Preparation method of compound plant extract capable of promoting salivation and increasing moisture and cold extraction electronic cigarette oil

A plant extract and compound technology, applied in the field of cold-extracted e-liquid, can solve the problems of throat irritation, dry throat, burnt feeling, etc., to enhance the moist feeling of the throat, reduce throat irritation, increase The effect of taste characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

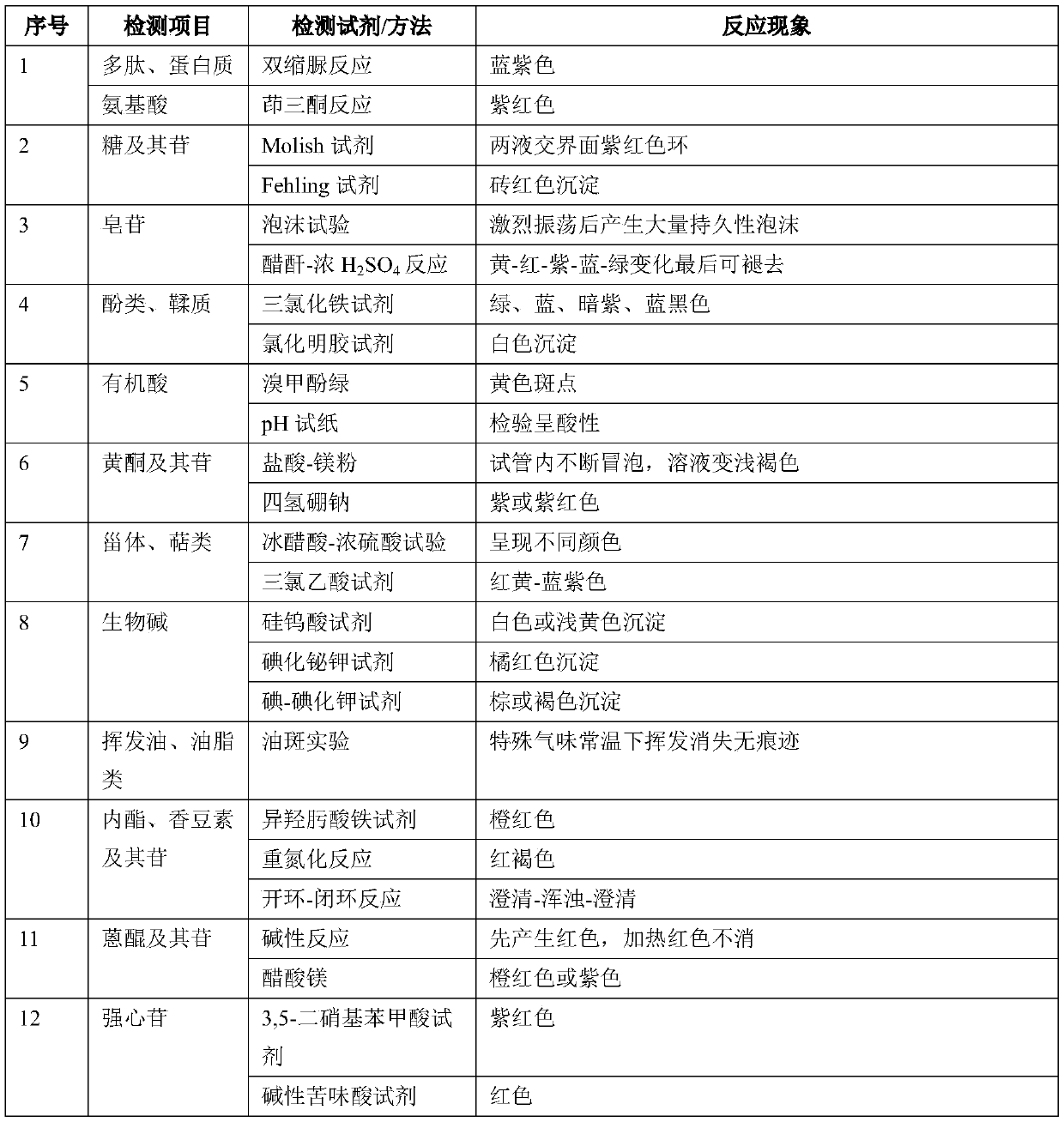

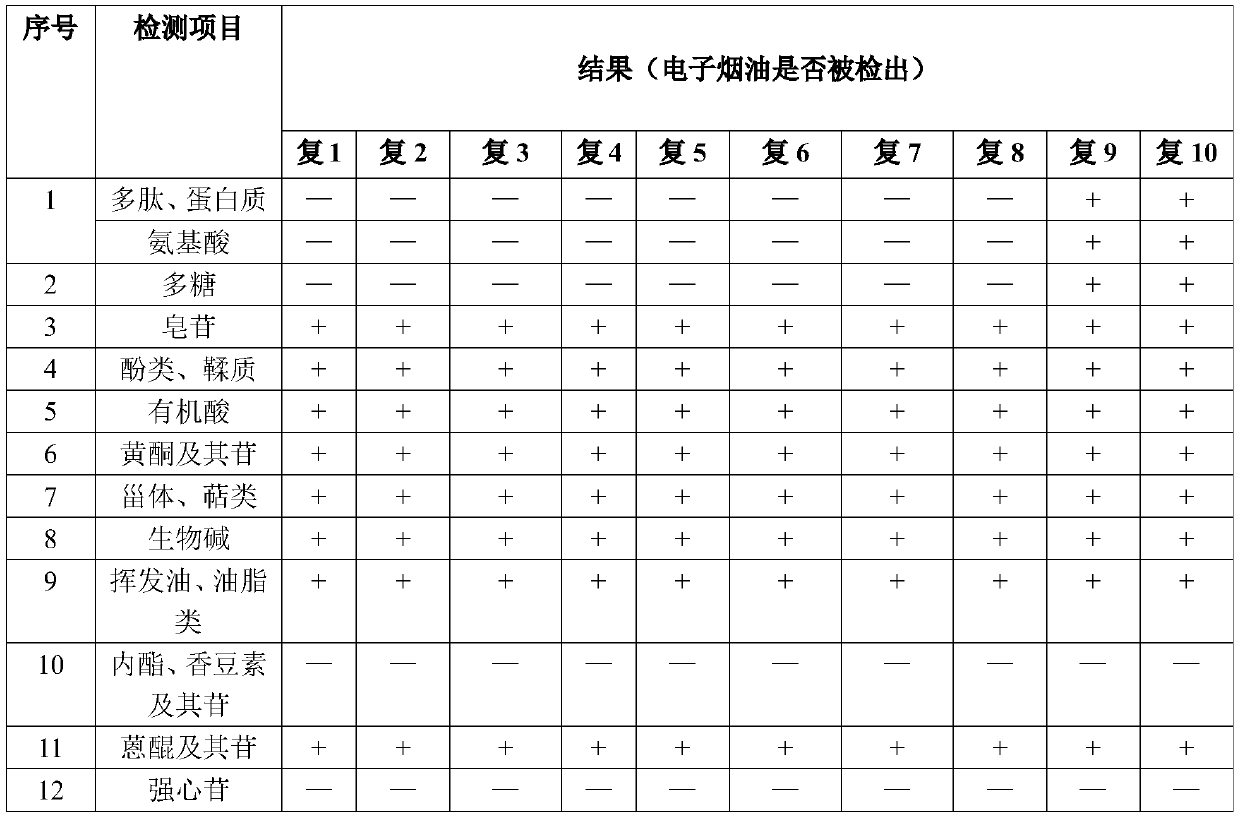

Method used

Image

Examples

Embodiment 1

[0029] Accurately weigh 40g of fresh roses, 220g of honeysuckle, 80g of aloe vera, 250g of green olives, 200g of green plums, and 60g of green tea, and place them on a vacuum freeze dryer at a pre-freezing rate of 0.7℃ / min, drying chamber pressure 84Pa, heating plate Freeze-dried at a temperature of 40℃ for 26 hours, then quickly pulverize, pass through a 120-mesh screen, and load the lyophilized raw material powder into a 2cm*100cm glass chromatography column and connect the glass chromatography column Add 250ml of propylene glycol into the upper liquid storage bottle, open the valve, control the flow rate at 1ml / min, and collect 120ml of extract; the extract is subjected to high-speed refrigerated centrifugation at a temperature of 4℃ and a rotational speed of 8000r / min. Compound plant extract 1; take 2.0 parts of compound plant extract 1, 2.0 parts of leaf alcohol, 1.5 parts of melon aldehyde, 3.5 parts of phenethyl alcohol, 6.0 parts of linalool, 2.0 parts of leaf alcohol ac...

Embodiment 2

