Anti-deformation suit door

A technology for suiting doors and anti-deformation, which is applied in the direction of door leaves, etc., can solve the problems of high cost, wood deformation, wooden door deformation, etc., and achieve the effect of cost saving and deformation prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments:

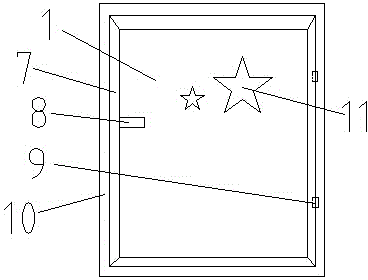

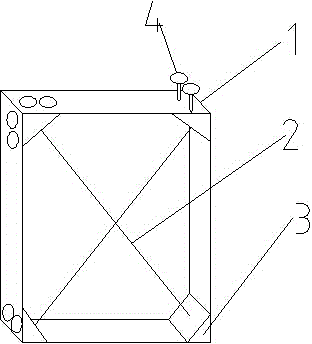

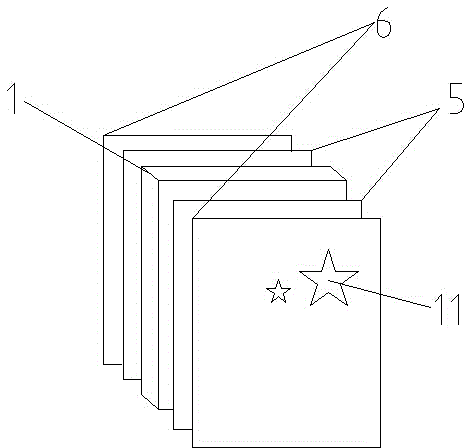

[0014] Such as figure 1 , figure 2 , Figure 4 The shown anti-deformation suit door includes a frame 1, a tie rod 2, a reinforcing rib 3, a screw 4, a door panel 5, a facing 6, a hemming 7, a door lock 8, a hinge 9, a door frame 10, and a relief pattern 11. .

[0015] Such as figure 2 As shown, the four corners of the box 1 are respectively provided with right-angled triangular reinforcing ribs 3, and the two right-angled sides of the reinforcing ribs 3 are attached to the two inner surfaces of the box 1, and are fixed by two side-by-side screws 4 On the frame 1, the reinforcement rib 3 is connected to the frame 1 on each side with two side by side screws 4 for connection. The reinforcement rib 3 is provided with two diagonally connected elastic pull rods 2, and the elastic pull rod 2 It can be made of general plastic or replaced by steel wire to s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com