Patents

Literature

38results about How to "Reduce the cost of cigarettes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing tobacco sheet and application thereof

ActiveCN101637298AGood physical propertiesExtract completelyTobacco preparationTobacco treatmentMaillard reactionFiber

The invention discloses a method for preparing tobacco sheets and an application of the method. In the method, enzymolysis is implemented when the tobacco stalk and the tobacco powder are soaked, solid-liquid separation is implemented after extraction, the solids are made into fiber sheet substrates, liquid is made into concentrated solution by alcohol precipitation and concentration, the concentrated solution is made into coating liquid by maillard reaction and coated on the fiber sheet substrates, and the fiber sheet substrates are dried and cut into tobacco sheets. In the invention, the macromolecular compounds that influence the quality of the tobacco sheets are sufficiently degraded by enzymolysis, the content of the impure taste in the tobacco sheets is decreased, the internal quality of the tobacco sheets is improved, and better aroma is obtained by the technical solution that produces prospective aroma by the maillard reaction to provide a rich aroma for the tobacco sheets so as to obtain tobacco sheet products fitting different types of cigarette products and having better internal quality. The tobacco sheets prepared by the method have excellent compatibility and harmonywith the conventional raw materials of the cigarettes, and have the advantages of good cigarette taste, various and rich aromas and less impure taste.

Owner:CHINA TOBACCO GUANGDONG IND

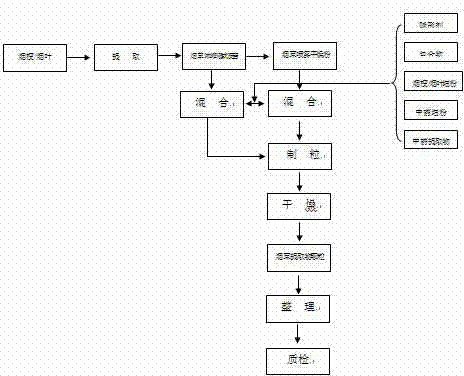

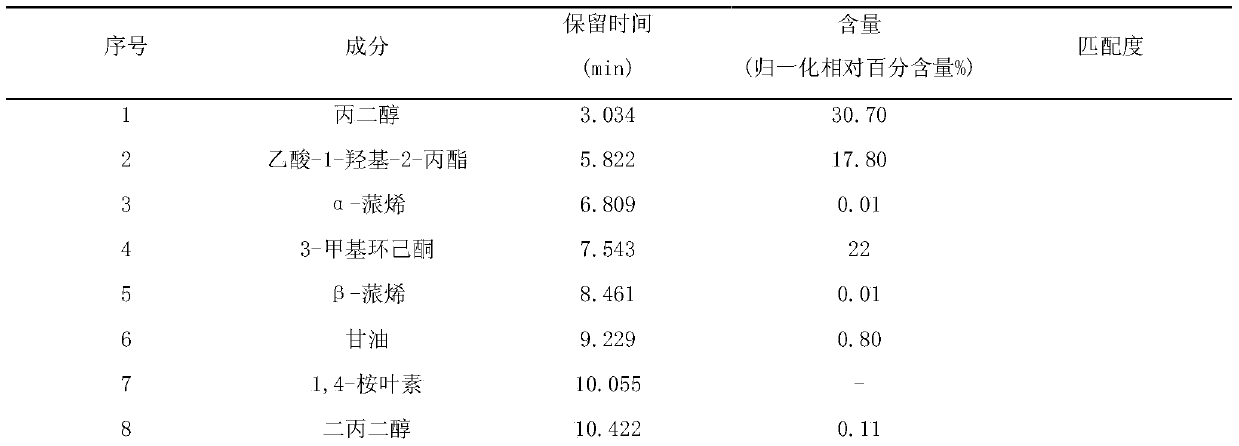

Preparation method of tobacco extract granules

The invention relates to a preparation method of tobacco extract granules, which comprises the following steps: firstly taking and cutting up tobacco leaves and / or tobacco stalks, taking water or ethanol or ethyl ether as a solvent for extraction, settling and filtering to obtain tobacco extract, then concentrating to the relative density of 1.00-1.30, and controlling the temperature to 20-40 DEGC to obtain tobacco extract concentrate or tobacco extractum; and including beta-cyclodextrin and flavouring essence for tobacco according to the mass ratio of 1-3:1 with the inclusion time of 1 / 5-3 hours to obtain a flavouring essence and beta-cyclodextrin inclusion compound, and then spray drying the flavouring essence for tobacco and beta-cyclodextrin inclusion compound and the tobacco extractconcentrate together to obtain tobacco spray dried powder; or directly spray drying the tobacco extractum to obtain the tobacco spray dried powder; and then adding excipient material to the tobacco spray dried powder for dry method or wet method granulation to obtain the tobacco extract granules. The tobacco extract granules obtained in the method disclosed by the invention are applied to cigarettes to improve the tar and harm reduction effect of the cigarettes, and can be used for aroma compensation, the utilization rate of waste tobacco leaf raw material is improved, and the cost of the cigarettes is reduced.

