Recombination wooden furniture board with natural wood grain and manufacturing method thereof

A manufacturing method and technology for furniture boards, which are applied in the manufacture of tools, wood layered products, wood processing appliances, etc., can solve the problems of low strength, no price advantage, excessive formaldehyde content, etc., and achieve high strength, low cost and high hardness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

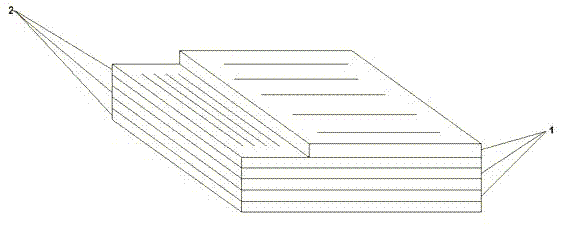

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0019] Such as figure 1 As shown, in the recombined wood furniture board with natural wood grain and its manufacturing method described in the present invention, the sliced poplar veneer is dried at the beginning of production, and then impregnated with phenolic resin. After the veneer is soaked in glue, after drying, the veneer layer 1 which is connected horizontally and the veneer layer 2 which is vertically distributed are vertically arranged in the mould. After being pressed and solidified by a hot press, a heavy wood board is obtained. After trimming and polishing the balanced restructured wooden boards, a furniture board with natural wood grain is obtained.

[0020] The manufacture method of the present invention is as follows:

[0021] Step 1: Plane the fast-growing wood into veneer;

[0022] Step 2: The veneer is dried in the sun or by a drying machine,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com