Patents

Literature

134results about How to "Increase the sense of thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Casing flavor for reconstituted tobacco leaves produced by using paper-making method

InactiveCN102010787ASolve the problem of excessive residualHigh extraction rateTobacco preparationTobacco treatmentChemistryFlavor

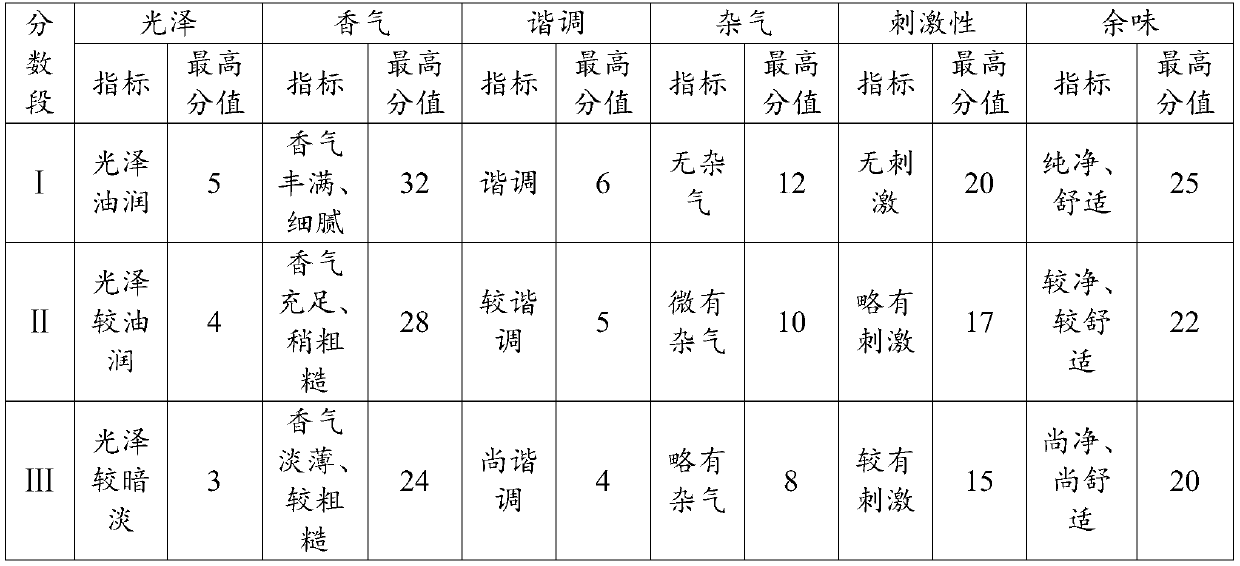

The invention relates to tobacco flavors, in particular to a casing flavor for reconstituted tobacco leave produced by using a paper-making method. The casing flavor is prepared by mixing the following raw material components according to weight percentage: 8-15 percent of cured tobacco extracts, 2-3 percent of yellow sun-cured tobacco extracts, 2-6 percent of red date extracts, 1-4 percent of reed root extracts, 2-8 percent of momordica grosvenori extracts, 3-8 percent of tamarind pulp extracts, 6-8 percent of plum extracts, 5-7 percent of wild jujube leaves extracts, 8-10 percent of elm bark extracts, 8-10 percent of water and 21-55 percent of propanediol. The invention overcomes the defects of insufficient fragrance quantity, denser wood miscellaneous gas, larger stimulation, remained sour and hot feeling and certain burning feeling of the reconstituted tobacco leaves produced by using the paper-making method. The casing flavor increases fragrance quantity, enriches fragrance, ensures better softness and fineness, smaller stimulation to the throat part and less residues, ensures that a firing sense basically disappears, and greatly improves the organoleptic quality of the reconstituted tobacco leaves by using the paper-making method.

Owner:HUBEI CHINA TOBACCO IND +1

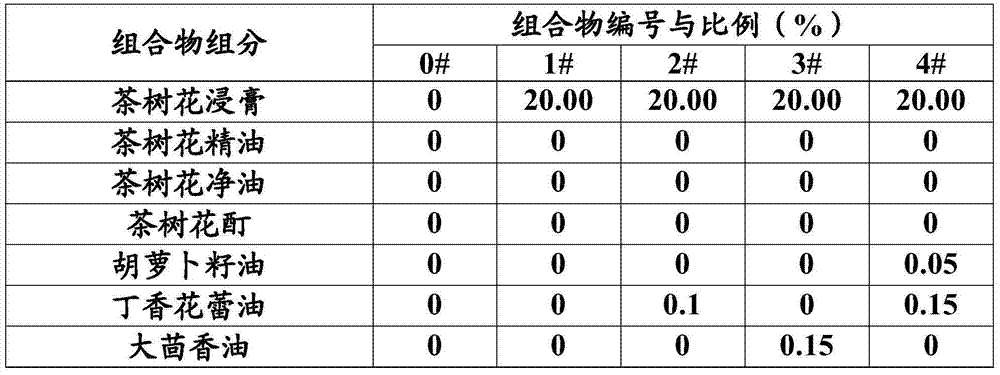

Camellia extract composition with spicy fragrance and application of same to cigarettes

ActiveCN103478894AElegant aromaIncrease diversityTobacco preparationTobacco treatmentFlavorAroma aroma

The invention relates to a camellia extract composition with spicy fragrance and application of the composition serving as a cigarette additive to cigarettes. The camellia extract composition is prepared from camellia extract and spice. After the camellia extract composition with the spicy fragrance is added into the cigarettes, fragrance of the cigarettes is harmonious, unique fragrance of the cigarettes is enhanced, the spicy fragrance is enhanced, cigarette flavor is enabled to be richer and more natural, richness, sense of thickness and mellowness of the cigarette fragrance are improved, smokers smoking the cigarettes can feel nature and relaxed, offensive odor and stimulation are reduced, and overall smoking quality is improved.

Owner:CHINA TOBACCO FUJIAN IND +1

Tobacco distillate, and preparation and application thereof

ActiveCN104757703AIncrease the sense of thicknessIncrease fine smokeTobacco preparationTobacco treatmentSolventElecampane

The invention discloses tobacco distillate, and preparation and application thereof. The tobacco distillate is obtained through distilling tobacco raw material. A preparation method for the tobacco distillate includes steps that 1) placing the tobacco raw material in solvent to extract, wherein the solvent is ethanol solution with mass fraction 40-99%; 2) heating the material of the step 1), and gathering the distillate of which the temperature is 150 to 400 degrees centigrade. The distillate is obtained through distilling tobacco material under a gas atmosphere in a certain temperature range, and the distillate has full-bodied scorch aroma, faint scent, elecampane and the like tobacco aroma.

Owner:CHINA TOBACCO GUIZHOU IND

Samara oil compound protein solid beverage and method for preparing same

ActiveCN104544432ANutrient PrecisePromote proliferationSugar food ingredientsVitamin food ingredientsFunctional foodWheat germ

The invention provides a samara oil compound protein solid beverage suitable for teenagers. The samara oil compound protein solid beverage is prepared from wheat germ flour, protein powder, whole grain flour, functional food composition, flavor additive, xylitol, samara oil, compound nutrient and food additive according to a certain percentage. The method comprises the following steps: sieving the raw materials and placing the raw materials in a mixing machine for mixing; dewatering and drying the mixture in a constant-temperature dry box, and finally packaging. The samara oil compound protein solid beverage has the advantages of providing rich nutritional ingredients and microelements which are necessary for the growth for the teenagers, and improving the immunity while supplementing nutrition for the body; moreover, the samara oil, taurine and vitamin A are added to promote the development of intelligence and vision, maintain the visual performance, and prevent juvenile myopia effectively. Therefore, the samara oil compound protein solid beverage provides accurate and comprehensive nutritional ingredients to meet the physiological characteristics and nutritional requirement of the teenagers.

Owner:山西琪尔康翅果生物制品有限公司

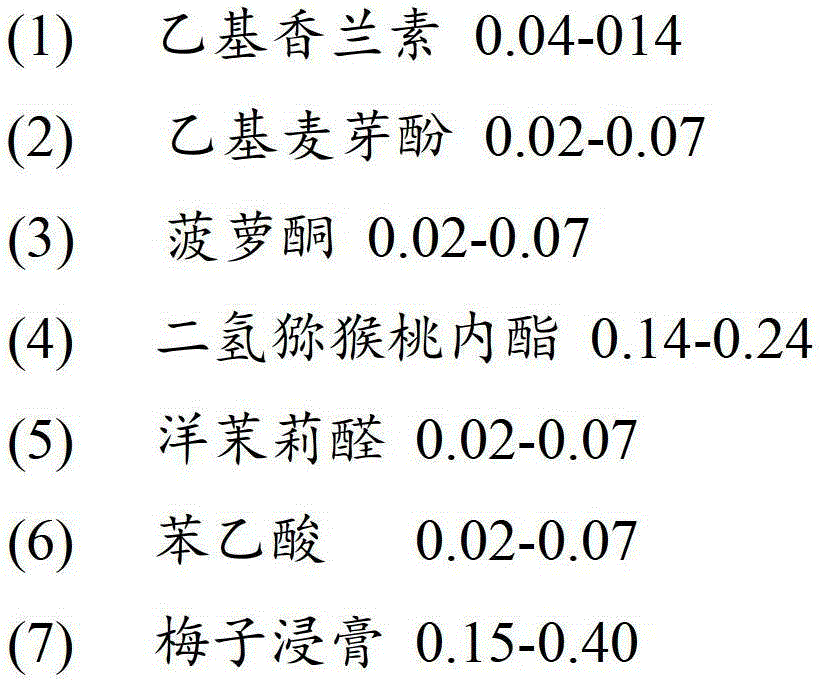

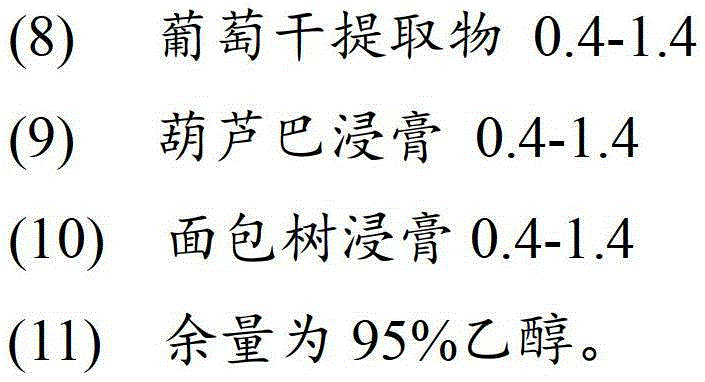

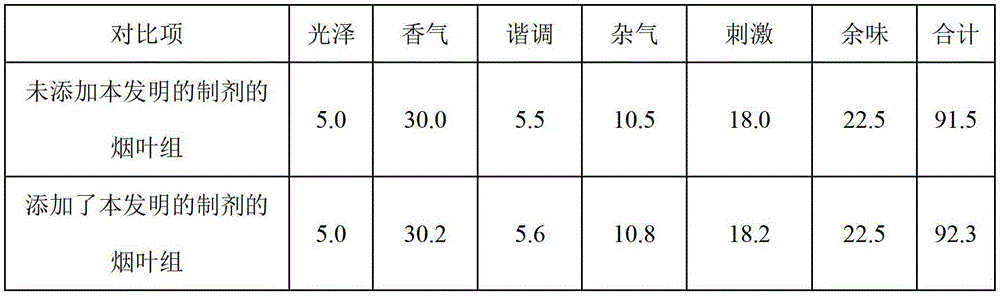

Enriching and thickening functional cluster substance preparation capable of obviously increasing richness and lumping of cigarette smoke

ActiveCN103141936AIncrease the sense of thicknessImprove clusteringTobacco treatmentEssential-oils/perfumesPhenyl acetic acidEthyl vanillin

The invention discloses an enriching and thickening functional cluster substance preparation capable of obviously increasing richness and lumping of cigarette smoke, relates to a tobacco additive, and aims to provide the enriching and thickening functional cluster substance preparation capable of obviously increasing the richness and the lumping of the cigarette smoke, which has the capabilities of enriching, thickening and improving the cigarette aroma and richness. The preparation is characterized in that the raw materials for preparing the preparation comprise the following basic raw materials in percentage by weight: ethyl vanillin, ethyl maltol, pineapple ketone, dihydroactinidiolide, heliotropin, phenyl acetic acid, plum extract, raisin extract, fenugreek concrete, breadfruit concrete and the balance of 95 percent ethanol. The preparation can be widely used in all the cigarette factories throughout the country.

Owner:SHENZHEN TOBACCO IND

Top dressing flavor capable of covering up couch grass-like miscellaneous gas of tobacco products

InactiveCN101444330AIncreases natural alcohol andIncrease the sense of thicknessTobacco treatmentFlavorSolvent

The invention discloses a top dressing flavor capable of covering up couch grass-like miscellaneous gas of tobacco products and relates to the technical field of flavors for tobacco. The top dressing flavor capable of covering up the couch grass-like miscellaneous gas of the tobacco products is composed of a plurality of flavors and a solvent, and the technical proposal is to utilize annular transitions with grass scent among the flavors to wrap the couch grass-like green miscellaneous gas; the flavor with paste scent is taken as a fixing agent to lead the scent to be difficult to be volatilized and avoid the green miscellaneous gas to be exposed at the later half of a cigarette; the flavors with tobacco scent and roasted sweet scent are selected to cover up the green miscellaneous gas, thereby increasing the thick sense of the scent and enhance the quality of the scent. The invention covers up the couch grass-like green miscellaneous gas in the tobacco products by preparing the functional plate flavors, thereby leading the scent of the whole formula to be harmonized, very natural and abundant. The top dressing flavor can avoid the green miscellaneous gas from being exposed at the later half of the cigarette. The tobacco scent and the roasted sweet scent can well cover up the green miscellaneous gas, increase the thick sense of the scent and enhance the quality of the scent.