Owner:云南拓宝科技有限公司

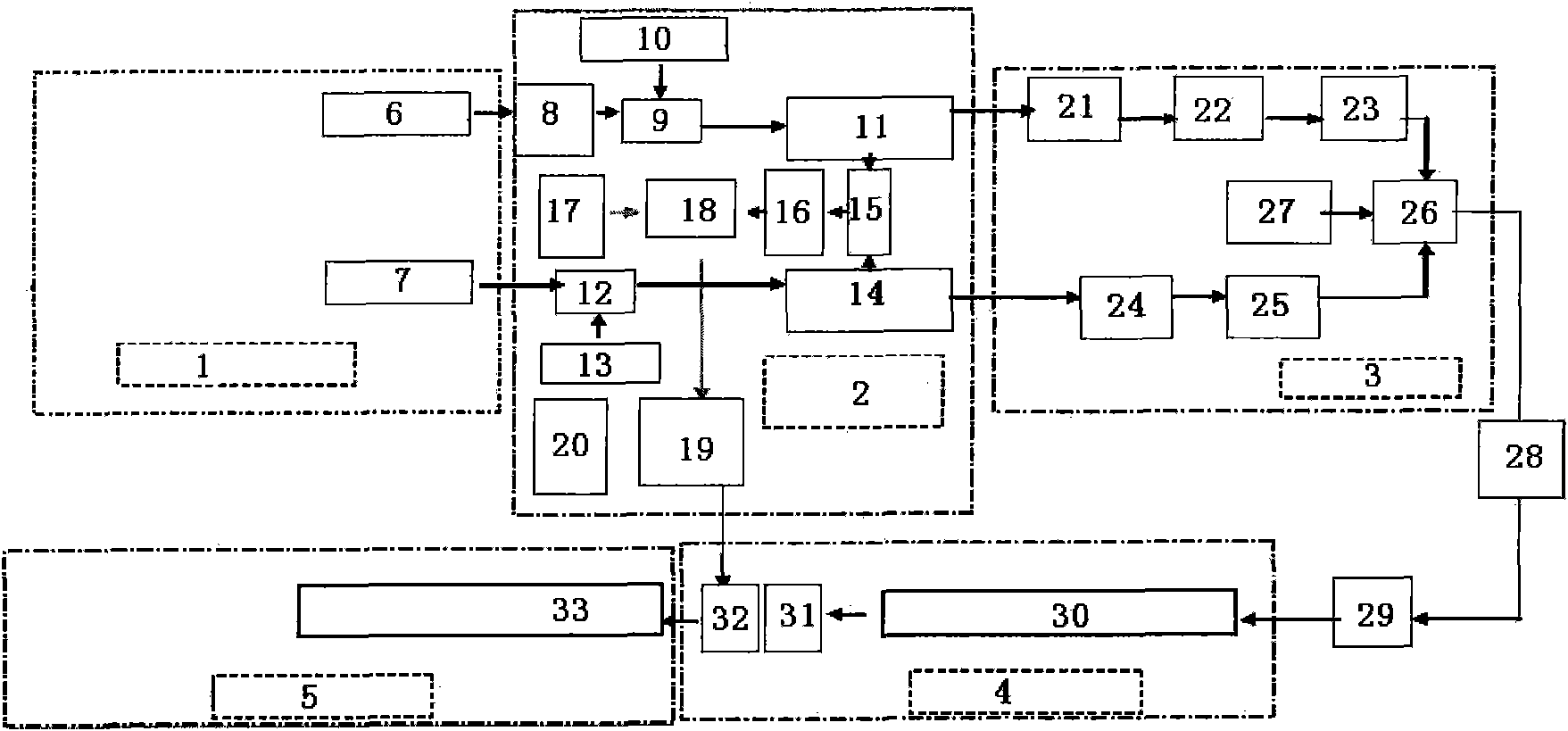

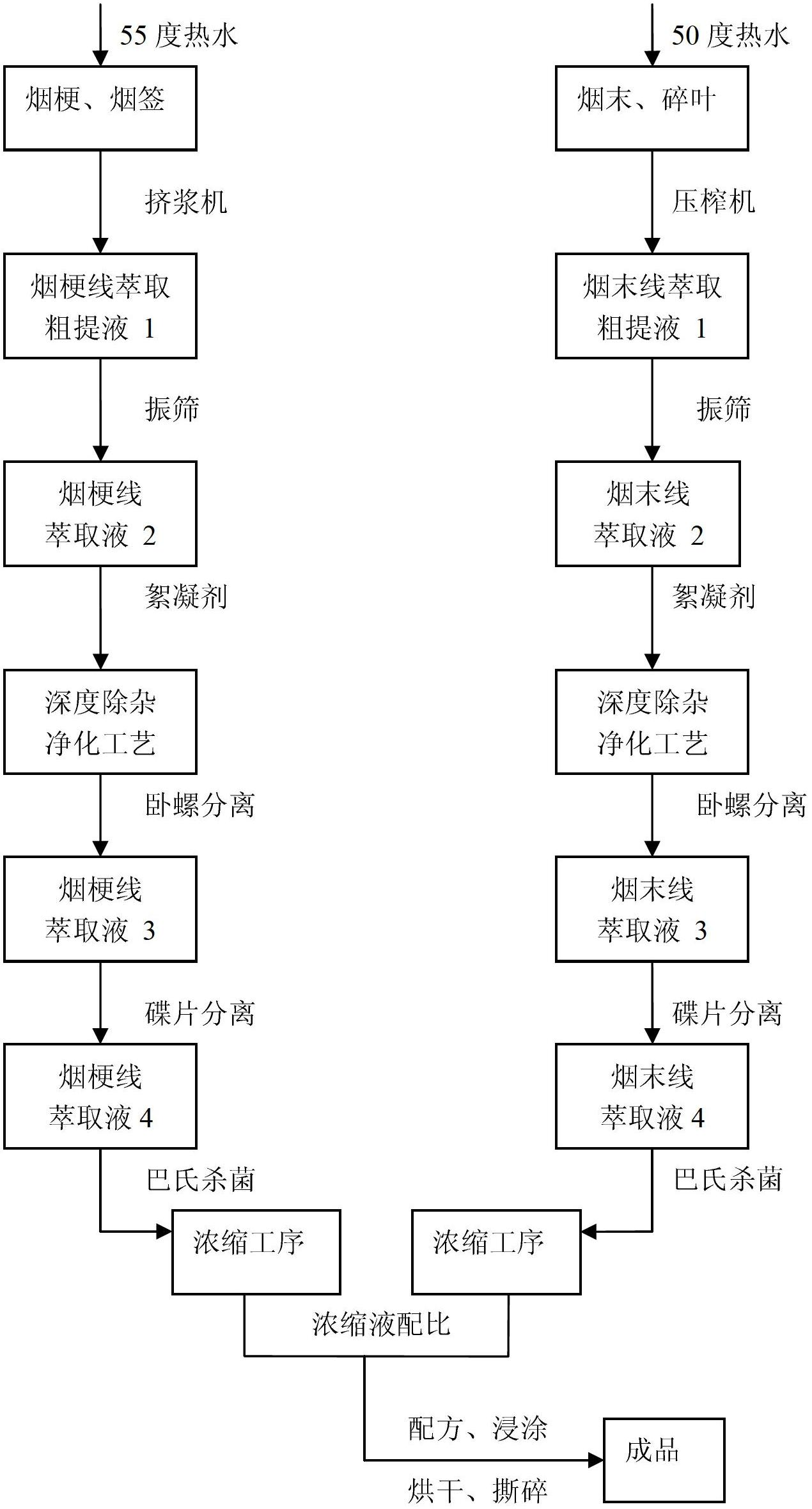

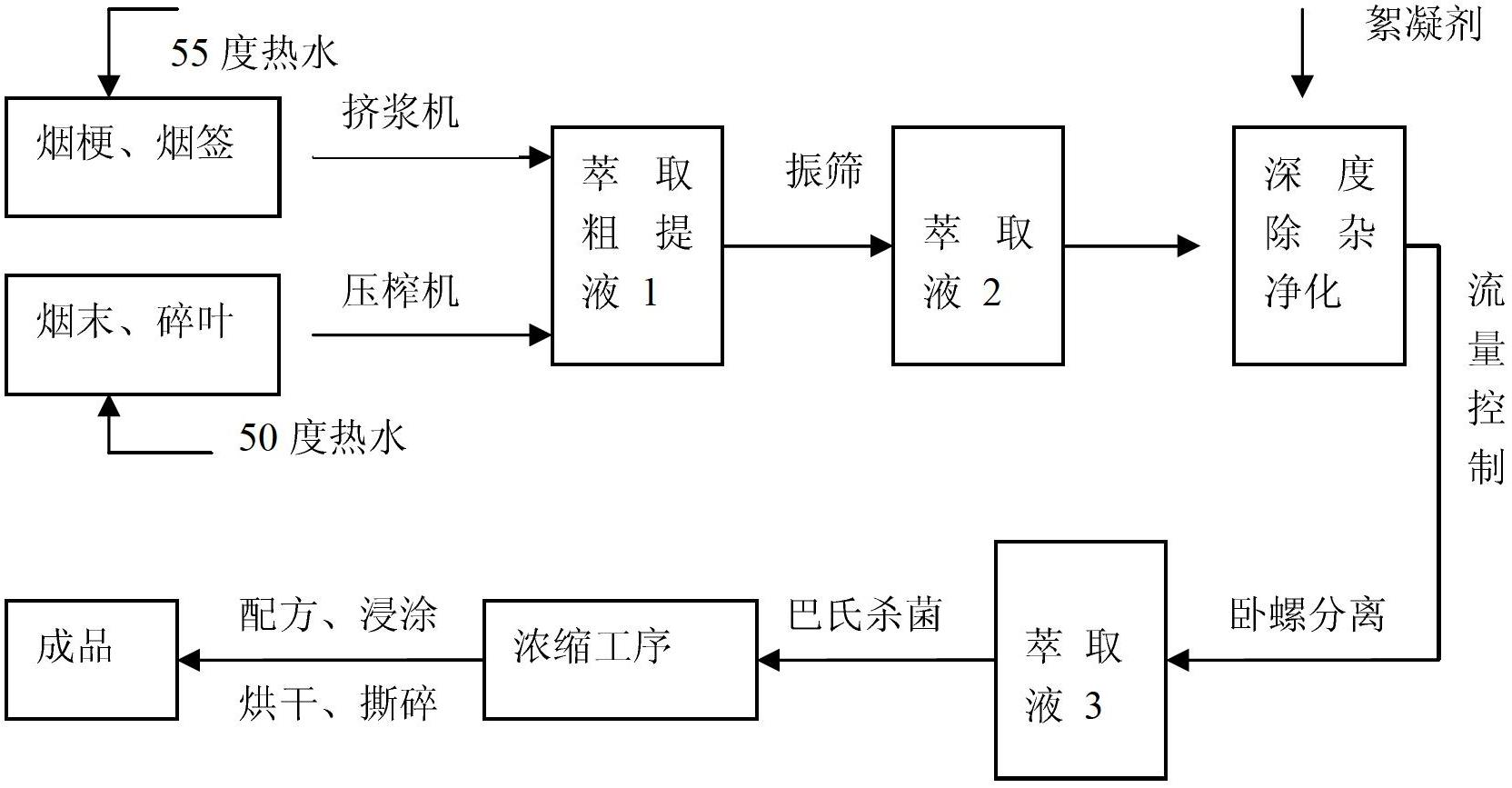

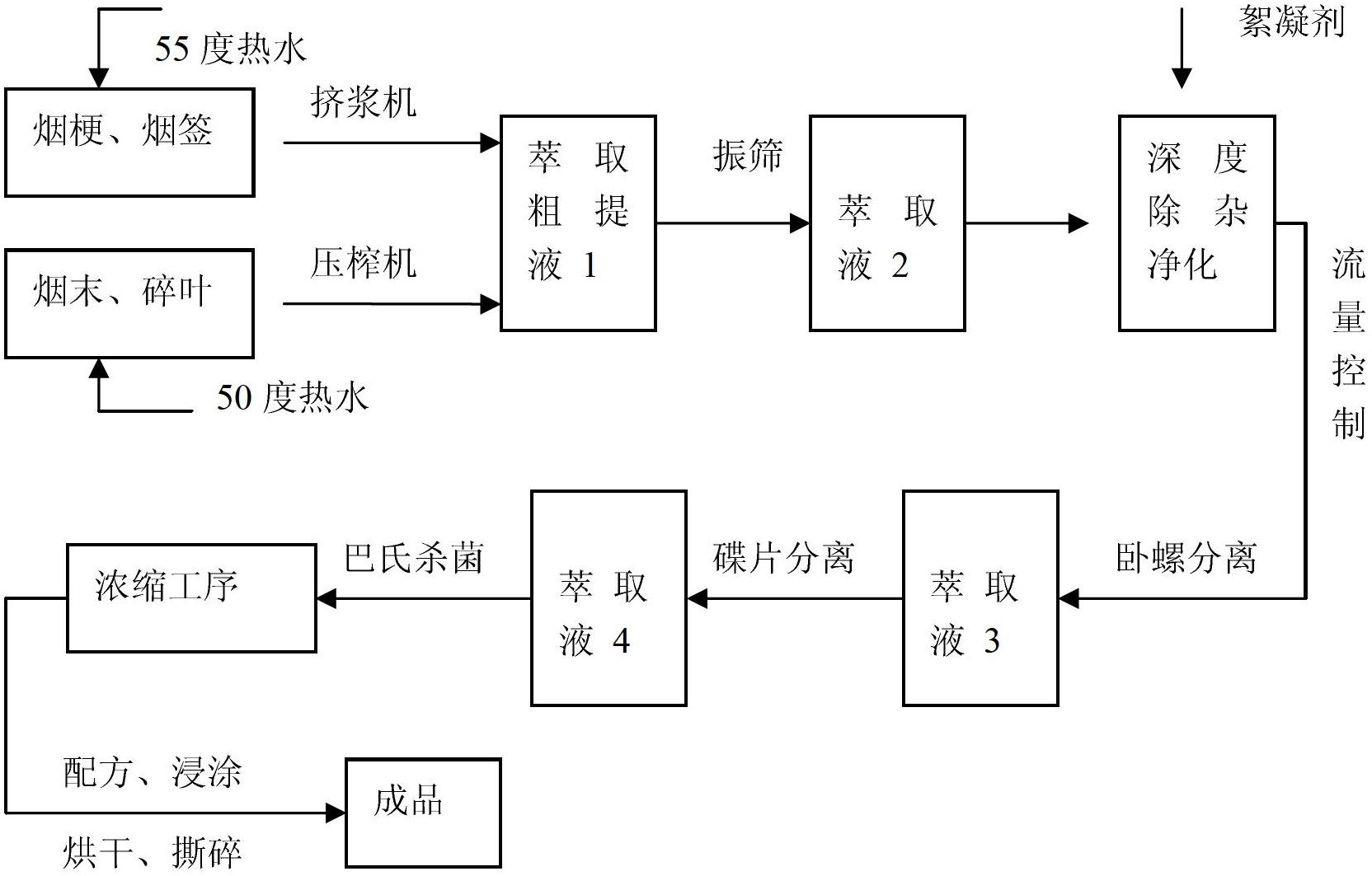

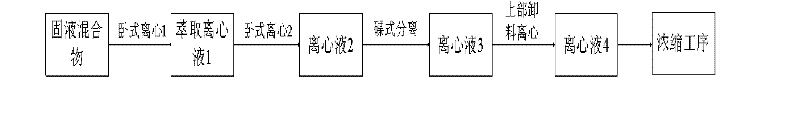

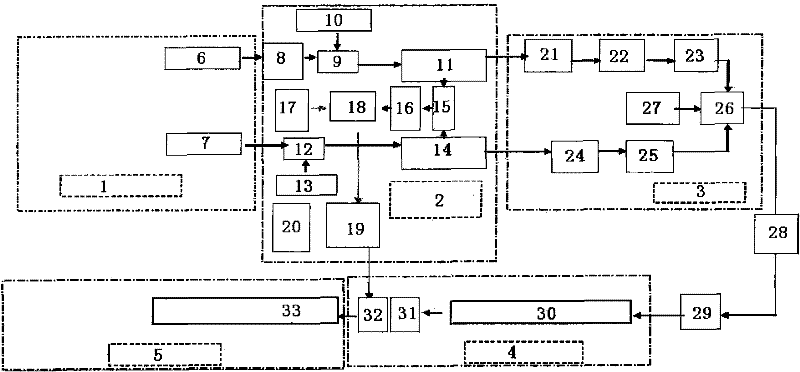

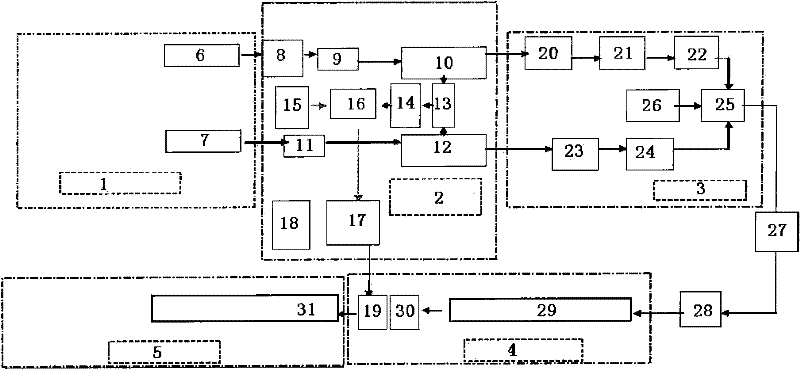

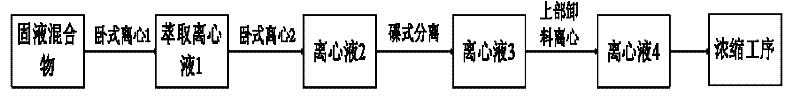

Extract deep purification and edulcoration process in manufacturing technology of papermaking tobacco sheets

ActiveCN102688613APrecise and efficient directional macromolecular separationOvercome the heavy airTobacco preparationCentrifugal force sediment separationScrapProcess module

The invention relates to an extract deep purification and edulcoration process in the manufacturing technology of papermaking tobacco sheets. The process comprises the following steps: a, tobacco waste including tobacco stems, tobacco sticks and tobacco powder is fully soaked in hot water and then extracted; b, the mixture of tobacco waste and water is fed into a squeezer and then squeezed for solid-liquid separation, and the liquid part is extracted crudely and is screened through a linear vibrating screen for solid-liquid separation; c, the liquid separated through the linear vibrating screen enters a filter aid process module to be processed through deep macromolecule flocculation, wherein an edible flocculating agent is adopted, the addition proportion is 0.1 to 0.8%, and the flocculation time is 5 to 50 minutes; liquid processed through deep macromolecule flocculation enters a primary horizontal spiral discharge settling centrifuge to be separated; and e, the liquid separated by the centrifuge in step d is pasteurized at the temperature of 60 to 70 DEG C for edulcoration, and then enters a concentration system to be concentrated. The process can effectively remove macromolecule particles, improves the concentration efficiency and ensures the quality of concentrate.

Owner:杭州利群环保纸业有限公司

Method for solid-liquid separation during sheet production through papermaking process

ActiveCN101744357AHigh yieldSave resourcesTobacco preparationCentrifugal force sediment separationFiberSlag

The invention discloses a method for solid-liquid separation during tobacco sheet production through papermaking process, which includes steps: respectively extracting the fragments of tobacco stalk and tobacco leaf through hot water; respectively implementing horizontal centrifugal separation on the mixture of the fragments of tobacco stalk or tobacco leaf, and water, moving solid slag to the working procedure of defibrination, and moving the extract liquor eliminating coarse slag into a disc type separator, and feeding the obtained clear liquid into the working procedure of concentrating in next section; then concentrating the extract liquor, and spraying or coating the concentrated extract liquor on a formed fiber sheet substrate, drying, tabletting and forming. The production technique method adopted by the invention improves the use ratio for sheet production concentrators through papermaking technique and increases the inherent quality of the concentrated liquor, thereby improving the inherent quality of sheet products through papermaking technique.

