Casing flavor for expanded cut tobacco

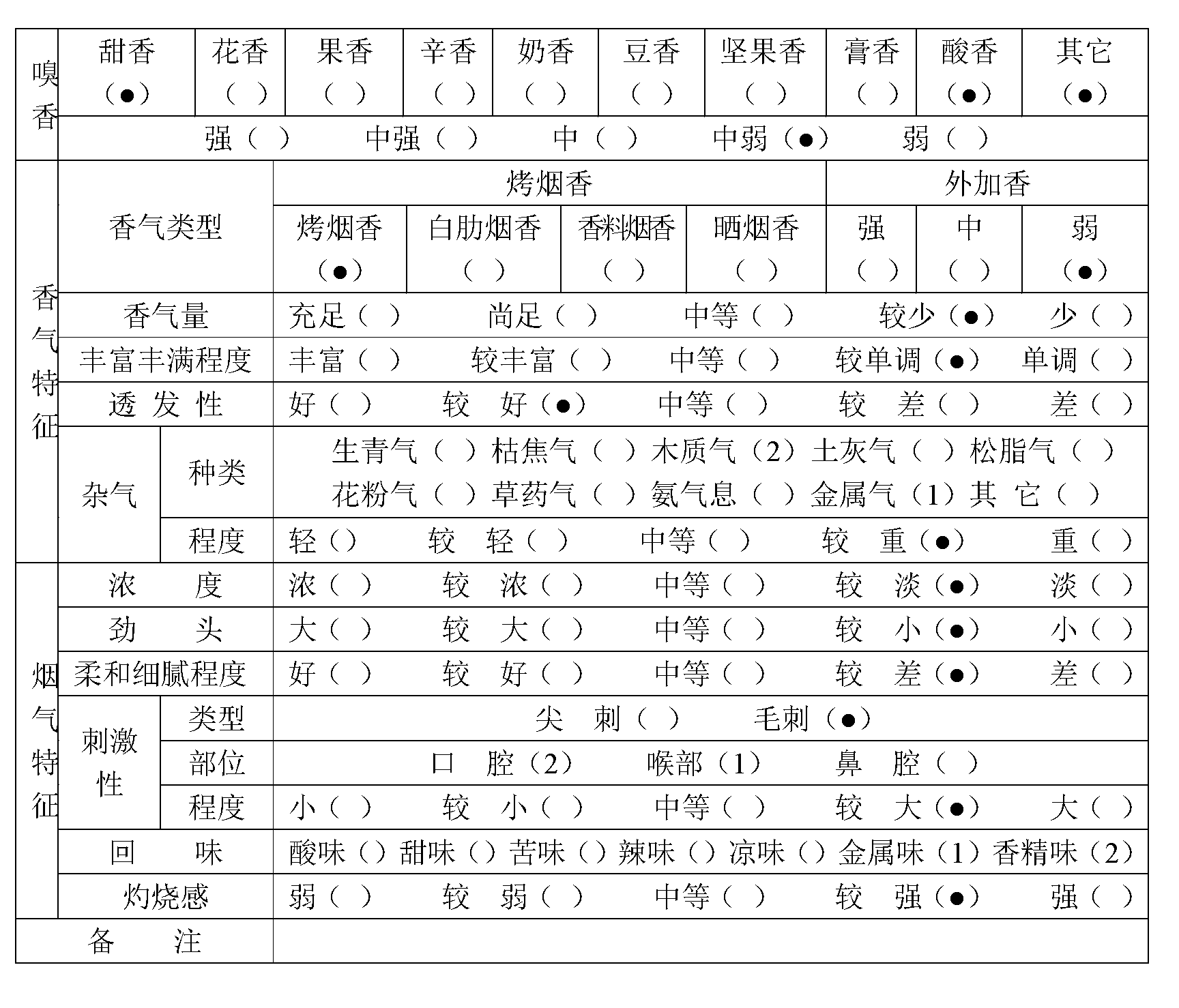

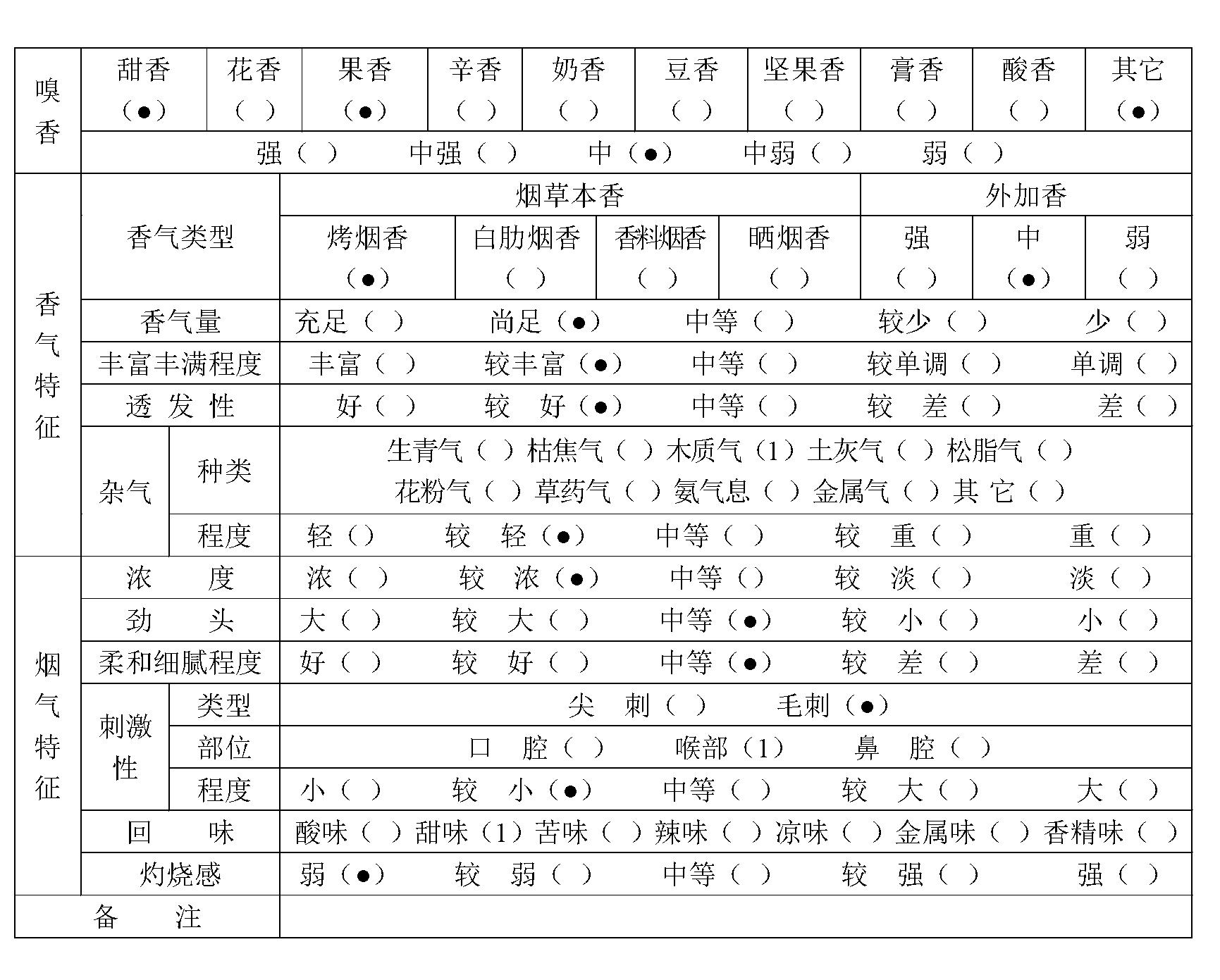

A technology of adding essence and expanding shredded tobacco, which is applied in the direction of essential oil/fragrance, tobacco, application, etc., and can solve the problems of strong irritation, residual metallic taste, heavy metal miscellaneous gas, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

