Patents

Literature

54 results about "Throat irritation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Throat irritation can refer to a dry cough, a scratchy feeling at the back of the throat, a sensation of a lumpy feeling, something stuck at the back of the throat, or possibly a feeling of dust in the throat. The symptoms are unpleasant and usually temporary, but occasionally signifies a more serious health issue, such as laryngitis.

Bletilla striata Chinese herbal medicine toothpaste

ActiveCN101380285AWith sore hemostasisPrevention and Treatment of Mouth UlcersCosmetic preparationsToilet preparationsDiseaseThroat irritation

The invention pertains to the field of daily chemical industry and discloses a Chinese herbal toothpaste made from bletilla striata. The Chinese herbal toothpaste made from bletilla striata contains a toothpaste matrix which comprises paeonol and bletilla striata or the bletilla striata polysaccharide. The toothpaste has the functions of antibiosis, anti-inflammation, promotion of wound healing, hemostasis and the like, therefore, the toothpaste can be applied to preventing and treating oral diseases and dental diseases such as ulcerative stomatitis, throat irritation, periodontitis, gingivitis, dental caries, oral malodor and the like, and provides a new toothpaste for health care of oral cavity.

Owner:广东康王日化有限公司

Sealwort pressed candy and preparation method thereof

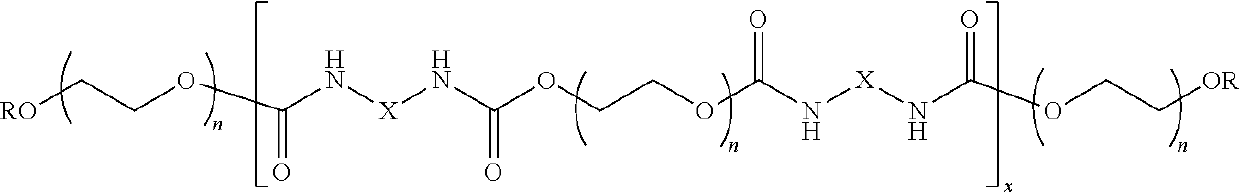

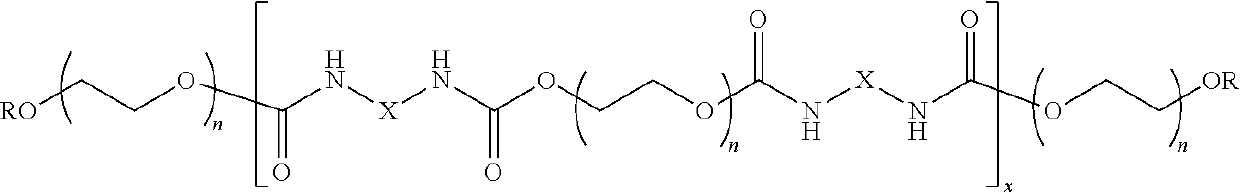

ActiveCN104782869AReasonable formulaAnti agingConfectionerySweetmeatsThroat irritationPolyethylene glycol

The invention provides a sealwort pressed candy and a preparation method thereof. The sealwort pressed candy is prepared from the following components in parts by weight: 10-60 parts of a sealwort extract, 5-20 parts of a Chinese yam extract, 5-10 parts of a radix polygonati officinalis extract, 10-30 parts of lactose, 5-20 parts of microcrystalline cellulose, 1-10 parts of maltodextrin, 1-10 parts of xylitol, 2-5 parts of hydroxypropyl methyl cellulose, 1-5 parts of honey, 0.5-2 parts of magnesium stearate, and 0.5-4 parts of polyethylene glycol. By extracting sealwort through a specific method, the astringency and the throat irritation feeling thereof can be effectively reduced; in addition, through the reasonable compatibility and proportioning of auxiliary materials, the astringency of sealwort can be further shielded, so that the sealwort pressed candy is good in taste. The sealwort pressed candy disclosed by the invention is reasonable in formula, and has the functions of delaying senescence, improving soreness and weakness of waist and knees, reducing blood sugar and blood fats, and the like.

Owner:杭州贝康广禾科技有限公司

Edible Oral Strip or Wafer Dosage Form Containing Ion Exchange Resin for Taste Masking

ActiveUS20140155483A1Facilitate ionic bindingGood dispersionBiocideAntipyreticThroat irritationAdditive ingredient

An edible oral film strip dosage form containing an unpalatable acidic active pharmaceutical ingredient, particularly ketoprofen, and an ion exchange resin as a primary taste masking agent, along with an optional alkaline agent and further optionally containing one or more secondary taste masking agents is provided. The edible oral film strip dosage matrix is formed from at least one water soluble or miscible polymer(s). The optional secondary taste masking ingredients include one or more of flavoring agent(s), sweetener(s), cooling sensation agent(s), and taste receptor blocker(s). The inventive dosages minimize or completely mask the bitterness, burning sensation and throat irritation associated with many acidic active pharmaceutical ingredients. Methods for preparing the inventive edible oral film strip dosage forms are disclosed, as well as their method of administration.

Owner:LTS LOHMANN THERAPIE-SYST AG

Smoke-free tobacco capable of reducing throat irritation and preparing method of smoke-free tobacco

InactiveCN103494323ASuitable for consumer psychologySuitable featuresTobacco treatmentBiotechnologyThroat irritation

The invention belongs to the field of smoke-free tobaccos, and particularly relates to a recipe of a smoke-free tobacco capable of reducing throat irritation and a preparing method of the smoke-free tobacco. According to the smoke-free tobacco, on the basis of a conventional product, throat-nourishing Chinese medicines and mucosa protection agents are added to a mixture, the throat-nourishing Chinese medicines account for 1-30% of total materials by weight, and the mucosa protection agents account for 1-4% of the total materials by weight. The tobacco improves the taste of an original tobacco, is good in smell, can well reduce irritation of nicotine at a throat mucosa, meanwhile can reduce the effect of exciting nerves, is suitable for consumption features of orientals, and has a throat-nourishing health care effect.