Owner:CHINA TOBACCO HUNAN INDAL CORP

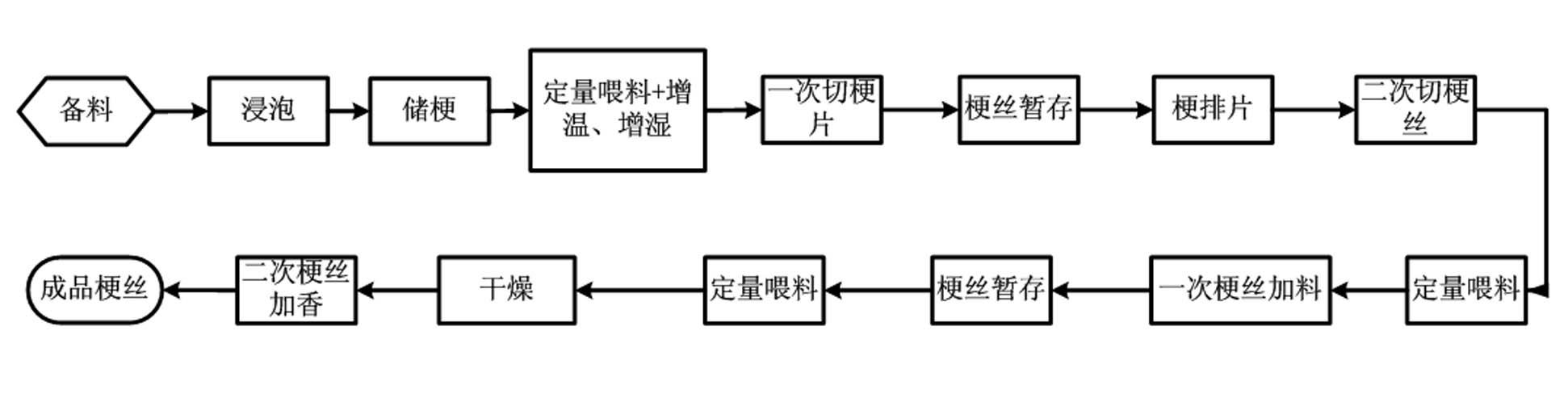

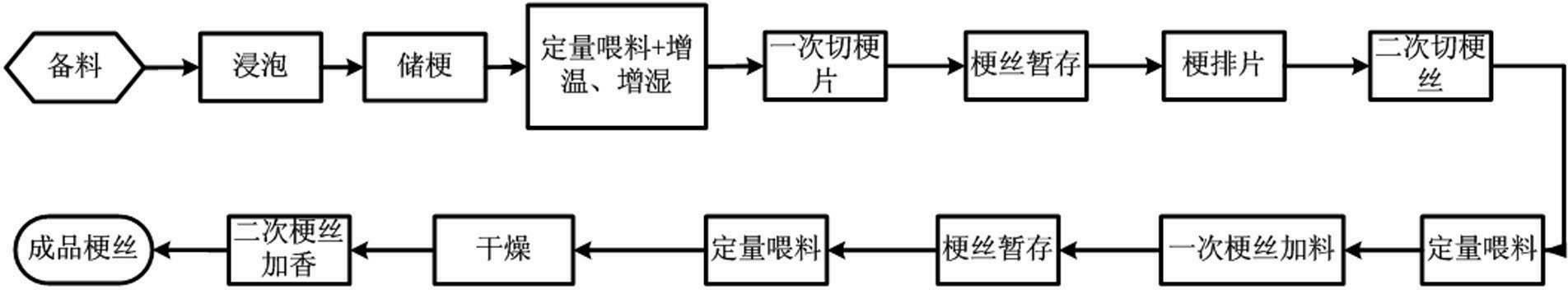

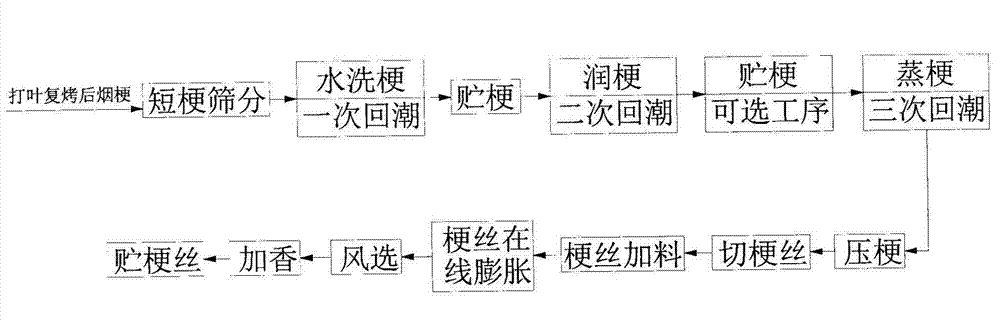

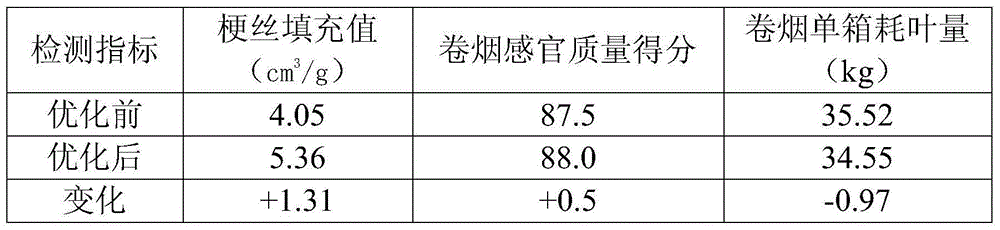

Technology for treating expanded stems

The invention discloses a technology for treating expanded stems, belongs to the technical field of shred making of tobacco, and in particular relates to the technical field of shred making with tobacco stems. The technology comprises the following steps of: soaking the tobacco stems, storing the stems, quantitatively feeding, heating and humidifying, slicing the stems for the first time, temporarily storing the stem slices, discharging the stem slices, cutting the stems into shreds for the second time, quantitatively feeding, adding the primary stem shreds, storing the stem shreds, quantitatively feeding, drying, and performing secondary flavoring, thus obtaining a stem shred finished product. The obtained product has the advantages of good bulkiness, low breaking rate, low production cost, pure aroma, high filling value, light wood mixed gas, comfortable mouthfeel, soft smoke, capability of reducing tar of cigarettes and good compatibility with the tobacco shreds.

Owner:HONGTA TOBACCO GRP

Method for adding tobacco ash during paper-making method type prodn. of tobacco sheet

ActiveCN1757334AHigh fillingImproved physical properties including filling propertiesTobacco preparationPulp and paper industryCoating

A method for using the fume dust as the filler in the process for preparing tobacco sheet by paper making method features that the fume dust (5-30 Wt%) can be added at 5 technological sites: pulp pool, pipeline between pulp stabilizing tank and pulp flowing tank, long screen, the position between vacuum floating roller and primary pressing, and the coating unit. It can improve the quality of tobacco sheet and low cost.

Owner:CHINA TOBACCO HUNAN INDAL CORP

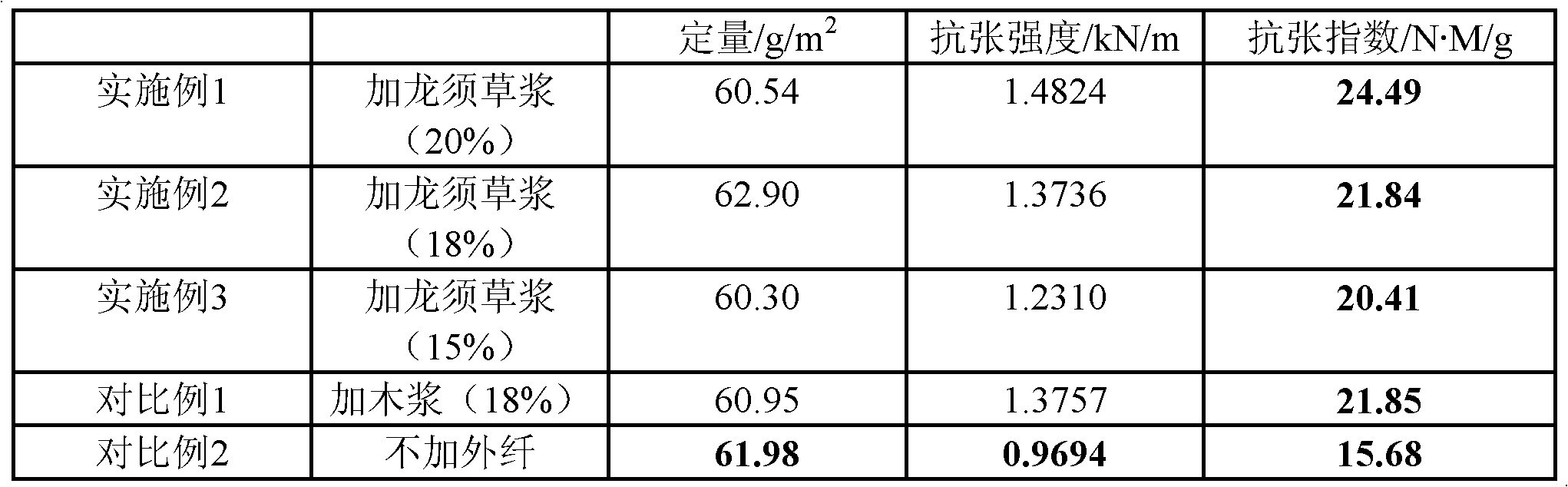

Tobacco additive for improving sensory quality of tobacco sheet and preparation method as well as application thereof

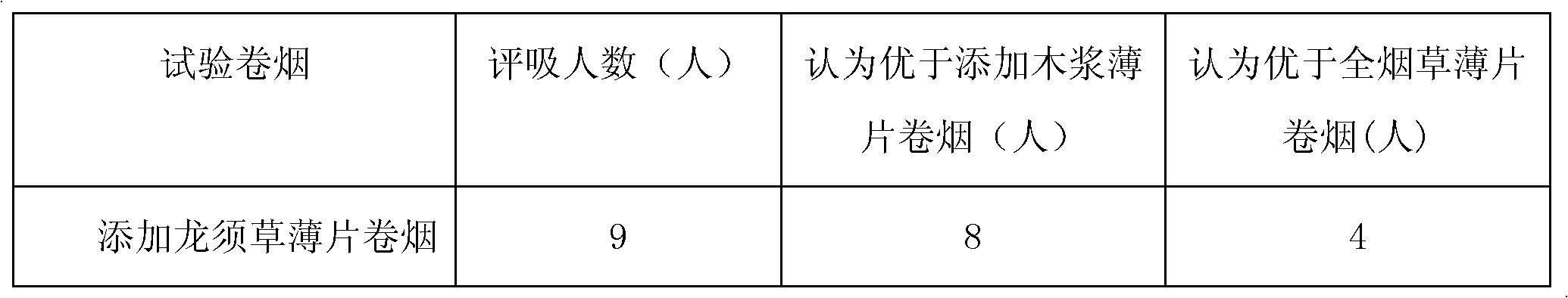

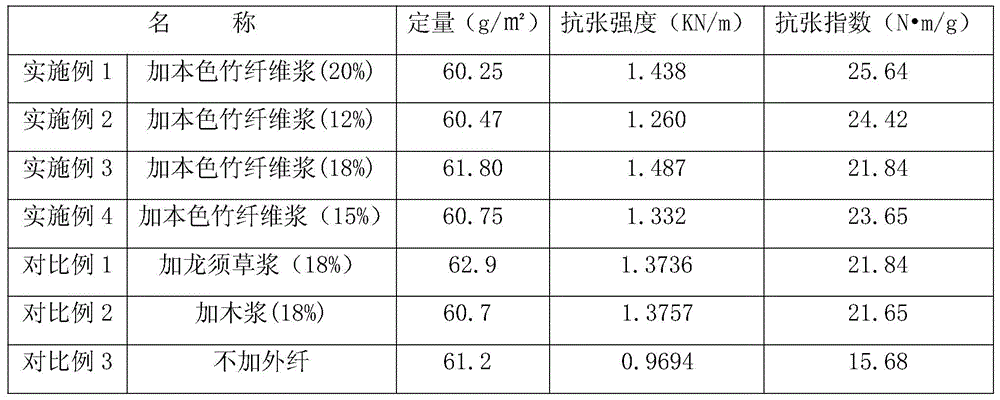

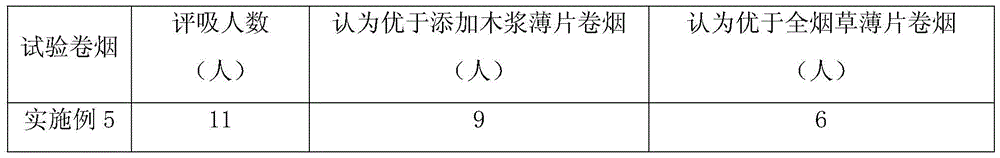

The invention provides a tobacco additive, Chinese alpine rush syrup, capable of reducing thrill of a tobacco sheet and reducing poor smell of woody smell and the like for improving intrinsic flavor of smoke and tobacco, and provides a method for preparing the tobacco sheet by taking the Chinese alpine rush syrup in place of wood syrup. The method comprises the following steps of: processing Chinese alpine rush through a beating stage in a sheet production process; and performing full fibrillation on Chinese alpine rush fiber, blending with tobacco syrup and performing papermaking to substitute the wood syrup which plays a role of a frame in the original production process. The use of tobacco stem resource and woody raw material is reduced, so that the tobacco raw material resource which grows increasingly tense throughout the country at present can be easily coped, forest resource can also be protected, and the cigarette cost is reduced; most importantly, the finished tobacco sheet is rolled into cigarette; compared with smoking assessment of the normal wood syrup product, the thrill of the cigarette finished product prepared by the invention is reduced, the poor smell of woody smell and the like is obviously relieved, and the intrinsic flavor of smoke and tobacco is obviously improved.

Owner:SHANGHAI TOBACCO GRP CO LTD +1

Cut tobacco fast puffing and drying process

InactiveCN1436495AReduce green miscellaneous gasHigh expansion rateTobacco preparationTarLower grade

The present invention relates to the tobacco processing process and is especially the puffing and drying process of cut tobacco. The tobacco process includes feeding material, heating cut tobacco, puffing and discharge. The beneficial effects of the present invention includes reserving tobacco fragrance in cut tobacco, reducing the green and sundry smell in cut tobacco, converting the color of low-grade cut tobacco, raising the puffing rate of cut tobacco, reducing cost of cigarette, raising filled tobacco amount, decreasing tar content in cigarette, making cut tobacco soft, loose elastic and no oxidation and browning, killing bacteria and other toxic microbes and producing no environmental pollution.

