Patents

Literature

150 results about "Tobacco leaf extract" patented technology

Efficacy Topic

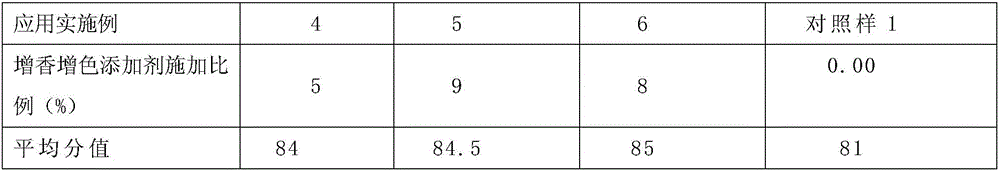

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Officinal health-care solid electronic aerosolization liquid and preparation method thereof

The invention provides an officinal health-care solid electronic aerosolization liquid, mainly comprising the following components by weight percent: 35-45% of propylene glycol, 30-35% of medicament, 10-15.0% of deionized water, 3-3.5% of tobacco leaf extract solution, 3-3.5% of tobacco flavour, 2-3.0% of excipient, 0.2-1.0% of calcium pectate and 0.3-0.8% of curing agent. The invention also provides a preparation method of the officinal health-care solid electronic aerosolizatioon liquid. The invention contains multiple officinal components having treating function on lungs, thus having treating function on symptoms such as dryness and itch of the throat and irritable cough which are caused by smoking, chronic pharyngitis and dryness of mouth and nose, thirst and dry cough, less sputum or distressed cough caused by the fact that sputum is glued; meanwhile the invention is solid, thus the stability of storing and use is improved, production and transportation are more convenient and flexible, and fragrance can be remained to be more complete.

Owner:FEELLIFE BIOSCI INT

Medicinal health type tobacco juice for electronic smoke

InactiveCN101461565AEasy to carryEasy to useOrganic active ingredientsTobacco treatmentPassive smokingItchy throat

The invention discloses a health-care electronic cigarette liquid for medical use, which mainly comprises: 3-5%w / v of tobacco leaf extract, 40-50%w / v of propanediol, 10-15%w / v of pure water, 3-5%w / v of tobacco essence, 0.2-1.0%w / v of stabilizer, 3-8%w / v of thickener, 15-20%w / v of medicament. Because of no harm of second-hand smoke, the invention can be used at public places without influence to body health of others. The invention is capable of treating cough, hacking cough, itchy throat, abundant expectoration, sensitive cough cause by acute upper respiratory tract infection of fever, influenza or the like while enjoying smoking, having treatment function to oral therapy, cough relieving, nasal and pharyngeal mucosa congestive swelling relieving and sneezing.

Owner:深圳来福士雾化医学有限公司

Electronic cigarette liquid prepared from strong-flavor tobacco

The invention discloses an electronic cigarette liquid prepared from strong-flavor tobacco. The liquid is made by mixing 10% to 30% of strong-flavor tobacco leaf extract, 5% to 10% flavoring essence for tobacco, 1% to 5% flavoring spices for tobacco, 5% to 10% deionized water, 10% to 20% glycerol, and the balance being propylene glycol. The strong-flavor tobacco leaf extract is selected from the group consisting of strong-flavor flue-cured tobacco leaf extract in Henan, Anhui, Guangxi, Guangdong and Hunan, or the mixtures thereof. The electronic cigarette liquid takes the strong-flavor tobacco leaf extract as a main component, so that the smell and the taste of electronic cigarettes are closer to the traditional cigarette. The electronic cigarette liquid is used for atomization of the electronic cigarettes without production of tar or carbon dioxide, so that the harm to consumers is greatly reduced and the harm of second-hand smoke is avoided.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

Pulping and extracting process for regenerated tobacco leaves

The invention relates to a pulping and extracting process for regenerated tobacco leaves, in particular to a process for preparing the regenerated tobacco leaves by using low-quality and waste tobacco raw materials which cannot be directly applied to producing cigarette products and by using a paper-making process of presoaking, pulping and extracting and countercurrent pulp washing. The process comprises the following steps of: presoaking tobacco leaf flakes and tobacco stalks which serve as raw materials; and directly performing pulping and extraction, countercurrent pulp washing, concentration and pulp mixing on the soaked materials. Compared with the conventional production process, the process has the advantages of accelerating lixiviation of the tobacco raw materials and dissolution of tobacco extract, and saving two to three steps of extraction process, an extractor before pulping and a spiral shoving separation system (inclined and flat helix) so as to simplify a tobacco regenerating process and equipment operation and flow and enhance dissolution and separation of the tobacco extract. By the step of countercurrent pulp washing, the tobacco raw materials can be extracted at a low temperature and the soluble extract in the raw materials can be recovered; extraction yield and leach liquor quality of the regenerated tobacco leaves are improved; load of treating sewage during generated tobacco leaf production is greatly reduced; and environmental friendliness, low carbon and energy conservation of the generated tobacco leaf production are realized.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Electronic cigarette liquid prepared from flat-flavor tobacco

The invention discloses an electronic cigarette liquid prepared from flat-flavor tobacco. The liquid is made by mixing 10% to 30% of flat-flavor tobacco leaf extract, 5% to 10% flavoring essence for tobacco, 1% to 5% flavoring spices for tobacco, 5% to 10% deionized water, 10% to 20% glycerol, and the balance being propylene glycol. The flat-flavor tobacco leaf extract is selected from the group consisting of flat-flavor flue-cured tobacco leaf extract in Guizhou, Sichuan, Shandong, Hubei, Heilongjiang, Liaoning and Jilin, or the mixtures thereof. The electronic cigarette liquid takes the flat-flavor tobacco leaf extract as a main component, so that the smell and the taste of electronic cigarettes are closer to the traditional flat-flavor cigarette. The electronic cigarette liquid is used for atomization of electronic cigarettes without production of tar or carbon dioxide, so that the harm to consumers is greatly reduced and the harm of second-hand smoke is avoided.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

Method for preparing tobacco-characteristic-taste tobacco flavor material and electronic cigarette fluid containing tobacco flavor material

ActiveCN105595411ACapture completelyImprove qualityTobacco treatmentEssential-oils/perfumesDistillationLiquid smoke

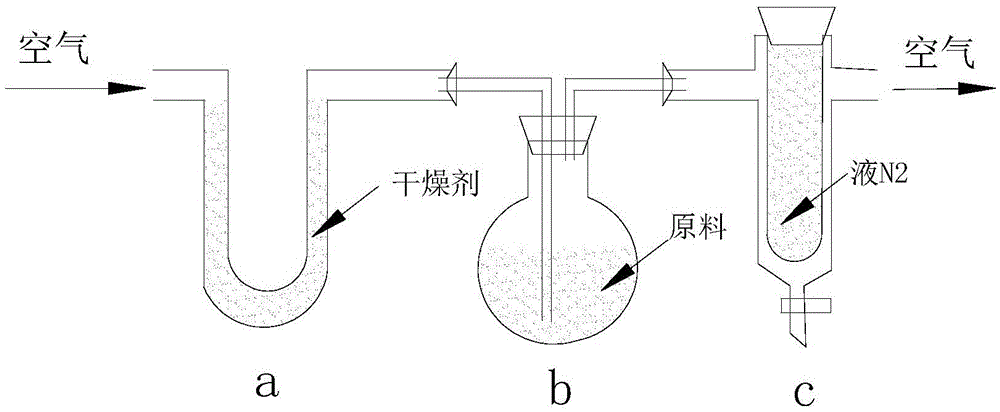

The invention provides a method for preparing a tobacco-characteristic-taste tobacco flavor material. The method comprises the following steps of choosing a raw tobacco material as a backing material, evenly spraying an atomizing agent on the surface of the raw tobacco material, standing, putting the backing material into a dry distilling device after the backing material is fully infiltrated by the atomizing agent, distilling the backing material under the temperature between 150 DEG C and 300 DEG C to obtain aromatic components, inducing dry air into the dry distilling device in distillation and catching the aromatic components through a condensing device to obtain the tobacco flavor material. The invention further provides electronic tobacco fluid which comprises basic tobacco fluid formed by essences, nicotine, glycerinum and propylene glycol in a mixing manner. The flycerinum and the propylene glycol serve as solvents, the tobacco flavor material and tobacco extracts are added into the basic tobacco fluid, the tobacco extracts comprise a red sun-cured tobacco reactant and a Zimbabwe tobacco extractive, and the essences comprise ethyl maltol and 2(H) beta-ionone. According to the tobacco flavor material prepared through a dry distilling-condensing catching method, a preparing process of the tobacco flavor material is closer to a burning and smoking process of traditional cigarettes, and the smoking taste of the tobacco flavor material is closer to the smoking taste of the traditional cigarettes.

Owner:HUBEI CHINA TOBACCO IND

Regulation and control method for paper-making method reproducing tobacco leaf extract liquor negative ion components

InactiveCN103082394ASimple production processImprove controllabilityTobacco preparationTobacco treatmentCombustionAdditive ingredient

The invention discloses a regulation and control method for paper-making method reproducing tobacco leaf extract liquor negative ion components. Extract liquor of paper-making method reproducing tobacco leaf raw materials such as cabo, tobacco powder and low-grade tobacco leaves is processed through an ionic membrane separation technique. Contents of inorganic negative ions in the reproducing tobacco leaf extract liquor are adjusted to improve the quality of paper-making method reproducing tobacco leaves, and injurious ingredient contents of the paper-making method reproducing tobacco leaf smoke are reduced. The regulation and control method for the paper-making method reproducing tobacco leaf extract liquor negative ion components is a negative ion removing method which is simple in manufacturing technique, strong in controllability, high in selectivity , stable in quality, capable of being widely applied to the removing method for removing the inorganic negative ions in the paper-making method reproducing tobacco leaf extract liquor, and therefore combustion performance, sensory quality and smoke injurious ingredient releasing quantity of the paper-making method reproducing tobacco leaves can be improved.