Owner:HONGTA TOBACCO GRP

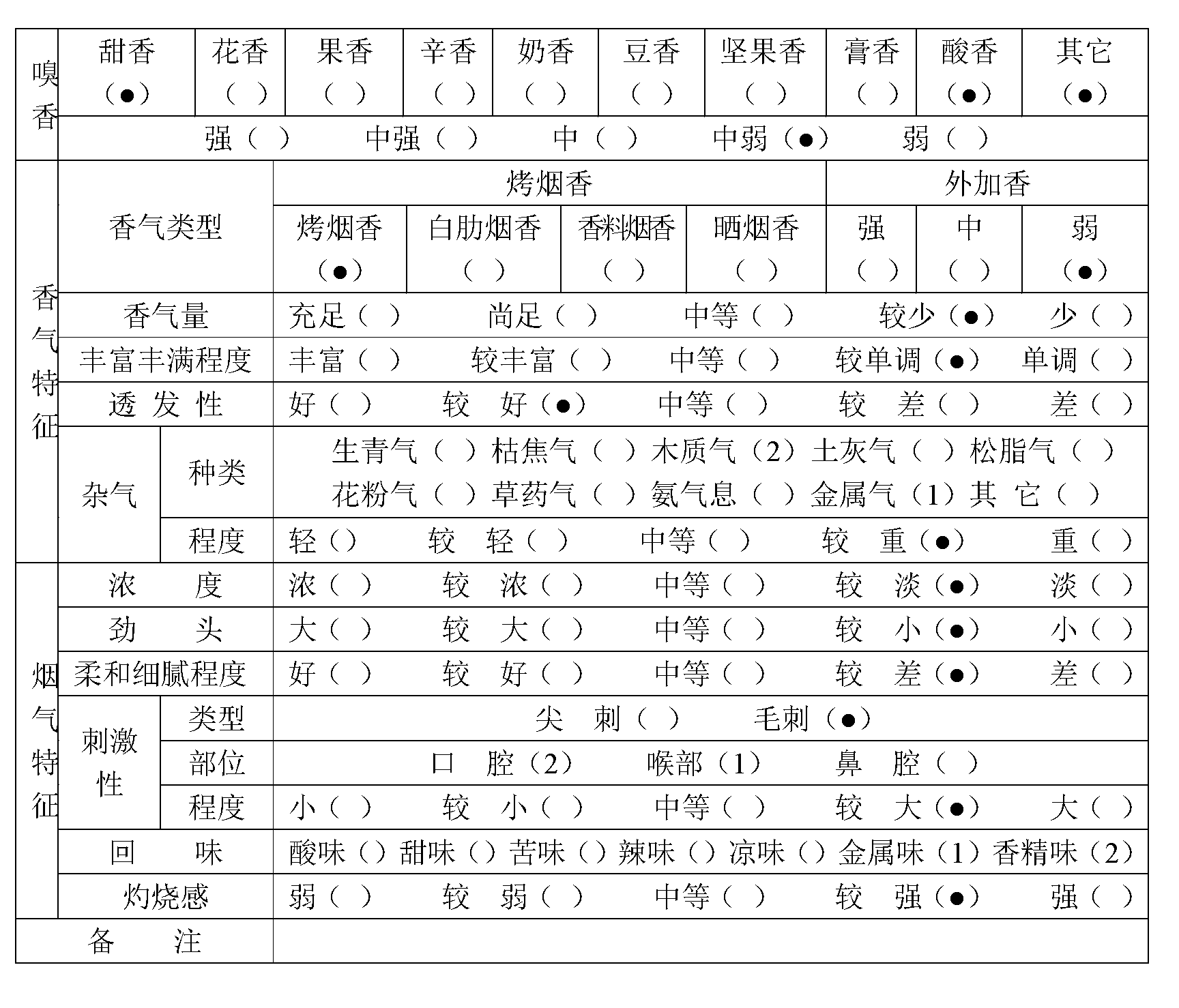

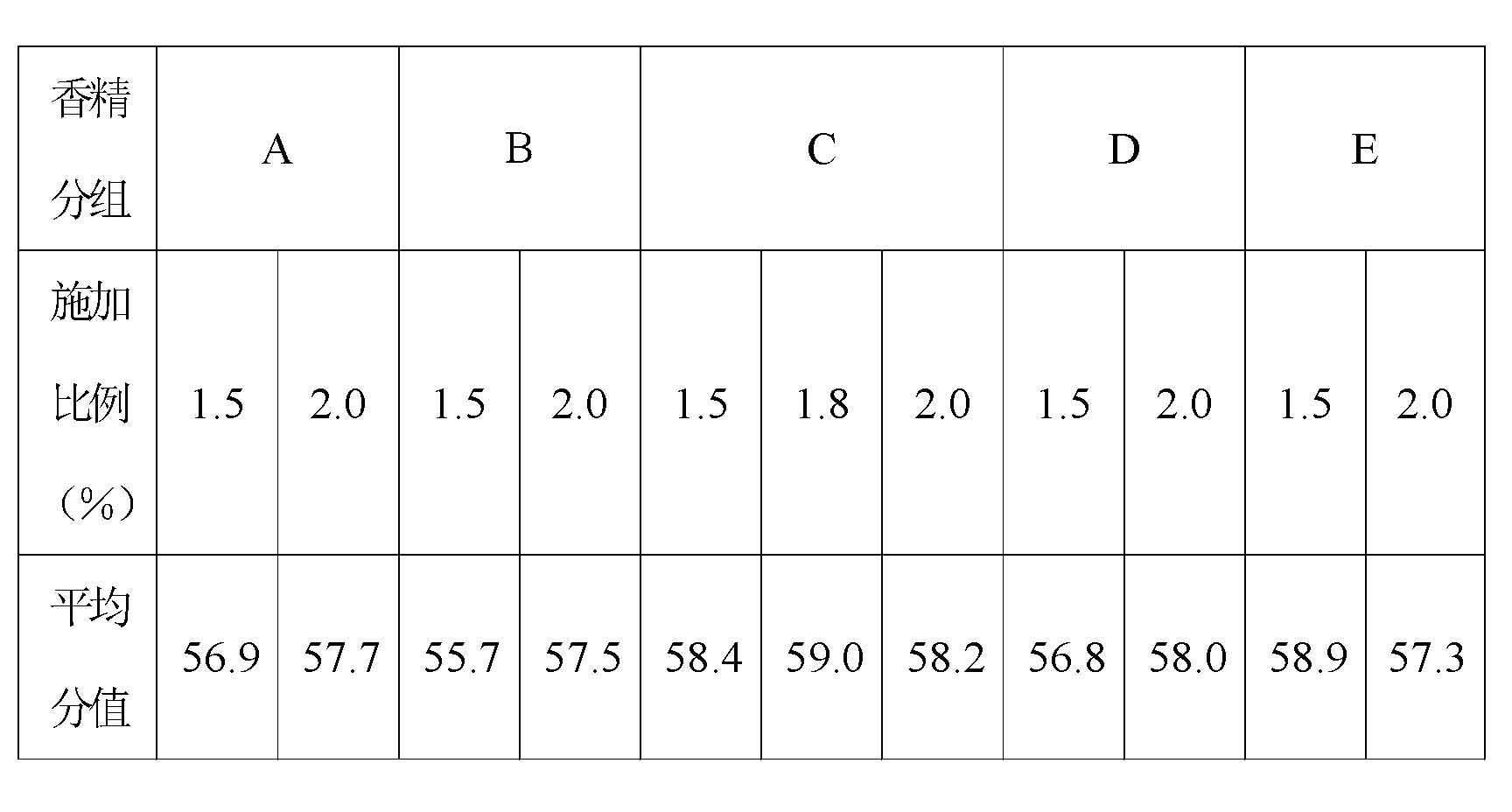

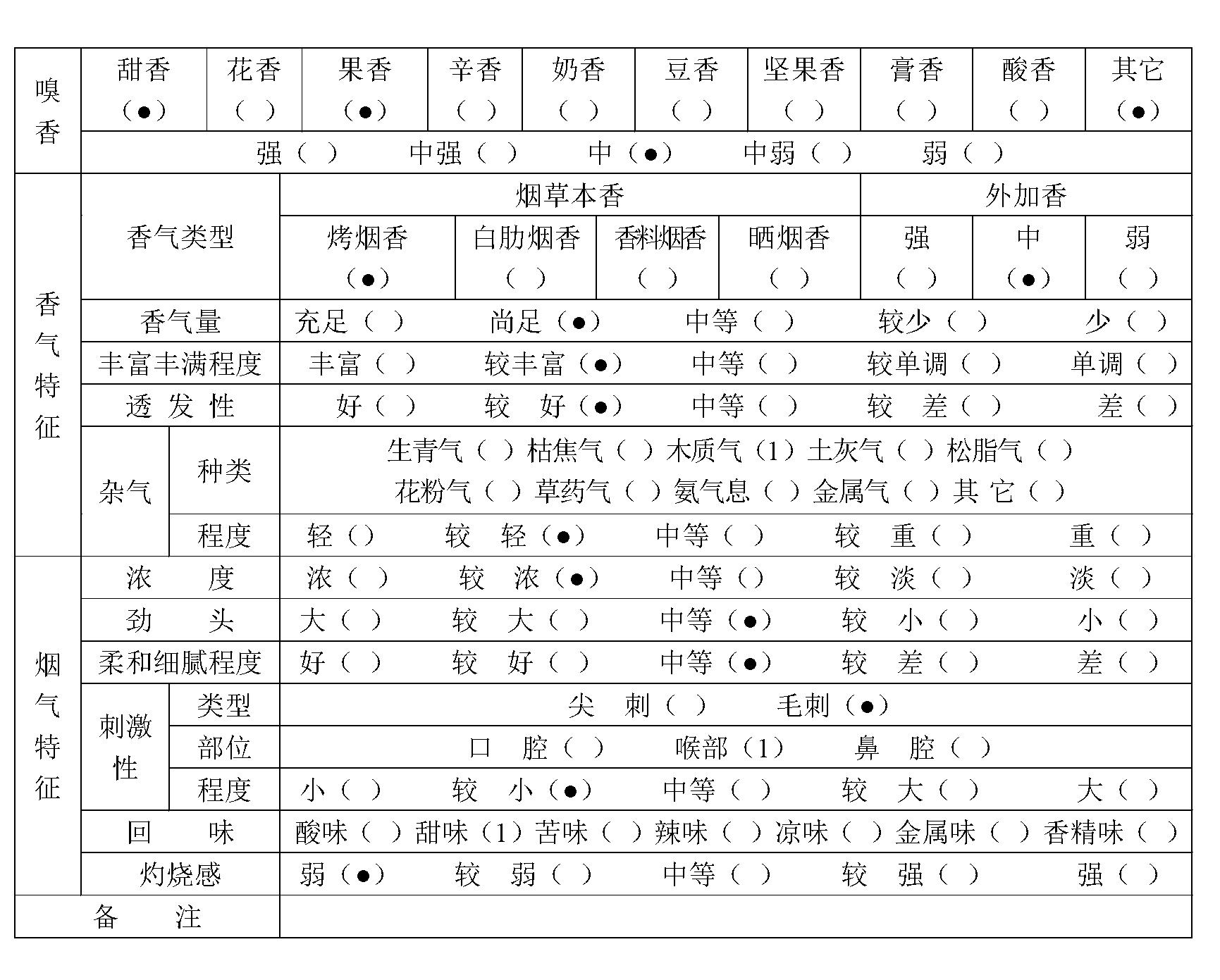

Casing flavor for expanded cut tobacco

ActiveCN103305342ARich fragranceIncrease sweetnessTobacco preparationTobacco treatmentThroat irritationMetal impurities