[0031] Accurately weigh 35g of fresh roses, 180g of honeysuckle, 60g of aloe vera, 230g of green olives, 180g of green plums, and 40g of green tea, and place them on a vacuum freeze dryer at a pre-freezing rate of 0.6°C / min, drying chamber pressure 88Pa, heating plate After being freeze-dried for 30 hours at a temperature of 38℃, the powder is quickly pulverized, and the lyophilized raw material powder is loaded into a 2.5cm*80cm glass chromatography column through a 120-mesh screen and connected to the glass chromatography Add 250ml of propylene glycol into the reservoir on the top of the column, open the valve, control the flow rate at 1.5ml / min, and collect 100ml of extract; freeze the extract at a high speed at a temperature of 4℃ and a rotation speed of 5000r / min Centrifuge to obtain compound plant extract 2; take 4.0 parts of compound plant extract 2, 3.0 parts of leaf alcohol, 2.0 parts of melon aldehyde, 3.0 parts of phenethyl alcohol, 5.0 parts of linalool, 2.5 parts of...

Embodiment 3

[0033] Accurately weigh 48g of fresh roses, 160g of honeysuckle, 50g of aloe vera, 230g of green olives, 160g of green plum, and 35g of green tea. Place them on a vacuum freeze dryer at a pre-freezing rate of 0.8℃ / min, drying chamber pressure 75Pa, heating plate After 42 hours of freeze-drying at a temperature of 45°C, it is quickly pulverized, and the lyophilized raw material powder is loaded into a 2.5cm*80cm glass chromatography column through a 200-mesh screen, and connected to the glass chromatography Add 220ml of propylene glycol to the reservoir on the top of the column, open the valve, control the flow rate at 2.0ml / min, collect 150ml of extract, and perform high-speed refrigerated centrifugation at a temperature of 25°C and a rotation speed of 10000r / min. Compound plant extract 3; take 6.0 parts of compound plant extract 3, 2.8 parts of leaf alcohol, 2.2 parts of melon aldehyde, 3.5 parts of phenethyl alcohol, 6.8 parts of linalool, 2.4 parts of leaf alcohol acetate, 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com