Owner:CHINA TOBACCO ANHUI IND CO LTD

Electronic cigarette liquid prepared from discarded tobacco

The invention discloses an electronic cigarette liquid prepared from discarded tobacco. The liquid is made by mixing 10% to 15% of discarded tobacco leaf extract, 5% to 10% flavoring essence for tobacco, 1% to 5% flavoring spices for tobacco, 5% to 10% deionized water, 10% to 20% glycerol, and the balance being propylene glycol. An effective way is provided to use of the discarded tobacco, so that the utilization rate can be increased and waste of resources and environmental pollution can be reduced. The electronic cigarette liquid takes the discarded tobacco leaf extract as a main component, so that the sensory quality of electronic cigarette is closer to the traditional cigarette. The electronic cigarette liquid is used for atomization of electronic cigarettes without generation of tar or carbon dioxide, so that the harm to consumers is greatly reduced, and harm of second-hand smoke is avoided.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

Electronic cigarette liquid

InactiveCN105455190ALow sweetnessSmooth tasteTobacco treatmentEssential-oils/perfumesLiquid smokeIrritation

The invention provides an electronic cigarette liquid. The electronic cigarette liquid comprises basic cigarette liquid formed by mixing tobacco extract, tobacco essence, glycerin solvent, propylene glycol and water. The electronic cigarette liquid is characterized in that nicotine salt or a mixture thereof or a mixture of the nicotine salt and nicotine is added to the basic cigarette liquid, the nicotine salt comprises citric acid nicotine, dipicric acid nicotine salt, tartaric acid nicotine salt and nicotine hydrochloride, the tobacco extract comprises red sun-cured tobacco reactants and Zimbabwe tobacco extract, and the tobacco essence comprises ethyl maltol and dihydro ionone beta. According to the electronic cigarette liquid, the nicotine salt or the mixture thereof or the mixture of the nicotine salt and the nicotine is added to the electronic cigarette liquid, strong irritation brought by only adding the nicotine to mucosa can be avoided on the condition that the same physiological intensity is provided, the red sun-cured tobacco reactants, the Zimbabwe tobacco extract, the ethyl maltol and the dihydro ionone beta can provide characteristic flavor of tobacco, and the smoking flavor of the electronic cigarette liquid can be made close to traditional cigarettes.

Owner:HUBEI CHINA TOBACCO IND

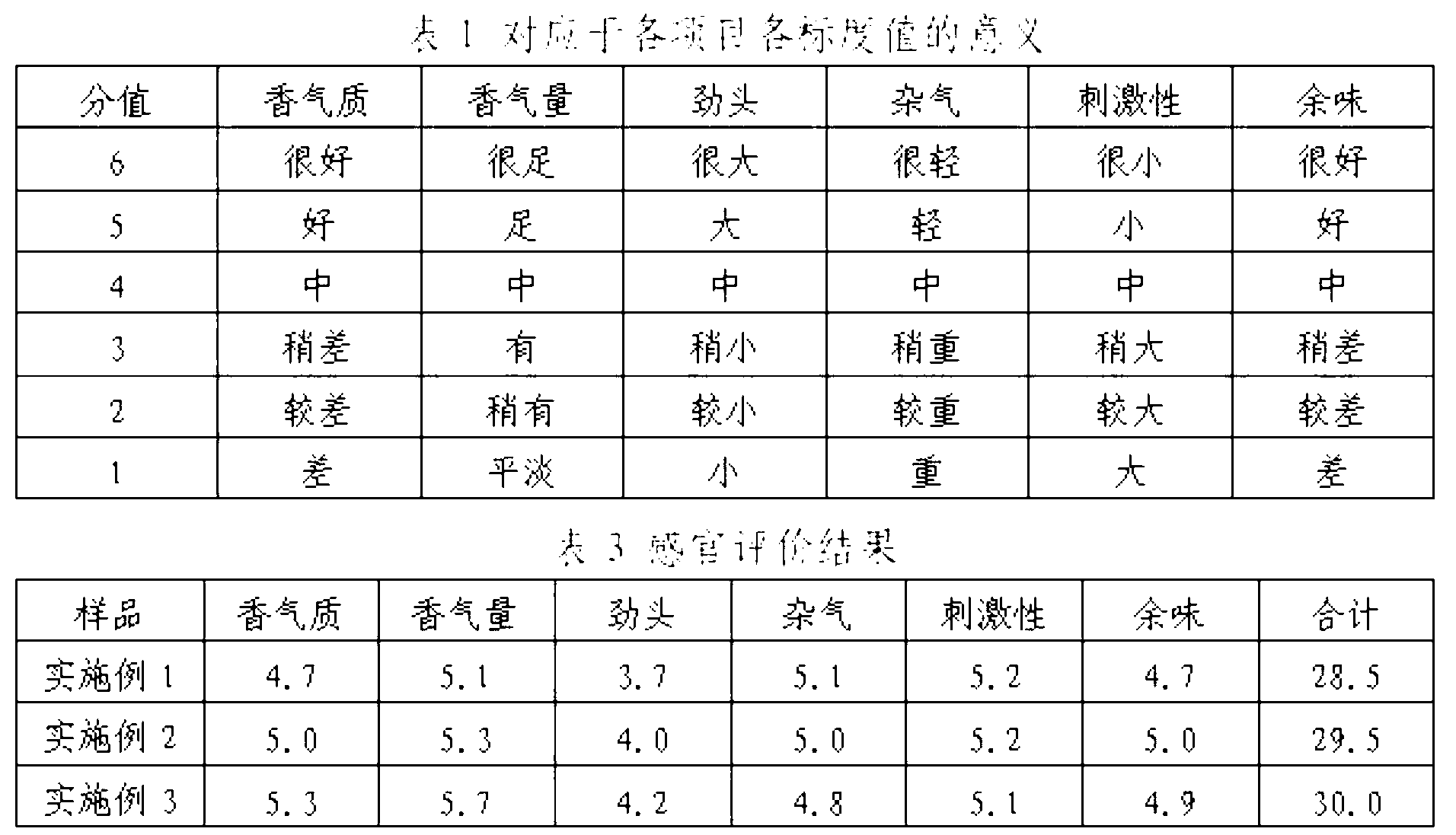

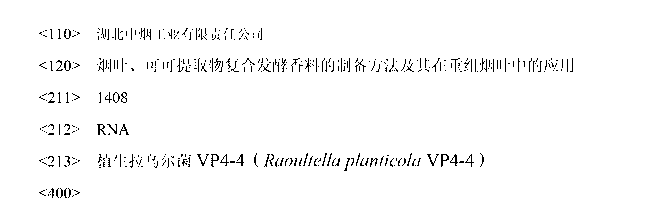

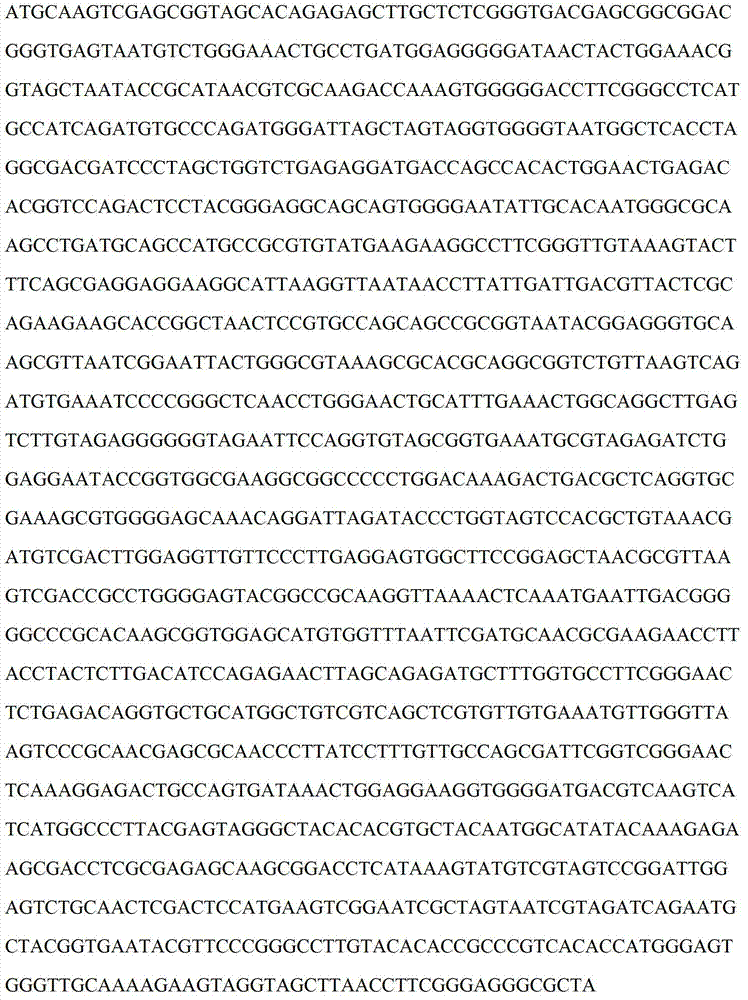

Tobacco leaf extract and cocoa extract composite fermentation perfume preparation method and applications of tobacco leaf extract and cocoa extract composite fermentation perfume in recombinant tobacco leaf

ActiveCN102978127AEasy to produce fragranceNatural, environmentally friendly and harmlessTobacco preparationBacteriaFlavorCocoa Extract

The present invention discloses a tobacco leaf extract and cocoa extract composite fermentation perfume preparation method and applications of a tobacco leaf extract and cocoa extract composite fermentation perfume in recombinant tobacco leaf. According to the present invention, a name of the strain is Raoultella planticola VP4-4, a preservation number is CCTCC M 2012005, the total 16SrRNA sequence length is 1408 bp, and similarity between the 16SrRNA sequence and Raoultella planticola is 99.563%. According to the method, the Raoultella planticola VP4-4 is adopted, and bacteria seed activation, seed culture liquid preparation, fermentation culture and fermentation solution transformation are performed to obtain the tobacco leaf extract and cocoa extract composite fermentation concrete. With the present invention, the process is simple, the raw materials are the cigarette product origin tobacco leaves and cocoa perfumes capable of applying in cigarettes, and the method has an industrial application prospect.

