Method for reconstructing tobacco cut-stems by using tobacco leaves

A technology for reconstituting tobacco and cut stems, which is applied in the field of tobacco technology and can solve problems such as the inability to actively adjust the chemical composition of cut stems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

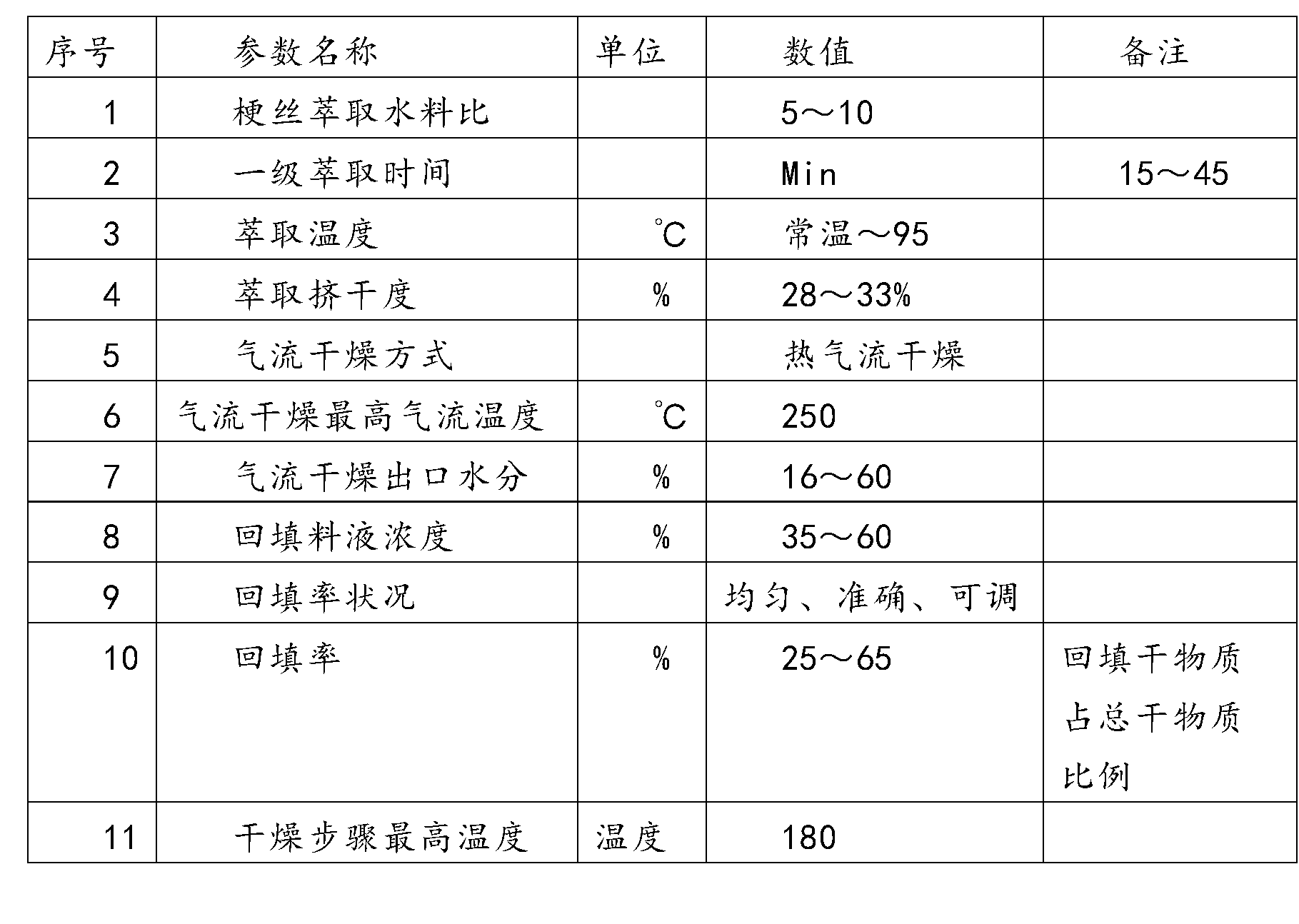

[0026] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments (the relevant proportions and percentages in the present invention, unless otherwise specified, are all regarded as mass ratios).