Owner:WUHAN TOBACCO GROUP

Cigarette paper and preparation method thereof

InactiveCN1793500AImprove aftertasteIncrease the sense of thicknessVegetable material additionPulp material addition processesHerbSmoke paper

The invention discloses cigarette paper and its manufacturing method. The cigarette paper is used working of paper as carrier, plant alcohol extract cream body with 1.2000+ / -0.0050 relative density as additive. The quality of the working of paper is used as criterion. Thus the mass percent of the additive is 0.01%-0.05%. the relative density of additive cream body is 1.2000+ / -0.0050. The plant is one of aromatic tobacco, burley tobacco, Maryland, drying tobacco, Pu'er tea, golden buckwheat rhizome, pseudo-ginseng, or Broadleaf Herb leaf, or their mixture. The invention can obviously improve cigarette sucking aftertaste, reduce sting, and coordinate cigarette smoke.

Owner:YUNNAN RES INST OF TOBACCO SCI

Antique tusche and new preparation method thereof

InactiveCN101787234AIncrease the sense of thicknessAvoid ambiguityInksGranularityTraditional medicine

The invention relates to an antique tusche and a preparation method thereof. The antique tusche comprises the components by weight percent: 75-85 bone glue solution, 3-25 oily fume, 0.05-0.5 powdery spice and 0.5-5 traditional Chinese medicine liquid, wherein the bone glue solution is prepared by mixing bone glue and water according to a certain mass ratio, heating to 110-120 DEG C, decocting for 20-50h, and filtering; the oily fume is light powder solid and has the granularity less than 1 micron; the powdery spice is prepared by grinding musk and borneol with the mass ration of 2: 8 and sieving by a 200-mesh sieve; the traditional Chinese medicine liquid is prepared by decocting Chinese herbal medicines; and the preparation method of the antique tusche comprises the steps of: evenly mixing the bone glue solution, the oily fume, the musk, the borneol and the traditional Chinese medicine liquid, and dispersing the mixture into paste with the fineness less than 15 microns and the viscosity of 0.01-200 Pa. S; and the antique tusche is used for writing or printing painting and calligraphy works.

Owner:北京今鼎新化文化有限公司 +1

Casing flavor for expanded cut tobacco

ActiveCN103305342ARich fragranceIncrease sweetnessTobacco preparationTobacco treatmentThroat irritationMetal impurities

The invention discloses a casing flavor for an expanded cut tobacco. The casing flavor comprises the following components in parts by weight: 8-15 parts of a Zimbabwe tobacco leaf extract, 5-12 parts of a Brazil tobacco leaf extract, 3-8 parts of honey, 1-3 parts of 10% by mass of a red jujube extract, 2-5 parts of 1% by mass of phenylacetaldehyde, 5-8 parts of 1% by mass of guaiac wood oil, 0.5-2 parts of a fenugreek fluid extract, 1-3 parts of a liquorice fluid extract, 2-5 parts of maple syrup, 1-2 parts of 10% by mass of an orris root extract, 10-25 parts of water and 12-61.5 parts of propanediol. After the casing flavor is added into the expanded cut tobacco, the sensory quality shortages of insufficient fragrance, high metal impurity gas content, high irritation, metallic flavor residues and the like in the existing expanded cut tobacco are overcome, the fragrance content is increased, the expanded cut tobacco is endowed with fragrance and sweetness of a fruit and is enriched in fragrance, the throat irritation is reduced, and the sensory quality of the expanded cut tobacco is remarkably improved.

Owner:HUBEI CHINA TOBACCO IND +1

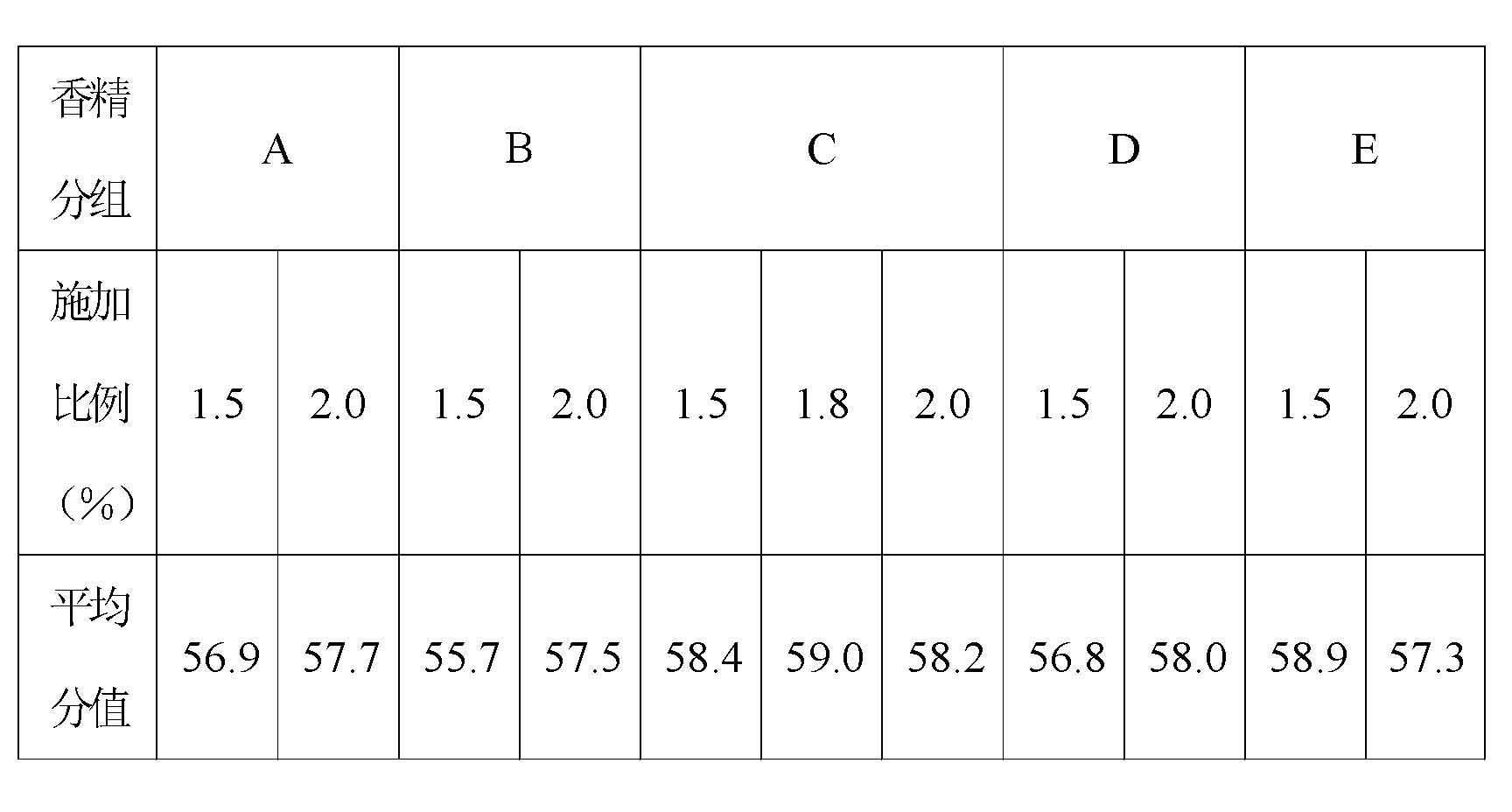

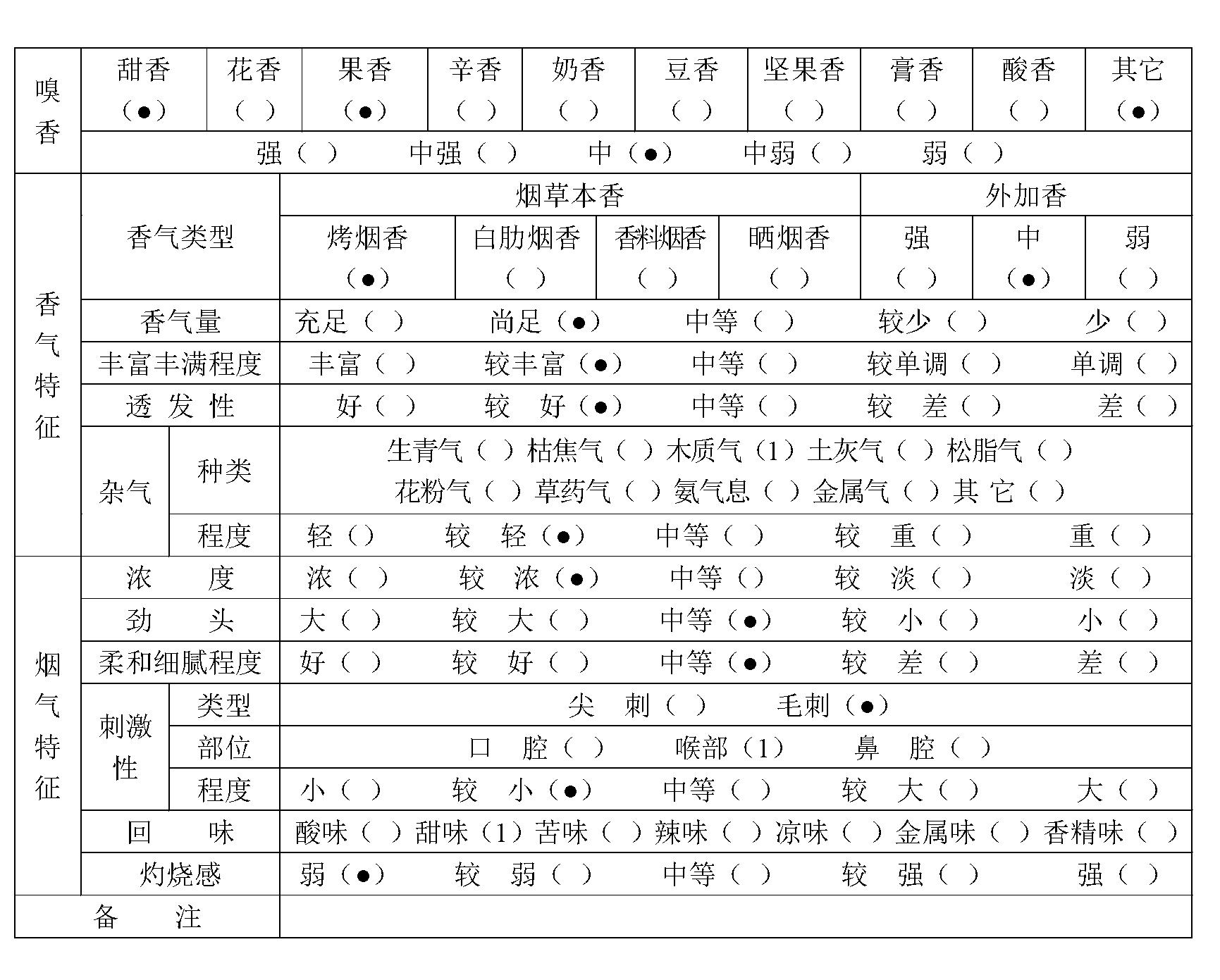

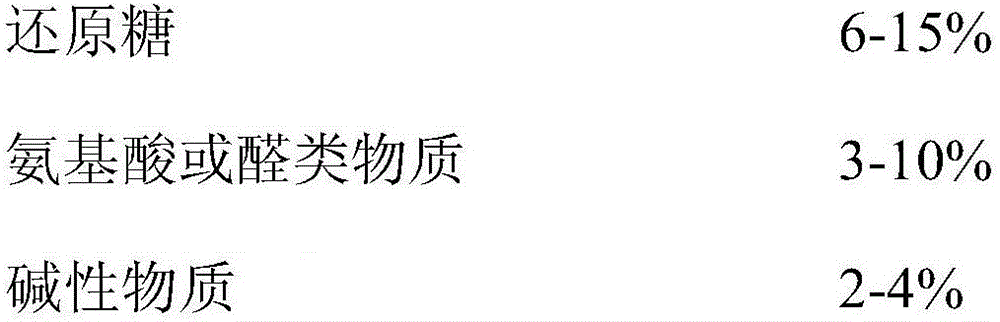

Formula of Amadori reactive flavor, preparation method of Amadori reactive flavor and use of Amadori reactive flavor

ActiveCN106520368AGreat tasteImprove fullnessTobacco preparationEssential-oils/perfumesSolventSide reaction

The invention provides a formula of an Amadori reactive flavor, a preparation method of the Amadori reactive flavor and a use of the Amadori reactive flavor. The preparation method comprises that reducing sugar, amino acids or an aldehyde substance as a raw material undergo a reflux reaction in a solvent with a drying agent in a basic environment to produce Schiff bases of the amino acid and reducing sugar, after the reaction, N-substituted glycosylamine is subjected to Amadori rearrangement to form an Amiadori reactant in the presence of a catalyst, the reactant is subjected to vacuum concentration to form a crude product, the crude product is subjected to recrystallization, and the crystals are dried to form an Amadori reactive mixture. The preparation method has the advantages of simple operation, low cost and high yield, prevents the dark brown viscous material which is produced from the reducing sugar and amino acid and is difficult to treat, and has les side reaction. The reaction product can be used in cut tobacco, cut stems, tobacco sheets and cigarette papers, improve the taste of cigarettes, increase the aroma of tobacco sheet cigarettes and improve the smoking effects.