Owner:HUBEI CHINA TOBACCO IND

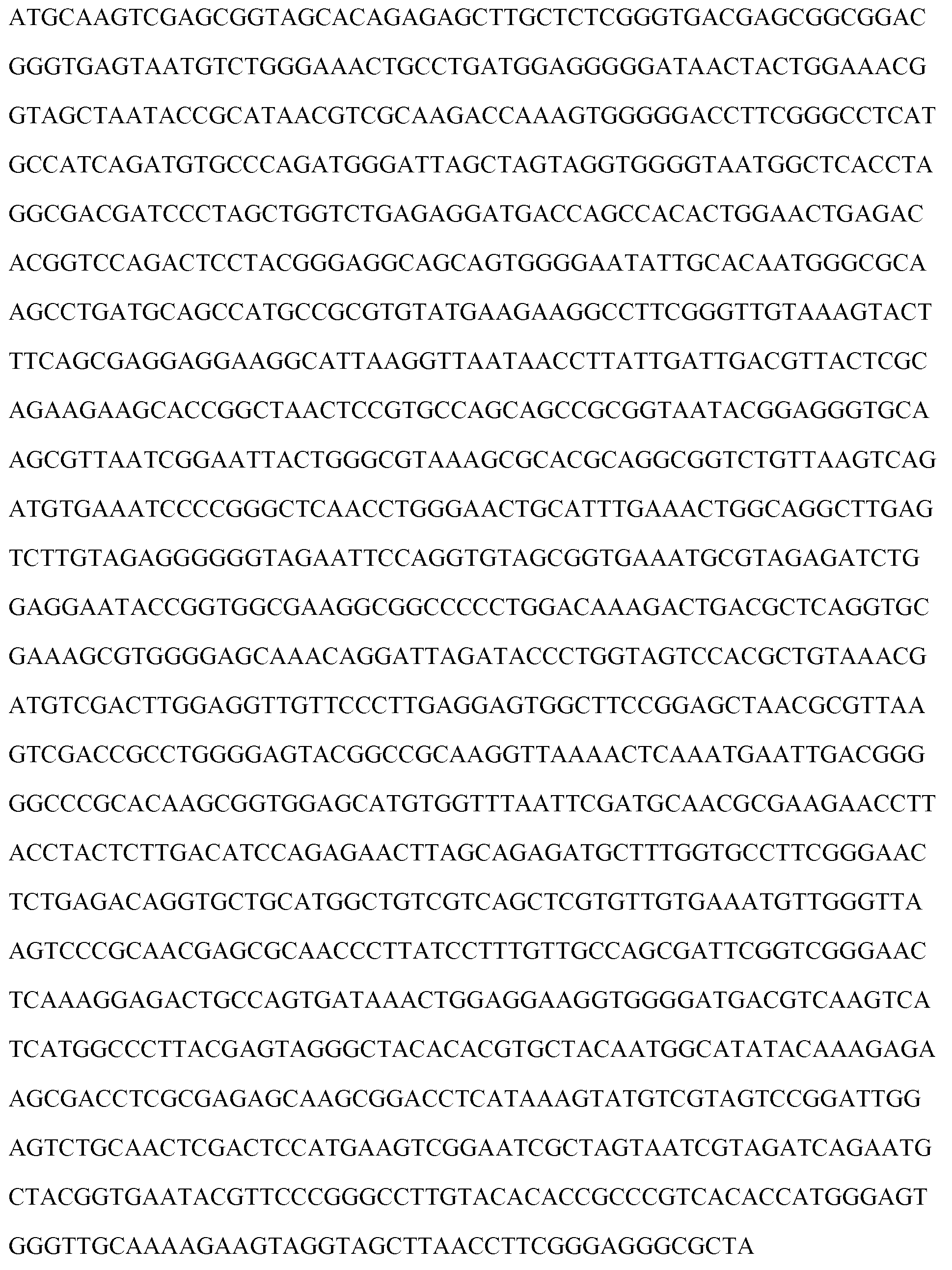

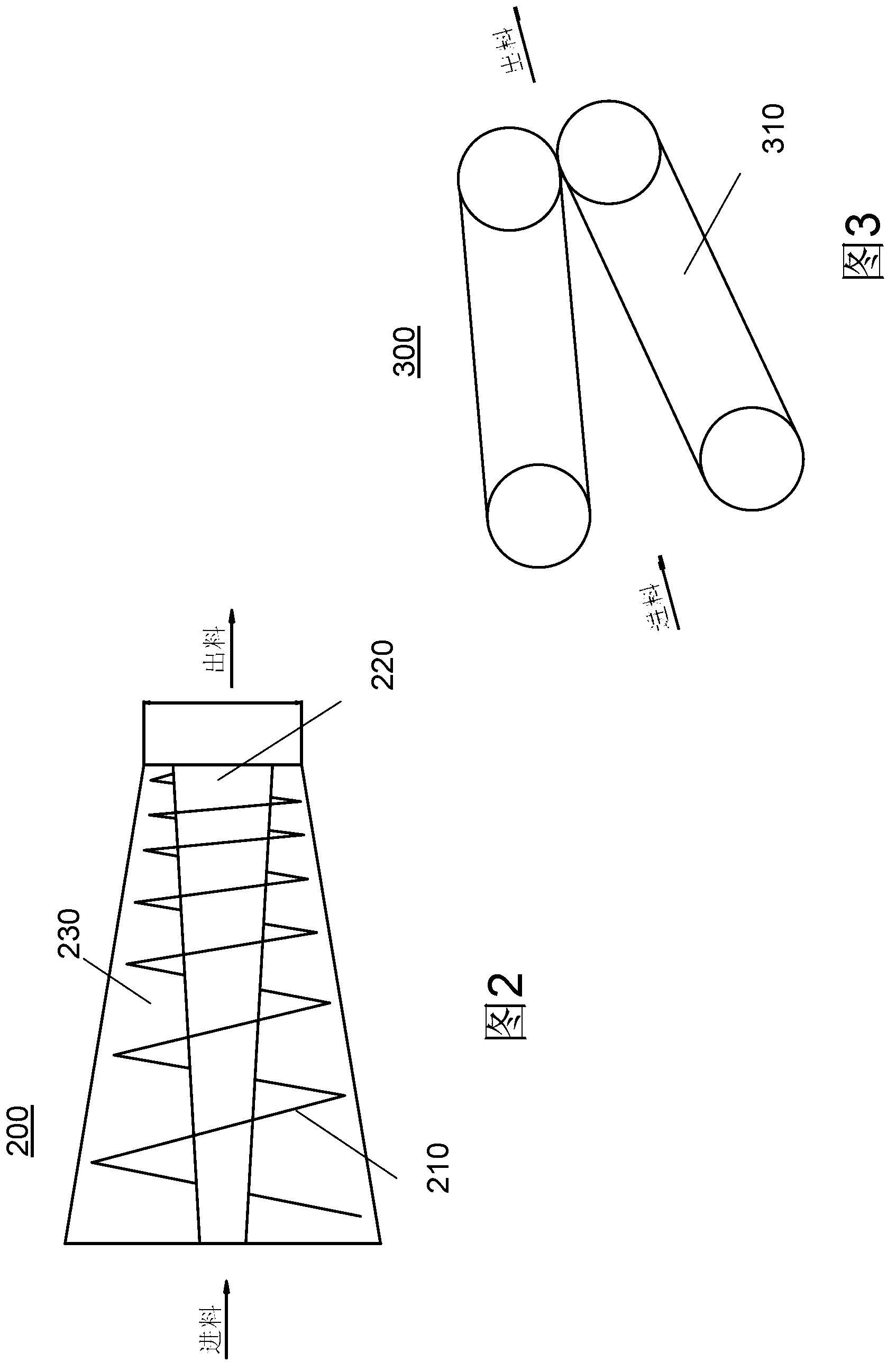

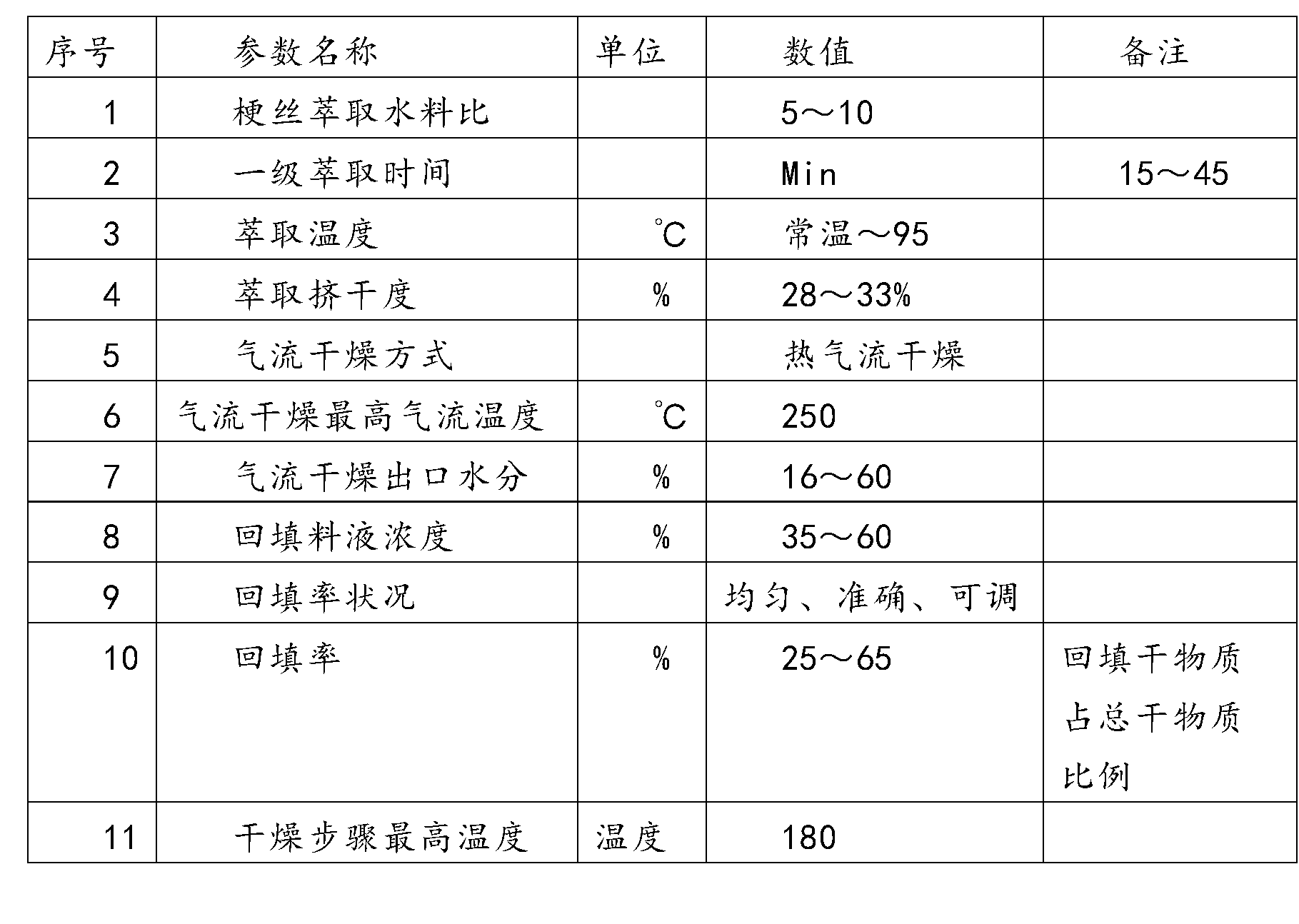

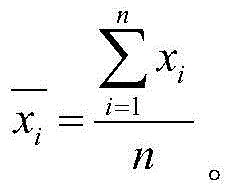

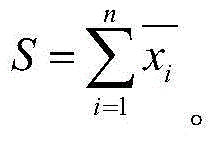

Method for reconstructing tobacco cut-stems by using tobacco leaves

ActiveCN102920012AImprove qualityImprove the compatibility of cigarettesTobacco treatmentNicotiana tabacumEngineering