Owner:江苏智思机械制造有限公司

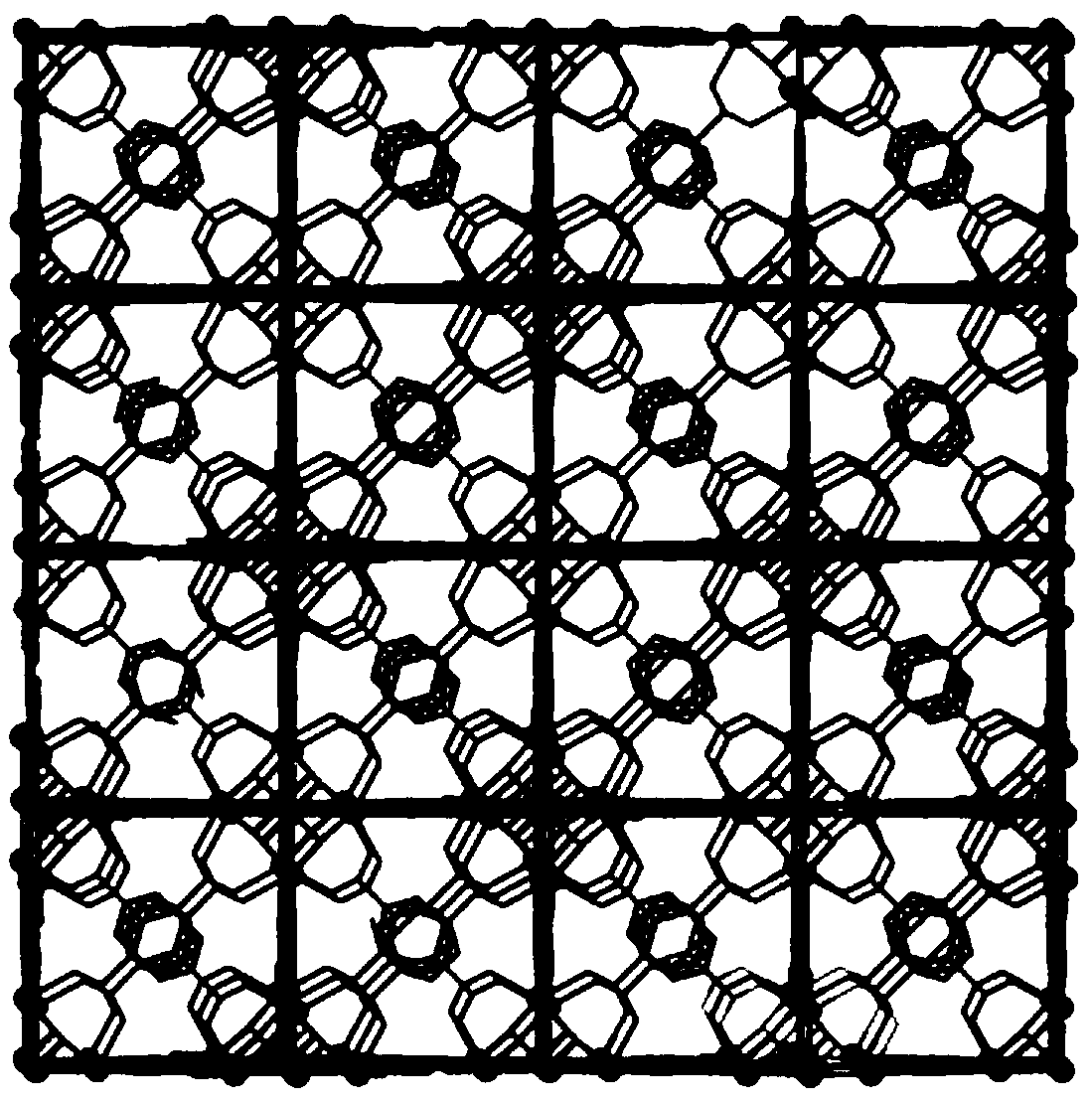

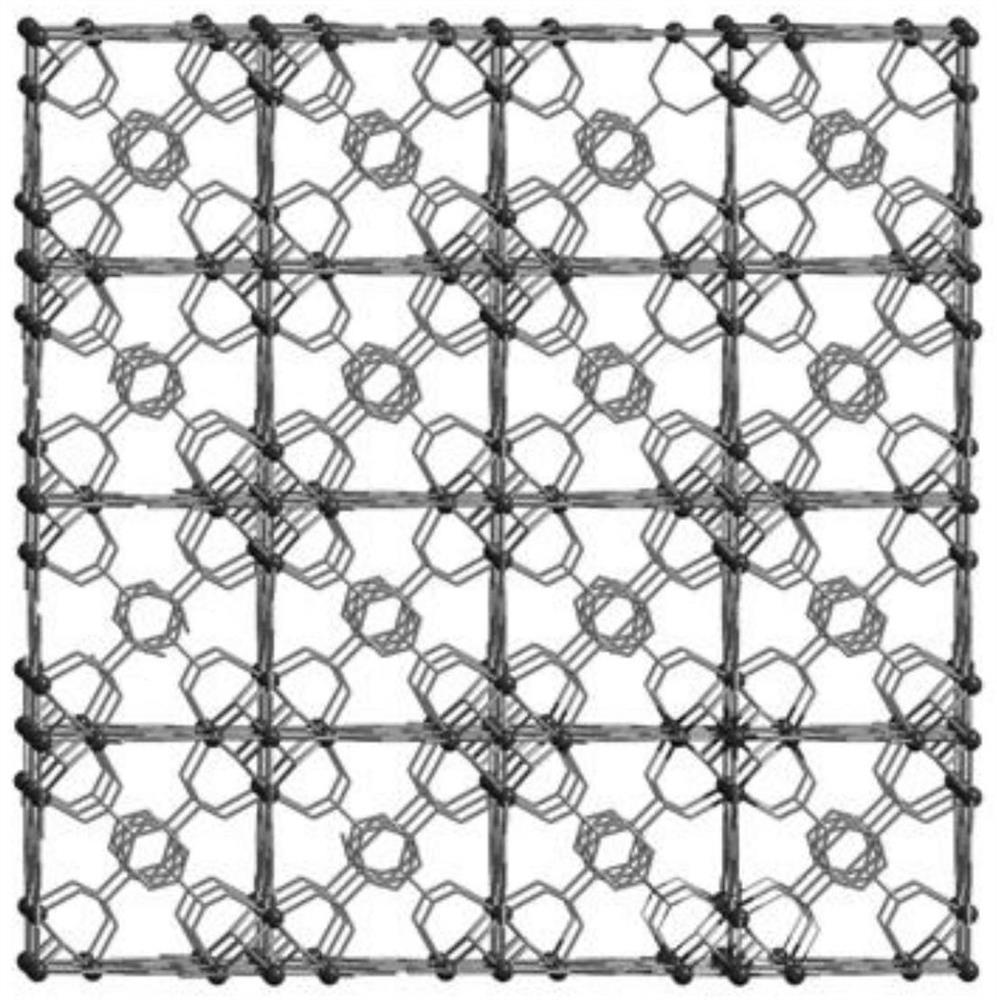

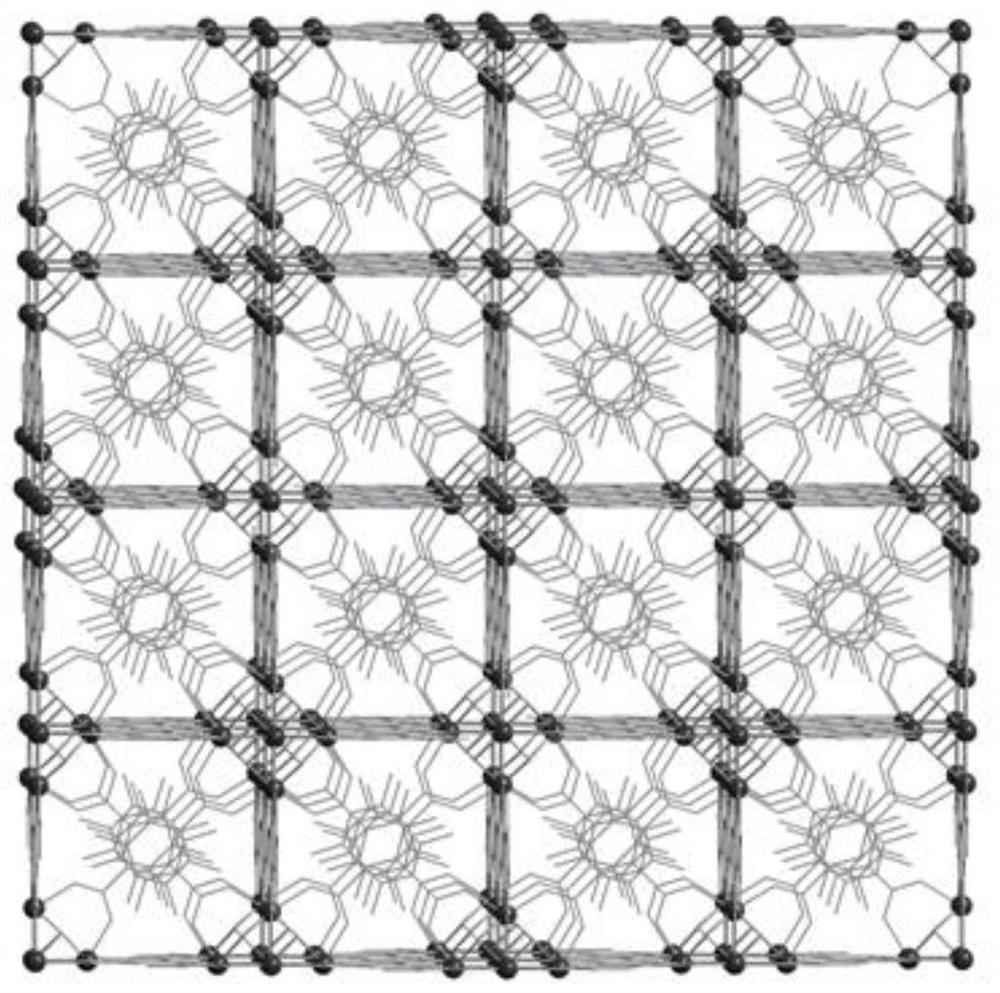

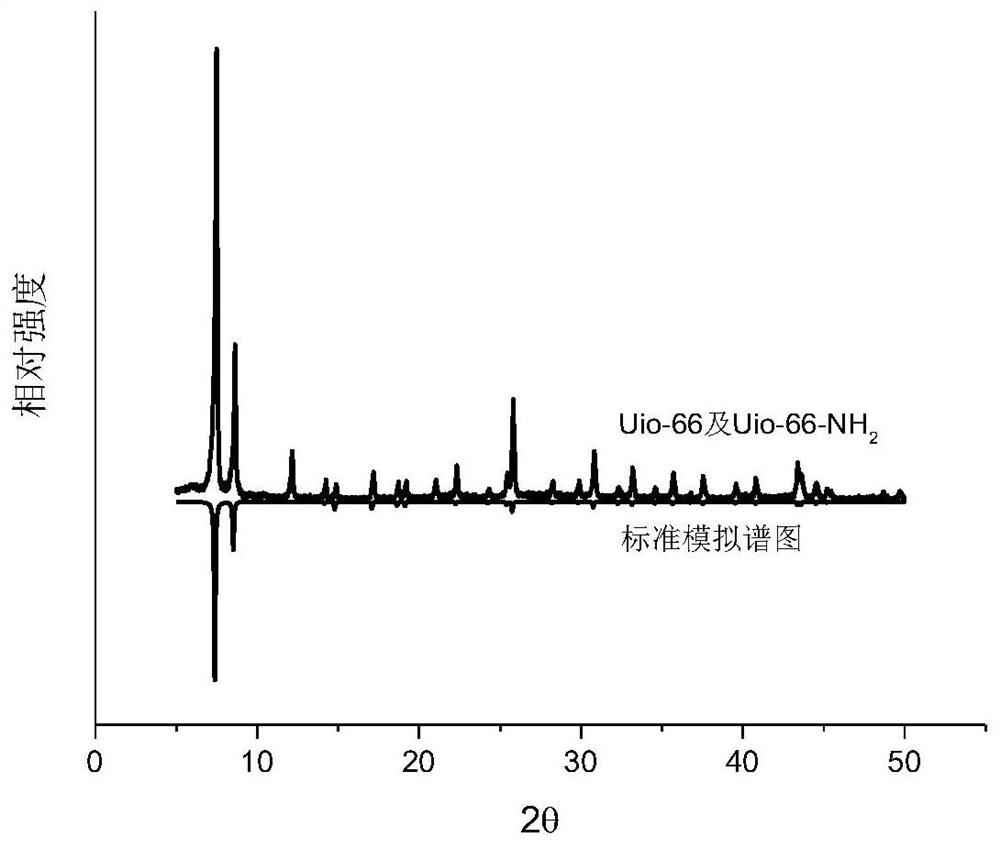

Tobacco moisturizer and preparation method and application thereof

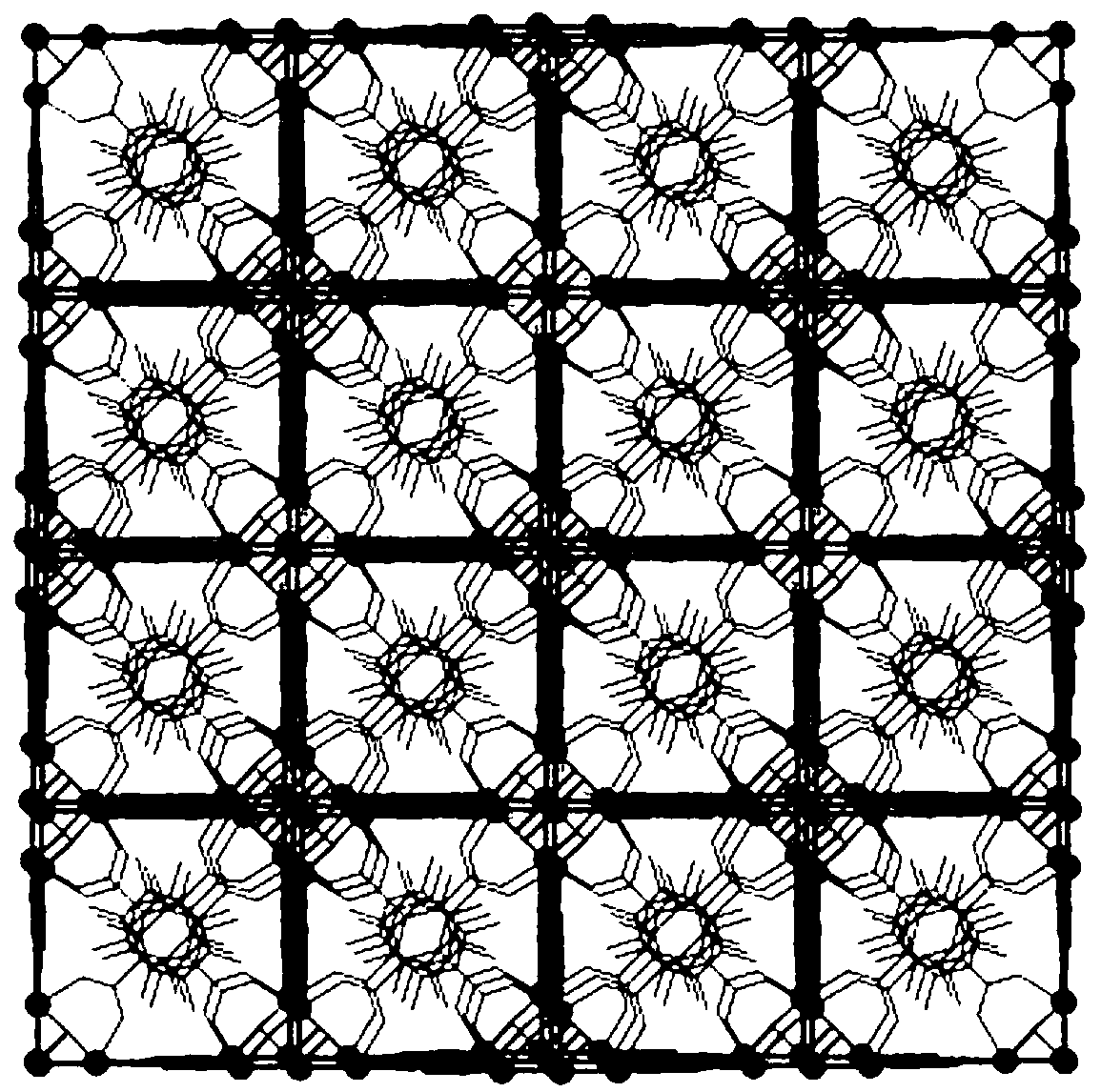

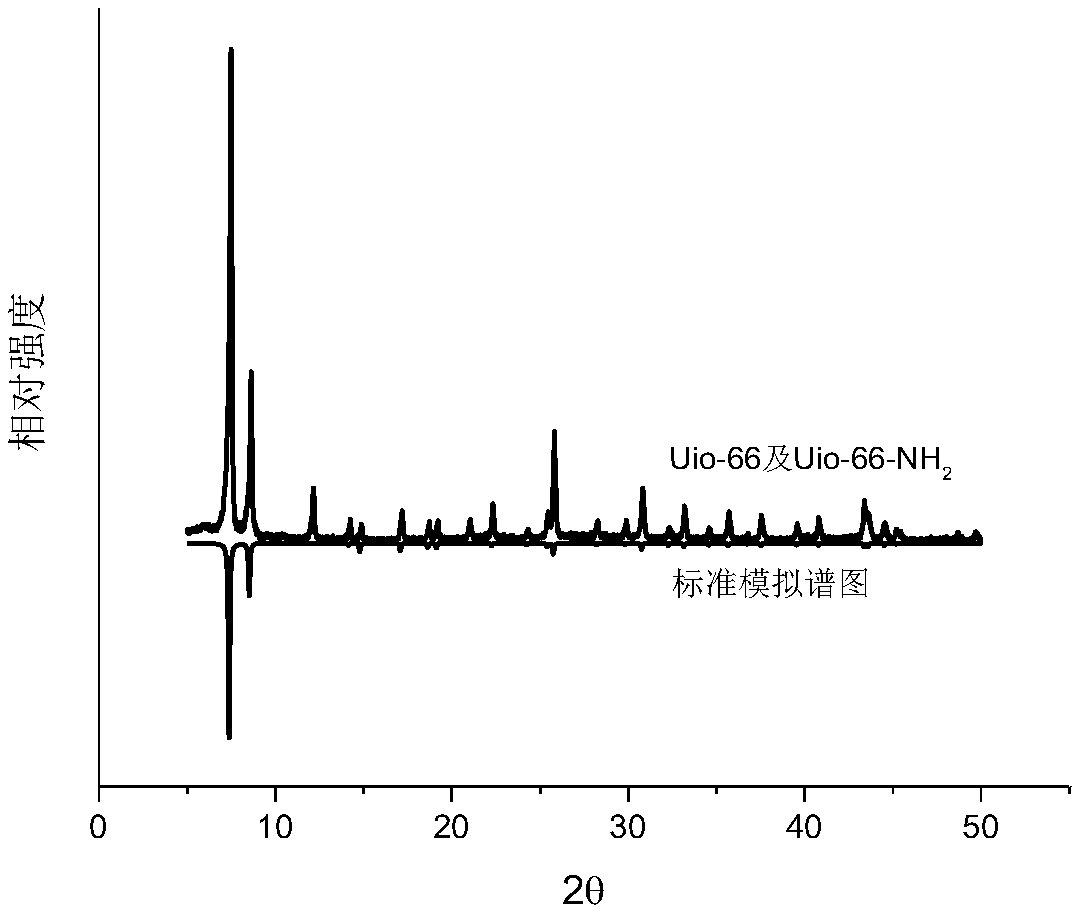

ActiveCN108851200AGood compatibilityDoes not affect aromaTobacco preparationTobacco treatmentMetal-organic frameworkDicarboxylic acid

The invention discloses a tobacco moisturizer. The tobacco moisturizer is a metallic organic skeleton material with a three-dimensional structure obtained through the self-assembling of Zr 4+ and p-phthalic acid or 2-aminobenzene-1,4-dicarboxylic acid, wherein the metallic organic skeleton material with a three-dimensional structure obtained by the self-assembling of the Zr 4+ and the p-phthalic acid is Uio-66, and the metallic organic skeleton material with a three-dimensional structure obtained by the self-assembling of the Zr 4+ and the 2-aminobenzene-1,4-dicarboxylic acid is Uio-66-NH2. The invention further discloses a preparation method of the tobacco moisturizer and the application of the tobacco moisturizer in tobacco.

Owner:CHINA TOBACCO YUNNAN IND

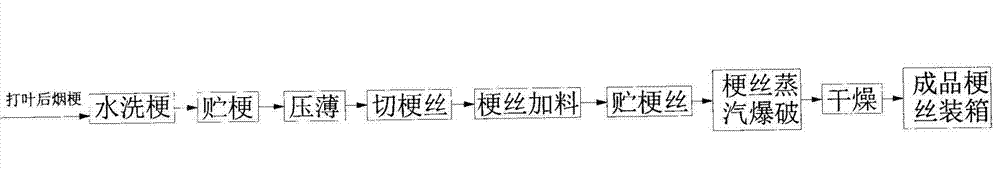

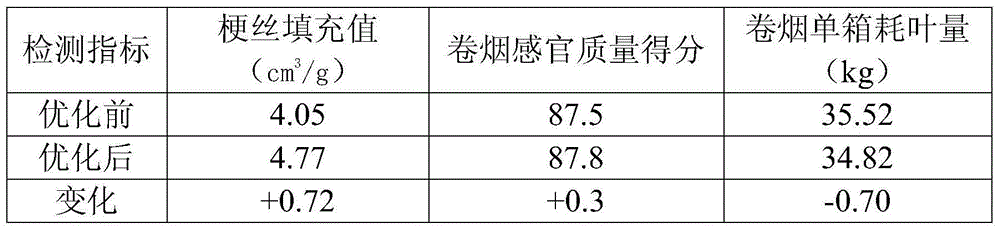

Tobacco stem cutting process by threshed tobacco stems

InactiveCN102783705AImprove qualityImprove blending uniformityTobacco treatmentIndustrial engineeringCigarette smoke

The invention discloses a tobacco stem cutting process by threshed tobacco stems. The process is characterized in comprising the following technical steps: washing stem, storing stem, thinning, cutting stem, carrying out steam explosion for cut stem, drying and so on. The process has the advantages that color and shape of the cut stem processed by the technical method are close to that of the cut tobacco; the breakage rate in the cut stem process is low; the blending uniformity is improved; when smoked, the tobacco is free from harmful wood flavor; the cigarette smoke is harmonized; the comfort of the tobacco is improved; the cut stem is strong in filling capability; and the internal quality of the cigarette is further improved. The power consumption of the corresponding tobacco stem processing enterprise can be reduced. At present, a threshing redrying factory usually stores a lot of tobacco stems, so that the direct stem cutting process provides a new method for comprehensive utilization of the tobacco stems for the redrying factory, and provides a technical economic scheme for forward leading the stem cutting process of a cigarette factory to the redrying factory.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