Owner:HUBEI CHINA TOBACCO IND

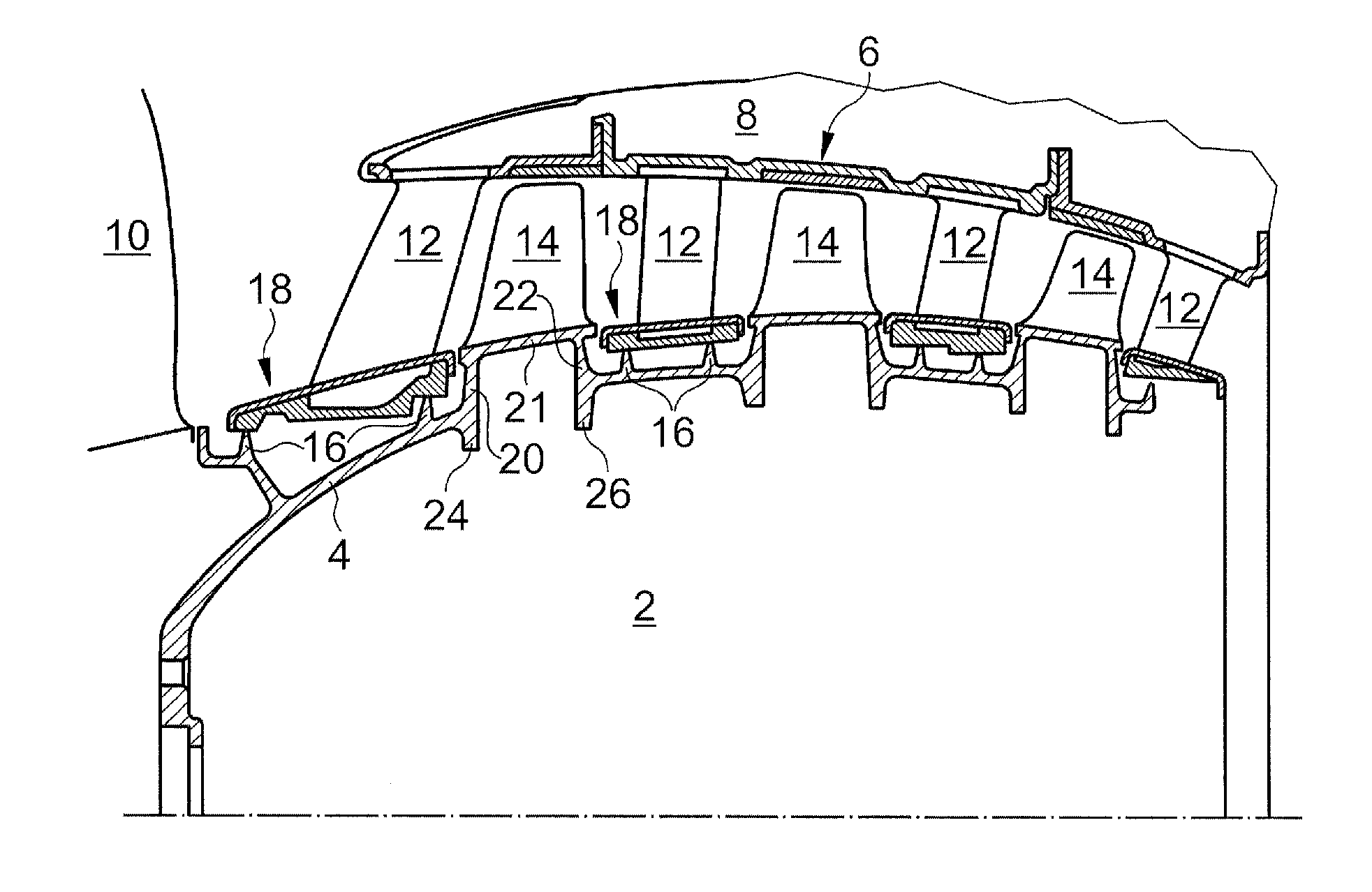

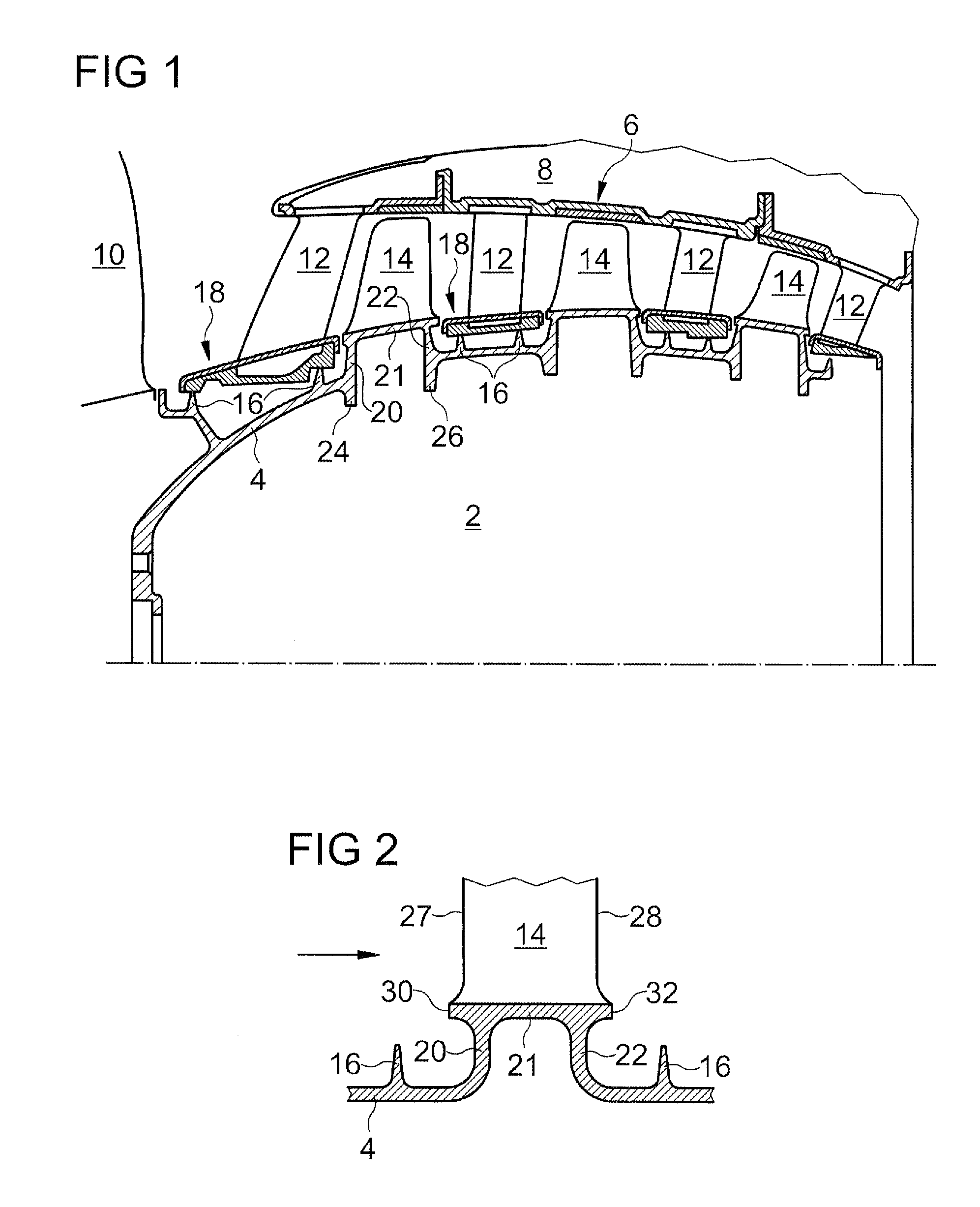

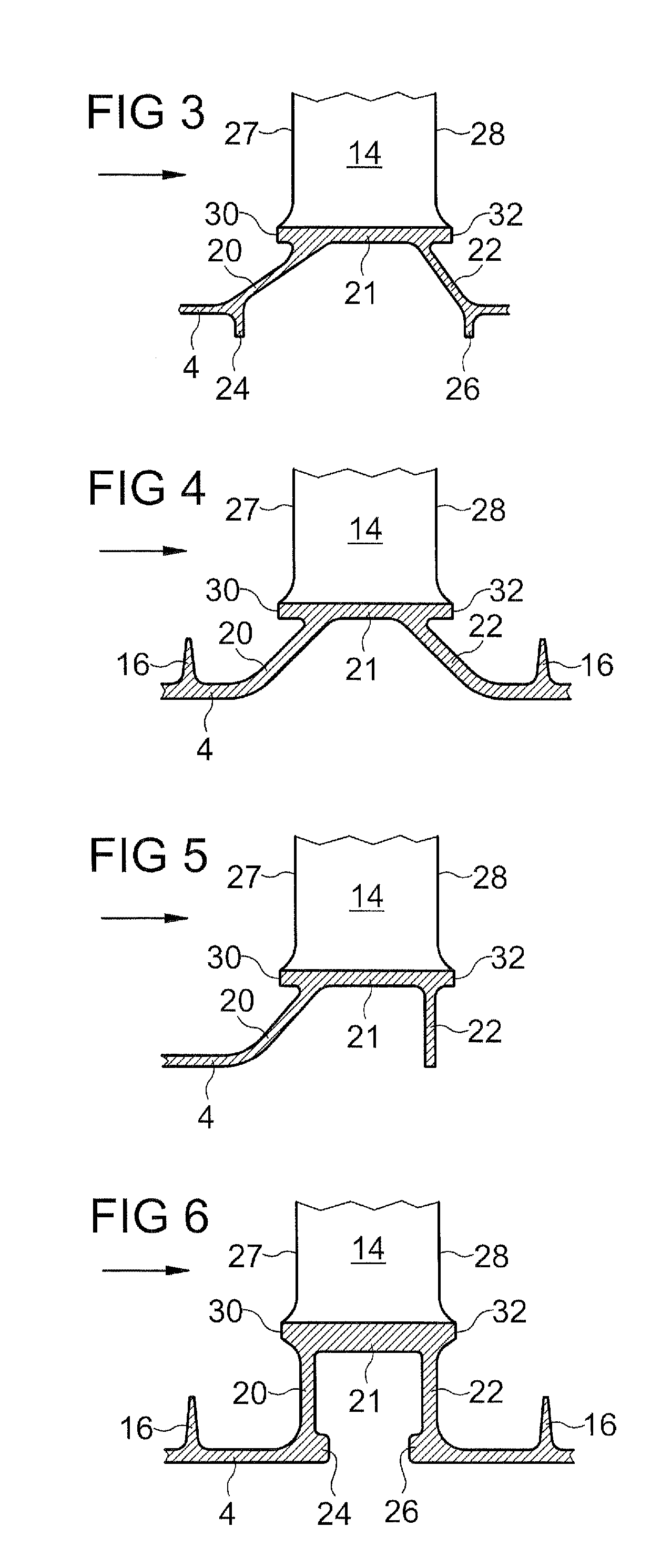

Reduced Monobloc Multistage Drum of Axial Compressor

ActiveUS20110223013A1Avoid attenuationStiffened and reduced drumPump componentsBlade accessoriesStress concentrationAxial compressor

A rotor stage of an axial turbomachine compressor drum includes a symmetrical wall in rotation around the axis of rotation. The wall comprises a veil defining the general form of the drum and an annular area intended to support a row of vanes, the aforesaid area being integrally formed with the veil. This area has a particular form in that it has an exterior surface delimiting the fluid stream, which is elevated in relation to the veil. This area has a “U”-shape cross-section, of which the open part is directed towards the axis of rotation. The annular area comprises two wall parts, one upstream and one downstream, ensuring the connection with the veil and being used as stiffeners. They are preferably perpendicular to the axis of rotation or inclined in relation to the perpendicular. The junction of each upstream and downstream wall part with the central part of the support area is at the distance of the corresponding edge of the central part, so as to avoid certain stress concentrations.