The invention discloses a method for reconstructing tobacco cut-stems by using tobacco leaves. The method disclosed by the invention comprises the following steps of: respectively carrying out extraction on tobacco cut-stems with poor cigarette compatibility and tobacco leaves with good cigarette compatibility, so that soluble substances of the tobacco cut-stems and soluble substances of the tobacco leaves are extracted, and a tobacco leaf extracting solution containing the soluble substances of the tobacco leaves is obtained; and then filling the tobacco leaf extracting solution back to the tobacco cut-stems subjected to extraction. According to the invention, through a substitutional way, related substances in tobacco leaves are substituted to the insides of tobacco cut-stems, thereby improving the cigarette compatibility of the tobacco cut-stems.

Owner:上海德明生物科技有限公司

Blast bead capable of making up for deficiencies in cigarette fragrance and moist sense and preparation method of blast bead

InactiveCN106036998AGreat suctionEasy to operateTobacco smoke filtersEssential-oils/perfumesDihydroactinidiolideGLYCERYL CAPRYLATE-CAPRATE

The invention relates to the technical field of cigarette blast beads, and in particular discloses a blast bead capable of making up for deficiencies in cigarette fragrance and moist sense and a preparation method of the blast bead. The blast bead is characterized by consisting of essence and a blast bead rubber cover solution, wherein the essence consists of the following components in percentage by weight: 75-90% of a Zimbabwe tobacco leaf extract, 0.1-4% of dihydroactinidiolide, 1-2% of rose essential oil, 0.5-3% of jujube essential oil and the balance of propylene glycol; the blast bead rubber cover solution is a mixed solution of 10% of paraffin oil and 90% of glyceryl caprylate-caprate; and the proportions of the essence and the blast bead rubber cover solution are as follows: 0.5-2% of the essence and the balance of blast bead rubber cover solution. The blast bead disclosed by the invention has the following advantages: the blast bead is prepared the Zimbabwe tobacco leaf extract, so that the fragrance generated by the blast bead can be combined with fragrance of cigarette; the blast bead is natural and smooth in fragrance and good in effect; the blast bead, when applied to a cigarette filter, has a quite outstanding smoking effect; and the difficulties of being insufficient in fragrance and dry in mouthfeel can be scientifically, reasonably and skilfully solved.

Owner:江苏浩丰生物科技有限公司

Preparation method of tobacco-aroma electronic cigarette liquid

ActiveCN104026734AReduce lossesIncrease the fragranceTobacco treatmentTobacco devicesMaillard reactionFiltration

The invention discloses a preparation method of tobacco-aroma electronic cigarette liquid. The preparation method includes: shredding tobacco leaves, using water and 95% ethanol as solvents for heating and extracting, performing hot filtration, cold storage, sedimentation and filtration to obtain tobacco extract, and concentrating to obtain tobacco leaf concrete; then weighing 5g of tobacco leaf concrete mixture with the weight ratio between the tobacco leaf concrete and amino acids of 10-2:1 and 100g of mixed solvent, putting the tobacco leaf concrete mixture into the solvent, and heating at the temperature of 80-100 DEG C for 3 to 12 hours to obtain a Maillard reaction product of the tobacco leaf extract; measuring the Maillard reaction product of dark red transparent liquid, peppermint oil and glycerin monostearate according to volume percents of 1-25%:0-40%:0-1%, supplying with propylene glycol or polyethylene glycol to the volume of 100%, and uniformly stirring to obtain the electronic cigarette liquid. By the method, aroma components enter the electronic cigarette liquid, tobacco feature aroma is given to the electronic cigarette liquid, irritation brought by an atomization agent is better covered, and the electronic cigarette liquid is closer to smoking feeling of consumers to true cigarettes.

Owner:CHINA TOBACCO GUANGXI IND

Fen-flavor electronic tobacco liquid

InactiveCN104544553AImproved taste and aromaGreat tasteTobacco treatmentTobacco devicesFlavorLiquid smoke

The invention provides a fen-flavor electronic tobacco liquid. Raw materials comprise the following components in weight by percentage: 30 percent of tobacco extracts, 0.5 to 10 percent of tobacco essence, 0. 5 to 15 percent of fen-flavor liquor, 0.5 to 10 percent of flavor-adjusting agent, 1 to 15 percent of deionized water, 1 to 25 percent of edible glycerin, and the balance of propylene glycol. According to the fen-flavor electronic tobacco liquid, the extracts of tobacco stored in a fen-flavor liquor cellar are taken as the raw material, and the flavor-adjusting agent and the fen-flavor liquor are adopted, so that the tobacco liquid is not only rich in tobacco flavor, but also full of unique faint scent. The tobacco liquid can meet the flavor and fragrance demands of users, the flavor and the fragrance of the traditional electronic tobacco liquid can be improved, the flavor and the fragrance gap between electronic tobacco liquid and the traditional cigarette can be reduced, and the tobacco liquid can further meet electronic tobacco requirements of the users.

Owner:CHINA TOBACCO GUIZHOU IND

Electronic mouth cavity atomized liquid using multi-element ethanediol series lower alcohols as base solution

The invention discloses electronic mouth cavity atomized liquid using multi-element ethanediol series lower alcohols as a base solution. The electronic mouth cavity atomized liquid is composed of 3%w / v to 5%w / v of tobacco leaf extracts, 30%w / v to 80%w / v of the lower alcohols, 5%w / v to 10%w / v of pure water, 3%w / v to 5%w / v of tobacco essence, 0%w / v to 3%w / v of nicotine, 0.2%w / v to 1.0%w / v of stabilizers, 3%w / v to 8%w / v of thickeners and 15%w / v to 20%w / v of taste modifiers, wherein the lower alcohols are the mixtures of triethylene glycol and / or tetraethylene glycol and / or pentaethylene glycol and / or hexaethylene glycol and / or heptaethylene glycol and / or octaethylene glycol and / or nonaethylene glycol. The electronic mouth cavity atomized liquid has the advantages that remaining taste is clear, fragrance lasts for a long time, and safety is realized after the electronic mouth cavity atomized liquid is used.

Owner:FEELLIFE BIOSCI INT

Process for purifying solanesol from tobacco leaf extract

InactiveCN1951888AEfficient separationImprove securityHydroxy compound separation/purificationChromatographic separationNicotiana tabacum

The invention discloses a preparing method of solanesol, which comprises the following steps: adopting tobacco leaf with solanesol content at 13-17% as raw material; saponifying through alkaline solution; extracting through saturated paraffin; decompressing extract to recycle the solvent; proceeding once molecular distillation for fluid extract; separating the dissolved solanesol through column chromatography; collecting solanesol segment by segment; desolventizing the solanesol; distilling to purity; obtaining the product with purity more than 95%. The invention can separate high-effect component of different tobaccos, which saves cost with high safety.

