Method for growing epitaxial chip of nitride LED structure by MOCVD

A technology of light-emitting diodes and epitaxial wafers, applied in gaseous chemical plating, coating, metal material coating process, etc., can solve problems such as the influence of GaN buffer layer LED structure performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

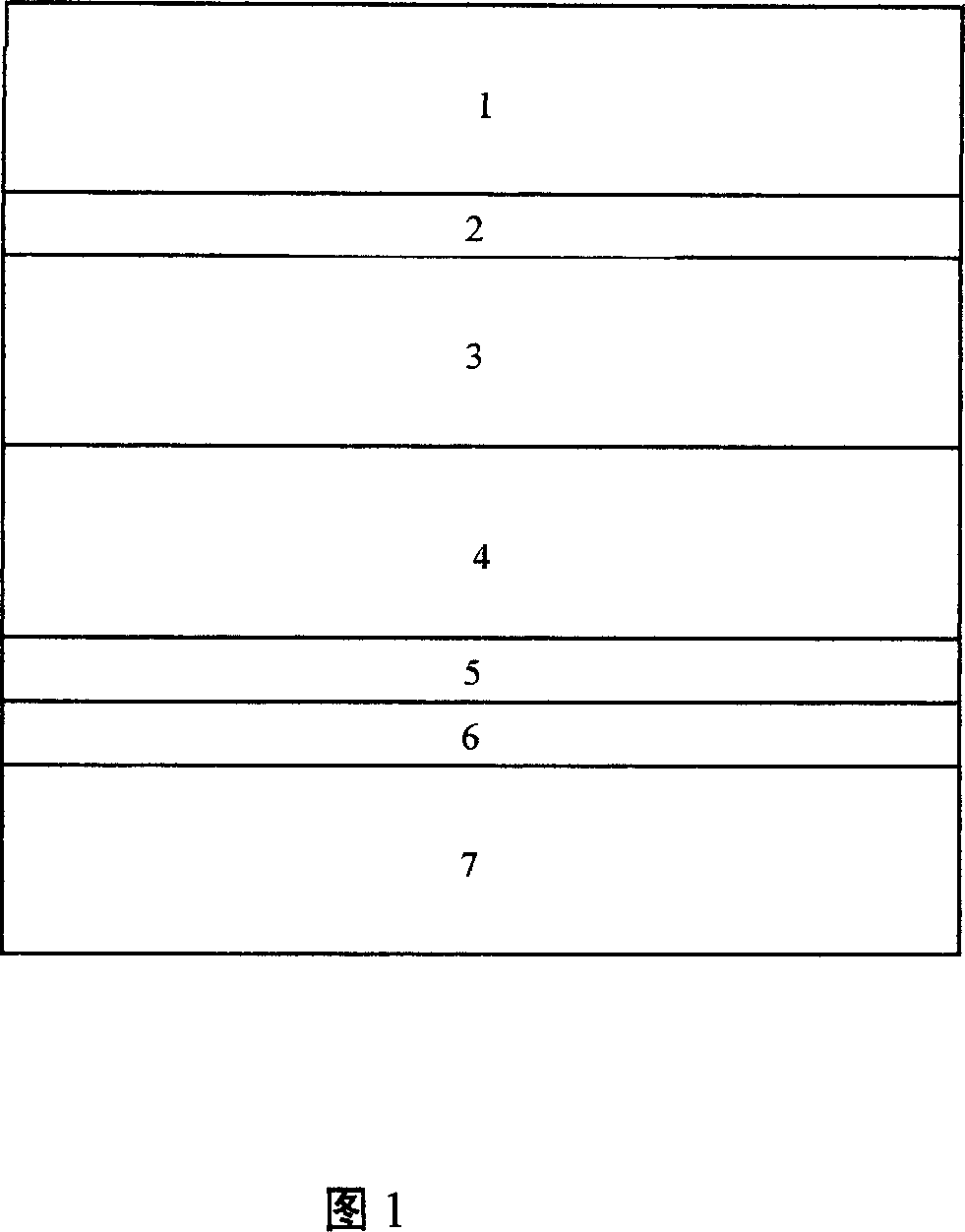

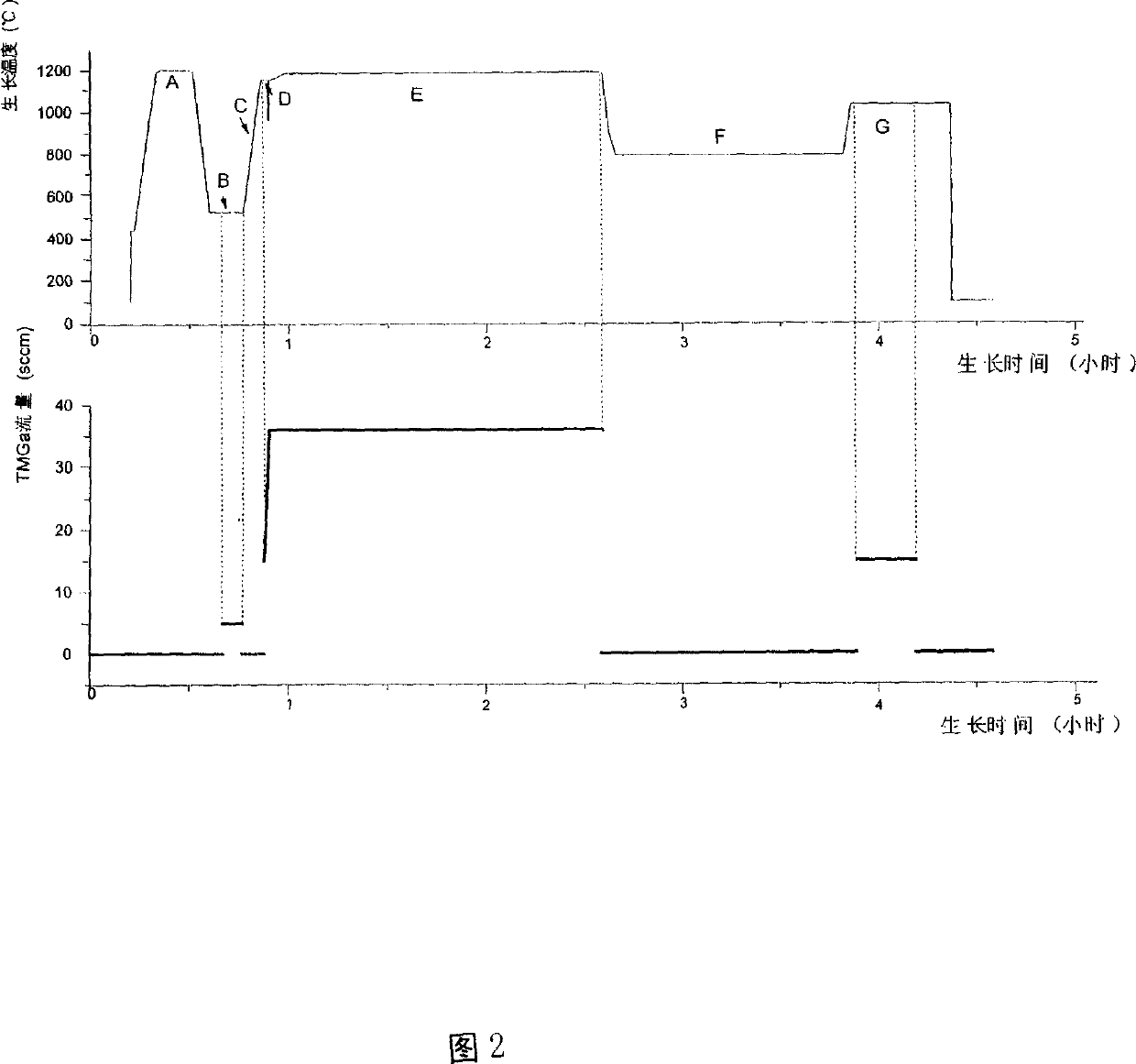

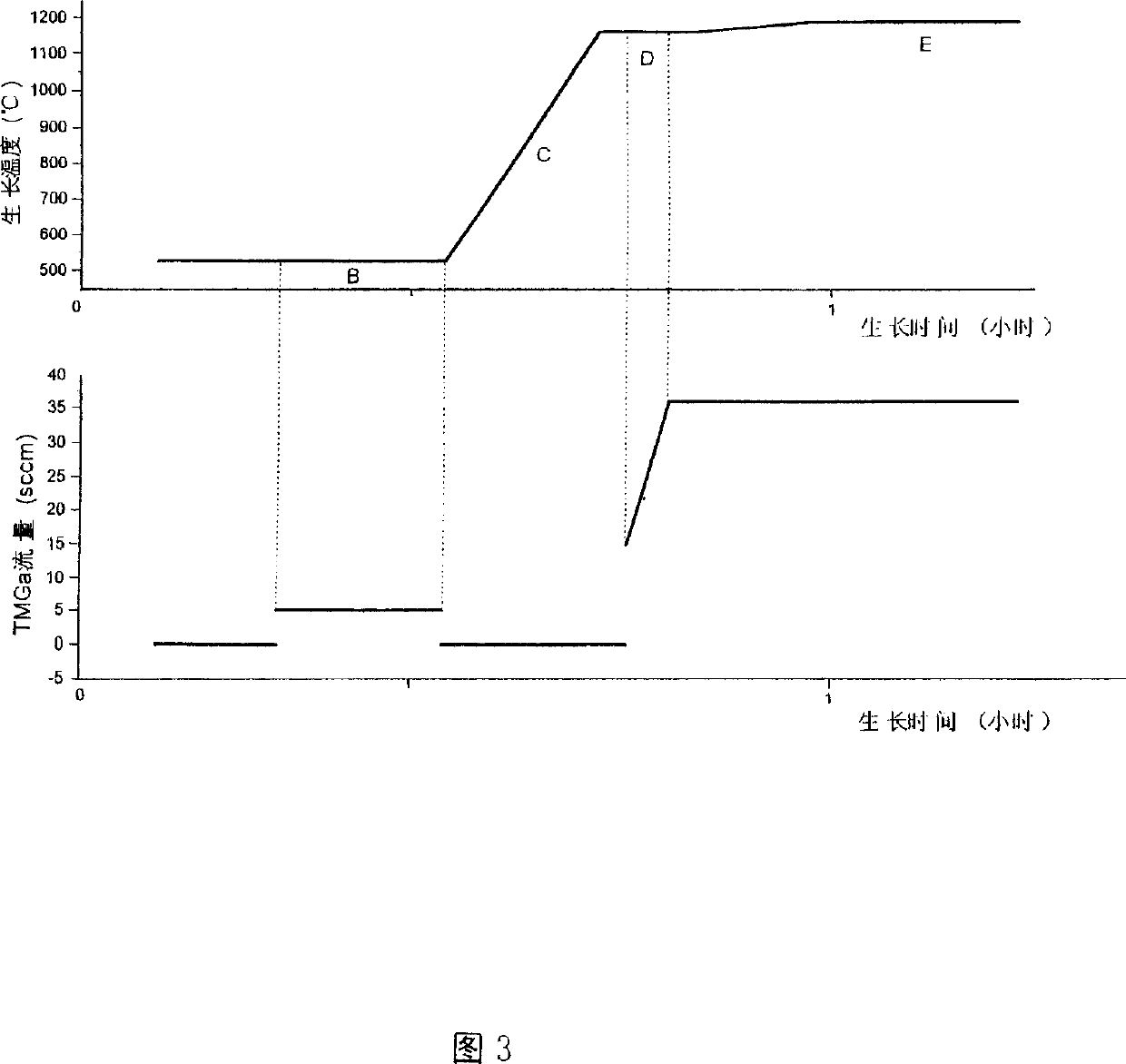

[0023] Using Aix 2000HT MOCVD system to epitaxially grow GaN-based ultra-high brightness LED structure epitaxial wafers. The substrate is (0001) sapphire (Al 2 o 3 ). As shown in Figure 1, first, the substrate 7 is heated to 1200°C, and treated at high temperature under hydrogen for 10 minutes; then the temperature is lowered to 500-540°C to grow a GaN nucleation