Owner:TECHSPACE AERO

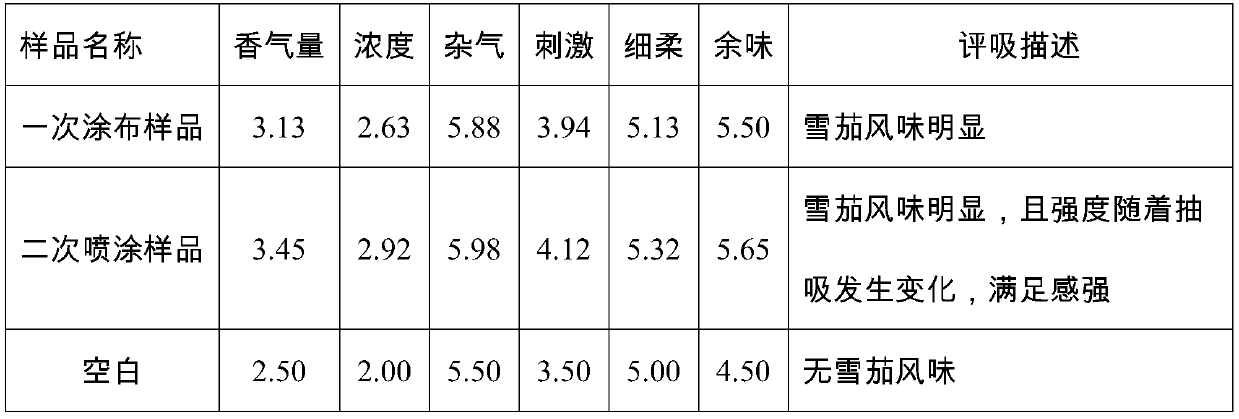

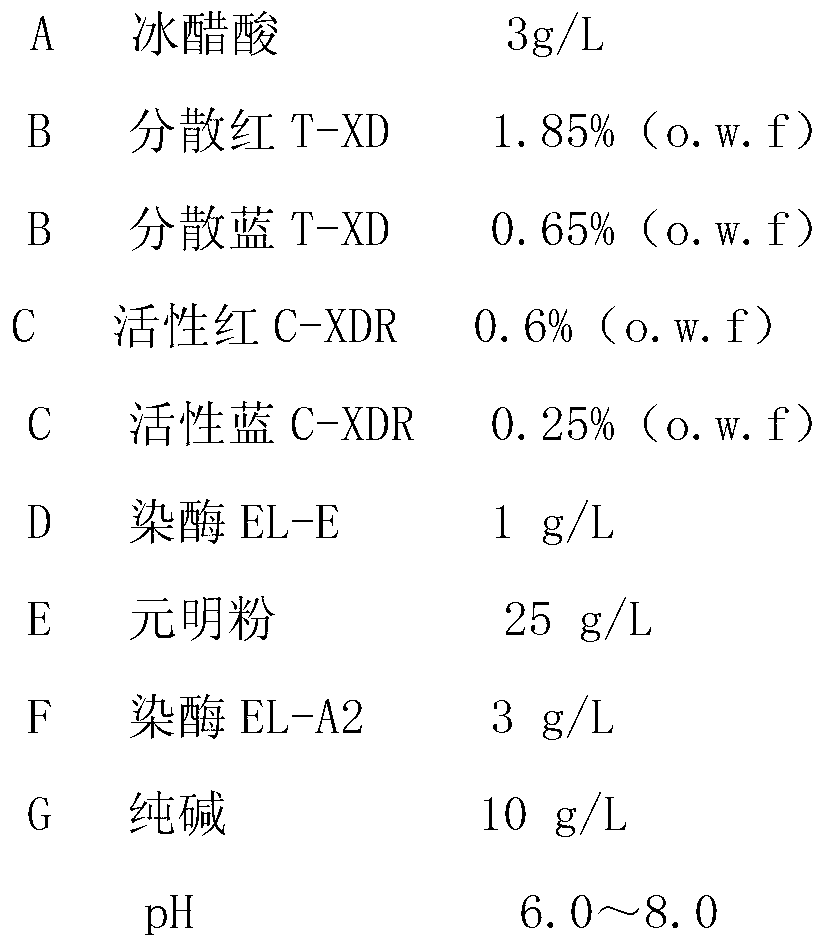

Coating preparation method of cigar-flavored cigarette paper

ActiveCN111418874AEnhance sensory experienceIncrease concentrationTobacco preparationTobacco treatmentBiotechnologySpray coating

The invention discloses a coating preparation method of cigar-flavored cigarette paper. The coating preparation method comprises the following steps: preparing a tobacco concentrate; carrying out molecular distillation treatment on the tobacco concentrate, and collecting light components to obtain a first tobacco extract; adding a mixture of amino acid and sugar into a tobacco leaf extract, and performing filtration, dilution, membrane separation and vacuum concentration after the reaction is finished so as to obtain a second tobacco extract; preparing a tobacco recombinant; preparing spice for cigar-flavored tobacco; preparing a cigar-flavored coating liquid; coating the cigarette paper for the first time by adopting a roller coating method; and coating the cigarette paper for the secondtime by adopting a spraying coating method to obtain the cigar-flavored cigarette paper. According to the coating preparation method of the cigar-flavored cigarette paper, the cigar flavor of cigarettes can be effectively enhanced, the concentration and thickness of smoke can be increased, the prepared cigar-flavored cigarette paper shows a dyeing effect without additionally adding pigments, and the sensory experience of the cigar-flavored cigarettes can be optimized.

Owner:CHINA TOBACCO HENAN IND +1

Any-arc-angle excircle-spherical-surface-displaying seamless display screen

InactiveCN106409156AIncrease the sense of thicknessIdentification meansSurface displayLandscape architecture

The invention discloses an any-arc-angle excircle-spherical-surface-displaying seamless display screen, and belongs to the technical field of VR displaying. The any-arc-angle excircle-spherical-surface-displaying seamless display screen comprises a pentagonal outer spherical surface splicing unit, a hexagonal outer spherical surface splicing unit, outer-spherical-surface-splicing-unit frame carriers and an outer-spherical-surface-splicing-unit fixing and supporting frame. The any-arc-angle excircle-spherical-surface-displaying seamless display screen has the advantages that due to excircle spherical surface displaying, the highlighting feeling and the decorous feeling of images are improved; particularly, when the any-arc-angle excircle-spherical-surface-displaying seamless display screen is used for AR scenarios, movement senses and changes can be given to static seal scenes, and the unexpected shocking effect can be generated for a person. The any-arc-angle excircle-spherical-surface-displaying seamless display screen can be widely applied to teaching, AR landscape architecture, exhibitions, showing, science and technology museums and other places.

Owner:BEIJING FANGRUI BOSHI DIGITAL TECH

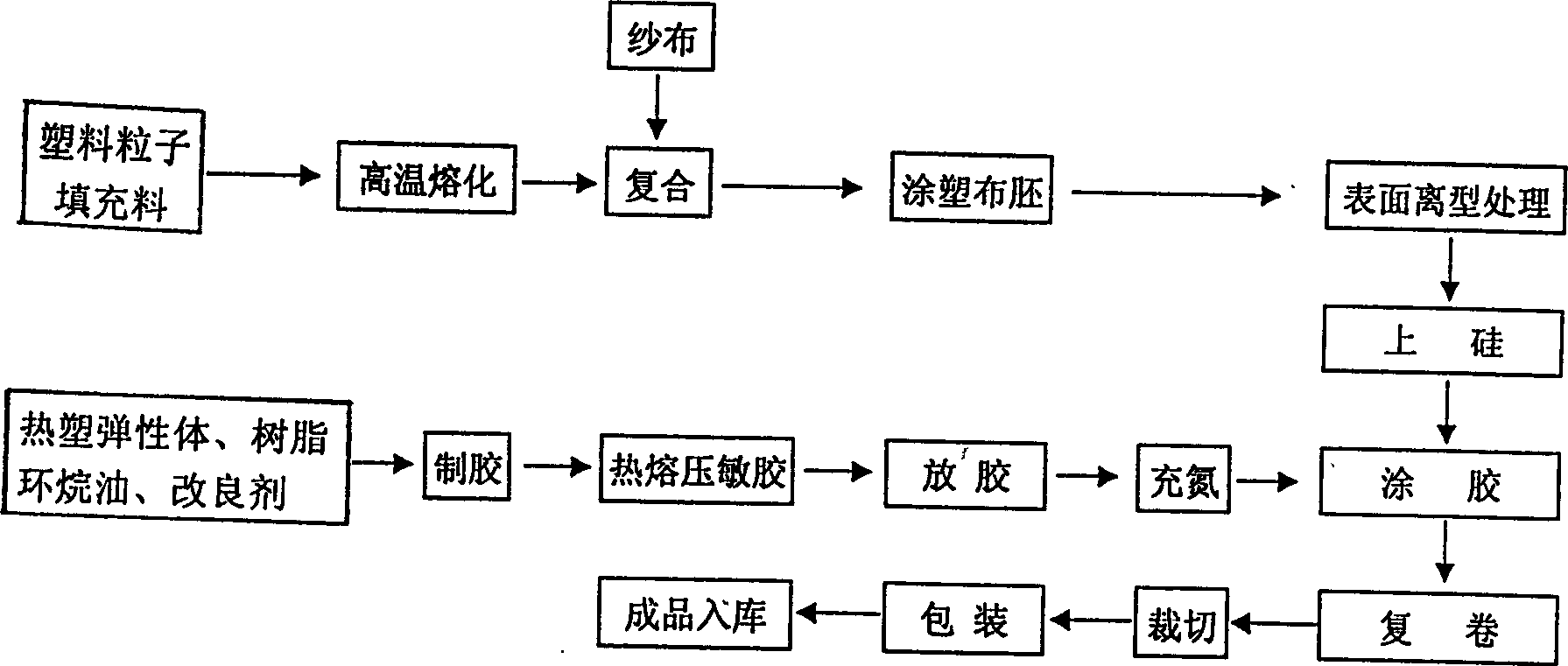

Process for making hot-melt pressure sensitive adhesive type fabric base adhesive tape

The manufacturing engineering for melten pressure-sensitive adhesive cloth-based belt belongs to manufacturing technique sphere of gel products. The method is characterized in that mixing and melting the PE plastic particles and filling materials; scoring with the gauze to produce plastic-coated cloth embryo; evenly daubing a non-silicon on the plastic-coated face of the plastic-coated cloth embryo; mixing and stirring thermoplastic elastomer, resin, naphthenic oil and modifying agent to prepare melten pressure-sensitive belt; inflowing into the gelholder filled with nitrogen; evenly covering the gel on the gaze cloth of the silicon-coated cloth embryo. The invention adds partial regenerative cotton into the pure polyester to obtain the product, which is of more adequate raw materials compared with pure polyester gauze and of moderate price, at the same time, adding mineral filler into PE largely reduces the cost of manufacture, and is of good suppleness, can not easily cock and can fast seal; the melten pressure-sensitive gel adopted by new cloth-based (pipe) gel is pure solid glue and is hard to burn, the industrial process can not produce any gaseous effluent and can not produce damage to people and environment, which belongs to a safety and environment-friendly type glue.

Owner:SHANGHAI YONGGUAN ADHESIVE PROD CORP LTD

Traditional Chinese medicine decoction additive for water-based ink and preparation method thereof

InactiveCN101792624AIncrease the sense of thicknessAvoid ambiguityBiocideInksCorrosion preventionGinger Rhizome

The invention relates to a traditional Chinese medicine decoction additive for water-based ink and a preparation method thereof. The additive comprises the following Chinese herbal medicine components in percentage by mass: 10-30% of garlic, 10-30% of eucommia, 2-20% of lavender, 0-20% of cinnamon, 0-20% of gamboge, 0-20% of saponin, 0-20% of mint, 0-20% of Amomum cardamomum, 0-20% of aniseed, 2-20% of clove, 2-20% of thyme, 2-20% of pomegranate rind, 2-20% of orange peel, 2-10% of pepper and 2-10% of ginger. The method comprises the following steps: adding water, wherein the weight ratio of the traditional Chinese medicine components to the water is 1:10; and slightly boiling on a slow fire with a stainless steel lid covered for about two hours, removing filter residues by filtration with a copper screen of 300 meshes to obtain the filtrate as the Chinese herbal medicine decoction. When the Chinese herbal medicine decoction is added to the water-based ink in the mass percentage of 1-10, the ink gives out faint scent, has the functions of corrosion prevention, sterilization and borer resistance, and has moist looking and thick color.