Owner:郑亚津

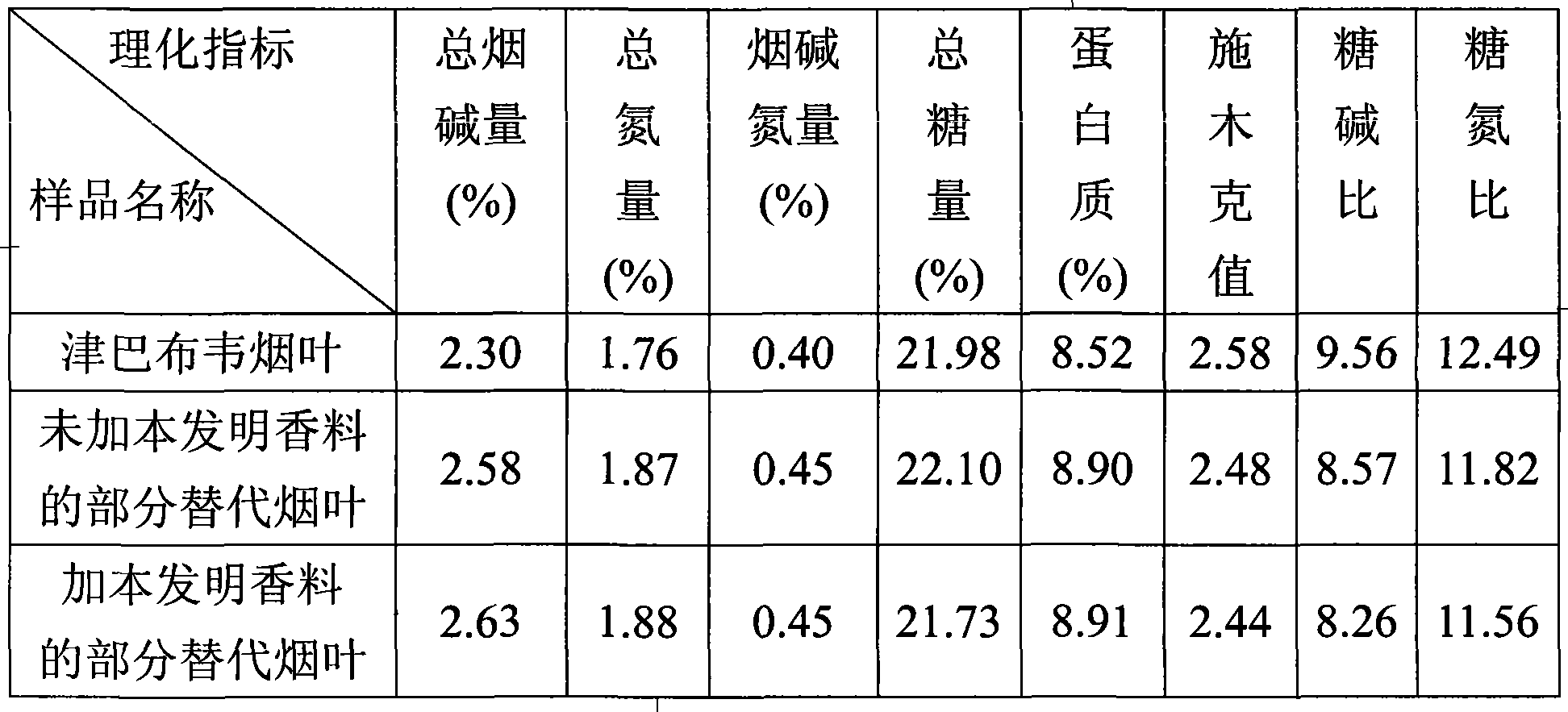

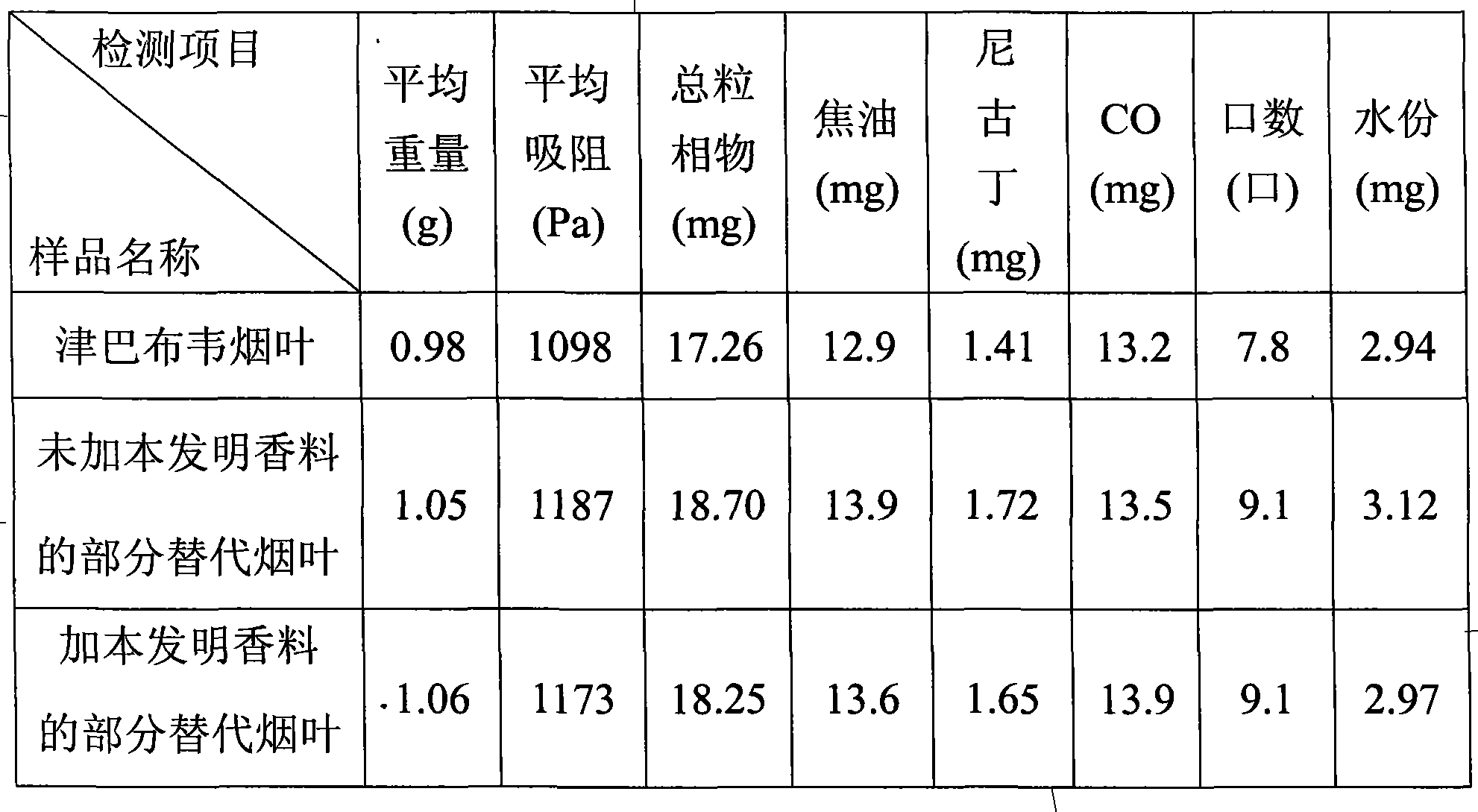

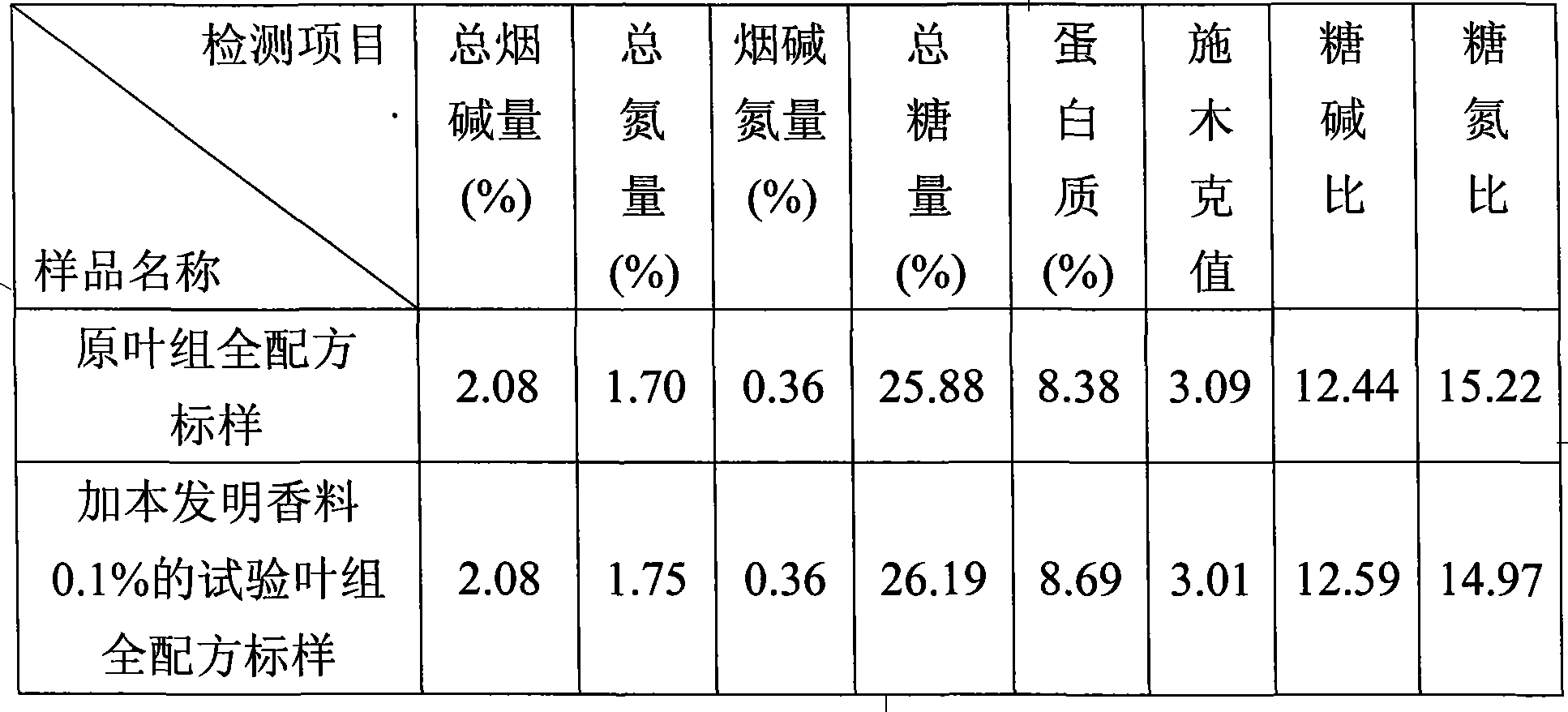

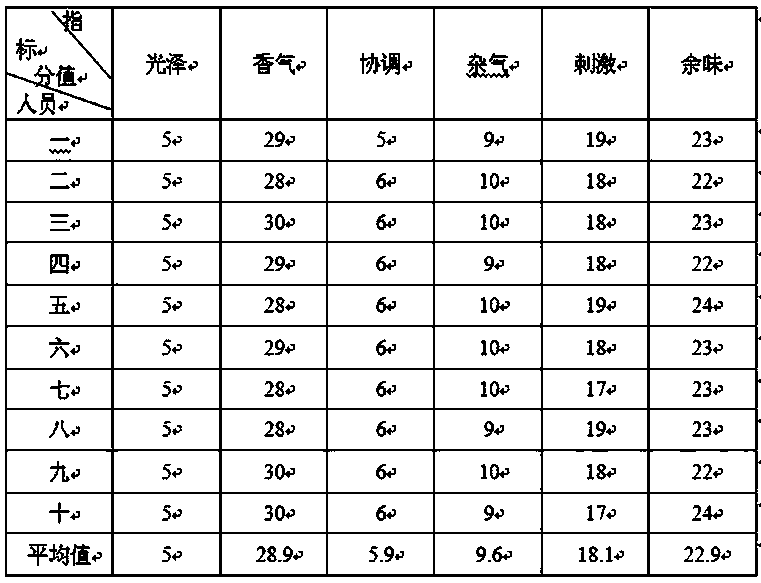

Spice for tobacco and method for partially substituting Zimbabwe tobacco leaf

The invention discloses a preparation method of a flavor used in cigarettes and partially substitutes Zimbabwe tobacco leaf. The components of the flavor comprise a Zimbabwe tobacco leaf extract with the content of 11.00-13.00 percent (weight percentage). The substituting method comprises the steps that the Zimbabwe tobacco leaf with the content of 55-65 percent (weight percentage) is mixed with a Yunnan tobacco leaf with the content of 35-45 percent (weight percentage); the flavor with the characteristic of Zimbabwe tobacco is added in the mixed tobacco leaves, with the content of 0.8-1.0 percent (weight percentage). The flavor of the invention is a flavor with the characteristic of Zimbabwe tobacco leaf used in cigarettes. When the flavor is added into the Yunnan tobacco leaves of 2000 Kunming B2F, 2003 Shiyi K326C2F and 2004 Wenshan B3F, each physical and chemical index detection data is very close to the property detection data of the Zimbabwe tobacco leaf and the smoking styles of the Yunnan tobacco leaf and the Zimbabwe tobacco leaf are similar, which obviously reduces the difference between the two types of leaves. The flavor can well present the style of the Zimbabwe tobacco and effectively substitute the Zimbabwe tobacco leaf partially and substantially enhance the inherent quality of tobacco leaves and cigarettes.