The invention discloses a casing flavor for an expanded cut tobacco. The casing flavor comprises the following components in parts by weight: 8-15 parts of a Zimbabwe tobacco leaf extract, 5-12 parts of a Brazil tobacco leaf extract, 3-8 parts of honey, 1-3 parts of 10% by mass of a red jujube extract, 2-5 parts of 1% by mass of phenylacetaldehyde, 5-8 parts of 1% by mass of guaiac wood oil, 0.5-2 parts of a fenugreek fluid extract, 1-3 parts of a liquorice fluid extract, 2-5 parts of maple syrup, 1-2 parts of 10% by mass of an orris root extract, 10-25 parts of water and 12-61.5 parts of propanediol. After the casing flavor is added into the expanded cut tobacco, the sensory quality shortages of insufficient fragrance, high metal impurity gas content, high irritation, metallic flavor residues and the like in the existing expanded cut tobacco are overcome, the fragrance content is increased, the expanded cut tobacco is endowed with fragrance and sweetness of a fruit and is enriched in fragrance, the throat irritation is reduced, and the sensory quality of the expanded cut tobacco is remarkably improved.

Owner:HUBEI CHINA TOBACCO IND +1

Preparation method for vacuum freeze drying fruit grain electronic cigarette liquid

ActiveCN104544540AExcellent natural fragrance feelingIncrease added valueTobacco treatmentThroat irritationFlavor

The invention discloses a preparation method for vacuum freeze drying fruit grain electronic cigarette liquid. The preparation method is characterized in that 1%-90% of vacuum freeze drying fruit grains in percentage by weight are added into base oil of the electronic cigarette liquid, and the fruit grains are formed by carrying out vacuum freeze drying on fruit pulps in arbitrary proportion and then breaking the fruit pulps into grains; the base oil comprises the components in percentage by weight: 0-10% of essence and flavor, 0-15% of deionized water, 2%-80% of glycerol and the balance of propylene glycol or polyethylene glycol which is supplemented to be 100%, and the vacuum freeze drying fruit grain electronic cigarette liquid can be obtained by uniformly stirring and mixing. Natural fruit aroma can be brought for the electronic cigarette fluid through the adding of the vacuum freeze drying fruit grains, and the vacuum freeze drying fruit grains have the obvious advantage of increasing the aroma. According to the preparation method disclosed by the invention, the aroma components are immersed into the electronic cigarette liquid, so that the characteristic flavor of fruits is given to the electronic cigarette liquid, the aroma quality and the aroma amount of the electronic cigarette liquid are increased, the throat irritation caused by an atomizing agent can be better covered, and the satisfaction of a customer is increased.

Owner:CHINA TOBACCO GUANGXI IND

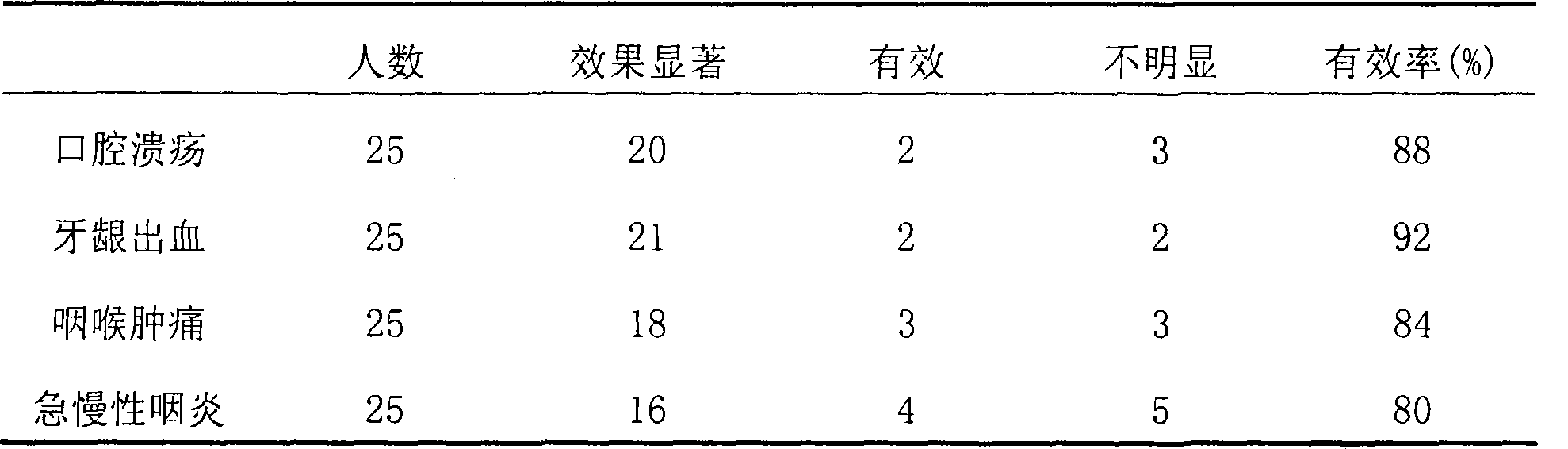

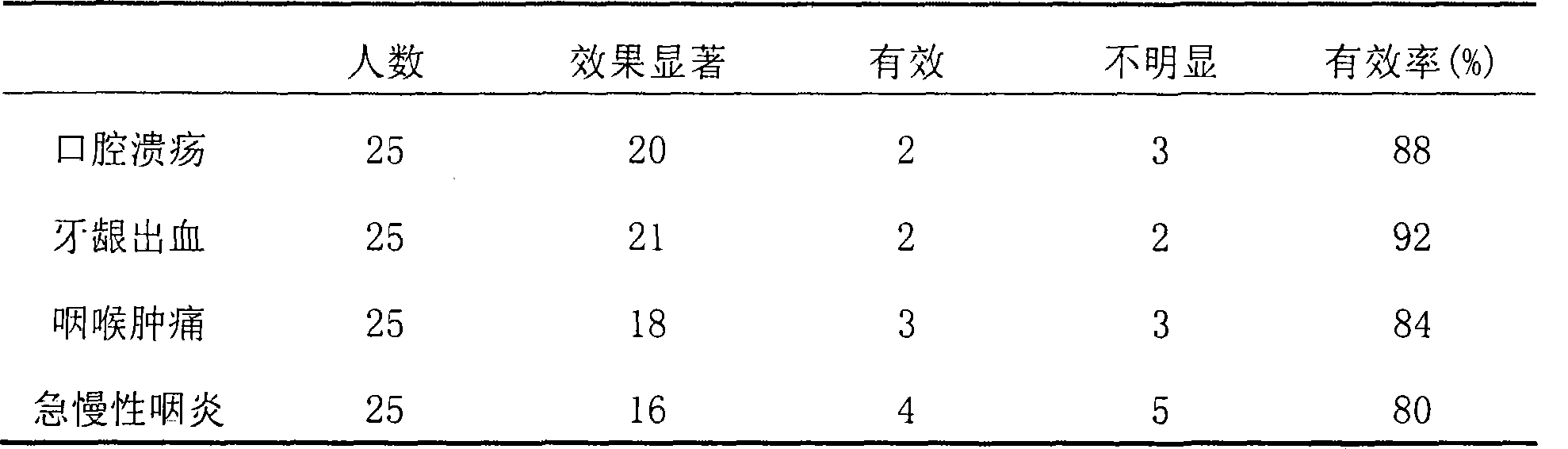

Traditional Chinese medicine preparation for treating throat irritation and preparation method thereof

The invention relates to a traditional Chinese medicine preparation for treating throat irritation and a preparation method thereof. The traditional Chinese medicine preparation comprises 90 to130 portions of Radix Trichosanthis, 90 to130 portions of radix sophorae subporstratae, 90 to130 portions of Indian Stringbush Root, 3 to 5 portions of artificial cow-bezoar, 3 to 5 portions of borneol, 3 to 5 portions of pearl layer powder, and 50 to 80 portions of Rhizoma et Radix Baphicacanthis Cusiae. Alcohol-soluble extractives are no less than 15 percent. The radix sophorae subporstratae contained in the preparation is counted as matrine (C15H24N2O) which is no less than 0.1 milligram.

