Three-phase jet extinguishing method

A jet, three-phase technology, applied in fire prevention equipment, fire rescue, etc., can solve the problems of non-resistance to re-ignition, difficulty in cleaning, irritation of the respiratory tract, etc., and achieve the effects of strong mobility of the device, prevention of caking problems, and high fire extinguishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

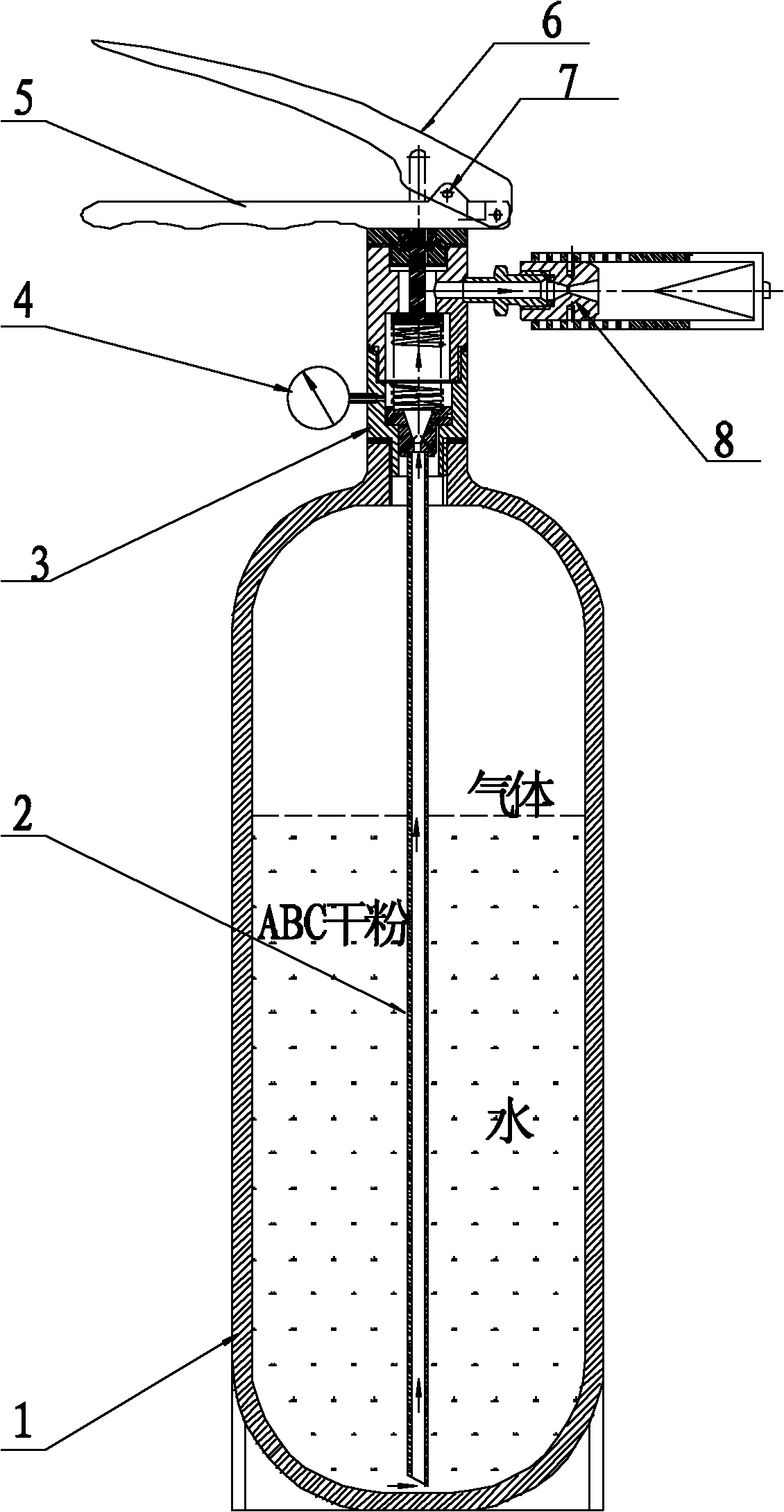

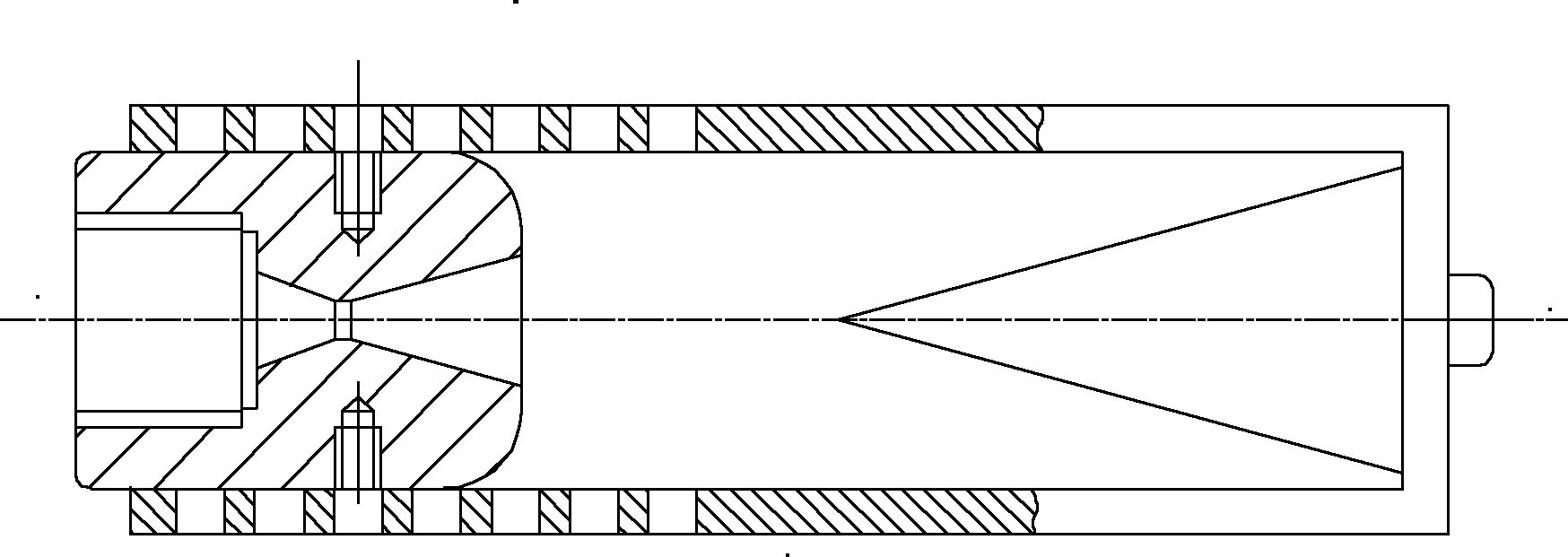

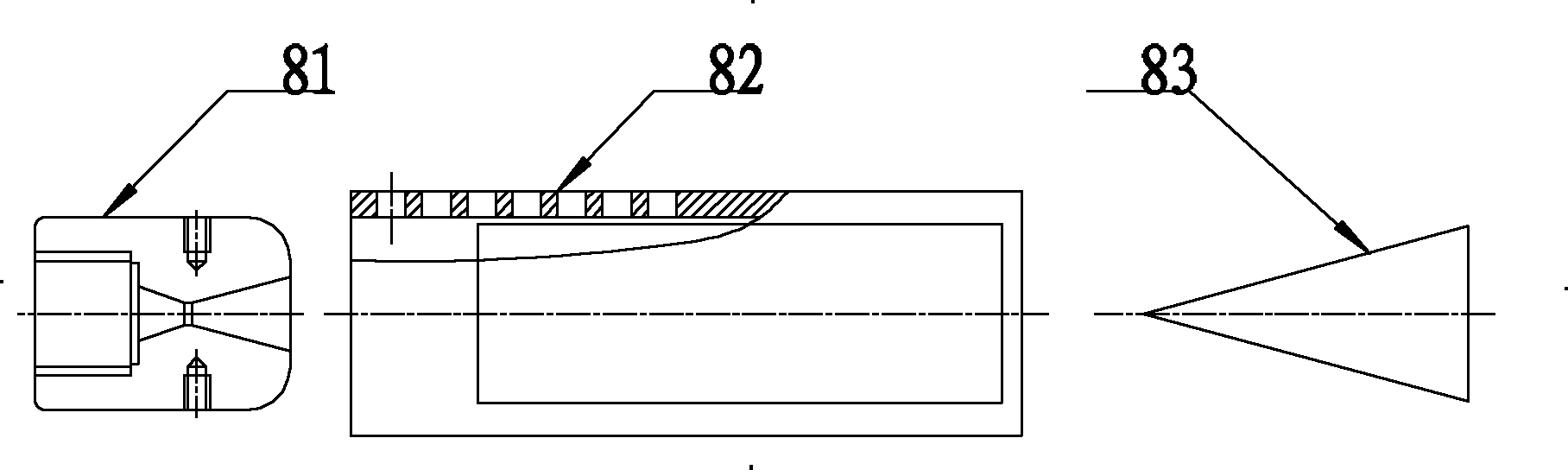

[0022] The inventive method is based on a portable two-phase flow fine water mist fire extinguishing device, such as figure 1 , 2A , 2B, 3, 4, specifically include: air-water mixed bottle 1, siphon 2, bottle head valve 3, pressure gauge 4, trigger fixed handle 5, trigger movable handle 6, safety pin 7, Laval nozzle 81, Suspension mechanism 82, triangular cone 83. The connection relationship is: the air-water mixed bottle 1 is connected with the bottle head valve 3 through a sealing thread. Siphon pipe 2 is welded with bottle head valve 3. The trigger fixed handle 5 is used as the opening element of the bottle head valve 3, and is fixed with a pin after the bottle head valve 3 is blocked by the draw-in groove, and the trigger movable handle 6 is connected with the same pin here with the trigger fixed handle 5. Laval nozzle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com