Owner:SHENZHEN BOTON FLAVORS & FRAGRANCES

Sun-cured red tobacco leaf extract, preparation method therefor and applications thereof in cigarettes

InactiveCN103627523AReduce bad miscellaneous gasOutstanding fragranceTobacco preparationEssential-oils/perfumesBiotechnologyTobacco leaf extract

Owner:CHINA TOBACCO JIANGXI IND CO LTD

Casing flavor for expanded cut tobacco

ActiveCN103305342ARich fragranceIncrease sweetnessTobacco preparationTobacco treatmentThroat irritationMetal impurities

The invention discloses a casing flavor for an expanded cut tobacco. The casing flavor comprises the following components in parts by weight: 8-15 parts of a Zimbabwe tobacco leaf extract, 5-12 parts of a Brazil tobacco leaf extract, 3-8 parts of honey, 1-3 parts of 10% by mass of a red jujube extract, 2-5 parts of 1% by mass of phenylacetaldehyde, 5-8 parts of 1% by mass of guaiac wood oil, 0.5-2 parts of a fenugreek fluid extract, 1-3 parts of a liquorice fluid extract, 2-5 parts of maple syrup, 1-2 parts of 10% by mass of an orris root extract, 10-25 parts of water and 12-61.5 parts of propanediol. After the casing flavor is added into the expanded cut tobacco, the sensory quality shortages of insufficient fragrance, high metal impurity gas content, high irritation, metallic flavor residues and the like in the existing expanded cut tobacco are overcome, the fragrance content is increased, the expanded cut tobacco is endowed with fragrance and sweetness of a fruit and is enriched in fragrance, the throat irritation is reduced, and the sensory quality of the expanded cut tobacco is remarkably improved.

Owner:HUBEI CHINA TOBACCO IND +1

Sauce-fragrance E-cigarette nicotine liquid

InactiveCN104489907AImproved taste and aromaGreat tasteTobacco treatmentTobacco devicesFlavorLiquid smoke

The invention provides sauce-fragrance E-cigarette nicotine liquid, by weigh, comprising 1 to 30% of tobacco extract, 0.5 to 10% of tobacco flavor, 0.5 to 15% of sauce-fragrance Chinese spirit, 0.5 to 10% of taste fragrance conditioner, 1 to 15% of deionized water, 1 to 25% of edible glycerin and the balance of propylene glycol. The sauce-fragrance E-cigarette nicotine liquid is made of extract of tobacco stored in a cellar for sauce-fragrance Chines spirits and is added the taste fragrance conditioner and the sauce-fragrance Chinese spirit; thus, the sauce-fragrance E-cigarette nicotine liquid has unique tobacco fragrance and has strong cause fragrance; the sauce-fragrance E-cigarette nicotine liquid has taste and fragrance meeting the needs of consumers, the taste and fragrance of the existing E-cigarette nicotine liquid is improved, the E-cigarette nicotine liquid is more similar to the traditional cigarettes in terms of taste and fragrance, and the needs of consumers for smoking E-cigarettes are further met.

Owner:CHINA TOBACCO GUIZHOU IND

Composite functional type electronic cigarette atomized liquid and preparation method thereof

InactiveCN105876863AReduce and ease dependenceHarm reduction and mitigationTobacco devicesVitamin CFruit juice

The invention provides a composite functional type electronic cigarette atomized liquid and a preparation method thereof; the electronic cigarette atomized liquid mainly is prepared by the following ingredients by weight percentage: vitamin E 0.001-0.05%, vitamin C 0.01-0.25%, vitamin B2 0.005-0.1%, vitamin D 0.005-0.1%, tobacco leaf extract product 0.00001-6%, deionized water 0.1-15%, tobacco flavouring agent 0.00001-6%, fruit juice 0.00001-10%, fruit flavor modification agent 0.00001-10%, guarana extract product 0.001-10%, taurine 0.00001-0.1%, and balance propylene glycol. The composite functional type electronic cigarette atomized liquid can mitigate or alleviate oral cavity disease, coughing, and sneezes, thus improving electronic cigarette health care physiotherapy effects.

Owner:SHENZHEN SMACO TECHNOLOGY LIMITED

Officinal health-care solid electronic aerosolization liquid and preparation method thereof

The invention provides an officinal health-care solid electronic aerosolization liquid, mainly comprising the following components by weight percent: 35-45% of propylene glycol, 30-35% of medicament, 10-15.0% of deionized water, 3-3.5% of tobacco leaf extract solution, 3-3.5% of tobacco flavour, 2-3.0% of excipient, 0.2-1.0% of calcium pectate and 0.3-0.8% of curing agent. The invention also provides a preparation method of the officinal health-care solid electronic aerosolizatioon liquid. The invention contains multiple officinal components having treating function on lungs, thus having treating function on symptoms such as dryness and itch of the throat and irritable cough which are caused by smoking, chronic pharyngitis and dryness of mouth and nose, thirst and dry cough, less sputum or distressed cough caused by the fact that sputum is glued; meanwhile the invention is solid, thus the stability of storing and use is improved, production and transportation are more convenient and flexible, and fragrance can be remained to be more complete.

Owner:FEELLIFE BIOSCI INT

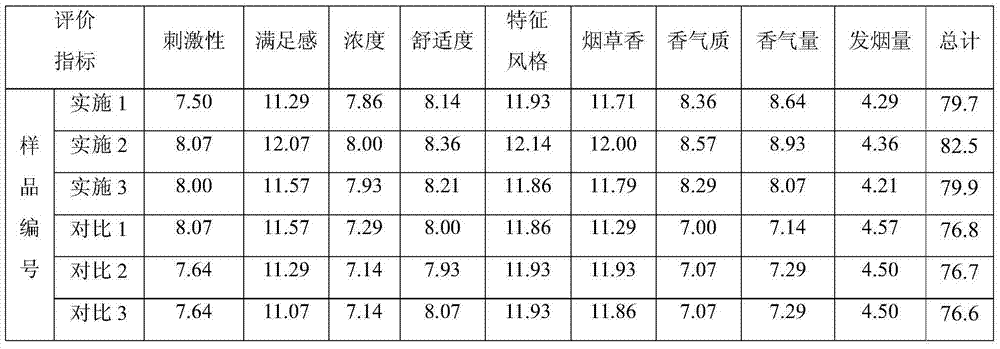

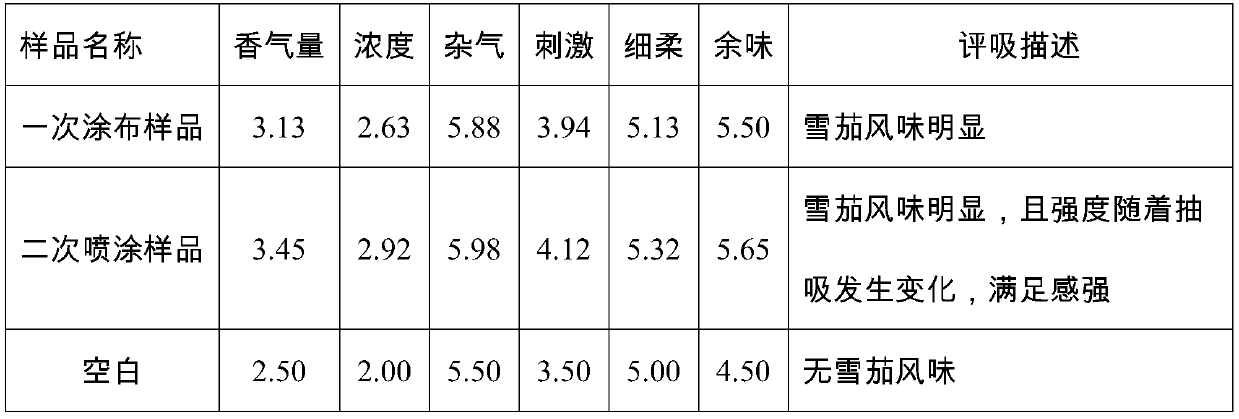

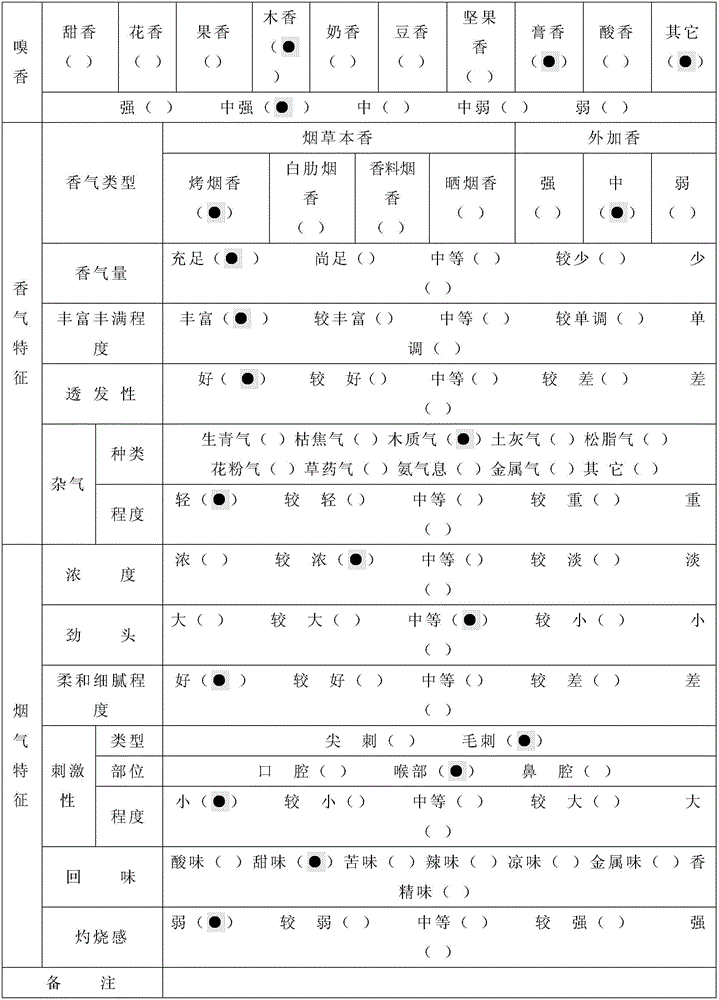

Coating preparation method of cigar-flavored cigarette paper

ActiveCN111418874AEnhance sensory experienceIncrease concentrationTobacco preparationTobacco treatmentBiotechnologySpray coating