Owner:林秀连

Processes for taste-masking of inhaled formulations

InactiveUS20080138397A1Minimizing bitter tasteMinimizing cough creationBiocideDispersion deliveryPulmonary inhalationThroat irritation

The present invention provides novel processes and methodologies to minimize the bitter or otherwise unpleasant taste, to minimize the tendency to stimulate the cough reflex, or to minimize oropharyngeal deposition of medically-active compounds administered by the pulmonary / inhalation route and to deliver hydroxychloroquine (HCQ) either singularly or in combination with an antimalarial and aminoquinolone by the pulmonary / inhalation route in a sustained release or other formulation that minimizes the bitter or otherwise unpleasant taste of HCQ or any potential to stimulate the cough reflex, and to deliver a dopaminergic compound or its prodrug, including ABT-431 by the pulmonary / inhalation route in a sustained release or other formulation that minimizes the unpleasant taste of the drug or any potential to stimulate the cough reflex, and to deliver a lantibiotic, including duramycin by the pulmonary / inhalation route in a sustained release or other formulation that minimizes the unpleasant taste of the drug or any potential to stimulate throat irritation.

Owner:ARADIGM

Chinese traditional medicine compounds for treating common cold and throat irritation, and preparing method thereof

InactiveCN101229290AEasy to takeSimple recipeAntiinfectivesPill deliveryThroat irritationAcute Pharyngitis

The invention discloses a traditional Chinese medicine composition for treating cold and throat swelling and pain and a preparation method thereof; the invention is mainly prepared with hill beans root, dyers woad leaf, honeysuckle, blackberry lily, great burdock achene, oil orange, oroxylum seed, figwort, peppermint and glycyrrhiza. The traditional Chinese medicine composition of the invention has the efficacies of clearing heat and detoxication, dispersing wind-heat, relieving sore throat and eliminating swelling, nourishing yin and moisturizing lung; the composition mainly cures fever and headache, colds, throat swelling and pain and cough and loss of voice which are caused by external colds or first pathogenic warmth and also cures acute pharyngitis and acute tonsillitis. The invention is simple in formula, easy in production, convenient in taking for patients, marked in curative effect and wide in application value.

Owner:BEIJING ZHONGKE YONGHE PHARMA TECH

Method for preparing camphor tree leaf tobacco flavor

ActiveCN102551192APreserve active ingredientsReduce harmTobacco preparationTobacco treatmentFlavorThroat irritation

The invention discloses a method for preparing camphor tree leaf tobacco flavor, comprising the steps of screening microbe on the surface of tobacco leaf, isolating the microbe capable of producing aroma, mixing with germfree camphor tree leaves, carrying out solid fermentation, extracting volatile oil in fermentation products, and diluting to obtain the camphor tree leaf tobacco flavor. In the invention, the tobacco flavor is obtained through a method of microbial fermentation to ensure that active constituents in the fermentation raw material can be effectively preserved, the process is simple and a new way is provided for flavor preparing industry. The obtained camphor tree leaf tobacco flavor is capable of reducing the harms of tobacco to human body to a certain degree; and the smoke is fine and smooth, and has moist feeling, slight sweet feeling and good penetration to ensure that the throat irritation is obviously relieved, the smoke has brewing aroma and fermented sour aroma and has no obvious residual on the tongue surface.

Owner:HUBEI CHINA TOBACCO IND +1

Preparation method for vacuum freeze drying flower grain electronic cigarette liquid

ActiveCN104544541AExcellent natural floral scentIncrease added valueTobacco treatmentThroat irritationFreeze-drying

The invention discloses a preparation method for vacuum freeze drying flower grain electronic cigarette liquid. The preparation method is characterized in that 1%-90% of vacuum freeze drying flower grains in percentage by weight are added into base oil of the electronic cigarette liquid, and the flower grains are formed by smashing and mixing at least one of lotus, oriental cherry, orchid, rape flower, osmanthus tea, honeysuckle, trollflower, rose, jasmine, magnolia flower, calendula and the like, pressing the flower mixture into blocks, carrying out vacuum freeze drying, and then breaking the blocks into grains; the base oil comprises the components in percentage by weight: 0-10% of essence and flavor, 0-15% of deionized water, 2%-80% of glycerol and the balance of propylene glycol or polyethylene glycol which is supplemented to be 100%, and the vacuum freeze drying flower grain electronic cigarette liquid can be obtained by uniformly stirring and mixing. According to the preparation method disclosed by the invention, the aroma components are immersed into the electronic cigarette liquid, so that the characteristic flavor of flowers is given to the electronic cigarette liquid, the aroma quality and the aroma amount of the electronic cigarette liquid are increased, the throat irritation caused by an atomizing agent can be better covered, and the satisfaction of a customer is increased.

Owner:CHINA TOBACCO GUANGXI IND

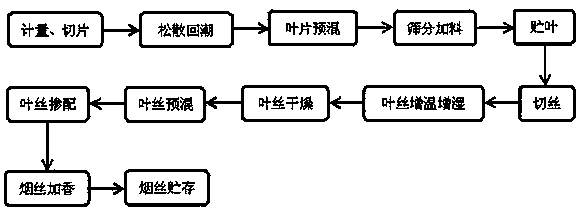

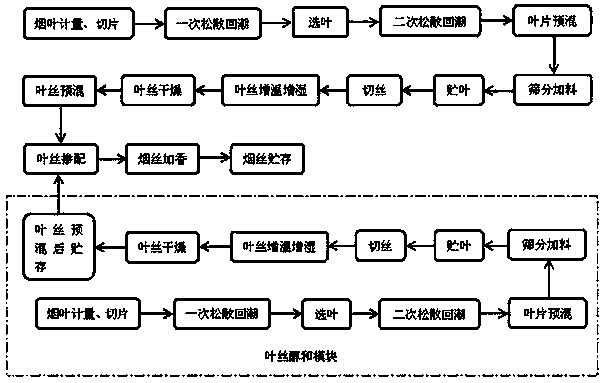

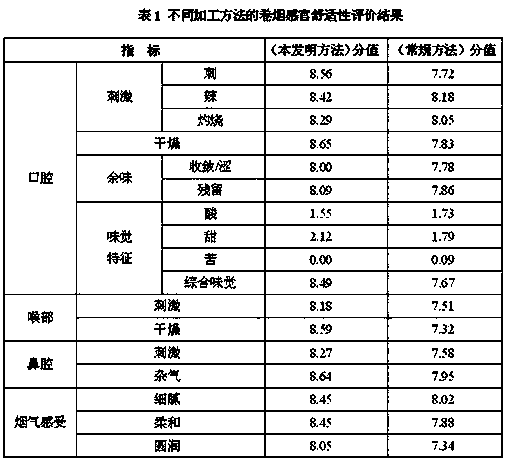

Tobacco shred preparation process capable of improving smoking comfort of cigarettes

The invention discloses a tobacco shred preparation process capable of improving the smoking comfort of cigarettes. The tobacco shred preparation process comprises the following processing steps: carrying out primary loosening and moisture regaining, leaf selecting and secondary loosening and moisture regaining on tobacco leaves, premixing the leaves, carrying out screening, carrying out materialadding, carrying out leaf storage on the tobacco leaves after material adding, carrying out shredding, carrying out heating and humidifying on the tobacco shreds, carrying out drying on the tobacco shreds, and carrying out premixing; carrying out storage on the premixed tobacco shreds, thus obtaining tobacco shred alcohol and modules; carrying out the same steps, adding tobacco shred alcohol and the module tobacco shreds into the premixed tobacco shreds, perfuming the tobacco shreds, and carrying out storage. After softened water is replaced with activated water, the mouthfeel of the cigarettes can be improved, and the dryness and astringency feeling of the oral cavity is reduced. The sensory comfort score value of the cigarettes including the oral cavity irritation, the oral cavity aftertaste, the throat irritation, the nasal cavity miscellaneous qi and the smoke feeling can be improved by 2.9%-17.3%. Due to secondary moisture regaining, the impurities having influences on the smoke are removed, the tobacco shred alcohol and modules are adopted as the external mixing ingredients, the alcoholized tobacco shreds can effectively improve the inherent quality of the tobacco shreds, andthus the comfort during the smoking process of the cigarettes is improved.