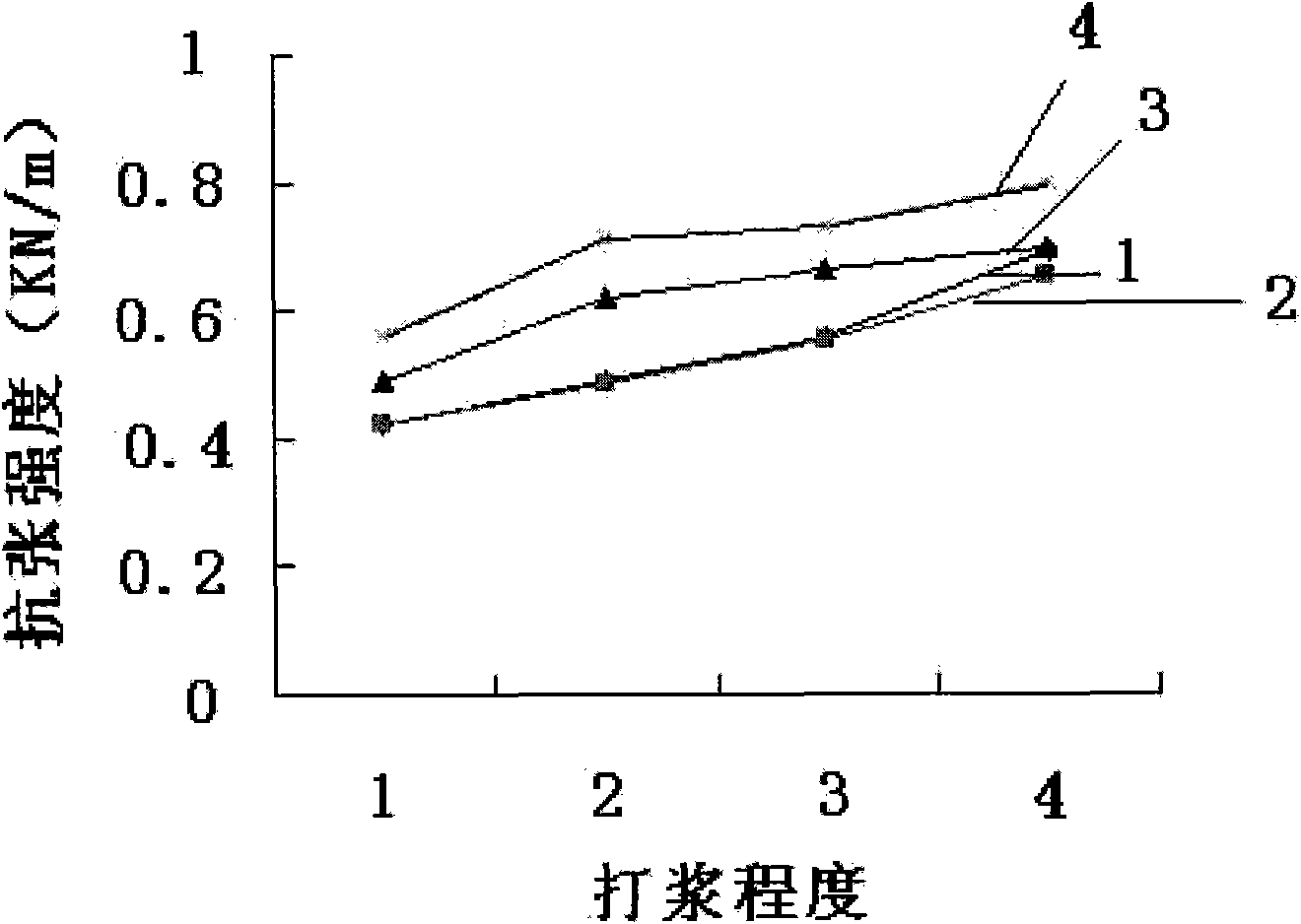

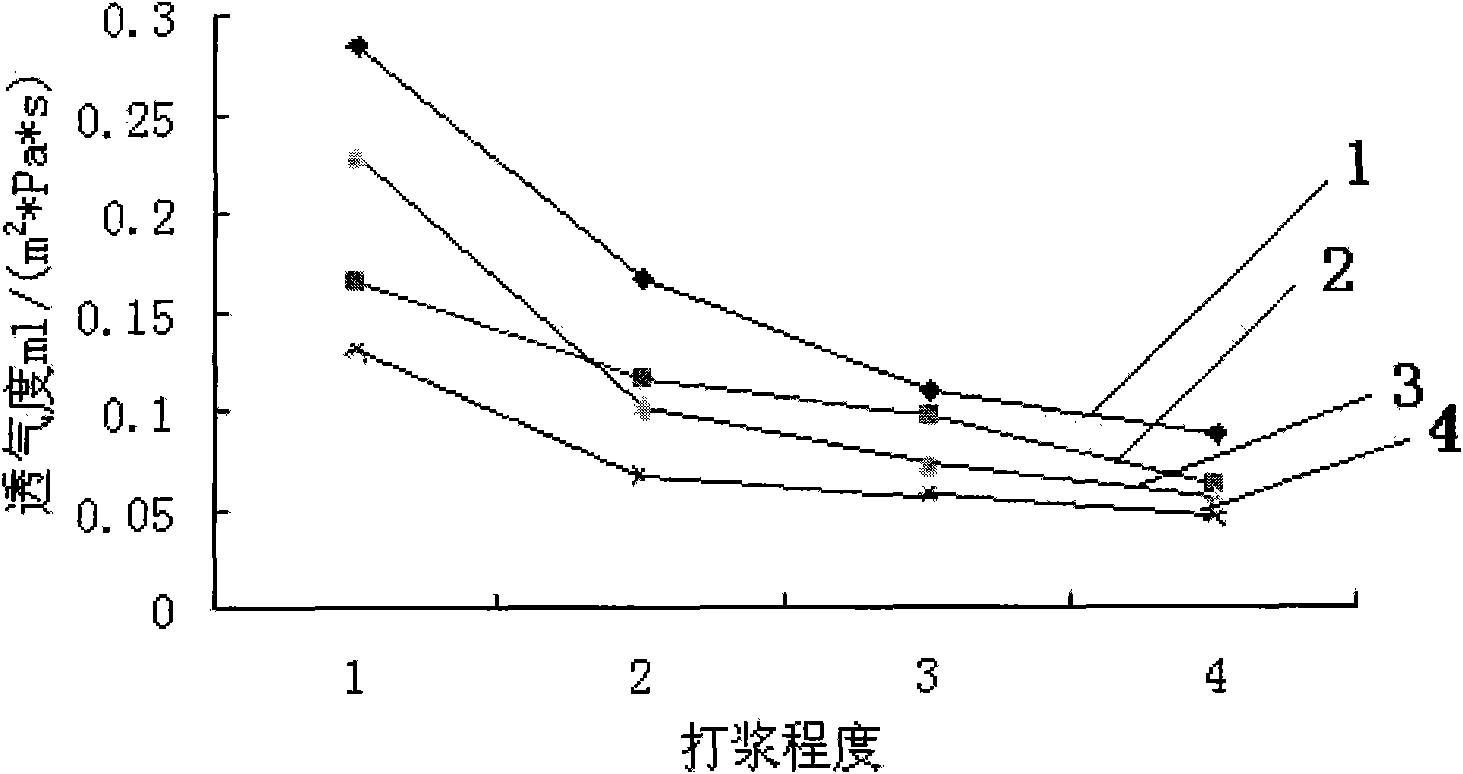

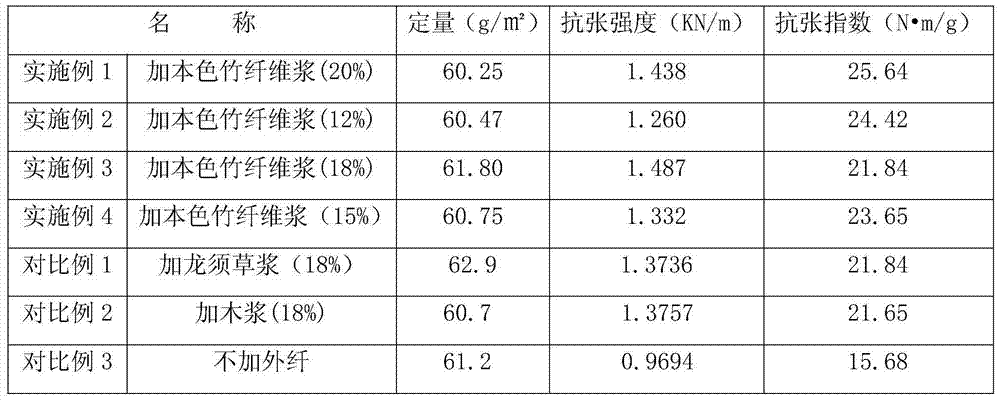

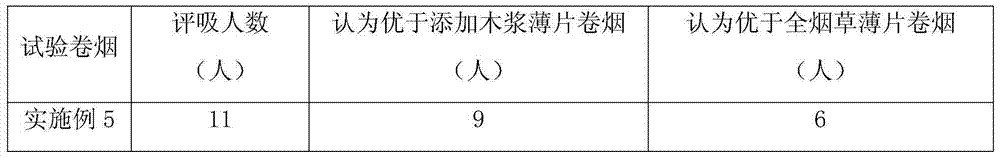

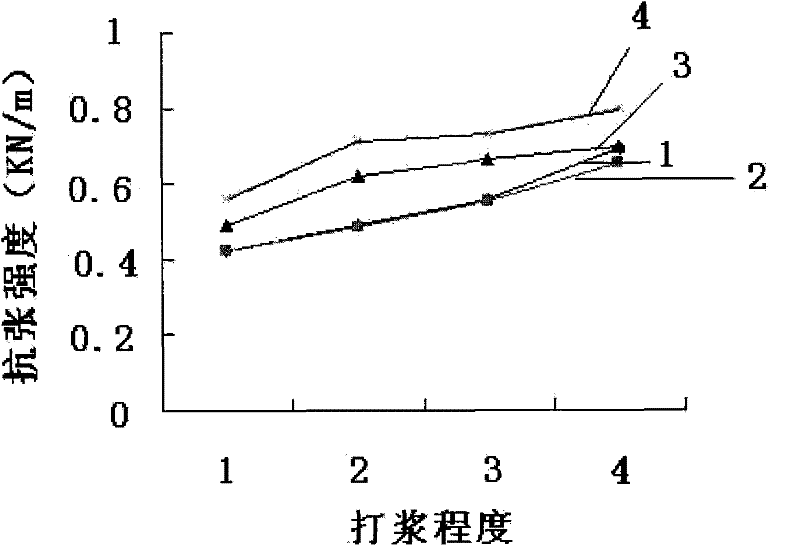

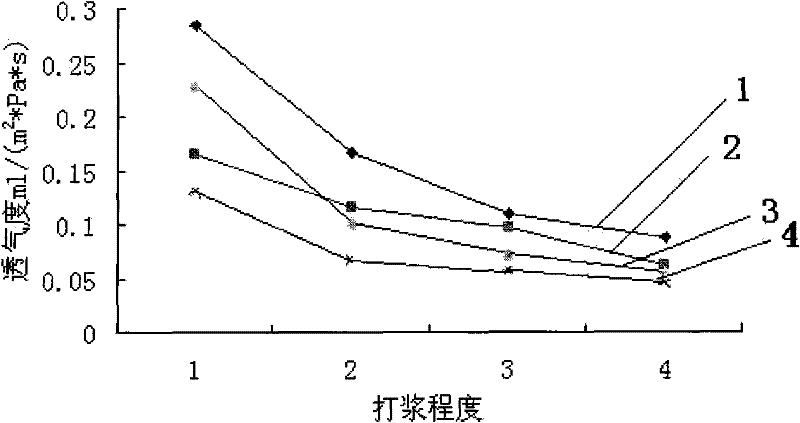

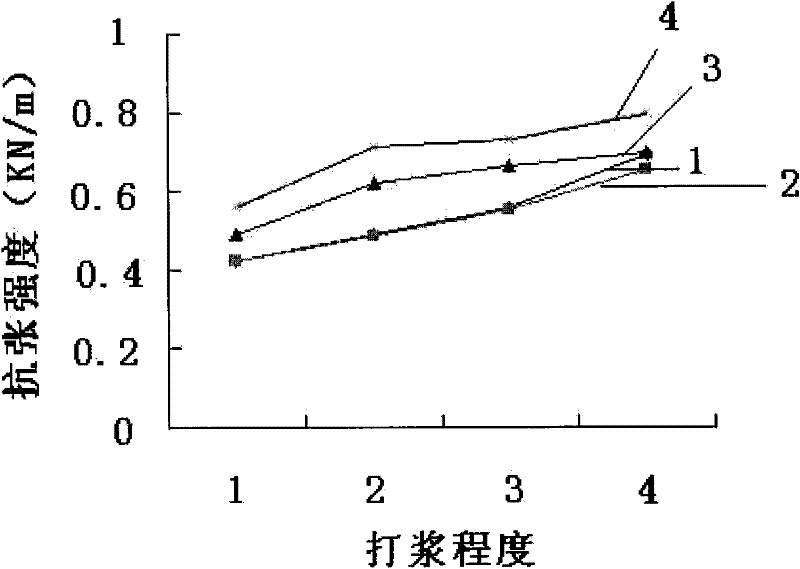

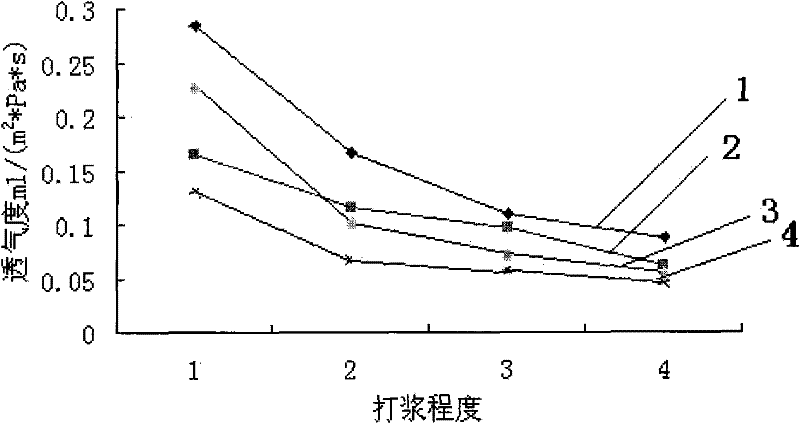

Original-color bamboo fiber pulp, preparation method thereof and an application of the bamboo fiber pulp as tobacco additive

ActiveCN104213458AReduce usageAvoid residual contaminationTobacco preparationWashing/displacing pulp-treating liquorsFiberBoiling process

The invention discloses an original-color bamboo fiber pulp, a preparation method thereof and an application of the bamboo fiber pulp as a tobacco additive. The original-color bamboo fiber pulp is 20-32 degree SR in a pulping degree and is 5-8g in wet weight. The preparation method includes following steps: S1: crush of raw materials: crushing bamboo fiber raw materials into fiber powder through a dry crushing method; S2: a steaming and boiling process: performing the steaming and boiling process to the fiber powder and a steaming and boiling liquid to obtain a low-hardness bamboo pulp; S3: a washing process: performing a crude selection process through a vibrating screen, a black solution extraction process through a vacuum pulp washing machine, a fine selection process through a pressure sieve, a dust removing process through a residue removing device and a pulp washing process through the vacuum pulp washing machine to obtain a screened pulp; S4: a drying process: performing a dewatering and drying process to the screened pulp to obtain an original-color bamboo fiber plate; and S5: a pulping process: performing a pulp crushing process and a pulping process to the original-color bamboo fiber plate with the pulping degree and the wet weight being controlled to prepare the original-color bamboo fiber pulp. The method is simple in operation, is convenient to carry out, is low in cost, and is green and environmental-protective. The original-color bamboo fiber pulp can be used as the tobacco additive, can reduce irritation of a tobacco sheet, can reduce bad smell of wood and the like, and can improve an original smell of tobacco.

Owner:SICHUAN HUANLONG NEW MATERIAL

Method for processing reconstituted tobaccos through homogeneous and isogenous paper-making process

ActiveCN104041933ALittle fluctuation in qualityImprove adaptabilityTobacco preparationProduction lineLiquid ratio

The invention discloses a method for processing reconstituted tobaccos through a homogeneous and isogenous paper-making process. The method comprises the following steps: step 1, collecting reconstituted tobacco raw materials with same marks and same dimensions on a cigarette on-line production line; step 2, extracting the reconstituted tobacco raw materials by using water according to the extracting solid-to-liquid ratio of 1:6 to 10 at an extracting temperature of 65 to 75 DEG C for 15 to 30 min; step 3, modulating and preparing a coating liquid through enzyme treatment and concentration on an extracting solution obtained; extracting residual solid matters to pulp and make a film base, coating the coating liquid onto the film base in a dipping manner through a papermaking and forming process, and drying so as to prepare the reconstituted tobaccos through the homogeneous and isogenous paper-making process. According to the method provided by the invention, after collecting, extracting on the reconstituted tobacco raw materials with the same marks and same dimensions is performed, the quality of the manufactured reconstituted tobaccos is smaller in volatility, the reconstituted tobaccos are better in suitability with the tobaccos with the same marks, sensory evaluation on cigarettes cannot be influenced when the use ratio of the reconstituted tobaccos reaches more than 20 percent, and the cost for the cigarettes is reduced.

Owner:CHONGQING CHINA TOBACCO IND CO LTD +1

Method for preparing cigarette fragrance compensation granules

InactiveCN102987547AStrong processing resistanceImprove securityTobacco treatmentTobacco smoke filtersCold airBroken rice

The invention relates to a method for preparing cigarette fragrance compensation granules, which comprises the steps of: weighing 30-50 parts by weight of tobacco waste, 20-30 parts by weight of rice and 30-50 parts by weight of starch; cooking the rice, then cooling the cooked rice and crushing by a sieve with 30-60 meshes to obtain broken rice; cooking the tobacco waste with water at the temperature of 50-80 DEG C for 25-50min, filtering and concentrating the filtrate to obtain a concentrated solution with the density of 1.1-1.6g / cm<3>; mixing the starch and the broken rice with the concentrated solution, then adding water into the mixture, evenly stirring until the mixture can be kneaded into a cake shape, and sending the mixture into an extruding machine; carrying out curing extrusion for 1-3min at the temperature of 75-95 DEG C, and then making into granules with 20-80 meshes; and blowing cold air to the prepared granules for drying, and then drying by hot air until the water content is less than 12% to obtain the cigarette fragrance compensation granules. The method fully utilizes the tobacco waste raw material; and the prepared granules have rice quality structures, are high in processing resistance and safety and obvious in cigarette fragrance compensation effect, and remarkably reduce the cigarette cost.

Owner:YUNNAN REASCEND TOBACCO TECH GRP

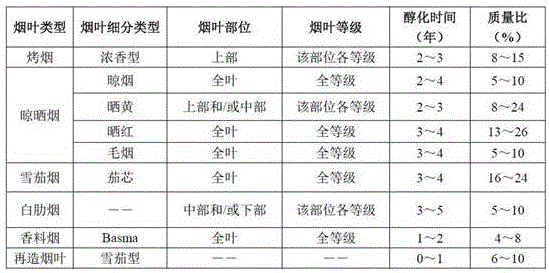

Cigar type cigarette tobacco leaf formulation

The invention belongs to the technical field of tobacco processing and particularly relates to a cigar type cigarette tobacco leaf formulation. The formulation is obtained by compounding of flue-cured tobaccos, sun-cured tobaccos, cigar tobaccos, burley tobaccos, aromatic tobaccos and reconstituted tobaccos. By taking the advantages of variety richness, low cost and unique flavor of the sun-cured tobaccos in China, the sun-cured tobaccos are reasonably compounded with the flue-cured tobaccos, the burley tobaccos and the aromatic tobaccos to obtain the novel cigar type cigarette tobacco leaf formulation. The cigar type cigarette tobacco leaf formulation is low in use ratio requirement; on the one hand, fast-rising demands of domestic consumers are met; on the other hand, optimal configuration of domestic tobacco material resource advantages is realized, the utilization range of the sun-cured tobaccos is expanded, cigarette cost is effectively reduced, and high practical value is achieved. According to preliminary smoking experiments of prepared cigar type cigarettes, the prepared cigar type cigarettes have a typical cigar style and are stable in flavor and low in harmful ingredients of smoke, thereby being worthy of popularization and application.

Owner:CHINA TOBACCO HENAN IND

Preparation method of cigarette products with plant pine needles

InactiveCN102920003AWide range of materialsEasy to processTobacco preparationSocial benefitsCurative effect

The invention discloses a preparation method of cigarette products with plant pine needles. The preparation method comprises the following steps of: (1) drying naturally green plant pine needles in the sun to become yellow or reddish yellow, and storing for later use; (2) after processing the stored pine needles, directly blending the pine needles in tobacco shreds according to a proportion that the used pine needles account for 1%-50% by weight of used tobacco; or after mixing the stored pine needles and tobacco materials according to a proportion that the used pine needles account for 1%-80% or 100% by weight of slice raw materials, processing the mixture into slices, and then blending the prepared slices into the tobacco leaves according to a proportion that the slices account for 1%-50% by weight of used tobacco leaves and then processing into the tobacco shreds. According to the preparation method, after being prepared, the plant pine needles with the healthcare and curative effects are directly blended into the tobacco shreds according to a certain proportion, so the prepared cigarette product has certain healthcare and curative effects, simultaneously, the using amount of the tobacco leaves also can be reduced, the quality and value of products are improved, and the high economic value and social benefits are created.

Owner:HUBEI CHINA TOBACCO IND

Method for preparing tobacco sheet and application thereof

ActiveCN101637298BGood physical propertiesExtract completelyTobacco preparationTobacco treatmentMaillard reactionFiber

The invention discloses a method for preparing tobacco sheets and an application of the method. In the method, enzymolysis is implemented when the tobacco stalk and the tobacco powder are soaked, solid-liquid separation is implemented after extraction, the solids are made into fiber sheet substrates, liquid is made into concentrated solution by alcohol precipitation and concentration, the concentrated solution is made into coating liquid by maillard reaction and coated on the fiber sheet substrates, and the fiber sheet substrates are dried and cut into tobacco sheets. In the invention, the macromolecular compounds that influence the quality of the tobacco sheets are sufficiently degraded by enzymolysis, the content of the impure taste in the tobacco sheets is decreased, the internal quality of the tobacco sheets is improved, and better aroma is obtained by the technical solution that produces prospective aroma by the maillard reaction to provide a rich aroma for the tobacco sheets so as to obtain tobacco sheet products fitting different types of cigarette products and having better internal quality. The tobacco sheets prepared by the method have excellent compatibility and harmonywith the conventional raw materials of the cigarettes, and have the advantages of good cigarette taste, various and rich aromas and less impure taste.