The invention discloses a coating preparation method of cigar-flavored cigarette paper. The coating preparation method comprises the following steps: preparing a tobacco concentrate; carrying out molecular distillation treatment on the tobacco concentrate, and collecting light components to obtain a first tobacco extract; adding a mixture of amino acid and sugar into a tobacco leaf extract, and performing filtration, dilution, membrane separation and vacuum concentration after the reaction is finished so as to obtain a second tobacco extract; preparing a tobacco recombinant; preparing spice for cigar-flavored tobacco; preparing a cigar-flavored coating liquid; coating the cigarette paper for the first time by adopting a roller coating method; and coating the cigarette paper for the secondtime by adopting a spraying coating method to obtain the cigar-flavored cigarette paper. According to the coating preparation method of the cigar-flavored cigarette paper, the cigar flavor of cigarettes can be effectively enhanced, the concentration and thickness of smoke can be increased, the prepared cigar-flavored cigarette paper shows a dyeing effect without additionally adding pigments, and the sensory experience of the cigar-flavored cigarettes can be optimized.

Owner:CHINA TOBACCO HENAN IND +1

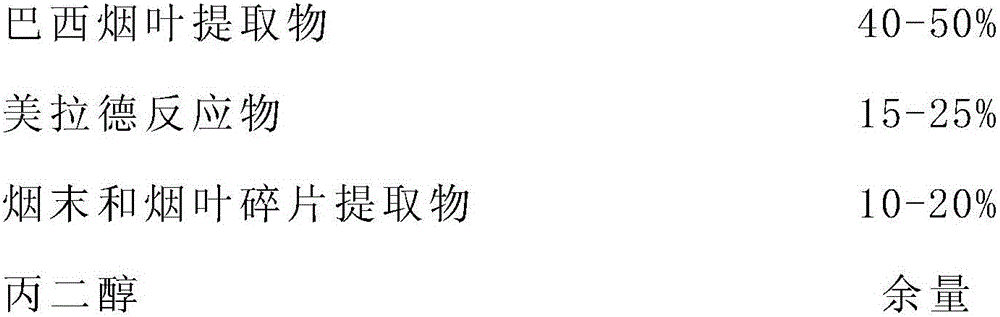

Aroma-increasing additive used for tobacco sheet as well as preparation method and application thereof

The invention provides an aroma-increasing additive used for a tobacco sheet as well as a preparation method and application thereof. The aroma-increasing additive used for the tobacco sheet is obtained by mixing Brazil tobacco leaf extract, Maillard reactant, tobacco powder and tobacco leaf fragment extract and propylene glycol, stirring and standing, wherein the Mailard reactant is obtained by carrying out reaction on purified water, glucose, praline, ammonia water with the concentration of 26% and caramel colour at specific temperature and under the regulation and has relative density of 1.1826 + / - 0.0080 (20 DEG C); and the tobacco powder and tobacco leaf fragment extract is obtained by extracting tobacco powder and tobacco leaf fragment with 50% ethanol, filtering, concentrating to the relative density of 1.3186 + / - 0.0080 (20 DEG C)and filtering again. When the aroma-increasing additive is added into coating liquid of the tobacco sheet, the problems that the tobacco sheet is dim in colour, aroma is missing and miscellaneous qi is strong can be effectively solved, aroma amount of tobacco in a suction process is increased, aroma texture is improved, and the miscellaneous qi is alleviated.

Owner:HUBEI CHINA TOBACCO IND

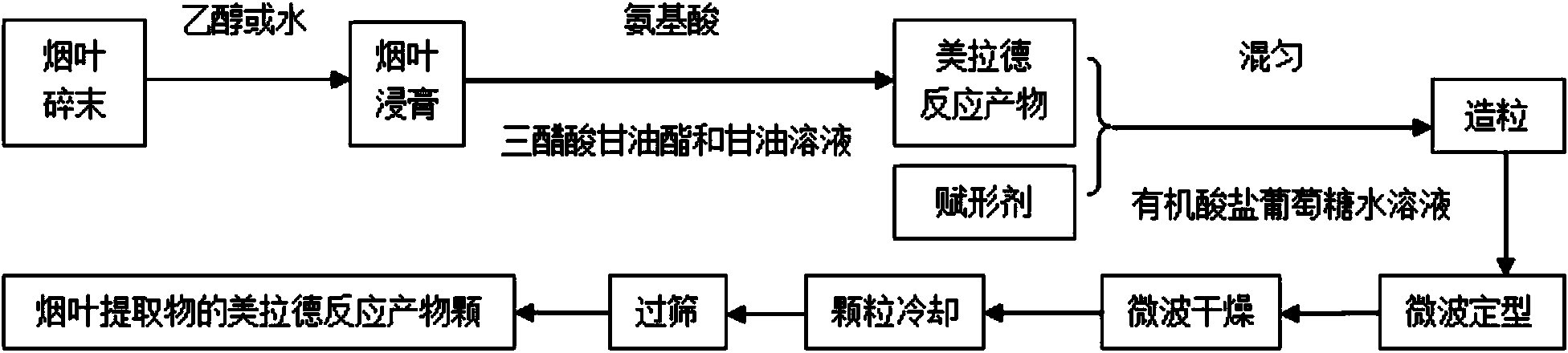

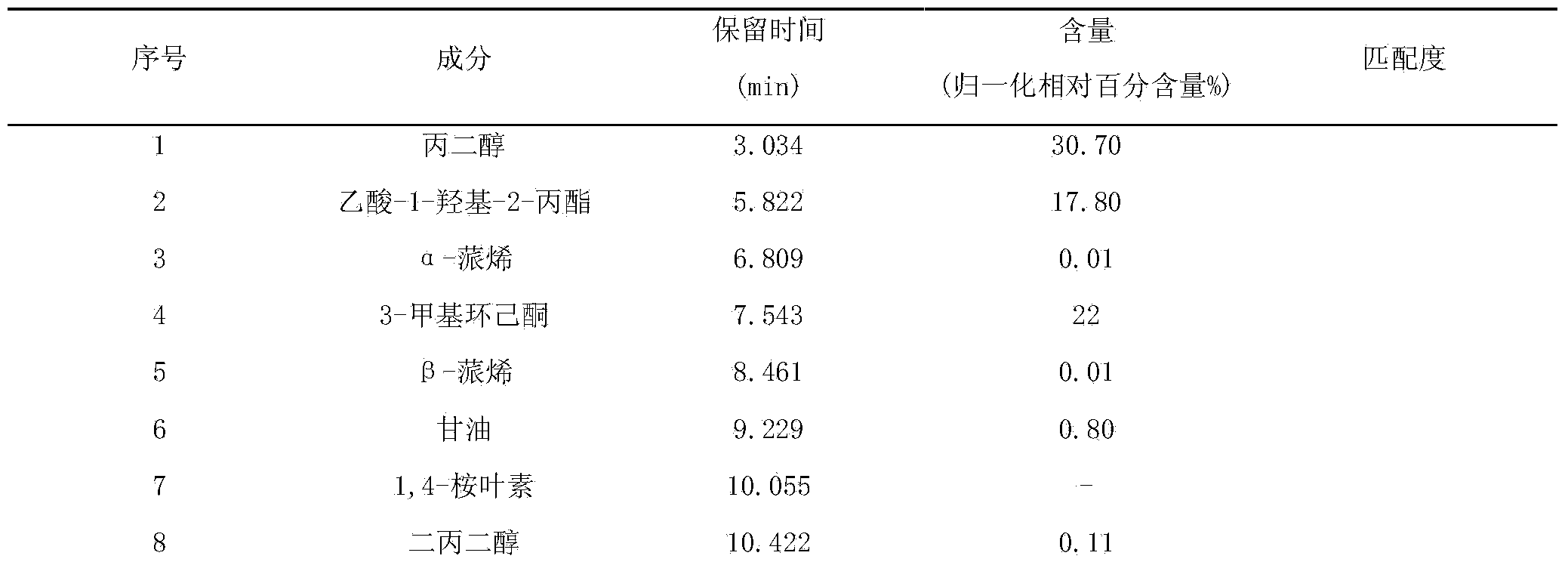

Preparation method for maillard reaction production particles of tobacco leaf extract

ActiveCN104031741AIncrease aromaSweet aftertasteTobacco smoke filtersEssential-oils/perfumesMaillard reactionFiltration

The invention discloses a preparation method for maillard reaction production particles of tobacco leaf extract. The preparation method comprises the following steps of firstly taking and cutting up tobacco leaves, heating and extracting by using water or alcohol, settling and filtering to obtain tobacco leaf extracting liquor by hot filtration and refrigeration settlement, an contracting to obtain tobacco leaf extract; adding a mixture of the tobacco extract and amino acid into a mixed solvent of glycerol triacetate and glycerol, heating for 3-12 hours at 80-100 DEG C to obtain a maillard reaction production product of the tobacco leaf extract; stirring and mixing maillard reaction production product which is yellow or brownish yellow transparent liquid of a glycerol triacetate layer with an excipient material to form wet composite powder; and obtaining the maillard reaction production particles of tobacco leaf extract by pelletizing, micro-wave sizing, microwave-drying, particle cooling and sieving. The maillard reaction production product of the granular tobacco leaf extract is applied to a cigarette filer rod, can effectively compensate tobacco fragrance drop caused by filter rod filtering and punching-diluting, and can improve suction quality of the cigarettes.