Owner:北京今鼎新化文化有限公司 +1

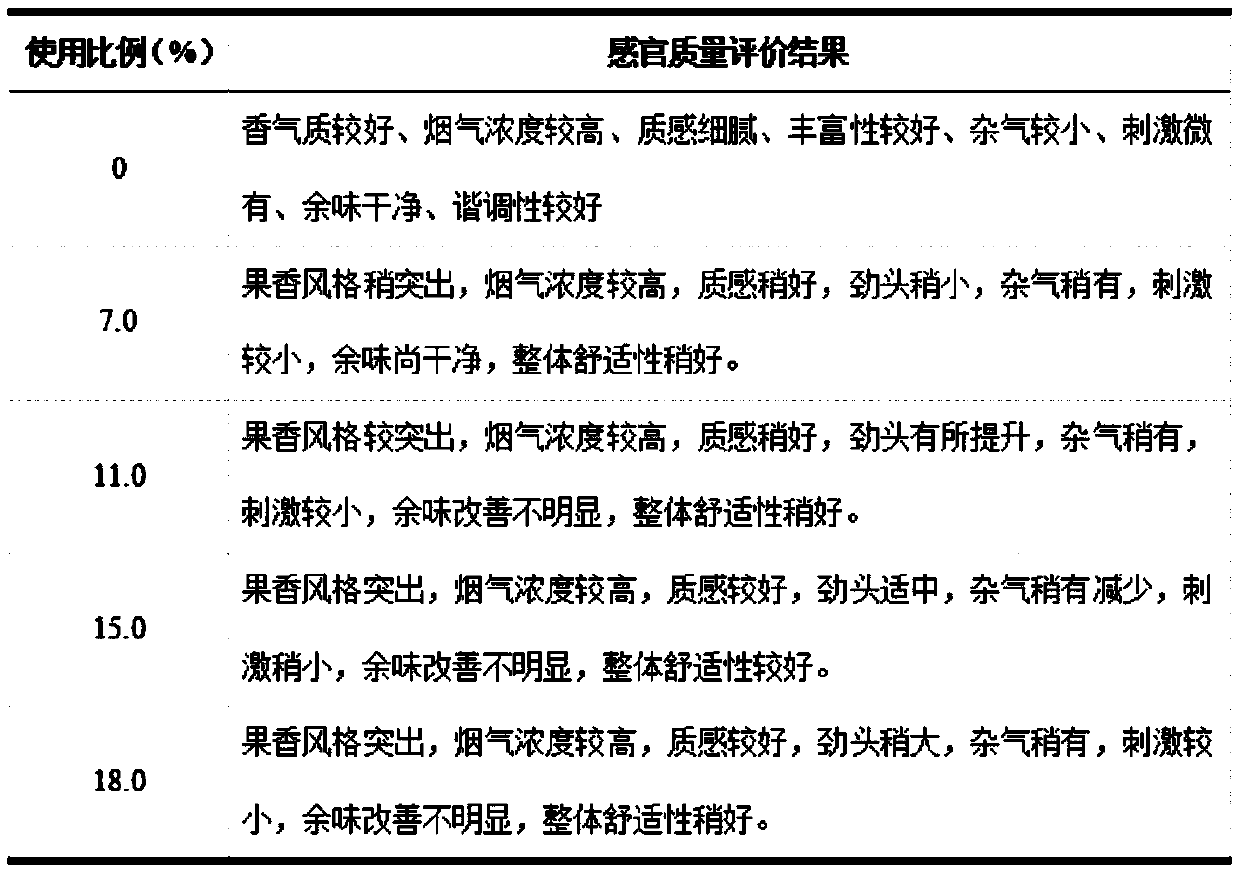

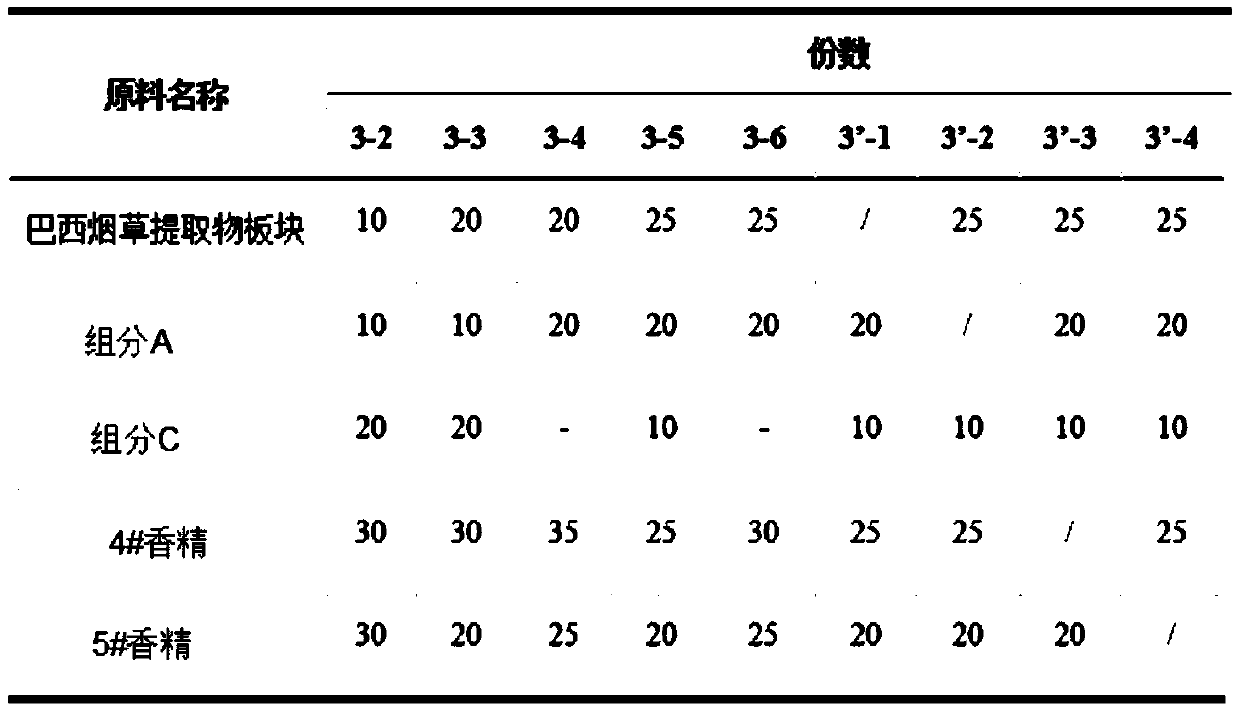

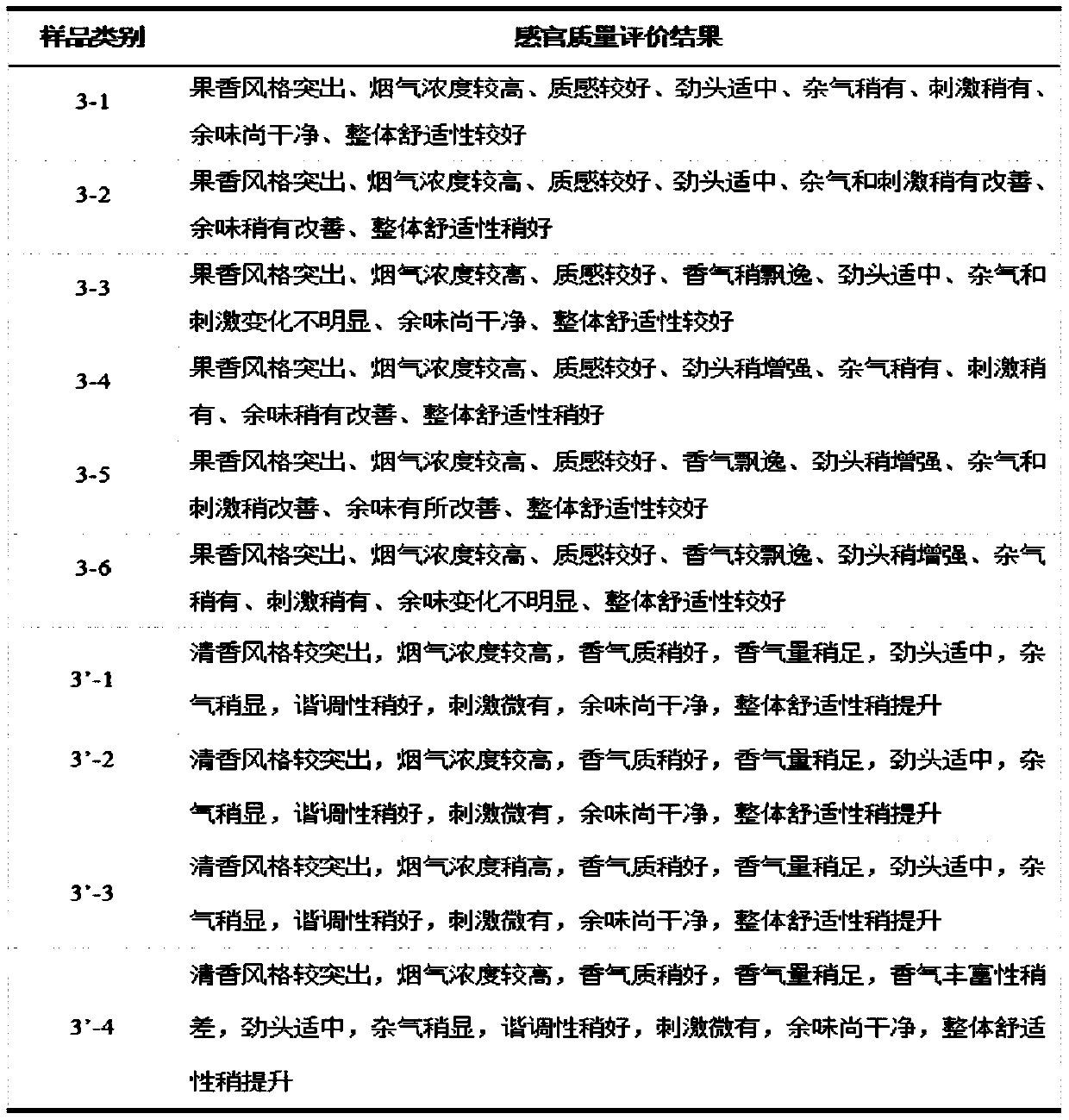

Cigarette flavoring coating material and application thereof

InactiveCN109875098AImprove comfortIncrease concentrationTobacco preparationTobacco treatmentFlavorHeat not burn

The invention discloses a cigarette flavoring coating material and application thereof. The cigarette flavoring coating material is prepared from, by mass, 10-40% of a component A, 0-40% of a component B, 0-30% of a component C and 0-70% of an essence. By selecting suitable essence and spice raw materials and adjusting compounding and dosage of the raw materials, the cigarette flavoring coating material which is high in overall smoke concentration, fine and soft in smoke, good in richness and harmony, moderate in strength, clean in remaining taste and good in sweet-and-moisturized feeling andoverall comfort is finally formed. The cigarette flavoring coating material is used for preparing and developing heat-not-burn cigarettes; the feasible cigarette flavoring coating material is providedfor low-temperature cigarettes, and powerful technical support is provided for conducting further development and improving the quality and mouthfeel of reconstituted tobacco.

Owner:CHINA TOBACCO GUANGDONG IND +1

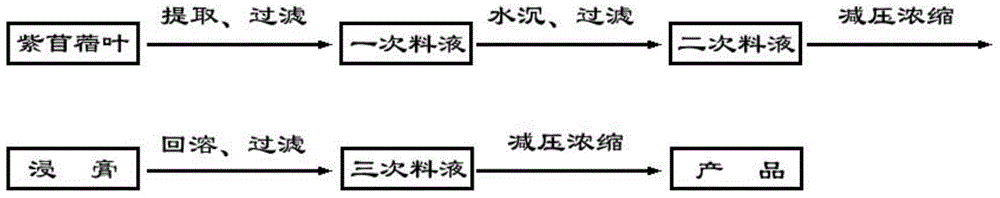

Alfalfa leaf extract preparation method and use as tobacco product additive

InactiveCN104905398AIncrease the sense of thicknessEffective fragranceTobacco preparationTobacco treatmentFlavorAlfalfa leaf

The invention discloses an alfalfa leaf extract preparation method and a use as a tobacco product additive. The method comprises the steps of using alfalfa leaves as extraction raw materials, and uniformly mixing alfalfa leaves with extracting agent according to volume ratio of 1:(10-30) to obtain mixture; extracting the mixture for 1-5h at 50-90DEG C and performing separation to obtain primary material liquid; adding water into the material liquid, separating sediment, performing separation to obtain secondary material liquid and concentrating the secondary material liquid to extract; redissolving the extract by using 5-10 multiples of extracting solution, filtering and separating byproducts and tertiary material liquid, and concentrating the tertiary material liquid to extract to obtain alfalfa leaf extract. By adding the alfalfa leaf extract prepared by adopting the method disclosed by the invention into tobacco products, an effect of effectively increasing the flavor of the tobacco products is achieved, the flavor is rich and the solidity of smoke is increased; the extract can also endow the tobacco products with unique flavor tones and notes, and can be used as a characteristic flavor.

Owner:HUBEI CHINA TOBACCO IND +1

Guqin

ActiveCN106297736AIncrease the volume of pronunciationIncrease volumeStringed musical instrumentsEngineeringSound Absorber

The invention discloses a guqin (a plucked seven-string Chinese musical instrument of the zither family), comprising a face plate and a bottom plate. The face plate comprises a first inner plate surface and a first outer plate surface. The first inner plate surface is provided with a dragon pool sound absorber and a phoenix pond sound absorber, and the structures of the dragon pool sound absorber and the phoenix pond sound absorber are the same and are characterized in that, a sound absorber and a connecting block are included, the cross section of the connecting block is in the shape of a trapezoid, the upper bottom surface of the connecting block is connected to the first inner plate surface, and the lower bottom surface of the connecting block is connected to the sound absorber. The bottom plate comprises a second inner plate surface and a second outer plate surface, and the second inner plate surface is laid with a felt layer. The guqin is advantageous in that, through the sound absorber shape and structure in a guqin face plate, a traditional mode is changed, and the effect of effectively increasing sound volume of the guqin can be achieved; the felt layer is added in the bottom plate, so that, in the time that the sound volume of the guqin is increased, tone quality is ensured; and a big breakthrough is made for a traditional guqin, and a guidance meaning in the development process of the guqin is provided.

Owner:邱长军 +2

Healthy dendrobium cordial and preparation method thereof

ActiveCN107460086AHigh in polysaccharidesSignificant liver protection effectDigestive systemAlcoholic beverage preparationDendrobium candidumAlcohol drink

The invention discloses a healthy dendrobium cordial. The healthy dendrobium cordial is a brewed alcohol drink with pure grain liquor as basic liquor, and dendrobium raw materials are added. The weight ratio of the basic liquor to the dendrobium raw materials is 10: 1. The dendrobium raw materials include, by weight, 20% of dendrobium candidum and 80% of dendrobium chrysotoxum. The invention further discloses a preparation method of the healthy dendrobium cordial. By reasonably proportioning dendrobium candidum and dendrobium chrysotoxum, the best health efficacy of the two kinds of dendrobium in the formula can be played, the taste and fragrance of the healthy dendrobium cordial can be regulated, the quality of the healthy dendrobium cordial is improved, and processes are simplified.

