Preparation method for maillard reaction production particles of tobacco leaf extract

A technology of Maillard reaction and tobacco leaf extract, which is applied in the field of preparation of Maillard reaction product granules, can solve the problems of unobvious characteristic aroma and insufficient aroma, achieve good market prospects and application value, easy to obtain, and aftertaste sweet effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

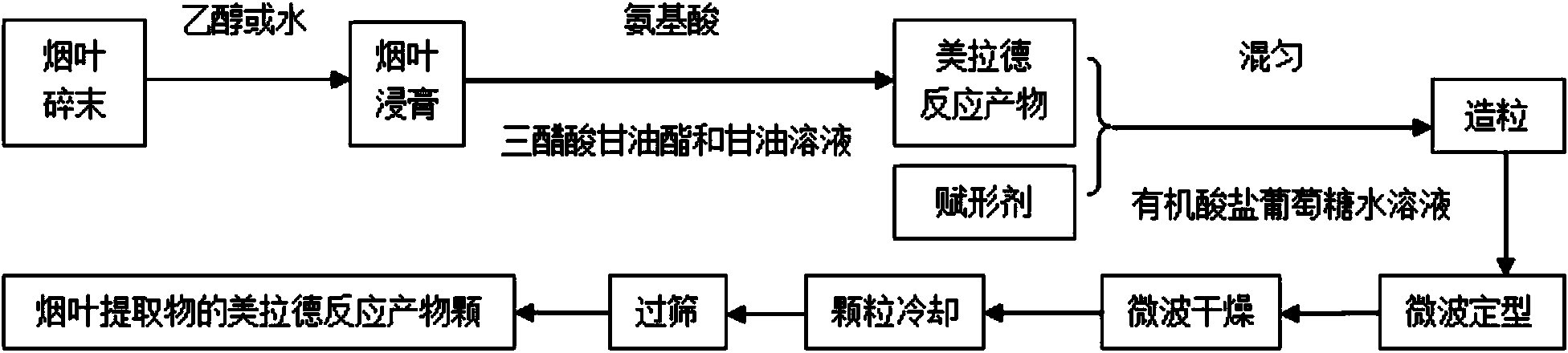

Method used

Image

Examples

Embodiment 1

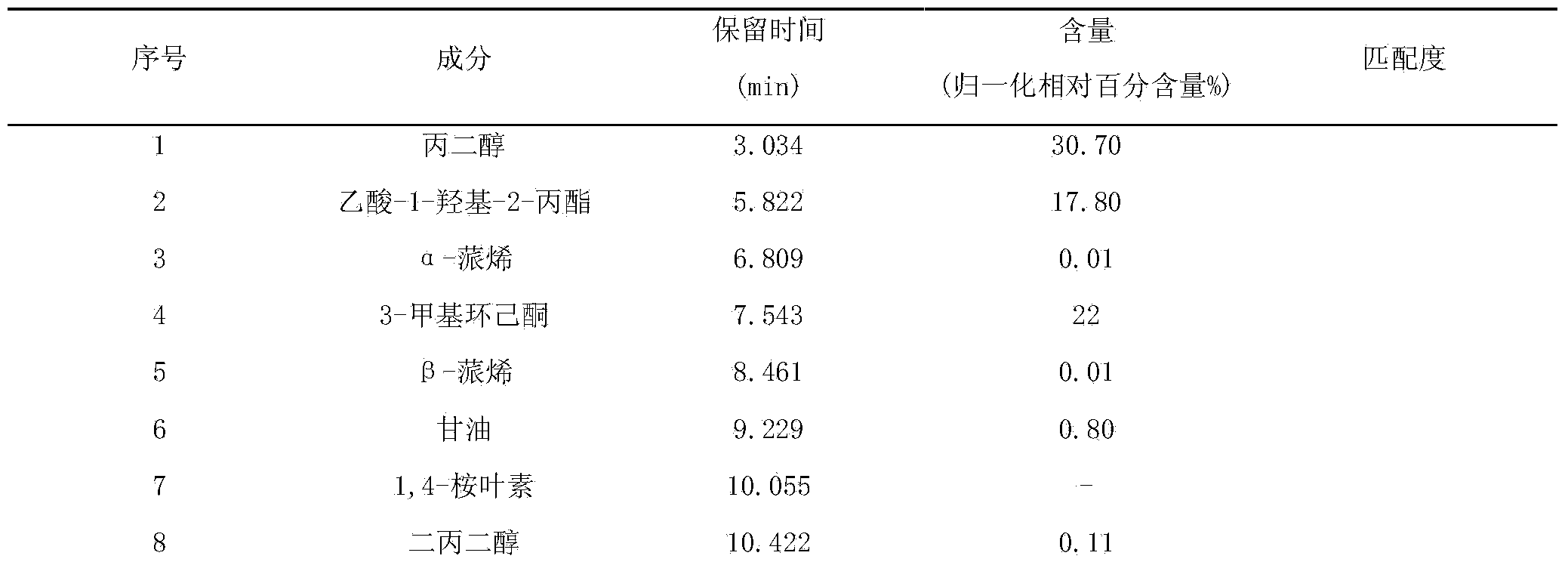

[0026] Firstly take the tobacco leaves and chop them up, use 20 times of water as the solvent to heat and extract at 100°C, and then obtain the tobacco leaf extract through hot filtration and refrigerated sedimentation filtration, and the concentrated yield is 23.95% of the tobacco leaf extract; Take 5g of tobacco paste mixture with an acid content of 10:1, weigh 100g of a mixed solvent with a mass ratio of triacetin:glycerol of 10:1, put the tobacco paste mixture into the mixed solvent, and heat it at 100°C for 12 hours to obtain tobacco leaves The Maillard reaction product of the extract; the Maillard reaction product of the triacetin layer is a yellow or brownish-yellow transparent liquid, weigh 1g, stir with the excipient material mass ratio of 120:1, weigh 0.1g lemon Dissolve sodium bicarbonate and 9.9g glucose in 95mL water, magnetically stir to dissolve completely, then spray it evenly into 110g corn porous starch and mix well to form a moist composite powder, and pass t...

Embodiment 2

