Method for preparing waxberry extract for cigarette by immobilized saccharomycetes

A technology of yeast and extract, which is applied in the field of preparation of bayberry extract for tobacco, to achieve the effects of strong anti-toxicity, increased fruity sweet aroma, and reduced irritation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

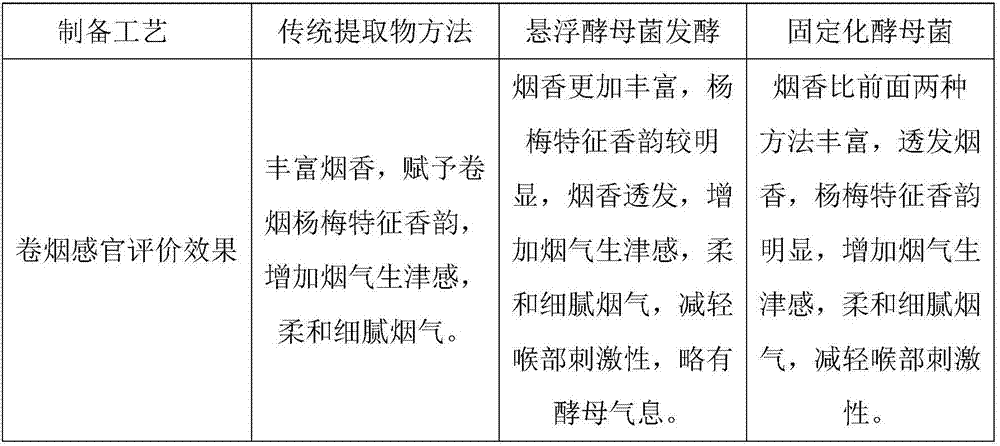

Method used

Image

Examples

Embodiment 1

[0020] (1) Take fresh bayberry, remove the core, squeeze the juice, sterilize at 121°C for 20 minutes, cool, and filter to obtain bayberry juice;

[0021] (2) Saccharomyces bacterium suspension preparation: inoculate saccharomycete in broth culture medium, the specific formula of broth culture medium is (per liter): peptone 10g, beef extract powder 3g, sodium chloride 5g, final pH7. 3±0.1, cultured for 48 hours at a temperature of 37°C and a stirring speed of 50 rpm, took the culture solution and centrifuged at 8000 rpm, and the wet cells after centrifugation were used for later use;

[0022] (3) Sodium alginate-CaCl of yeast 2 Immobilization: Prepare a sodium alginate solution with a mass fraction of 4%, and then add 3% of its volume of the yeast wet cell prepared in the step (2) to prepare a mixed solution, and use a peristaltic pump to pass through a 1mm aperture Add the prepared mixture dropwise to the CaCl with a mass fraction of 3% 2 solution, into balls, and the CaCl ...

Embodiment 2

[0026] (1) Take fresh bayberry, remove the core, squeeze the juice, sterilize at 121°C for 20 minutes, cool, and filter to obtain bayberry juice;

[0027] (2) Saccharomyces bacterium suspension preparation: inoculate saccharomycete in broth culture medium, the specific formula of broth culture medium is (per liter): peptone 10g, beef extract powder 3g, sodium chloride 5g, final pH7. 3±0.1, cultured for 48 hours at a temperature of 37°C and a stirring speed of 50 rpm, took the culture solution and centrifuged at 8000 rpm, and the wet cells after centrifugation were used for later use;

[0028] (3) Sodium alginate-CaCl of yeast 2 Immobilization: Prepare a sodium alginate solution with a mass fraction of 5%, then add 4% of its volume of the yeast wet cell prepared in the step (2), prepare a mixed solution, and use a peristaltic pump to pass through a 3mm aperture Add the prepared mixture dropwise to the CaCl with a mass fraction of 4% 2 solution, into balls, and the CaCl 2 The...

Embodiment 3

[0032] (1) Take fresh bayberry, remove the core, squeeze the juice, sterilize at 121°C for 20 minutes, cool, and filter to obtain bayberry juice;

[0033] (2) Saccharomyces bacterium suspension preparation: inoculate saccharomycete in broth culture medium, the specific formula of broth culture medium is (per liter): peptone 10g, beef extract powder 3g, sodium chloride 5g, final pH7. 3±0.1, cultured for 48 hours at a temperature of 37°C and a stirring speed of 50 rpm, took the culture solution and centrifuged at 8000 rpm, and the wet cells after centrifugation were used for later use;

[0034] (3) Sodium alginate-CaCl of yeast 2 Immobilization: Prepare a sodium alginate solution with a mass fraction of 5%, then add 5% of its volume of the yeast wet cell prepared in the step (2), prepare a mixed solution, and use a peristaltic pump to pass through a 4mm aperture Add the prepared mixed solution drop by drop to the CaCl with a mass fraction of 6%. 2solution, into balls, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com