Owner:深圳市天之宝生物科技股份有限公司

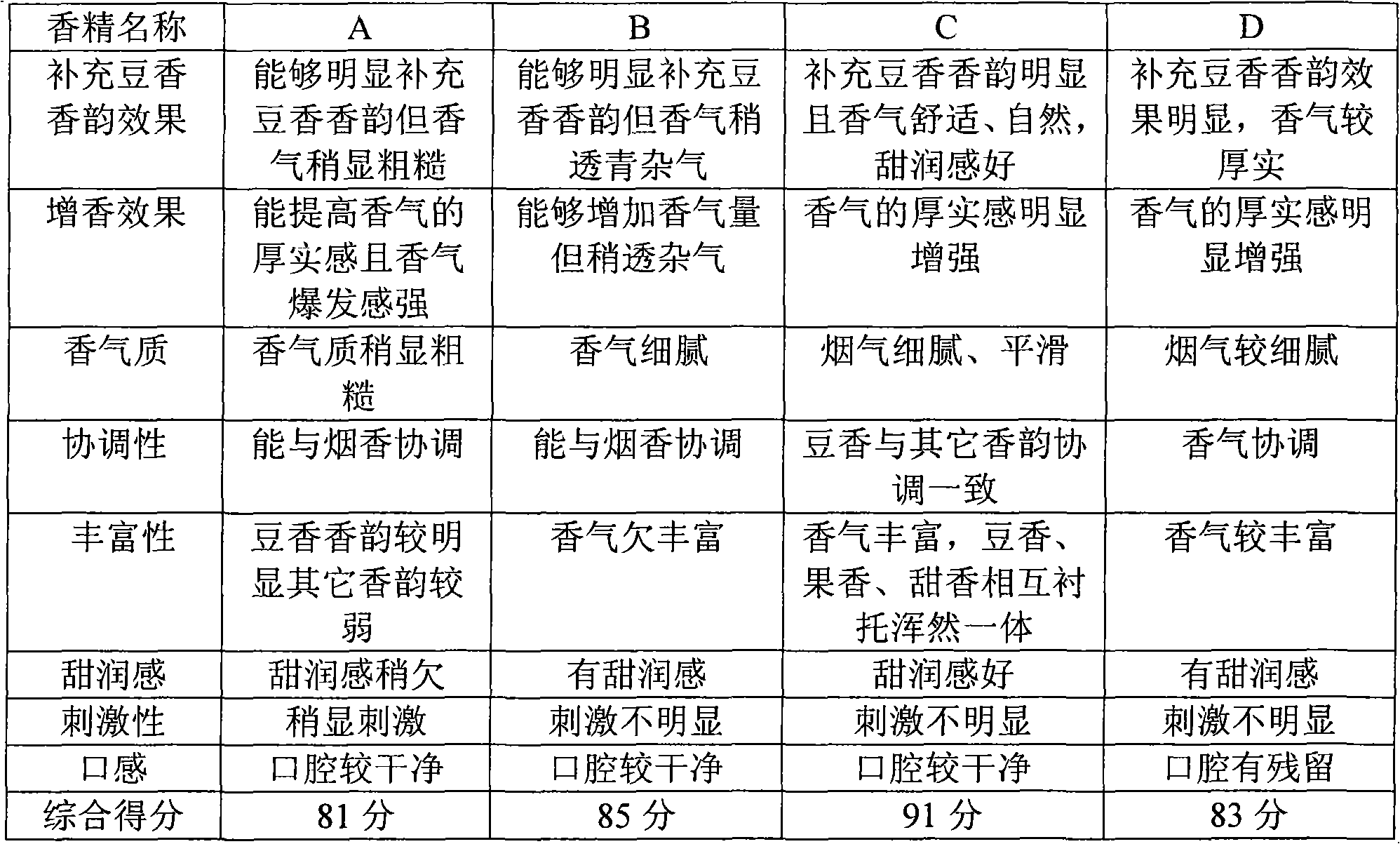

Tobacco feeding essence for replenishing bean-flavor

InactiveCN102031198AObvious fragranceComfortable aromaTobacco treatmentEssential-oils/perfumesFlavorNicotiana tabacum

The invention relates to a tobacco feeding essence, in particular to a tobacco feeding essence for replenishing bean-flavor note, which is formed by mixing the following raw materials in part by weight: 16-18 parts of black vanilla bean derivatives, 1.5-2 parts of cocoa extractives, 6-8 parts of almond derivatives, 2-3 parts of white hyacinth bean extractives, 2-2.5 parts of daidzein, 5-7 parts of fig extracts, 2.5-3 parts of plum extracts, 10-12 parts of Tsaoko Amomum fruit derivatives, 4-5 parts of balsamroot extractives, 1-1.5 parts of graecum extracts and 38-50 parts of propylene glycol water solutions. The tobacco feeding essence obviously replenishes the bean-flavor note and has comfortable and natural fragrance and good sweet feel, obviously enhances the concentration of the fragrance in tobaccos and also improves fragrance quality and smoking comfortableness when improving the concentration of the fragrance in tobaccos.

Owner:HUBEI CHINA TOBACCO IND +1

Painting Xuan paper treating method

The painting Xuan paper treating method can solve the problems of available Xuan paper, which is easy to shrivel, damage, contaminate, fade, moth bite, etc. The painting Xuan paper treating method includes the following steps: painting one layer of paste on palette, soaking silk with clear water and wringing, spreading the moistened silk on the paste layer, painting one other layer of paste onto the silk, flatening the Xuan paper to be painted on the silk for pasting, and drying before painting on the Xuan paper. After painting and drying, one layer of wax is painted to the surface and stoved at 45-300 deg.c to make molten wax penetrate into Xuan paper.

Owner:李文华

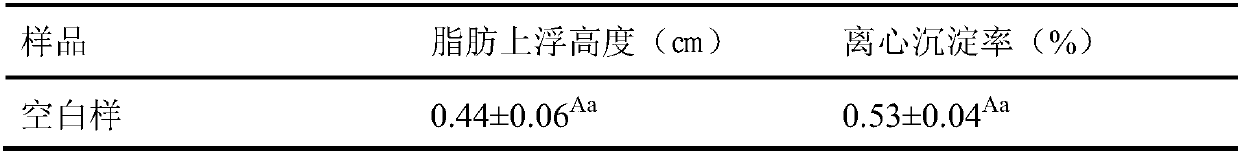

Emulsion stabilizer for soymilk beverages and preparation method of emulsion stabilizer

ActiveCN107821615AIncrease the sense of thicknessPrevent gelationMilk substitutesFood scienceCarboxymethyl celluloseEmulsion

The invention discloses an emulsion stabilizer for soymilk beverages and a preparation method of the emulsion stabilizer and relates to plant protein beverages. The emulsion stabilizer comprises, by mass percentage, 10-40% of xanthan gum, 15-40% of sodium carboxymethyl cellulose, 10-40% of mono-, bis-glycerin fatty acid ester, 1-15% of carrageenan, 1-15% of sodium alginate and 5-15% of sodium tripolyphosphate. The preparation method includes: mixing the xanthan gum, the sodium carboxymethyl cellulose, the sodium alginate, the mono-, bis-glycerin fatty acid ester, the carrageenan and the sodiumtripolyphosphate to obtain the emulsion stabilizer. The emulsion stabilizer is used for producing the soymilk beverages, the produced soymilk beverages do not have bleeding, layering and precipitation within the warranty period, and the quality and taste of the soymilk beverages are increased.

Owner:厦门唯康食品科技有限公司

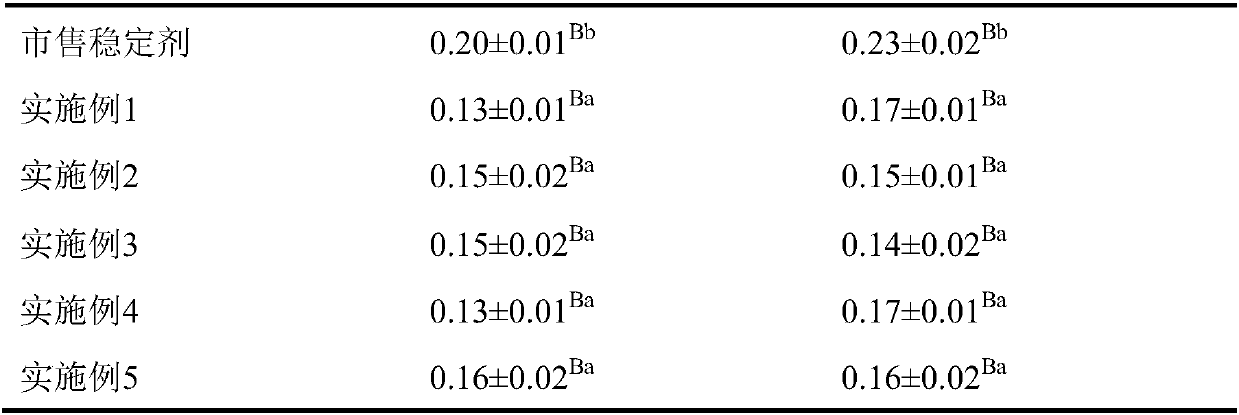

Manufacturing method for chinlon Dacron twill vertical strip fabric

InactiveCN103215726AWon't breakSolve the problem of poor color fastness of nylonDyeing processWoven fabricsTextile printerColour fastness

The invention relates to a manufacturing method for chinlon Dacron twill vertical strip fabric. The manufacturing method for the chinlon Dacron twill vertical strip fabric comprises steps of raw material preparation, beaming, weaving to form a twill vertical strip blank, alkali reduction, dying, fixation, textile printing, shape forming and testing. The dying adopts two-bath process inclined tube dying. The two-bath process inclined tube dying comprises the following steps: step 1, one bath, Dacron composition in the twill vertical strip blank is dyed firstly and step 2, two bath, chinlon composition in the twill vertical strip blank is dyed secondly. Due to adoption of the two-bath process inclined tube dying, the problem that chinlon is poor in color fastness in common technology for processing the chinlon Dacron twill vertical strip fabric in the prior art is solved. Due to the fact that the steps that the Dacron composition in the twill vertical strip blank is dyed firstly and the chinlon composition in the twill vertical strip blank is dyed secondly are adopted, the Dacron composition and the chinlon composition in the fabric can not be damaged, color fastness is good, and color is real.

Owner:SUZHOU CINC TEXTILE TECH RP

Production process of extra hard hat lining

InactiveCN102273763AIncrease the sense of thicknessHigh hardnessLoomsLiquid/gas/vapor removalCooking & bakingHardness

The invention discloses a production process of an ultrahard cap lining, which orderly comprises the following steps of: base cloth weaving, alkali padding and piling, oxygen delignification processing, ultrahard finishing, coating, baking, calendaring, reeling, final detecting, and finished product obtaining. The advantages of the invention are that: the product has hand feel with quite high hardness, a stable dimension, a low shrinkage, and excellent shape retention; the cap lining has high massiness, does not blister or degum after being washed with 90 DEG C water for several times, and has quite bright press polish.

Owner:HANGZHOU JINMUZHI GARMENT ACCESSORIES

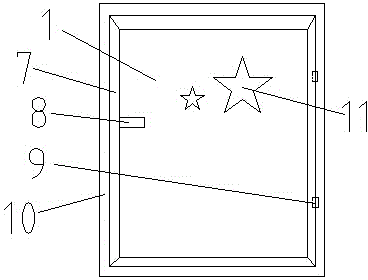

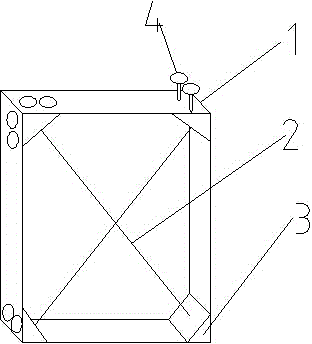

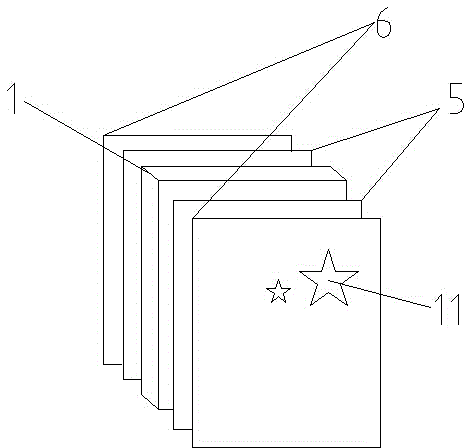

Anti-deformation suit door

The invention relates to a suit door, in particular to an anti-deformation suit door. The anti-deformation suit door comprises a doorframe, a door plate and a door lock, wherein a square frame in clearance fit with the doorframe is arranged in the doorframe; a triangular reinforcing rib is arranged at each of the four corners in the square frame; elastic pull rods which are diagonally connected are arranged on the reinforcing ribs; pressed wood chips are arranged in the square frame and are fully filled in the whole square frame; the door plate with the same size as the square frame is respectively arranged on the side surface of the square frame; a wood skin decorating surface is arranged on each door plate; wood lacquer is sprayed to each decorating surface; relief patterns are arranged on each decorating surface; solid wood covered edges are arranged on the sides of the door plate; the thickness of the covered edges is equal to a clearance between the doorframe and the square frame; the door lock is arranged on the door plate; hinges connected with the door plate are arranged on the doorframe; a lock hole used for accommodating the lock cylinder of the door lock is formed in the doorframe. The anti-deformation suit door has the beneficial effects that the suit door can be prevented from being deformed, and meanwhile, the manufacturing cost is saved.