[0028] Firstly take the tobacco leaves and chop them up, use 15 times of ethanol as a solvent to heat and extract at 100°C, and obtain the tobacco leaf extract through hot filtration and refrigerated sedimentation filtration, and the concentrated yield is 23.70% of the tobacco leaf extract; Take 5g of the tobacco cream mixture with a ratio of 9:1, weigh 100g of a mixed solvent with a mass ratio of glycerol triacetate:glycerol of 8:1, put the smoke cream mixture into the mixed solvent, and heat it at 100°C for 10 hours to obtain tobacco leaves The Maillard reaction product of the extract; the Maillard reaction product of the triacetin layer is a yellow or brownish yellow transparent liquid, weigh 1g, stir with the excipient material at 150:1, weigh 0.1g sodium citrate and 9.9g of glucose were dissolved in 100mL of water, magnetically stirred to dissolve completely, and then evenly sprayed into 140g of glutinous rice flour and mixed well to form a moist composite powder, which wa...

Embodiment 3

[0029] Example 3 Tobacco leaves were firstly taken and chopped, heated and extracted with 10 times of ethanol as a solvent at 60°C, filtered through hot filtration and refrigerated sedimentation to obtain tobacco leaf extract, and the concentration yield was 23.20% of tobacco leaf extract; then the tobacco extract was weighed: Take 5g of smoke paste mixture with a mass ratio of proline of 2:1, weigh 100g of a mixed solvent with triacetin:glycerol with a mass ratio of 0.5:1, put the smoke paste mixture into the mixed solvent, and heat it at 100°C for 3 hours, the Maillard reaction product of the tobacco leaf extract was obtained; the Maillard reaction product of the triacetin layer was a yellow or brownish-yellow transparent liquid, weighed 0.5g, stirred at 100:0.5 with the excipient material, weighed Dissolve 0.1g of sodium malate and 6.9g of sucrose in 90mL of water, magnetically stir to dissolve completely, then evenly spray it into 93g of corn porous starch and mix well to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com