Owner:CHINA TOBACCO GUANGXI IND

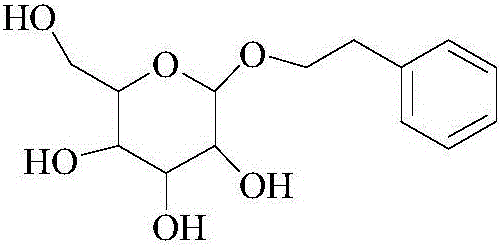

Electronic cigarette liquid containing phenylethanol glycosides

InactiveCN106072756AAchieve chemical synthesisImprove sensory qualitySugar derivativesTobacco treatmentFlavorChemical synthesis

The invention discloses an electronic cigarette liquid containing phenylethanol glycosides. The electronic cigarette liquid is prepared from components in percentage by weight as follows: 3%-10% of tobacco leaf extract, 3%-8% of tobacco essence, 1%-5% of tobacco flavors, 5%-15% of deionized water, 10%-20% of glycerin, 3%-10% of phenylethanol glycosides and the balance of propylene glycol; the phenylethanol glycosides are prepared with a preferred chemical synthesis method. The method for preparing the phenylethanol glycosides is environment-friendly, rapid and efficient, the glycosides can promote electronic cigarette smoke to be fine, the drying stimulation is reduced, the smoking comfort is improved, the fragrance characteristic of an electronic cigarette can be further enhanced, the electronic cigarette liquid is used for electronic cigarette atomization, no tar or CO is produced, danger to consumers is greatly reduced, and damage of second hand smoking cannot be caused.

Owner:SHANGHAI INST OF TECH

Botanical pesticide

The invention relates to a botanical pesticide. The botanical pesticide is prepared from the following raw materials in parts by weight: 10-20 parts of tobacco leaf extract, 1-5 parts of baicalein, 0.5-2 parts of garlic oil, 2-6 parts of sophocarpidine, 1-5 parts of starch, 4-30 parts of onion, 1-15 parts of pepper seed extract and 2-6 parts of dogwood seed extract. The botanical pesticide is prepared by use of the plant raw materials as the major materials; the adopted raw materials are proportioned simply, and the botanical pesticide is environment-friendly and low in cost.

Owner:内蒙古崇用农业科技发展有限公司

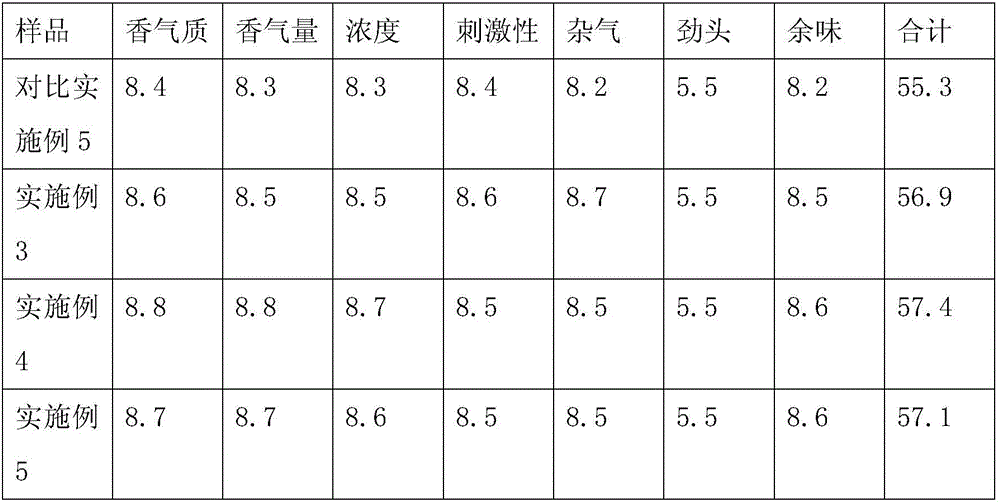

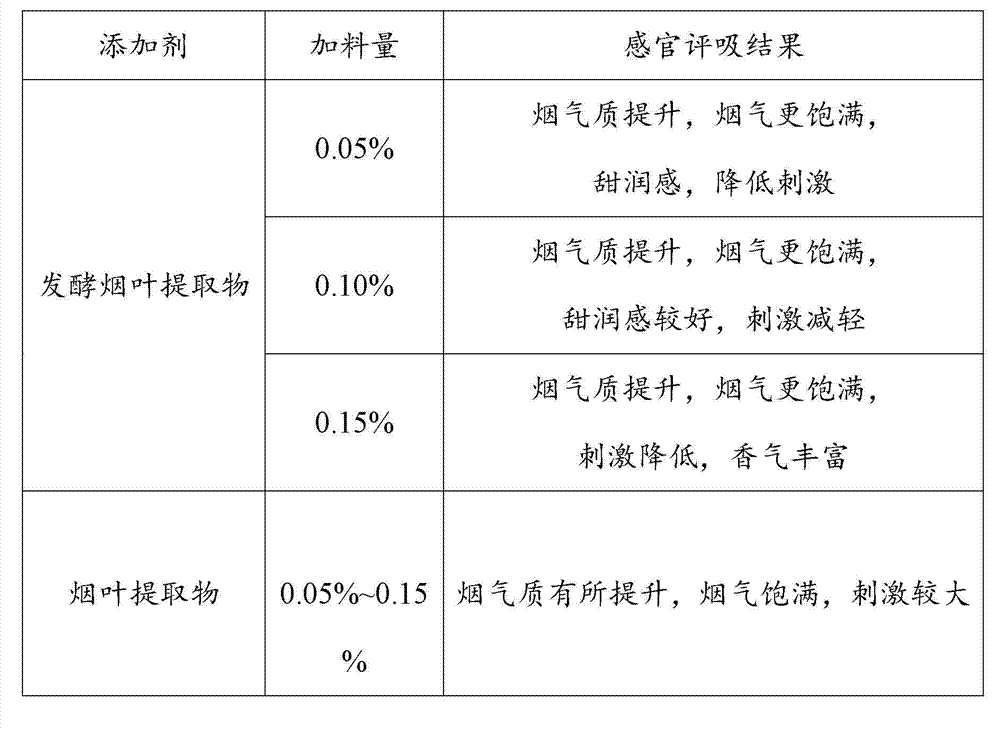

Preparation method for irritation reducing fermentation tobacco extract, and applications of irritation reducing fermentation tobacco extract in recombinant tobacco

InactiveCN102851241ANatural, environmentally friendly and harmlessSmoke liftTobacco treatmentBacteriaBiotechnologyIrritation

The present invention discloses a method for an irritation reducing fermentation tobacco extract, and applications of the irritation reducing fermentation tobacco extract in recombinant tobacco. According to the present invention, a name of strain is Raoultella planticola VP4-4, a preservation number is CCTCC M 2012005, the total 16SrRNA sequence length is 1408 bp, and similarity between the 16SrRNA sequence and Raoultella planticola is 99.563%. According to the method, the Raoultella planticola VP4-4 is adopted, and bacteria seed activation, seed culture liquid preparation, fermentation culture and fermentation solution transformation are performed to obtain the irritation reducing fermentation tobacco extract. With the present invention, the tobacco extract is adopted as a single carbon source, a nitrogen source, and a substrate, is a cigarette origin material, and is easily utilized by a microbe enzyme system to ferment so as to produce cigarette fragrance. In addition, the method of the present invention has a simple process, the raw material is the cigarette product origin tobacco, and the method has an industrial application prospect.

Owner:HUBEI CHINA TOBACCO IND

Electronic cigarette liquid containing polysaccharide

The invention discloses an electronic cigarette liquid containing polysaccharide. The electronic cigarette liquid is prepared by mixing the following components in percentage by mass: 5-10% of tobacco extract, 5-8% of tobacco essence, 1-5% of tobacco flavor, 5-15% of deionized water, 10-20% of glycerol, 5-20% of polysaccharide, and the balance of propylene glycol, wherein the tobacco extract is preferably Zimbabwe tobacco extract. The electronic cigarette liquid has the advantages that the electronic cigarette liquid contains the polysaccharide, so the irritation of an electronic cigarette is reduced, the mouthfeel of the electronic cigarette is more comfortable, and the fragrance is finer and softer; the electronic cigarette liquid is used for atomizing the electronic cigarette, the tar and CO2 (carbon dioxide) are not produced, the hazard on consumers is greatly reduced, and the hazard of second-hand smoking is avoided; the obtaining of raw materials of the prescription is easy, the international and domestic laws, rules and relevant regulations are met, and the production technology is simple.

Owner:CHINA TOBACCO SICHUAN IND CO LTD +1

Preparation method and application of tobacco flavor

ActiveCN105199850APreserve Aroma IngredientsRich fragranceTobacco treatmentEssential-oils/perfumesMaillard reactionMass ratio

The invention relates to a preparation method and application of tobacco flavor. The preparation method comprises the following steps: adopting Yunnan tobacco leaf as a raw material, drying, smashing, adding water of which the mass is 4-5 times than that of the Yunnan tobacco leaf, heating to 80-85 DEG C, soaking for 1-1.5 h, then adding ethyl alcohol of which the mass is 6-6.5 times than that of the Yunnan tobacco leaf for extracting, concentrating to obtain a primary Yunnan tobacco leaf extract, adding the primary Yunnan tobacco leaf extract and a granular filler according to the mass ratio of (10-30):1 into a carbon dioxide supercritical extraction device for supercritical extraction to obtain an extract liquor, and performing a Maillard reaction on the extract liquor, xylose, phenylalanine, glycerol and purified water according to a mass ratio of (50-70):(5-7):(1-3):(20-50):(2-5) to prepare the tobacco flavor. The preparation method provided by the invention is simple in steps and easy to control, combines the supercritical extraction and the Maillard reaction for use, is low in extraction temperature and short in extraction time, and allows the aroma components in tobacco to be preserved to the utmost extent, the note of the tobacco flavor can be richer through the followed Maillard reaction, and the flavor of the tobacco flavor can be full and heavy.

Owner:HUABAO FLAVOURS & FRAGRANCES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com