layer 6, about 25 nanometers, and the flow rate of TMGa is 2.2×10 -5 mol / min, NH 3 The flow rate is 5 liters / minute; thereafter, the growth temperature is raised to 1160° C. to anneal the nucleation layer 6 for 4-8 minutes. After the annealing, at 1160° C., by linearly changing the flow rate of TMGa, the variable-rate epitaxial growth of the GaN buffer layer 5 was started, and the growth time was 90 seconds. TMGa flow from 2-6.63 to 15-20×10 -5 mol / min, NH 3 The flow rate is 3.5 l / min. Thereafter, the growth temperature was increased to 1180° C., and a GaN buffer layer with a thickness of 3.5 microns was grown ...

Embodiment 2

[0025] Using Aix 2000HT MOCVD system to epitaxially grow GaN-based ultra-high brightness LED structure epitaxial wafers. The substrate is (0001) sapphire (Al 2 o 3 ). As shown in Figure 1, first, the substrate 7 is heated to 1200°C, and treated at high temperature under hydrogen for 10 minutes; then the temperature is lowered to 510-540°C to grow a GaN nucleation layer 6, about 25 nanometers, and the flow rate of TMGa is 2.2×10 -5 mol / min, NH 3 The flow rate is 5 liters / minute; thereafter, the growth temperature is raised to 1160° C. to anneal the nucleation layer 6 for 4-8 minutes. After the annealing, at 1160° C., by linearly changing the flow rate of TMGa, the variable-rate epitaxial growth of the GaN buffer layer 5 was started, and the growth time was 90 seconds. TMGa from 2-6.63 to 15-17.7×10 -5 mol / min, NH 3 The flow rate is 3.5 l / min. Thereafter, the growth temperature was increased to 1180° C., and a GaN buffer layer with a thickness of 3.5 microns was grown at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com