Tobacco shred preparation process capable of improving smoking comfort of cigarettes

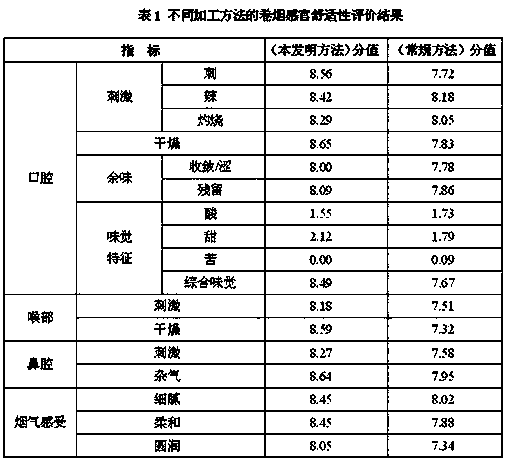

A technology of comfort and craftsmanship, applied in the field of cigarette shred processing, can solve problems such as difficult dissolution, absorption, impact on oral cavity residue, weak water penetration, etc., and achieve the effects of strong solubility, improved internal quality, and high penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

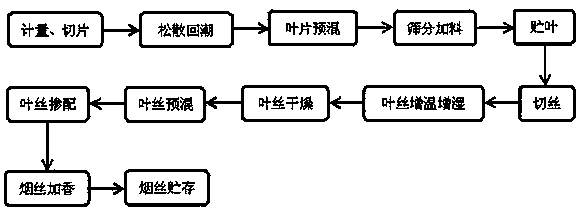

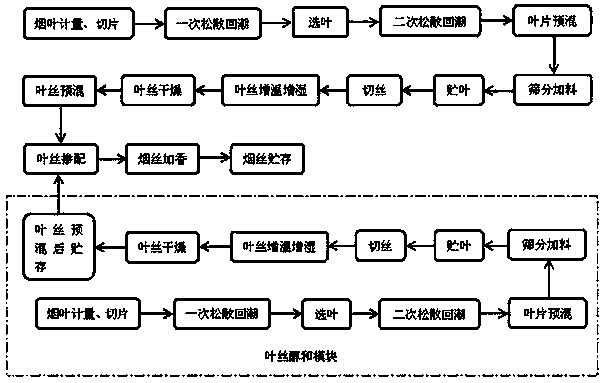

Method used

Image

Examples

Embodiment Construction

[0020] Hereinafter, the present invention will be further described with reference to the accompanying drawings and embodiments, but the embodiments do not limit the technical solutions of the present invention. Any person skilled in the art within the technical scope disclosed in the present invention, equivalent replacements or changes according to the solutions and ideas of the present invention should be covered by the protection scope of the present invention.

[0021] Firstly, 1000kg of drinking natural mountain spring water (provided by Guangdong Zhengenergy Food and Beverage Co., Ltd.) that meets the water quality requirements of GB8537 5.2 is poured into a container containing 8kg of hydrogen-rich activated ceramics (provided by Shandong Muqi Health Technology Co., Ltd.) and soaked for 4 hours. Activated water. The prepared activated water is injected into the storage tank for the first loose moisture regain, the second loose moisture regain, and the screening and feedin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com