add 10mol / L sodium hydroxide solution to adjust pH to 4; adjust the temperature of acid hydrolyzed starch milk to 80℃ at a rate of 1℃ / min, 30min;

[0076] (3) get 0.51g initiator and be dissolved in 40g water and make initiator solution, get and account for initiator solution total mass 15% initiator solution and emulsifier and grafting monomer mix, make seed emulsion, step (2) After cooling the system at a rate of 1°C / min to 70°C, drop the seed emulsion into the reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com