Owner:CHINA TOBACCO HEBEI INDUSTRIAL CO LTD

Production method of ginsenoside gel filter stick

InactiveCN110946324ADistinct taste characteristicsQuality improvementTobacco smoke filtersThroat irritationMedicine

The invention relates to a production method of a ginsenoside gel filter stick. The production method comprises the following steps: preparing ginsenoside gel, adding the ginsenoside gel, cooling, drying, packaging and the like. The filter stick produced by the method disclosed by the invention is stable in quality, uniform in ginsenoside gel addition amount, obvious in ginsenoside taste characteristic, low in oral cavity and throat irritation, free of obvious offensive odor and clean and comfortable in aftertaste.

Owner:王传涛

Fine mist hard surface cleaning spray

ActiveUS20190359909A1Surface-active detergent compositionsDetergent mixture composition preparationThroat irritationSurface cleaning

The need for a spray application of detersive compositions comprising perfume and low levels of surfactant, which provides more even coverage of the surface to be treated, while limiting nose and throat irritation is met by limiting the spray droplet size, such that the spray droplets have a particle size distribution such that the Dv10 is greater than about 40 microns.

Owner:THE PROCTER & GAMBLE COMPANY

Processes for taste-masking of inhaled formulations

InactiveUS20110104259A1Reduce interactionReduce concentrationDispersion deliveryAerosol deliveryThroat irritationHydroxychloroquine

The present invention provides novel processes and methodologies to minimize the bitter or otherwise unpleasant taste, to minimize the tendency to stimulate the cough reflex, or to minimize oropharyngeal deposition of medically-active compounds administered by the pulmonary / inhalation route and to deliver hydroxychloroquine (HCQ) either singularly or in combination with an antimalarial and aminoquinolone by the pulmonary / inhalation route in a sustained release or other formulation that minimizes the bitter or otherwise unpleasant taste of HCQ or any potential to stimulate the cough reflex, and to deliver a dopaminergic compound or its prodrug, including ABT-431 by the pulmonary / inhalation route in a sustained release or other formulation that minimizes the unpleasant taste of the drug or any potential to stimulate the cough reflex, and to deliver a lantibiotic, including duramycin by the pulmonary / inhalation route in a sustained release or other formulation that minimizes the unpleasant taste of the drug or any potential to stimulate throat irritation.

Owner:ARADIGM

Preparation method of crisp pear tobacco flavor

ActiveCN106833897AImprove coordinationEnhance the sweetness of cigarettesTobacco preparationEssential-oils/perfumesThroat irritationPEAR

The invention belongs to the technical field of tobacco flavors and particularly discloses a method for preparing a sweetening and moistening tobacco flavor from a Dangshan crisp pear as an extract by adopting an enzymolysis approach and a column chromatography technology. Through the operations of pulping, enzymolysis, column chromatography separation and eluting, vacuum concentration and the like, on the one hand, the juice yield of the Dangshan crisp pear is improved, a natural tobacco extract is reserved to the maximal extent, the aroma quality, the sweetness, liquid-engendering feeling and the taste softness are improved; and on the other hand, macromolecular substances affecting the sensory quality of the smoke are removed to obtain the high-quality extract. The crisp pear tobacco flavor prepared by the method is natural in aroma and distinct in fragrance characteristic, and is capable of playing a role in harmonizing the smoke, giving smoke sweetness, relieving throat irritation and improving the taste after being added to a cigarette at a proper ratio.

Owner:CHINA TOBACCO JIANGXI IND CO LTD

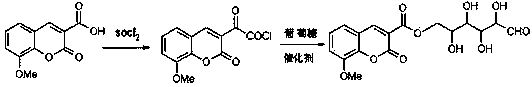

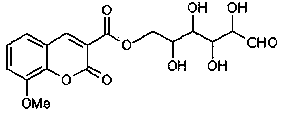

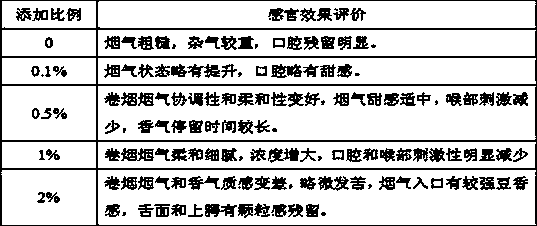

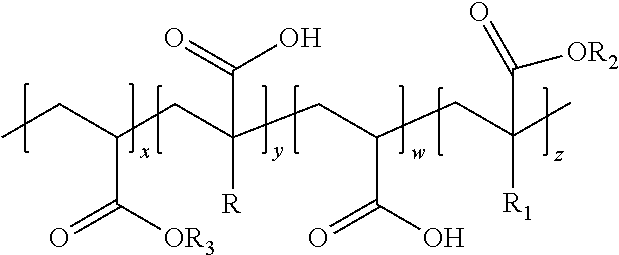

Preparation method and application of 8-methoxycoumarin-3-glucose ester formate

InactiveCN103965268AModerate sweetnessEasy to makeEsterified saccharide compoundsSugar derivativesThroat irritationFormate

The invention discloses a preparation method and an application of 8-methoxycoumarin-3-glucose ester formate. The preparation method comprises the following steps: mixing 8-methoxycoumarin-3-formic acid with thionyl chloride, subsequently performing backflow reaction till the 8-methoxycoumarin-3-formic acid is completely reacted, removing excessive thionyl chloride, further adding a solvent, a catalyst and glucose, reacting for 2-6 hours at 10-40 DEG C, and after the reaction is accomplished, separating and purifying to obtain a tobacco bean fragrance type condiment, namely, the 8-methoxycoumarin-3-glucose ester formate. The 8-methoxycoumarin-3-glucose ester formate is used in tobacco for improving the harmony and the gentleness of smoke of cigarette and reducing the oral and throat irritation and can remarkably improve the taste of cigarette, the fragrance is similar to that of 8-methoxycoumarin, but the fragrance lasts longer. The preparation process is simple, the reaction condition is gentle and safe, the industrial production is easy to achieve, a remarkable effect of improving the smoke of cigarette can be achieved by only adding a small amount of the 8-methoxycoumarin-3-glucose ester formate, the production cost of cigarette is hardly influenced, and great practicability is achieved.

Owner:CHINA TOBACCO HEBEI INDUSTRIAL CO LTD

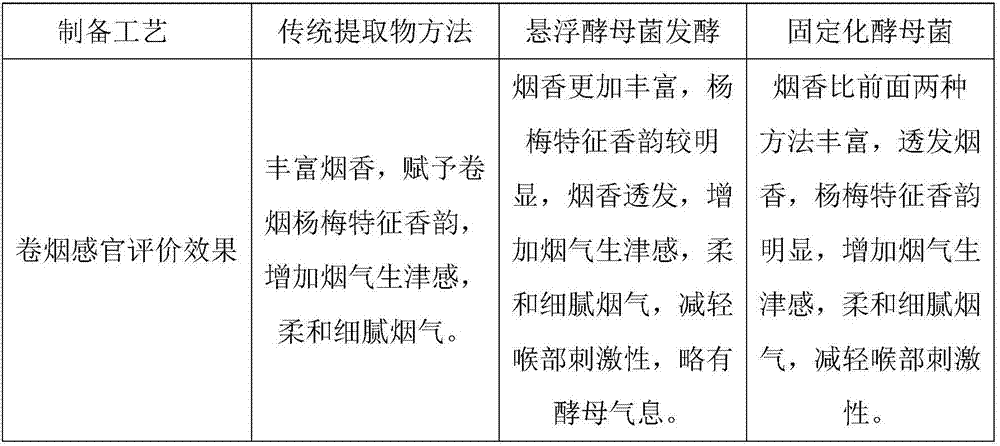

Method for preparing waxberry extract for cigarette by immobilized saccharomycetes

InactiveCN106957866AImprove the efficiency of fermentation processFacilitate solid-liquid separationMicroorganismsMicroorganism based processesThroat irritationFlavor

The invention provides a method for preparing a waxberry extract for cigarette by immobilized saccharomycetes. The method comprises the following steps: (1) juicing fresh waxberry; (2) preparing a saccharomycetes bacterial suspension; (3) immobilizing saccharomycetes with sodium alginate-CaCl2; (4) performing fermenting reaction on the immobilized saccharomycetes and the waxberry juice; (5) filtering fermentation liquor, thereby acquiring clear fermentation liquor, and then performing alcohol precipitation and vacuum concentration, thereby acquiring the waxberry extract. According to the invention, the waxberry is taken as a raw material and the immobilized saccharomycetes are utilized to ferment the waxberry juice, so that the high-quality waxberry extract for cigarette can be acquired. The extract in cigarette has the functions of enriching cigarette flavor, inducing cigarette fragrance, increasing fruity sweet and fragrance, enhancing smoke saliva-generating feel, softening and fining smoke, relieving throat irritation, and the like.

