Method for manufacturing wood panels

A wood material board, wood material technology, applied in wood processing utensils, applications, home utensils, etc., to achieve the effect of improving the adjustment potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

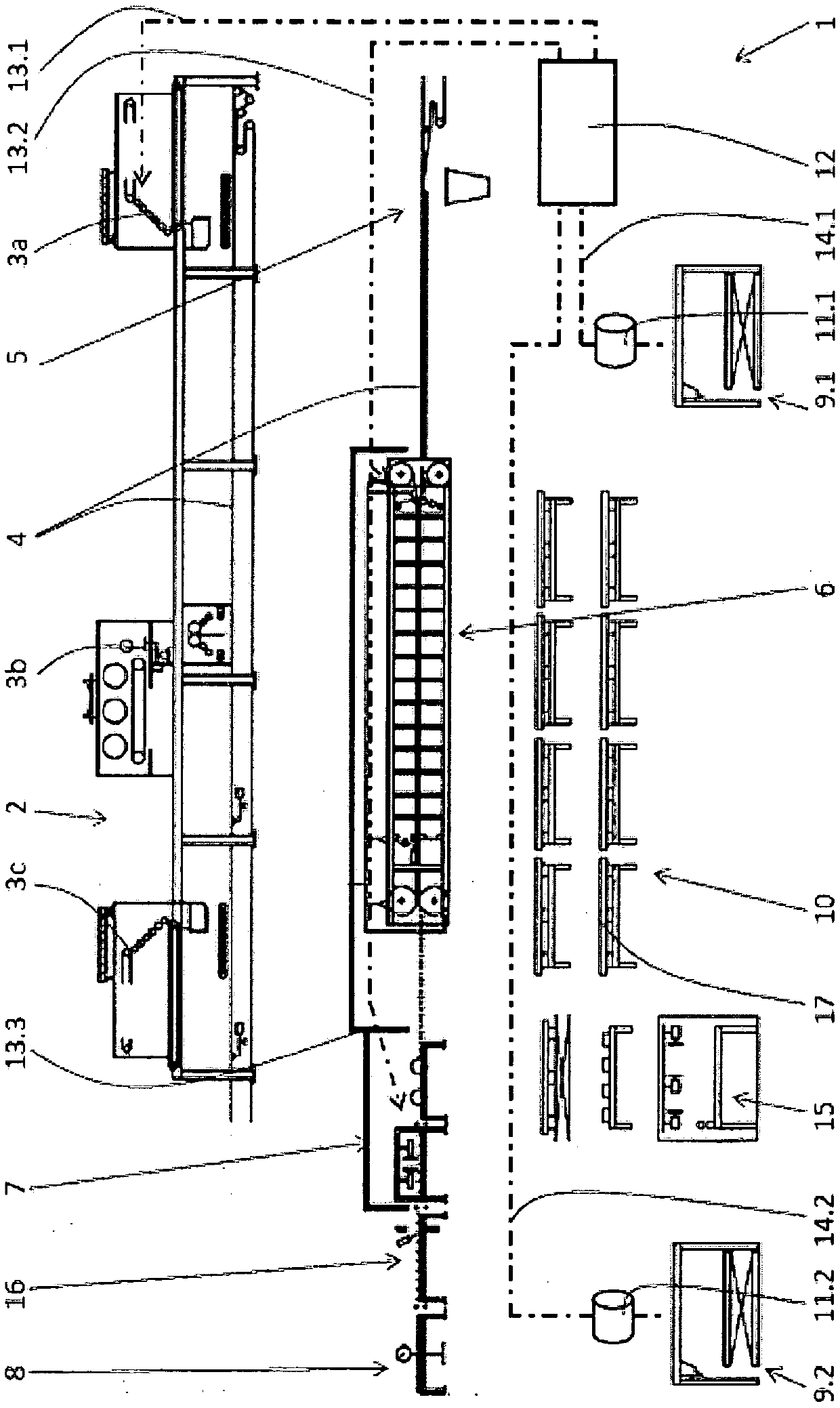

[0038] Three rows one above the other schematically illustrate the units or stations of the device for manufacturing wood material panels 1 , which are actually passed sequentially from right to left.

[0039] In the upper row a spreading device 2 comprising three spreading stations 3a, 3b, 3c is shown. Spreading stations 3 a and 3 c spread the lower and upper covering layers of the mat of wooden material, not shown, onto the conveyor belt 4 , and station 3 b spreads the middle layer of the mat of wooden material, not shown, on the conveyor belt 4 . The throughput of spreading material, ie wood material, can be metered by means of the shown spreading rollers and possible guide and closing plates and preferably can also be metered differently in the transverse profile.

[0040] In the second row, the mat of wood material spread on the conveyor belt 4 is conveyed to the continuous double-belt press 6 via the shown error bulk container 5 . In the twin-belt press the mat of woody...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com