Owner:CHINA TOBACCO GUANGDONG IND

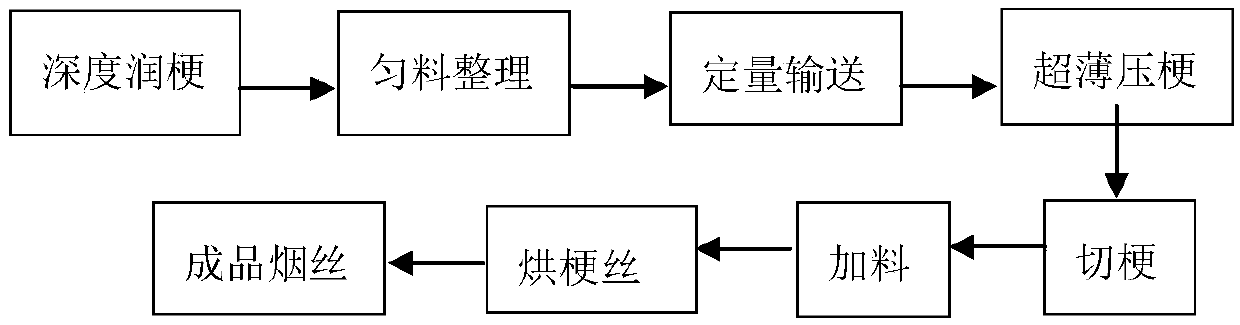

Tobacco cut stem preparation method

InactiveCN110810884AReduce the cost of cigarettesControl harmful ingredients and tar releaseTobacco preparationTobacco treatmentHorticultureEngineering

The invention discloses a tobacco cut stem preparation method. The method comprises the steps of deep stem moistening, uniform material finishing, quantitative conveying, ultrathin stem pressing, stemcutting, feeding, cut stem drying, finished cut stem forming and the like; the cut stems obtained by the method are the same in shape with cut leaves and can be used in high-grade cigarettes like cutleaves, so the cigarette cost is reduced, and meanwhile the harmful components and tar release amount of the cigarettes are effectively controlled.

Owner:CHINA TOBACCO MACHINERY TECH CENT

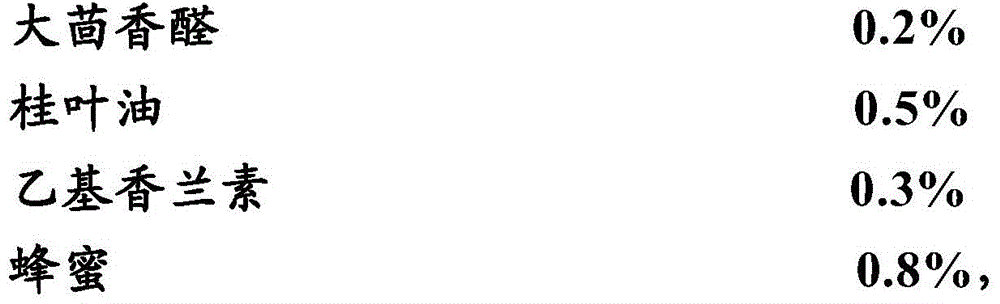

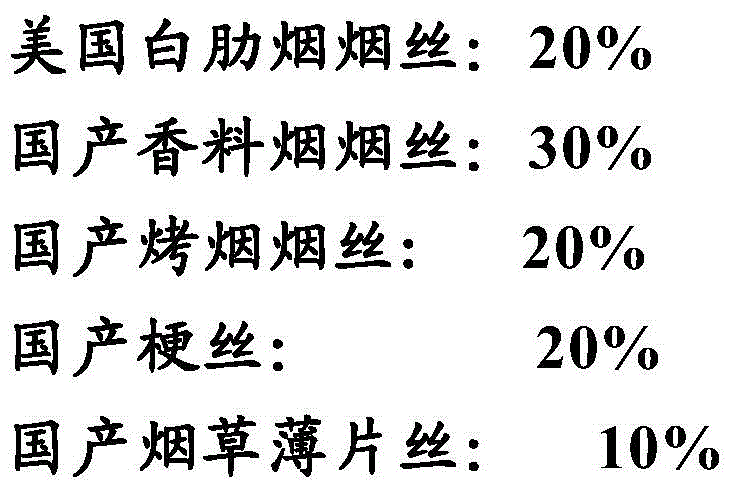

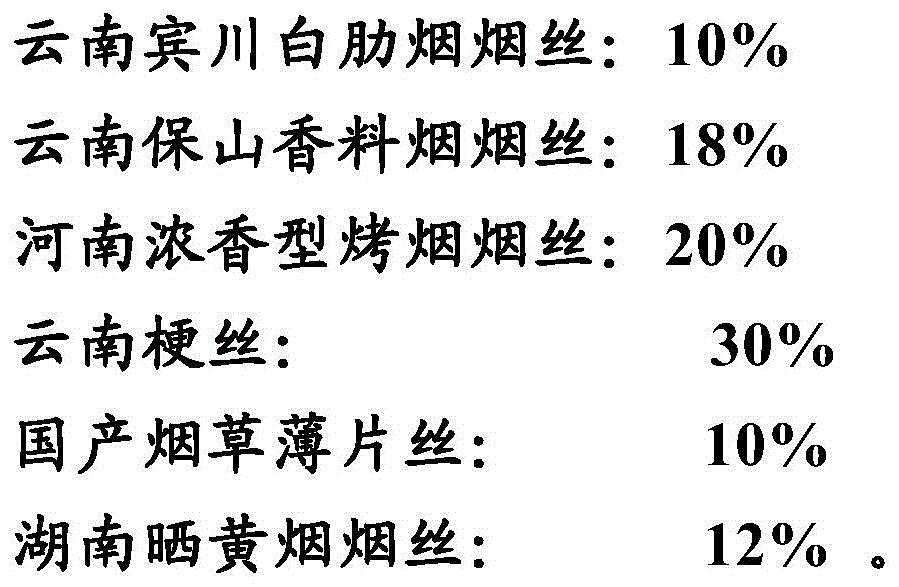

A Chinese-style mixed cigarette and its preparation method

ActiveCN103815539BRich and beautiful aromaIncrease aromaTobacco preparationTobacco treatmentFlavorEnvironmental health

Owner:CHINA TOBACCO FUJIAN IND

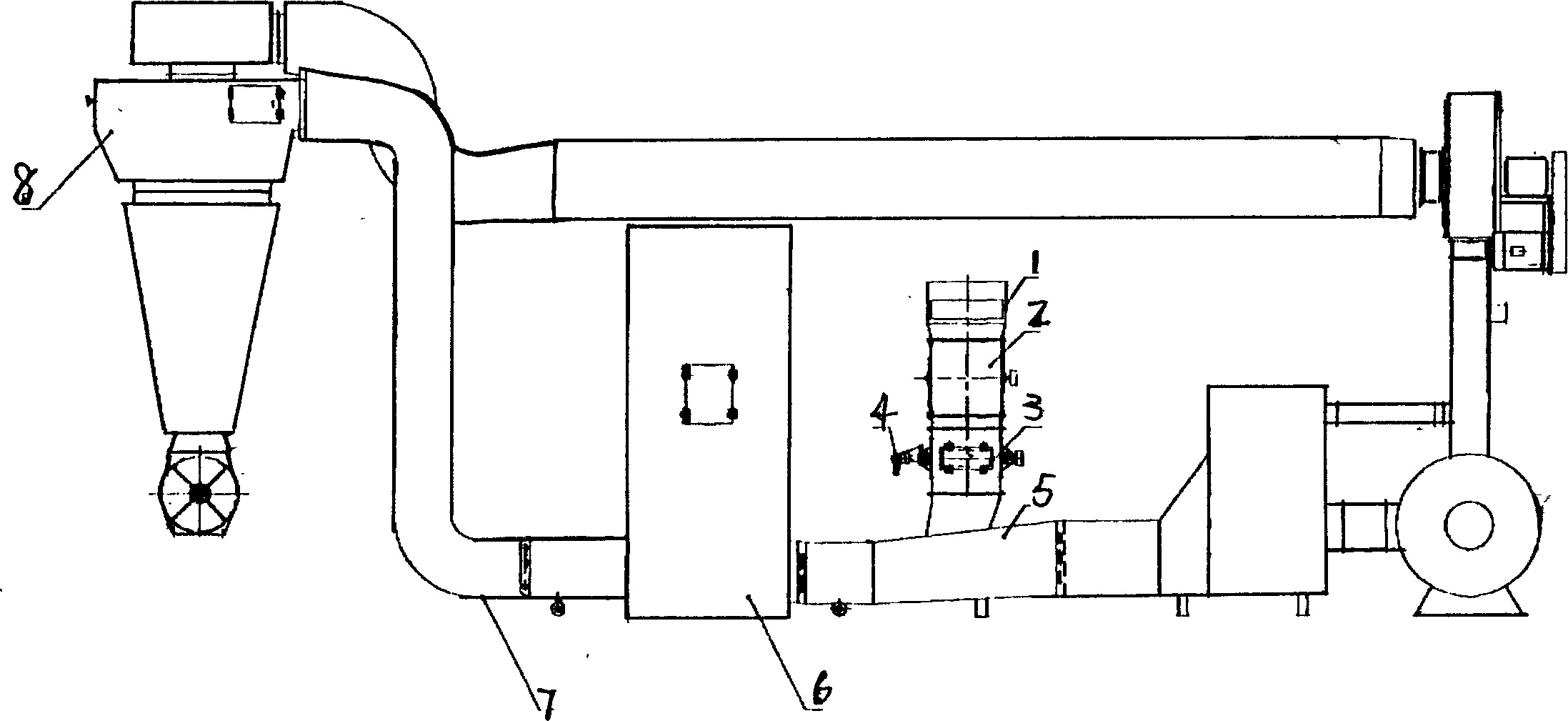

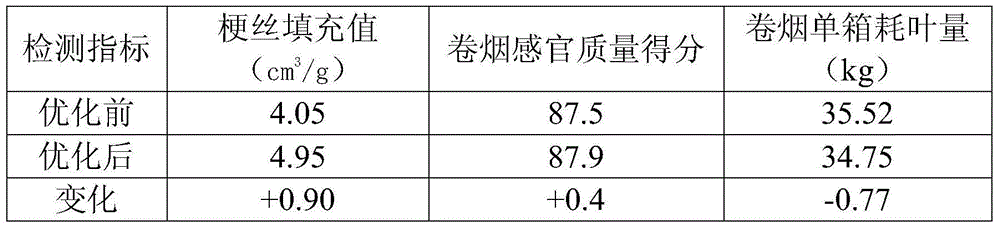

CTD pneumatic drying technology for stem

InactiveCN104522866AReduce consumptionImprove usabilityTobacco preparationTobacco treatmentEngineeringIncrease temperature

The invention belongs to the tobacco processing technical field, and in particular relates to a CTD pneumatic drying technology for stem. The pneumatic drying technology for stem CTD comprises the steps as follows: pressing the tobacco stem after increasing temperature and moistening, shredding, and CTD pneumatic drying the stem, the stem temperature increasing and increasing process (HT) is executed before the CTD pneumatic drying process for the stem, and the outlet temperature of the stem temperature increasing and increasing process (HT) is 90-95 DEG C. by adopting the technology, the filling value of CTD pneumatic drying for the stem can be raised, the inherent quality of the stem is effectively improved, the use ratio of the stem in the tobacco is raised and the tobacco cost is reduced.

Owner:CHINA TOBACCO GUANGXI IND

Application method of burley tobacco in cigarette formula

InactiveCN101530236ALoose organizational structureIncrease useTobacco preparationTobacco treatmentLand resourcesEngineering

The invention provides an application method of burley tobacco in cigarette formula, comprising the following steps: processing the burley tobacco into expanded tobacco shreds; uniformly mixing the burley tobacco shreds with the cured tobacco type tobacco shreds according to the weight ratio of 1:100-30:100 to form mixed tobacco shreds; perfuming and storing the mixed tobacco shreds; processing the mixed tobacco shreds into cigarettes. The burley tobacco is processed into expanded tobacco shreds and then mixed with the cured tobacco type tobacco shreds to produce cigarettes, because the price of the burley tobacco is cheaper, the cigarette cost is reduced, in addition, the use of the burley tobacco and the resource of the expanded tobacco shreds are expanded and the cured tobacco can be made at tobacco production area and the burley tobacco alternation crop can be realized in some measure, thus the land resource plays a more important role.

Owner:CHINA TOBACCO ANHUI IND CO LTD

Natural color bamboo fiber pulp, its preparation method and its application as tobacco additive

ActiveCN104213458BReduce usageAvoid residual contaminationTobacco preparationWashing/displacing pulp-treating liquorsFiberBoiling process

The invention discloses an original-color bamboo fiber pulp, a preparation method thereof and an application of the bamboo fiber pulp as a tobacco additive. The original-color bamboo fiber pulp is 20-32 degree SR in a pulping degree and is 5-8g in wet weight. The preparation method includes following steps: S1: crush of raw materials: crushing bamboo fiber raw materials into fiber powder through a dry crushing method; S2: a steaming and boiling process: performing the steaming and boiling process to the fiber powder and a steaming and boiling liquid to obtain a low-hardness bamboo pulp; S3: a washing process: performing a crude selection process through a vibrating screen, a black solution extraction process through a vacuum pulp washing machine, a fine selection process through a pressure sieve, a dust removing process through a residue removing device and a pulp washing process through the vacuum pulp washing machine to obtain a screened pulp; S4: a drying process: performing a dewatering and drying process to the screened pulp to obtain an original-color bamboo fiber plate; and S5: a pulping process: performing a pulp crushing process and a pulping process to the original-color bamboo fiber plate with the pulping degree and the wet weight being controlled to prepare the original-color bamboo fiber pulp. The method is simple in operation, is convenient to carry out, is low in cost, and is green and environmental-protective. The original-color bamboo fiber pulp can be used as the tobacco additive, can reduce irritation of a tobacco sheet, can reduce bad smell of wood and the like, and can improve an original smell of tobacco.