Owner:WUHAN HUANGHELOU FLAVOR & SPICES

Preparation method of compound plant extract capable of promoting salivation and increasing moisture and cold extraction electronic cigarette oil

InactiveCN110628508AGreat tasteKeep the fragranceTobacco treatmentTobacco devicesThroat irritationFreeze-drying

The invention discloses a preparation method of a compound plant extract capable of promoting salivation and increasing moisture, and cold extraction electronic cigarette oil. The method comprises thefollowing steps: fresh plant materials such as fresh rose flowers, honeysuckle flowers, aloe vera, green olives, green plums and green tea are selected to form a compound plant combination, the compound plant combination are subjected to vacuum freeze drying treatment, and crushing is performed to obtain freeze-dried raw material powder; and cold extraction is performed on the freeze-dried raw material powder by using a chromatographic column to obtain the compound plant extract. The method can keep the fragrance of the fresh plant materials, retain most of other functional active substanceswith lower boiling points and heat sensitivity, and reduce dissolution of macromolecular substances; the compound plant extract can remarkably reduce throat irritation and enhance throat moisturizingfeeling; and the obtained compound plant extract is combined with an electronic cigarette essence base to be applied to the electronic cigarette oil, the taste characteristic of the electronic cigarette oil is improved, some adverse effects such as scorching feeling and atomizer blockage easily caused by natural extract atomization in the smoking process are reduced, and the user experience is improved.

Owner:SHENZHEN BOTON FLAVORS & FRAGRANCES

Chinese herbal medicine herbal tea

InactiveCN104126716AGreat tasteFull effectSenses disorderAntipyreticThroat irritationTherapeutic effect

The invention discloses a Chinese herbal medicine herbal tea. The Chinese herbal medicine herbal tea includes the following components in parts by weight: honeysuckle 10-20, chrysanthemum 10-20, loosestrife 5-15, plantain 5-15, rhizoma imperatae 5-15, and thesium Chinese turcz 3-9. The herbal tea can clear away the heat evil and remove dampness, has the prevention and treatment effects on constipation and reddish urine, abdomen stagnancy and dull pain, throat irritation, swelling in the gum, appetite stimulation, eye bloodshot and nasal obstruction and drinking of excessive alcohol, and has good taste and obvious effect.

Owner:王会杰

Fine mist hard surface cleaning spray

ActiveUS11485933B2Organic detergent compounding agentsSurface-active detergent compositionsThroat irritationSurface cleaning

The need for a spray application of detersive compositions comprising perfume and low levels of surfactant, which provides more even coverage of the surface to be treated, while limiting nose and throat irritation is met by limiting the spray droplet size, such that the spray droplets have a particle size distribution such that the Dv10 is greater than about 40 microns.

Owner:THE PROCTER & GAMBLE COMPANY

Bletilla striata Chinese herbal medicine toothpaste

ActiveCN101380285BWith sore hemostasisPrevention and Treatment of Mouth UlcersCosmetic preparationsToilet preparationsDiseaseThroat irritation

The invention pertains to the field of daily chemical industry and discloses a Chinese herbal toothpaste made from bletilla striata. The Chinese herbal toothpaste made from bletilla striata contains a toothpaste matrix which comprises paeonol and bletilla striata or the bletilla striata polysaccharide. The toothpaste has the functions of antibiosis, anti-inflammation, promotion of wound healing, hemostasis and the like, therefore, the toothpaste can be applied to preventing and treating oral diseases and dental diseases such as ulcerative stomatitis, throat irritation, periodontitis, gingivitis, dental caries, oral malodor and the like, and provides a new toothpaste for health care of oral cavity.

Owner:广东康王日化有限公司

Green wrinkled gianthyssop herb chafing dish bottom material and preparation technology thereof

ActiveCN107173773AKeep it spicyFresh tasteFood thermal treatmentFood ingredient as taste affecting agentThroat irritationMonosodium glutamate

The invention discloses a green wrinkled gianthyssop herb chafing dish bottom material. The green wrinkled gianthyssop herb chafing dish bottom material consists of 40-50 parts of pickled Chinese cabbages, 10-20 parts of capsicum frutescens, 5-12 parts of animal oil, 5-12 parts of vegetable oil, 0.5-1.5 parts of salt, 0.5-1.5 parts of monosodium glutamate, 0.5-1.5 parts of chicken powder, 0.5-1.5 parts of Xianwei powder, 0.5-1.5 parts of malt flour, 1-3 parts of pepper fruits, 1-5 parts of chicken essence, 0.5-2 parts of wrinkled gianthyssop herbs, 0.5-1.5 parts of scallions, 0.5-1.5 parts of garlic, 0.5-1.5 parts of fresh ginger, 0.5-2 parts of star anise and 0.5-1.5 parts of rhizoma kaempferiae. The invention further discloses a preparation technology of the green wrinkled gianthyssop herb chafing dish bottom material. The chafing dish bottom material is green and healthy and good in taste, the preparation technology of the green wrinkled gianthyssop herb chafing dish bottom material is simple and hygienic, and the green wrinkled gianthyssop herb chafing dish bottom material is better in mouth feel and taste than conventional chaging dish, can eliminate the adverse reactions of xerostomia, throat irritation, discomfort of stomach and intestine and the like, and is favorable for health of human bodies.

Owner:尹媛媛

Method for preparing tobacco flavor by adopting carrots fermented by aspergillus oryzae

InactiveCN107236767ALow priceRich sourcesTobacco preparationMicroorganismsThroat irritationLiquid medium

The invention discloses a method for preparing a tobacco flavor by adopting carrots fermented by aspergillus oryzae. The aspergillus oryzae strain has the classification and name of Aspergillus oryzae YNCA9804 and the collection number of CCTCC NO:M 2016654. Liquid seeds of the strain are added into a liquid medium for the carrots, carrying out fermentation culture, and then filtering, deslagging and carrying out reduced pressure concentration on fermentation products, so that the required tobacco flavor is obtained. The tobacco flavor has strong sweet fruit taste, a smoke panel test is carried out by adding the tobacco flavor into a cigarette, and the tobacco flavor has the effects of enriching cigarette fragrance, reducing throat irritation and improving aftertaste. The culture medium used in the invention is simple, and the strain is stable in characters and easy in storage, activation and fermentation. The production technology is simple, the operability, normalization and controllability are strong, and large-scale industrial production can be conveniently realized, so that the tobacco flavor has good development and application prospects.

Owner:CHINA TOBACCO YUNNAN IND

Instant canned polygonatum sibiricum porridge and preparation method thereof

InactiveCN109315683AReduce lossesJerky noFood ingredient as flavour affecting agentNatural extract food ingredientsThroat irritationBiotechnology

The invention discloses instant canned polygonatum sibiricum porridge and a preparation method thereof, and belongs to the field of polygonatum sibiricum processing. The instant canned polygonatum sibiricum porridge is prepared from the following raw materials in parts by weight: 20-30 parts of black rice, 14-16 parts of black soya beans, 35-55 parts of rice, 4-8 parts of corn, 1-3 parts of Chinese wolfberres, 1-4 parts of millet, 3-5 parts of lotus seeds, 1-3 parts of rock candies, 0.2-0.4 part of chitosan, 1-3 parts of polygonatum sibiricum and 0.2-0.6 part of yellow rice wine. The instant canned polygonatum sibiricum porridge prepared through the preparation method for the instant canned polygonatum sibiricum porridge has the advantages of being easy to digest and capable of achieving the effects of invigorating spleen-stomach and replenishing vital energy, and the polygonatum sibiricum has no astringent taste and throat irritation feeling.