Owner:CHONGQING YISHI TIANRUN SUIT DOOR

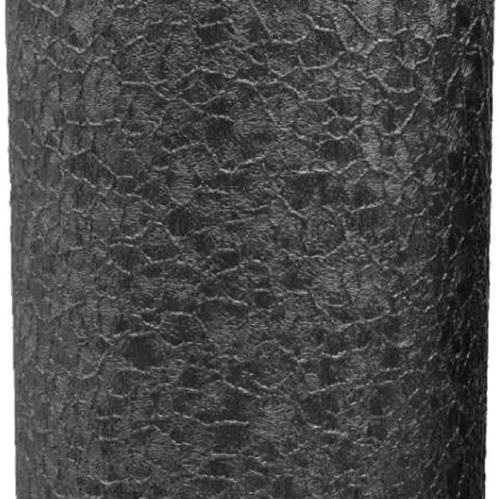

Stainless steel vacuum container surface treatment method with three-dimensional fabric sense

ActiveCN109848009AThick solidIncrease the sense of thicknessPretreated surfacesPowdery paintsAcrylic resinPolyester resin

The invention discloses a stainless steel vacuum container surface treatment method with a three-dimensional fabric sense. The stainless steel vacuum container surface treatment method comprises the following steps of a, taking the stainless steel vacuum container and carrying out surface treatment; b, weighing polyester resin, colored pigment, filler and turtle crack promoter, and then extrudingand grinding the mixture into powder coating; c, carrying out powder spraying operation on the powder coating, forming a cracking texture layer after curing; d, carrying out air spraying operation oncolored acrylic resin coating, and forming a color texture layer after curing; e, carrying out air spraying operation on transparent bright acrylic resin coating, and forming a bright color layer after curing; and f, carrying out air spraying operation on transparent matte acrylic resin coating, and forming a matte color layer after curing to finish the surface treatment of the stainless steel vacuum container. Through the above steps, the three-dimensional distribution grid effect with different shapes, sizes and thicknesses can be finally formed on the surface of the stainless steel vacuum container, the color is soft, the surface effect is vivid, and the living requirements of people can be better met.

Owner:浙江飞剑科技有限公司

Song brocade fabric

InactiveCN104480615AIncrease weaving difficultyImprove wrinkle resistanceSwivel-woven fabricsLappet-woven fabricsYarnEngineering

The invention discloses a Song brocade fabric. The warp of the fabric is woven by two kinds of warp through two warp beams, and the two kinds of warp are defined as the warp A and the warp B. The weft of the fabric is a five-weft dyed yarn, and the five kinds of weft are defined as the weft A, the weft B, the weft C, the weft D and the weft E. The warp A is a boiled-off dyed yarn with the twist of 6T / S, the warp B is a raw dyed yarn, the weft A, the weft B, the weft C and the weft D are boiled-off yarns with the twist of 1.5T / S respectively and are mulberry silk, and the weft E is a wool dyed yarn; the fabric is woven through an electronic jacquard machine according to a set pattern. According to the Song brocade fabric, the anti-creasing effect of the fabric is improved, the comfort and wearability of the fabric are increased, and the fabric can be applied to the field of clothes more widely.

Owner:DING SHENG SILK

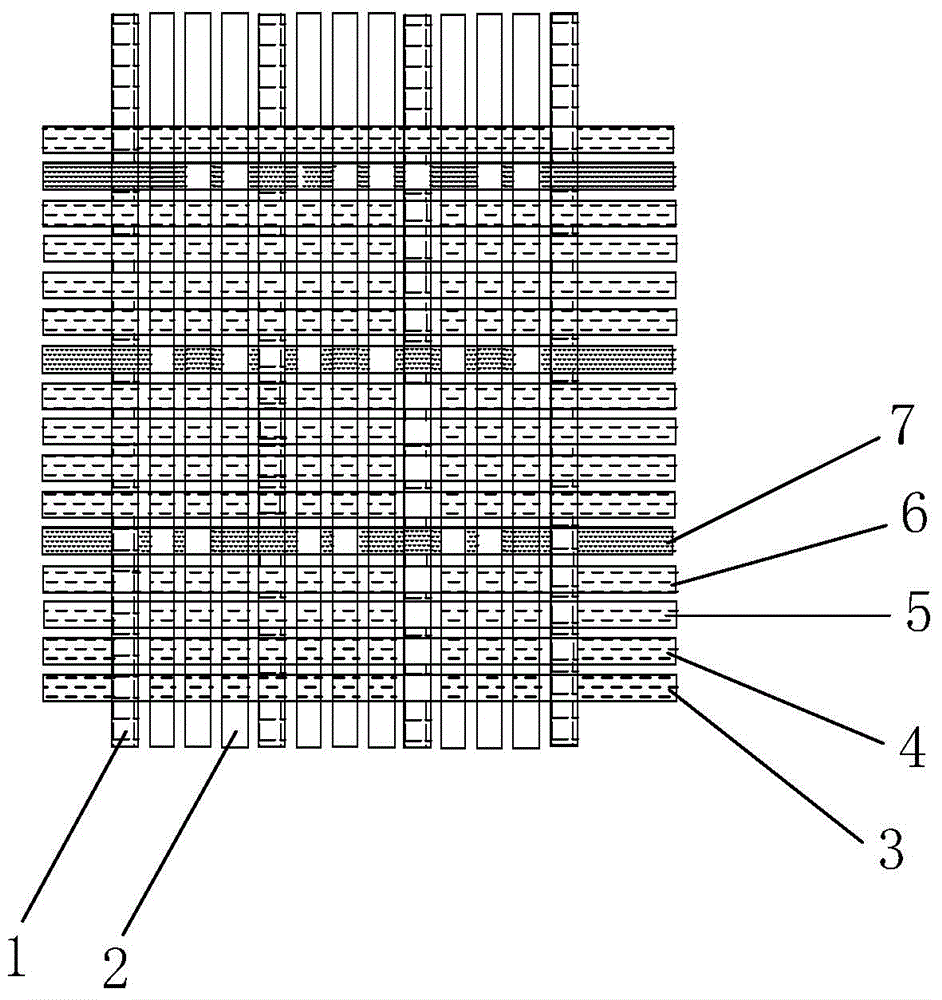

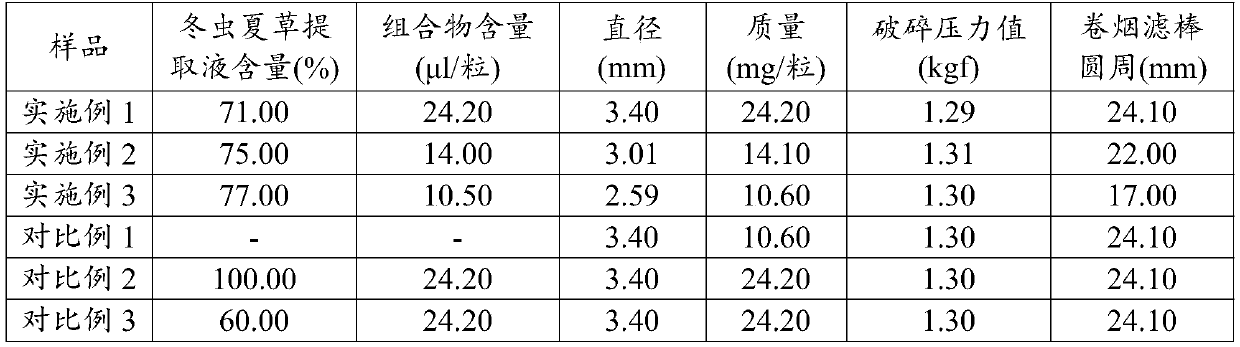

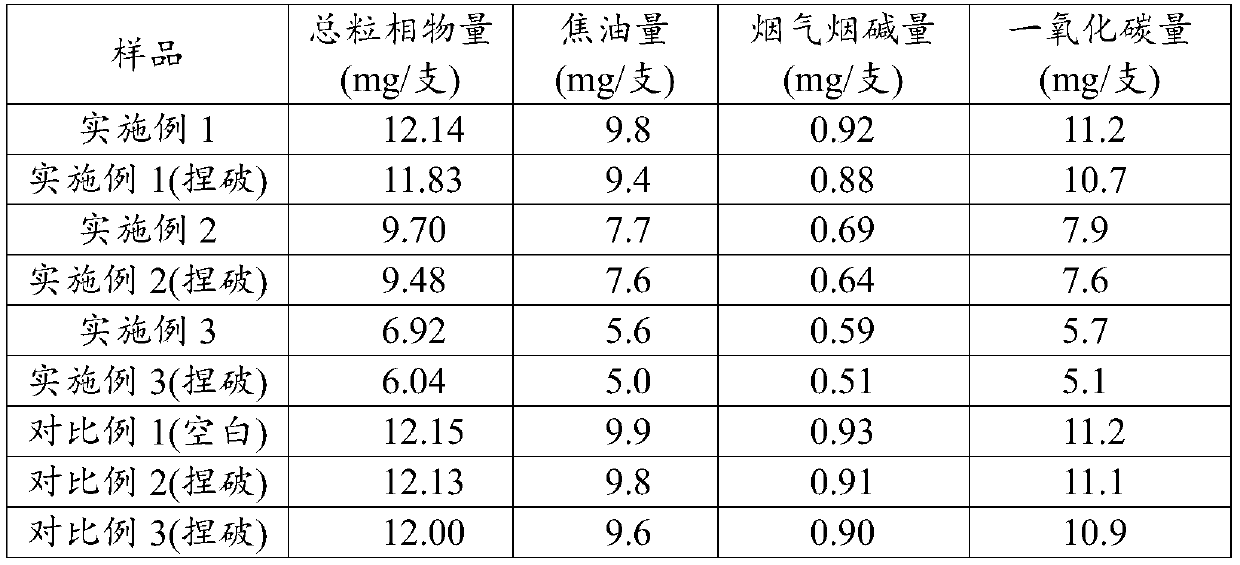

Cordyceps sinensis extraction liquid, and preparation method, composition and application thereof

ActiveCN109953366AThe active ingredients are small in sizeImprove sensory qualityTobacco preparationTobacco treatmentEnzymeOrganoleptic

The invention provides cordyceps sinensis extraction liquid, and a preparation method a composition and application of the cordyceps sinensis extraction liquid, wherein the preparation method of the cordyceps sinensis extraction liquid comprises the following steps of extracting cordyceps sinensis dry substances so as to obtain the cordyceps sinensis extraction liquid; adding enzyme preparations into the cordyceps sinensis extraction liquid; then performing concentration. The invention also provides the composition containing rich cordyceps sinensis extraction liquid and application of the cordyceps sinensis extraction liquid to cigarette sensory quality improvement. A cigarette containing cordyceps sinensis blast beads provided by the invention has higher sensory quality evaluation duringthe smoking; the smoke delicate sense is improved; the mouth feeling is soft and smooth; the sweet aftertaste is obviously enhanced; the aftertaste is clear; meanwhile, the physicochemical index content of the cigarette smoke is reduced; the effect of reducing the cigarette smoking harm is achieved.

Owner:INNER MONGOLIA KUNMING CIGARETTE CO LTD +1

Soft pear fruit vinegar beverage and production method thereof

ActiveCN103535810AFruity aromaFruityNatural extract food ingredientsVinegar preparationPEARFood flavor

The invention relates to a soft pear fruit vinegar beverage and a production method thereof. The soft pear fruit vinegar beverage takes soft pears as a raw material and is produced with processes of fruit sorting, storing, juicing, instant high-temperature sterilization, enzyme treatment, primary fermentation, secondary fermentation, preparation, filtering, desaeration, encapsulation and sterilization. The soft pear fruit vinegar beverage is simple in production method and low in cost, and the soft pear fruit vinegar in the beverage has prominent fruit fragrance, strong vinegar fragrance and distinct flavor.