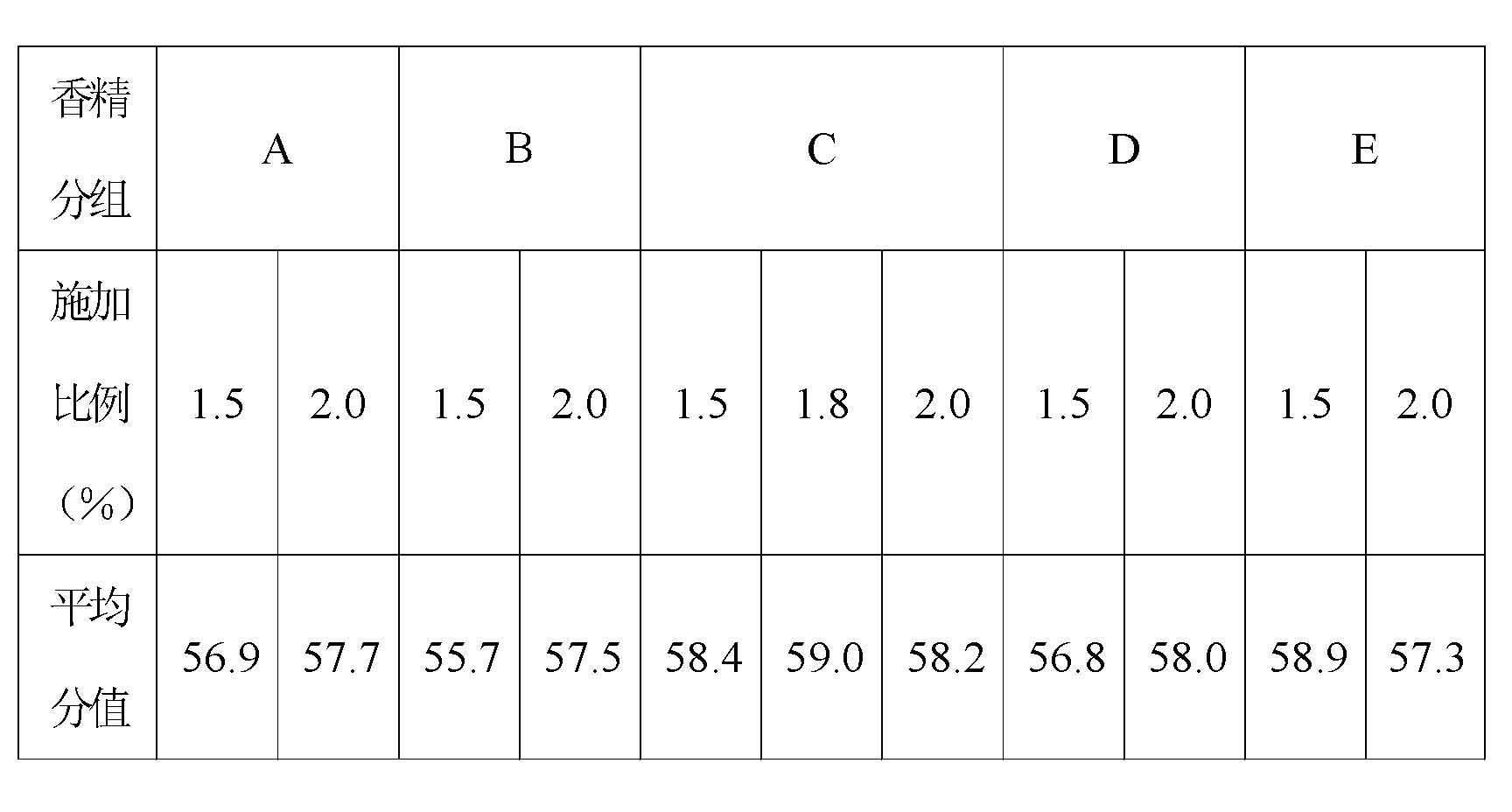

Examples

Embodiment 1

[0018] According to the following components by weight: 8 parts of Zimbabwean tobacco leaf extract, 12 parts of Brazilian tobacco leaf extract, 3 parts of honey, 3 parts of jujube extract with a mass fraction of 10%, 5 parts of phenylacetaldehyde with a mass fraction of 1%, 8 parts of guaiac wood oil with a mass fraction of 1%, 0.5 parts of fenugreek liquid extract, 3 parts of licorice liquid extract, 2 parts of maple syrup, 1 part of orris root extract with a mass fraction of 10%, 25 parts of water , 29.5 parts of propylene glycol. Mix the above raw materials evenly to obtain the required flavoring essence for expanding shredded tobacco.

Embodiment 2

[0020] According to the following components by weight: 9 parts of Zimbabwean tobacco leaf extract, 11 parts of Brazilian tobacco leaf extract, 5 parts of honey, 2.5 parts of jujube extract with a mass fraction of 10%, 4.5 parts of phenylacetaldehyde with a mass fraction of 1%, 7 parts of guaiac wood oil with a mass fraction of 1%, 1 part of fenugreek liquid extract, 2.5 parts of licorice liquid extract, 2.5 parts of maple syrup, 1 part of orris root extract with a mass fraction of 10%, 22 parts of water , 32 parts of propylene glycol. Mix the above raw materials evenly to obtain the required flavoring essence for expanding shredded tobacco.

Embodiment 3

[0022] According to the following components by weight: 12 parts of Zimbabwean tobacco leaf extract, 8 parts of Brazilian tobacco leaf extract, 5.5 parts of honey, 2 parts of jujube extract with a mass fraction of 10%, 3.5 parts of phenylacetaldehyde with a mass fraction of 1%, 6.5 parts of guaiac wood oil with a mass fraction of 1%, 1.5 parts of fenugreek liquid extract, 2 parts of licorice liquid extract, 3.5 parts of maple syrup, 1.5 parts of orris root extract with a mass fraction of 10%, 18 parts of water , 36 parts of propylene glycol. Mix the above raw materials evenly to obtain the required flavoring essence for expanding shredded tobacco.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com