Owner:安徽省旌德博仕达农业科技有限公司

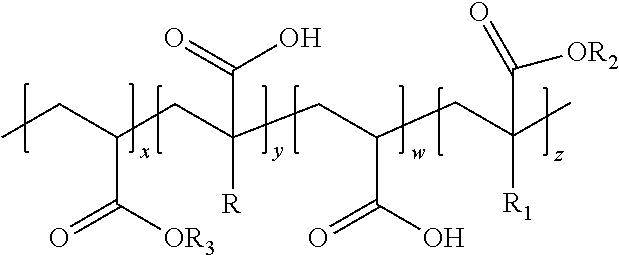

Edible oral strip or wafer dosage form containing ion exchange resin for taste masking

ActiveUS9597287B2Good dispersionGood film formingOrganic active ingredientsAntipyreticThroat irritationTaste receptor ligand

An edible oral film strip dosage form containing an unpalatable acidic active pharmaceutical ingredient, particularly ketoprofen, and an ion exchange resin as a primary taste masking agent, along with an optional alkaline agent and further optionally containing one or more secondary taste masking agents is provided. The edible oral film strip dosage matrix is formed from at least one water soluble or miscible polymer(s). The optional secondary taste masking ingredients include one or more of flavoring agent(s), sweetener(s), cooling sensation agent(s), and taste receptor blocker(s). The inventive dosages minimize or completely mask the bitterness, burning sensation and throat irritation associated with many acidic active pharmaceutical ingredients. Methods for preparing the inventive edible oral film strip dosage forms are disclosed, as well as their method of administration.

Owner:LTS LOHMANN THERAPIE-SYST AG

Ginger vinegar beverage

The present invention discloses a ginger vinegar beverage, which comprises the following raw material: 10% of vinegar, 7.5% of sucrose, 3% of a ginger juice, 0.1% of a licorice root juice, 0.015% of stevioside, 3% of honey, and the balance of mineral water. According to the invention, the fresh ginger juice is added to the vinegar beverage, such that the beverage can be endowed with the refreshing and special taste and aroma, and the significant inhibition effect is provided for the microorganisms capable of causing rancidness deterioration and generating toxic metabolites in the fruit and vegetable composite juice beverage; the licorice root has the throat irritation reducing effect, such that the beverage taste is soft; and the obtained ginger vinegar beverage has characteristics of mellow flavor and good taste, and is a novel nutritional health beverage.

