Electronic cigarette liquid prepared from flat-flavor tobacco

A technology of e-cigarette liquid and intermediate flavor, which is applied in the fields of tobacco, application, and tobacco processing, which can solve the problems of large sensory gap, unacceptable consumers, and affecting the quality of e-cigarettes, and achieve the effect of reducing harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

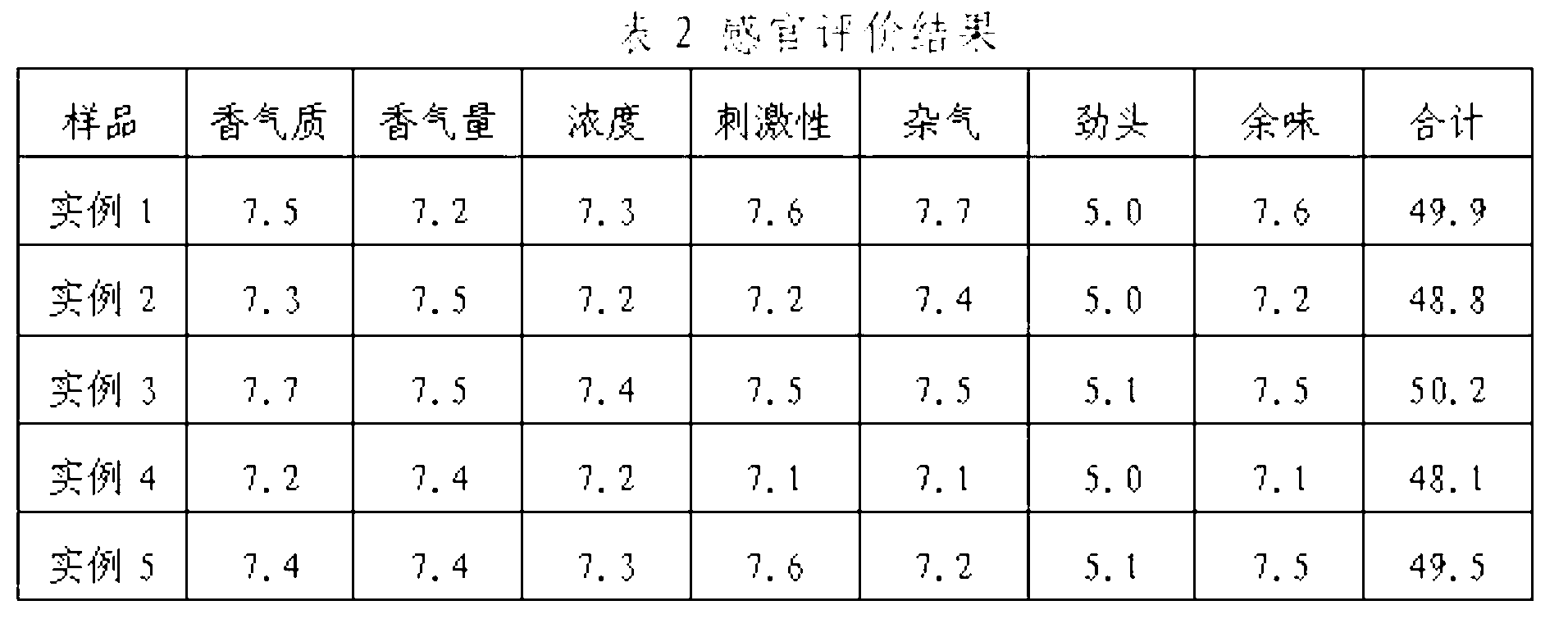

Embodiment 1

[0021] An e-cigarette liquid prepared by using intermediate-flavored tobacco leaves, comprising the following components by mass ratio: Guizhou Anshun flue-cured tobacco leaf extract 10%, Sichuan Liangshan flue-cured tobacco leaf extract 5%, Shandong Qingzhou flue-cured tobacco leaf extract 2%, Hubei Enshi flue-cured tobacco leaf extract 2%, Heilongjiang Fujin flue-cured tobacco leaf extract 2%, tobacco flavor 6%, tobacco flavor 3%, deionized water 7%, glycerin 18%, and the balance is propylene glycol. Mix the raw materials in proportion and stir at room temperature for 30 minutes to fully mix the components.

[0022] The preparation method of the tobacco leaf extract is as follows: take a tobacco leaf sample, dry it in an oven at 40°C for 1 hour, cool it to room temperature, and pulverize it with a cyclone mill. Take 50g of tobacco powder and place it in a 500mL conical flask, add 250mL of deionized water, extract it with ultrasonic waves at 45-50°C for 60min, centrifuge at 5...

Embodiment 2

[0026] Repeat Example 1, with the following differences: the e-cigarette liquid prepared by using middle-flavored tobacco leaves contains the following components by mass ratio: Guizhou Panxian flue-cured tobacco leaf extract 3%, Sichuan Ningnan flue-cured tobacco leaf extract 8%, Shandong Zibo flue-cured tobacco leaf extract 3%, Hubei Xiangfan flue-cured tobacco leaf extract 3%, Heilongjiang Dongning flue-cured tobacco leaf extract 1%, tobacco flavor 7%, tobacco flavor 2%, deionized water 8%, glycerol 18 %, the balance is propylene glycol.

Embodiment 3

[0028] Example 1 was repeated, with the following differences: the e-cigarette liquid prepared by using intermediate-flavored tobacco leaves contained the following components by mass ratio: Guizhou Shibing flue-cured tobacco leaf extract 2%, Sichuan Yanyuan flue-cured tobacco leaf extract 3%, Shandong Linyi flue-cured tobacco leaf extract 7%, Hubei Xianfeng flue-cured tobacco leaf extract 2%, Liaoning Jianping flue-cured tobacco leaf extract 2%, tobacco flavor 5%, tobacco flavor 4%, deionized water 6%, glycerol 18 %, the balance is propylene glycol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com