Owner:青海兴农实业有限公司

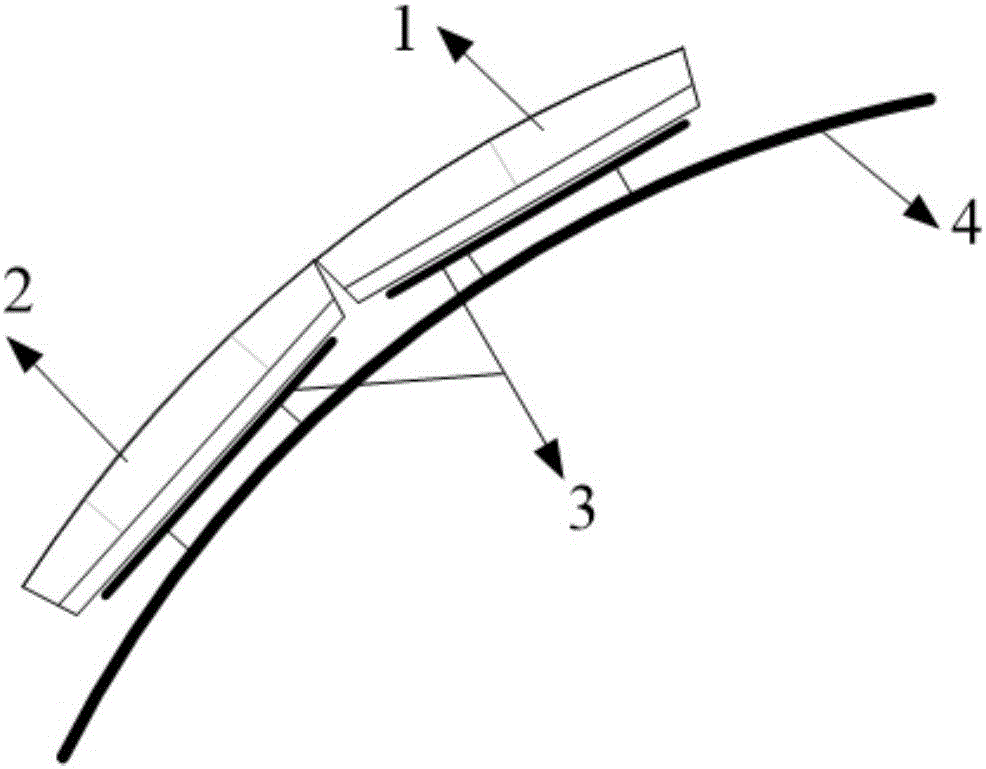

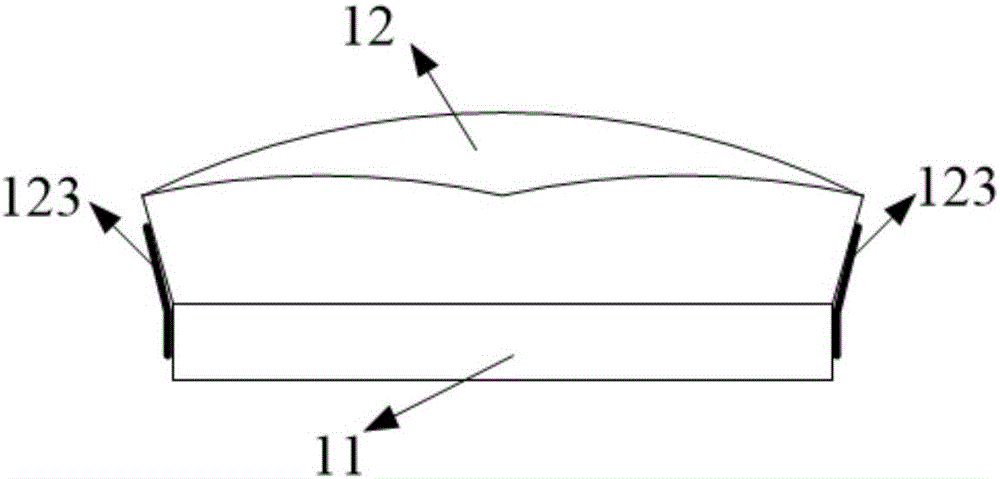

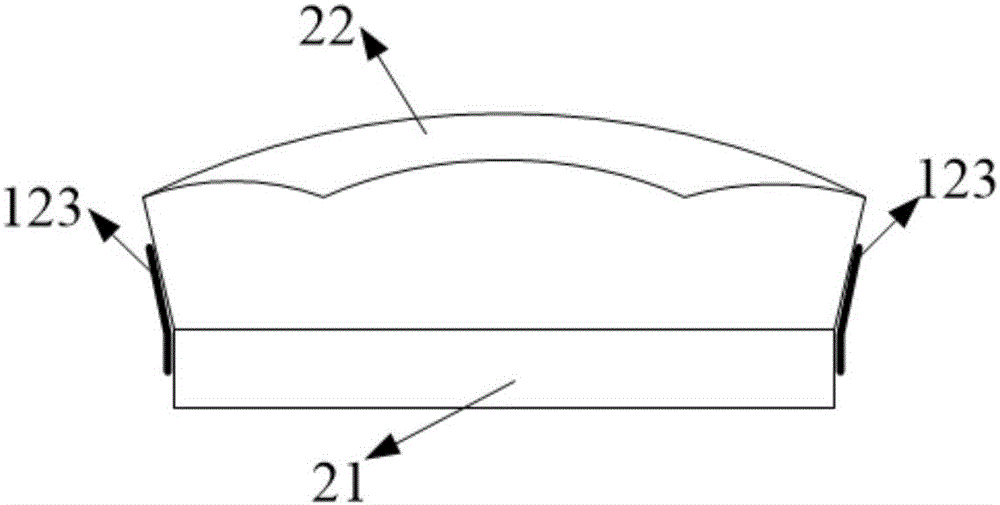

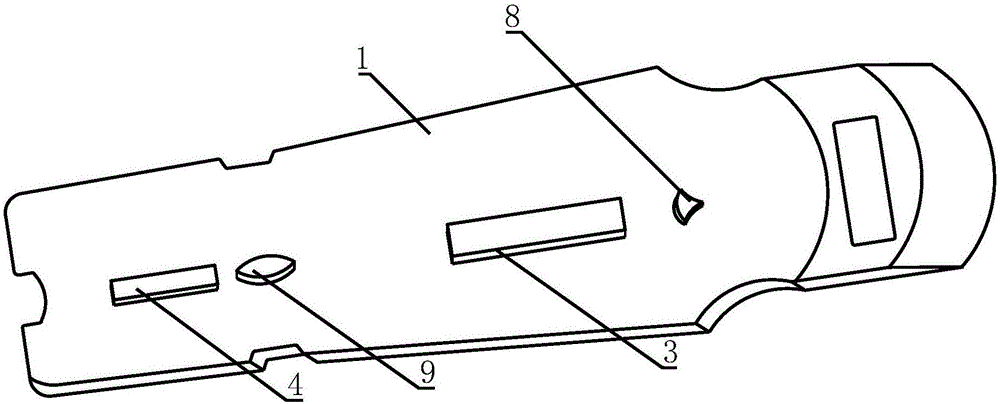

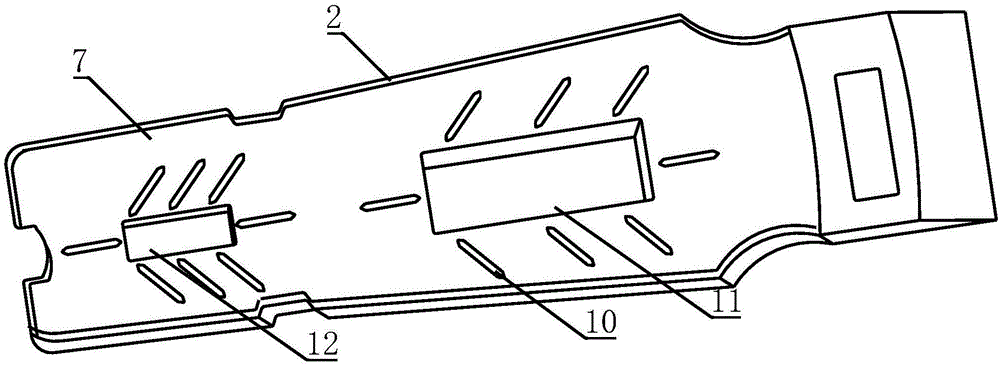

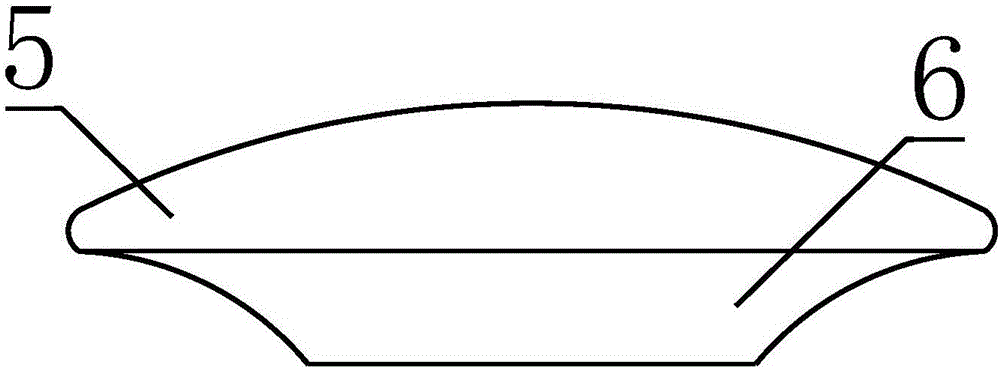

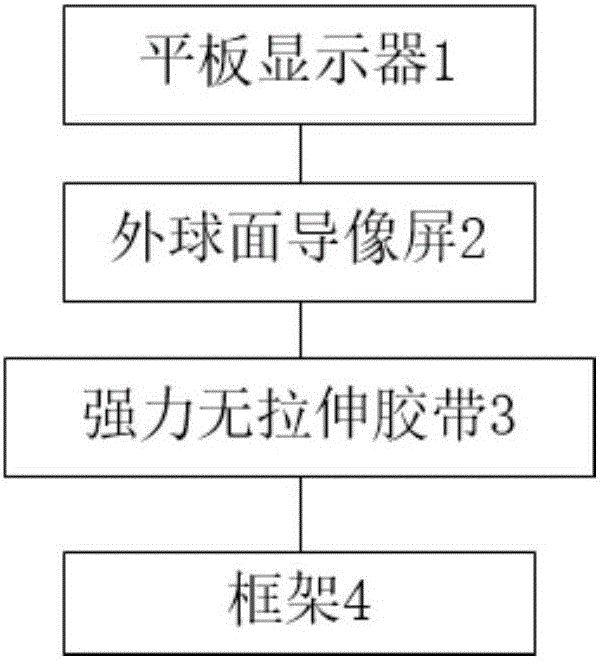

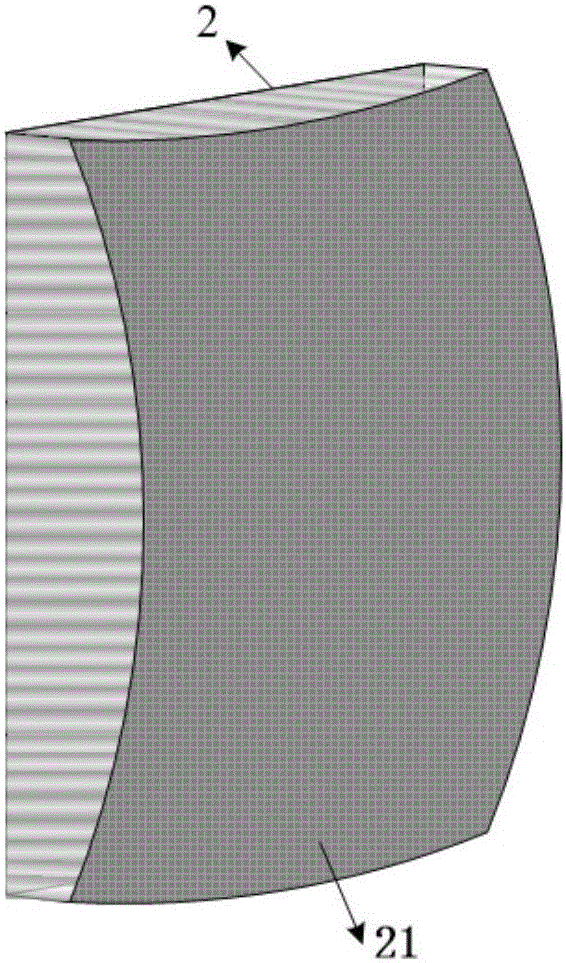

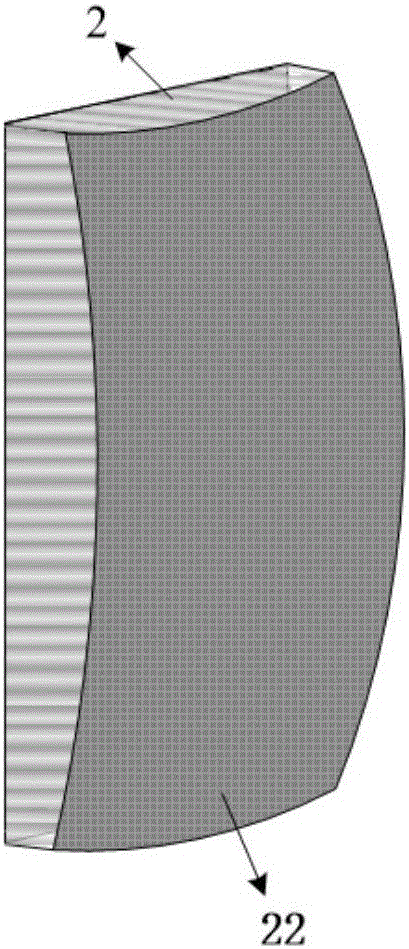

Rectangular external spherical display

InactiveCN105976723AIncrease the sense of prominenceIncrease the sense of thicknessIdentification meansDisplay deviceFlat panel display

The invention discloses a rectangular external spherical display and belongs to the technical field of VR (visual reality) display. The rectangular external spherical display comprises a flat-panel display (1), an external spherical image guide screen (2), a strong non-stretching adhesive tape (3) and a frame (4), wherein the flat-panel display (1) and the external spherical image guide screen (2) are bonded from side surfaces by the strong non-stretching adhesive tape (3) and are supported by the frame (4); the external spherical image guide screen (2) comprises optical fibers perpendicular to the flat-panel display (1), and is used for converting images of the flat-panel display (1) into images displayed on the external spherical surface. The rectangular external spherical display has the advantages that the highlight and deep sense of the images are enhanced, particularly, when the display is applied to an AR (augmented reality) scene, static scenery can be endowed with dynamic and change, and an unexpected shocking effect can be realized.

Owner:BEIJING VOFRID CULTURE MEDIA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com