Owner:QINGDAO XIUXIAN FOODS

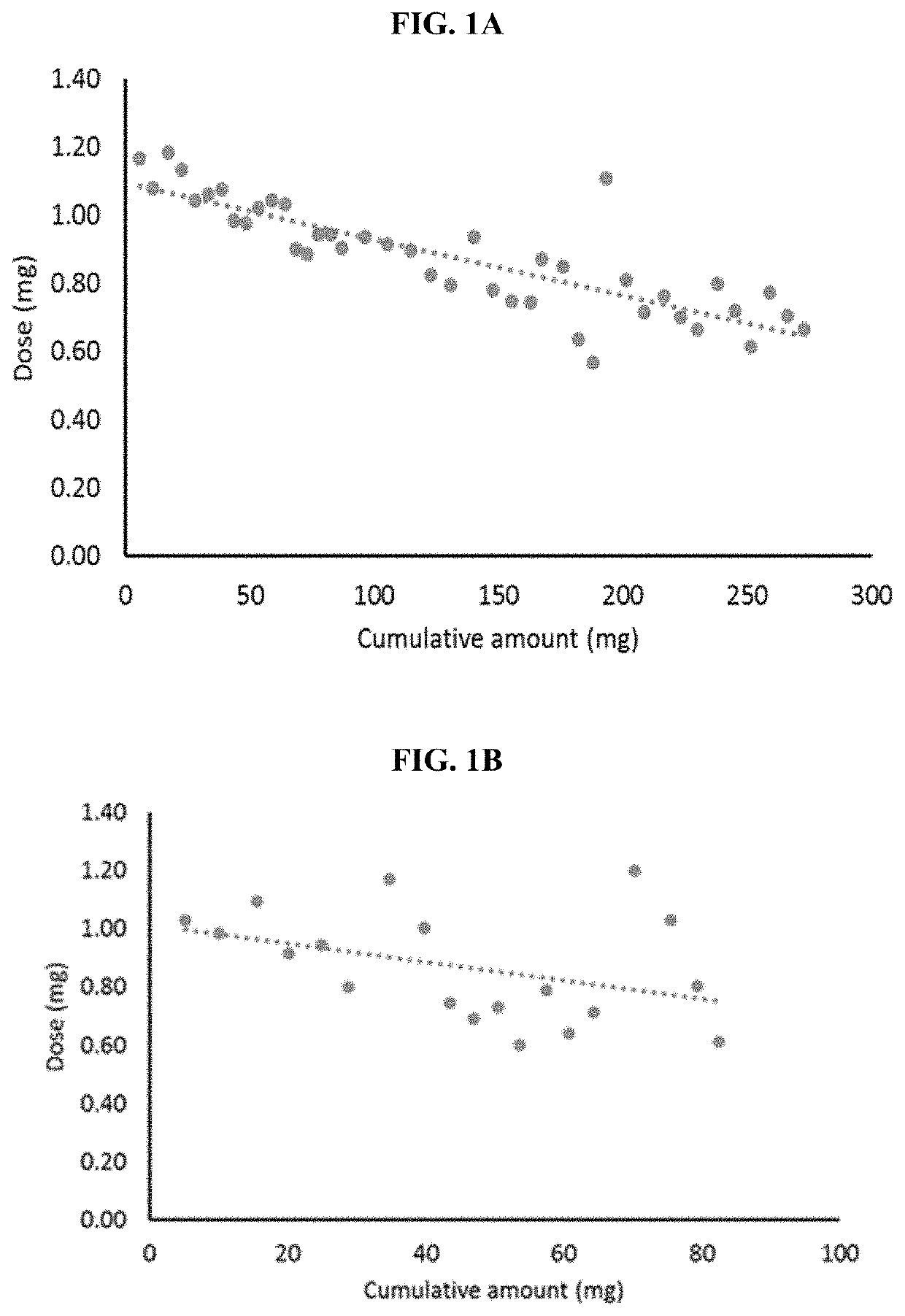

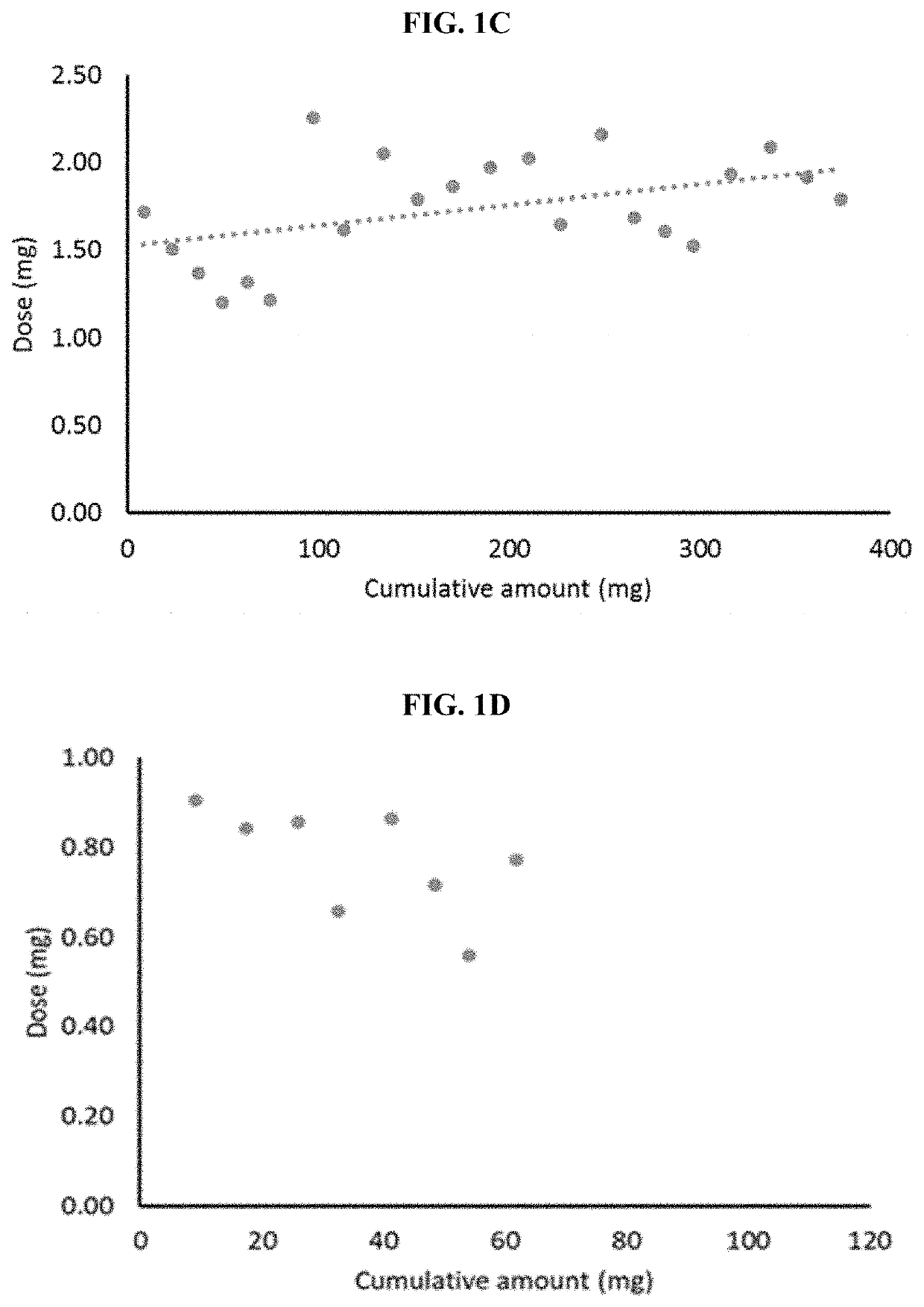

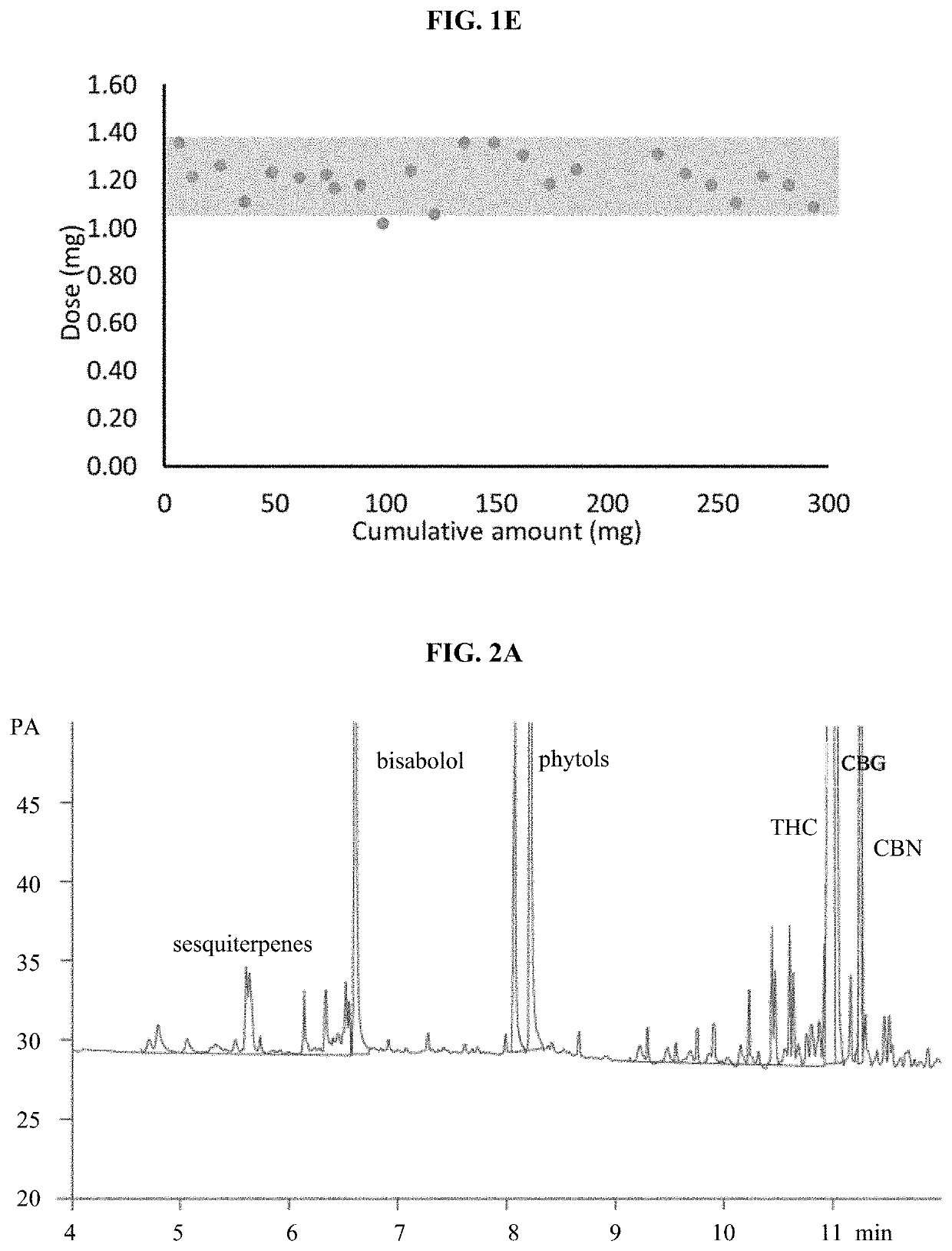

Diluents for compositions of cannabinoids and uses thereof

The present invention provides a stock compositions comprising a combinations of terpenes, that, when used as diluents in vaporizable formulations comprising cannabinoids, confer administration of reproducible constant dose of the formulations and its components such as cannabinoids, reduce throat irritation and improve the flavor of said formulations. The invention further provides vaporizable formulations comprising defined concentrations of the diluent(s) and cannabinoids. Use of the vaporizable formulations is provided as well.

Owner:KANABO RES LTD

Gentiana pubigera Marq health tea

InactiveCN104543233AClearing heat and reducing fireAnti-inflammatory and detoxifyingTea substituesThroat irritationPubigera

The invention discloses a gentiana pubigera Marq health tea. The gentiana pubigera Marq health tea is prepared by mixing gentiana pubigera Marq, galinsoga parviflora Cav, lentil and fritillaria taipaiensis according to a certain weight ratio. The health tea has the efficacies of reducing fever and reducing heat, diminishing inflammation and disintoxicating, clearing throat and relieving pain, moistening lung by reducing phlegm, and suppressing cough, is low in cost, good in effect, reasonable in formula, simple in preparation, easy to store, and convenient to drink, is suitable for being drunk by people for four seasons, can realize the effect of treatment of diseased people, and health protection of healthy people, is suitable for being drunk by people suffering from throat irritation, tonsils inflammation, acute gastroenteritis, lung heat cough, bronchitis, uncomplete sputum and the like, has an excellent effect after being drunk, and is an ideal and excellent health drink.

Owner:蓝照斓

Aromatic flavored candied syzygium brachyantherum

InactiveCN106538803AEasy to storeIncrease health functionAnthropod material medical ingredientsConfectioneryFruit wineThroat irritation

The invention discloses aromatic flavored candied syzygium brachyantherum. According to the aromatic flavored candied syzygium brachyantherum, syzygium brachyantherum is used as a raw material, and besides, cherry leaves, leontopodium forrestianum and lilium pumilum are added, so that the aromatic flavored candied syzygium brachyantherum is made. The nutrient value of the syzygium brachyantherum is fully utilized, and the syzygium brachyantherum and traditional Chinese medicines are in mutual compatibility and synergistic interaction, so that the aromatic flavored candied syzygium brachyantherum has the efficacies of relieving cough and asthma and removing dysphoria with smothery sensation. According to the aromatic flavored candied syzygium brachyantherum disclosed by the invention, traditional Chinese medicine materials are subjected to primary fermentation with fruit wine distiller's yeast, so that aromatic taste of products is increased, the prepared finished products are aromatic and delicious, fragrant, sweet and tasty, easy to preserve and outstanding in health care functions, and after the aromatic flavored candied syzygium brachyantherum is eaten for a long term, the discomfort of crowds suffering from throat irritation caused by long-term smoking can be obviously alleviated. The aromatic flavored candied syzygium brachyantherum is simple in making technology, easy to realize and notable in economic benefits and social benefits.

Owner:ANHUI LIANZHE JADE & BAMBOO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com