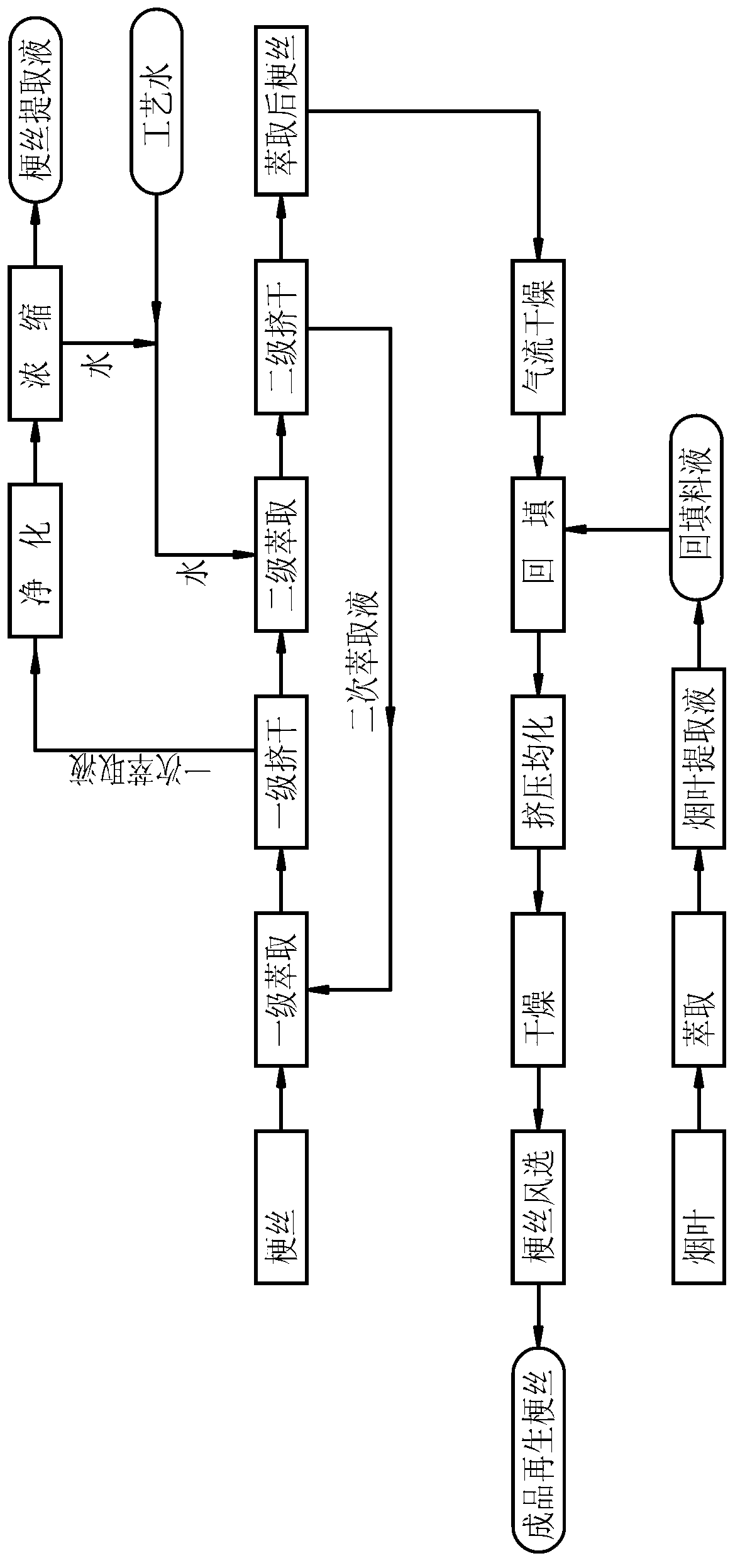

[0027] see figure 1 , the invention provides a method for remaking cut tobacco stems from tobacco leaves, comprising:

[0028] In the step of extracting cut stems, the soluble substances in the cut stems are extracted by a solvent to obtain extracted cut stems.

[0029] In the tobacco leaf extraction step, the soluble substances in the tobacco leaves are extracted with a solvent to obtain a tobacco leaf extract.

[0030] In the feed liquid configuration step, a backfill liquid is configured according to the tobacco leaf extract.

[0031] In the backfilling step, backfill the prepared backfill liquid into the extracted shredded stems.

[0032] In the drying step, the backfilled cut stems are dried ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com