Owner:SICHUAN HUANLONG NEW MATERIAL

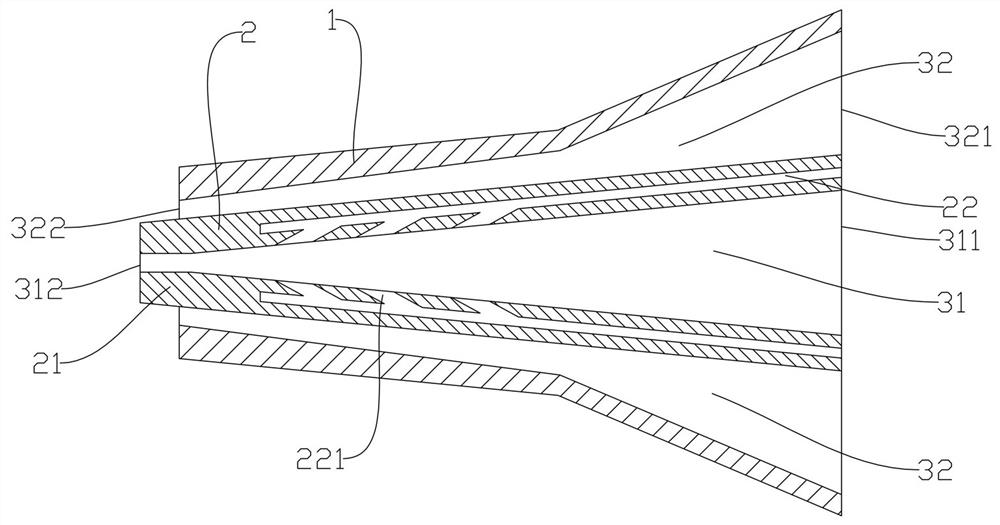

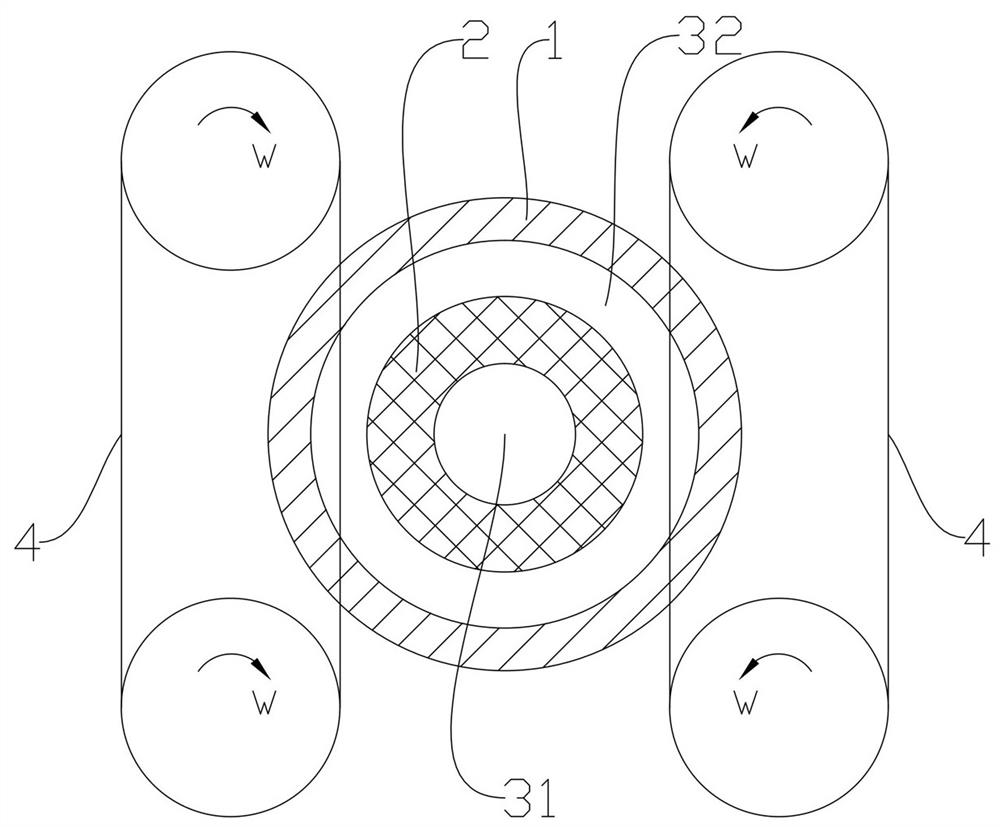

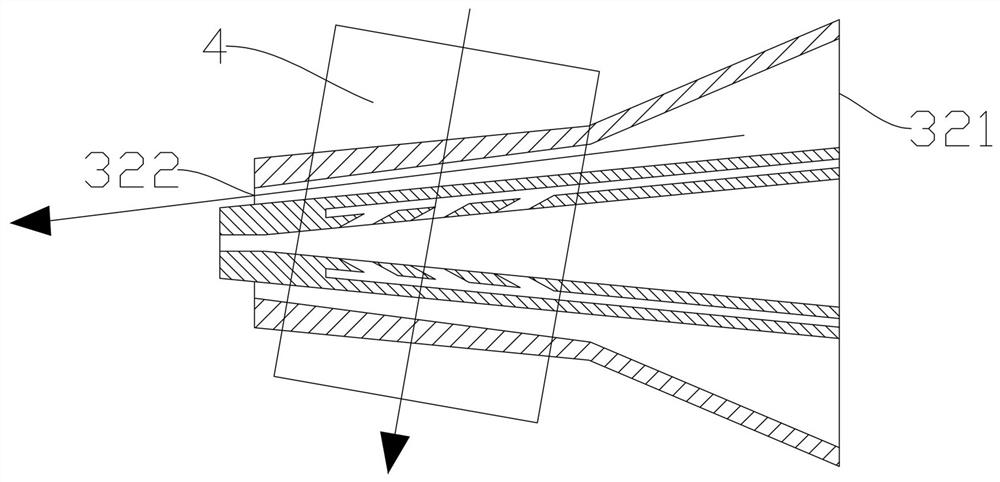

Heating cigarette double-filament gathering device and cigarette core rod forming system

PendingCN112450485AImprove suction qualityReduce the cost of cigarettesCigarette manufactureFilament handlingMechanical engineeringComposite material

The invention relates to the technical field of heating cigarettes, in particular to a heating cigarette double-filament gathering device and a cigarette core rod forming system. The gathering devicecomprises a gathering shell, and openings are formed in the two ends of the gathering shell to form a tobacco shred inlet and a tobacco shred outlet respectively; the gathering shell comprises an outer shell and an inner shell which are coaxial, a first tobacco shred gathering cavity is formed in an inner cavity of the inner shell, and a second tobacco shred gathering cavity is formed between theinner shell and the outer shell; the tobacco shred inlet comprises a first tobacco shred inlet positioned in the first tobacco shred gathering cavity and a second tobacco shred inlet positioned in thesecond tobacco shred gathering cavity; the tobacco shred outlet comprises a first tobacco shred outlet located in the first tobacco shred gathering cavity and a second tobacco shred outlet located inthe second tobacco shred gathering cavity. Double cut tobaccos with different characteristics can be synchronously rolled into the cigarette core rod, and the design and manufacturing level of a heating cigarette is improved.

Owner:CHINA TOBACCO JIANGSU INDAL

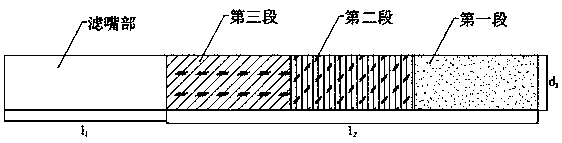

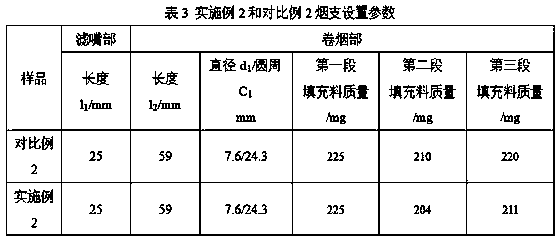

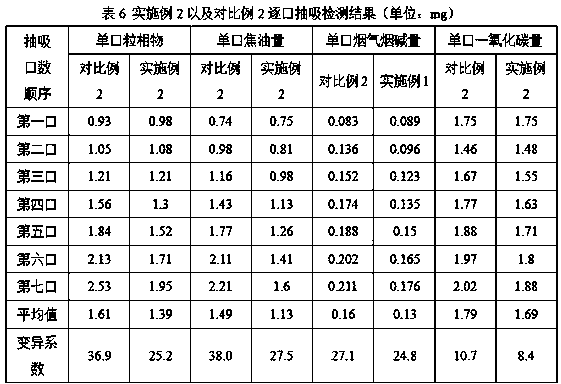

Cigarette with uniform partial smoking effect of cigarette part

InactiveCN109123778AReduce presenceAroma volume is close and balancedTobacco smoke filtersEngineeringCigarette smoke

The invention discloses a cigarette with uniform partial smoking effect of a cigarette part, comprising a filter part and the cigarette part, wherein the filter part is cylindrical, 5.4 to 7.6 mm in diameter and 20 to 30 mm in length, the cigarette part is cylindrical and 5.4 to 7.6 mm in diameter, the lighting end of the cigarette part to the cigarette lighting end near the filter pat is 50-80mm.The cigarette part is composed of a plurality of sections including one section of 100% leaf shreds, and the remaining sections are composed of the following fillers in parts by weight: 92-97% leaf shreds, 3-8% mixture of stem shreds and expanded tobacco shreds. The filling amount of the cigarette part is 5 to 12 mg / mm. The cigarette consume feels uniform and consistent during the smoking process, the aroma quantity, the strength and the satisfaction are more close and balanced, the weight of the whole cigarette is reduce, the consumption of tobacco is reduced, and the cost of cigarettes is saved. Cigarette stuffing is fuller, appearance texture is improved.

Owner:CHINA TOBACCO HENAN IND

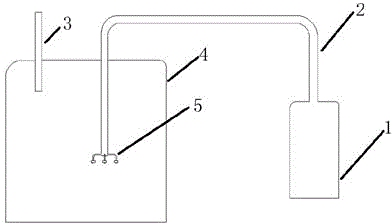

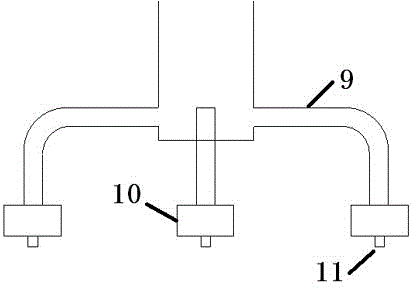

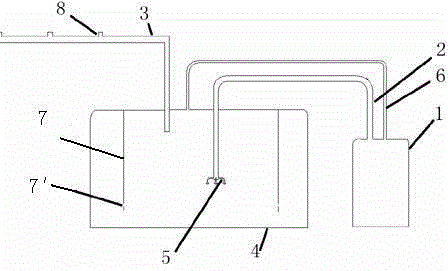

Stage smoke sprayer

Provided is a stage smoke sprayer. An air pressing device (1) which provides high-pressure air and a water storing tank (4) are included. One end of a first high-pressure air inlet pipeline (2) is connected with the air pressing device (1). The other end of the first high-pressure air inlet pipeline (2) is inserted into the water storing tank (4). A nozzle mechanism (5) is arranged at the lower end of the first high-pressure air inlet pipeline (2) in the water storing tank (4). The nozzle mechanism (5) comprises flow dividing pipes (9), buffer chambers (10) and nozzles (11). The number of the flow dividing pipes (9) is at least three. The upper ends of the flow dividing pipes (9) are respectively connected with the first high-pressure air inlet pipeline (2). The lower ends of the flow dividing pipes (9) are respectively connected with one buffer chamber (10). One nozzle (11) is arranged at the lower end of each buffer chamber (10). The water level in the water storing tank (4) is higher than the position where the nozzles (11) are placed. A smoke outlet pipeline (3) is arranged on the tank wall of the upper portion of the water storing tank (4).

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

A kind of tobacco humectant, its preparation method and application

ActiveCN108851200BGood compatibilityDoes not affect aromaTobacco preparationTobacco treatmentPolymer scienceMetal-organic framework

The invention discloses a tobacco humectant, which is Zr 4+ A metal-organic framework material with a three-dimensional structure obtained by self-assembly with terephthalic acid or 2-aminoterephthalic acid; Zr 4+ The three-dimensional metal-organic framework material self-assembled with terephthalic acid is Uio‑66, Zr 4+ The three-dimensional metal-organic framework material self-assembled with 2-aminoterephthalic acid is Uio-66-NH 2 . The invention also discloses the preparation method of the tobacco humectant and its application in tobacco.

Owner:CHINA TOBACCO YUNNAN IND

Method for preparing tobacco sheet based on paper making technique and application thereof

The invention discloses a method for preparing tobacco sheets based on the paper making technique and an application of the method. In the method, the tobacco materials are soaked and extracted, solid-liquid separation is implemented, the solids are made into fiber sheet substrates, the liquid is made into concentrated solution by alcohol precipitation and concentration, reducing sugar and amino acid are added in the concentrated solution to implement Maillard reaction to make coating liquid that is coated on the fiber sheet substrates, and the fiber sheet substrates are dried and cut into tobacco sheets. The invention adds Maillard reaction in the conventional method for preparing tobacco sheets based on the paper making technique, and obtains tobacco sheets in different aromas accordingto different compatible solutions of reducing sugar and amino acid so as to fit cigarette products in different aromas. The tobacco sheets prepared by the method have excellent compatibility and harmony with the cigarette raw materials, have the capability of effectively decreasing the tar release quantity and the contents of the total particle substances in the main taste, and have the advantages of good cigarette taste, various and rich aromas and less impure taste.

Owner:CHINA TOBACCO GUANGDONG IND

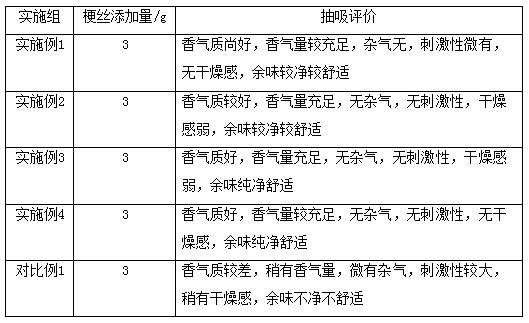

A Processing Technology for Improving the Smell of Cut Stem Tobacco

ActiveCN111820447BAdd effective aroma componentsReduce mistTobacco preparationTobacco treatmentBiotechnologyBotany

The invention relates to the technical field of tobacco processing, in particular to a processing technology for improving the smell of cut tobacco. It comprises the following steps: extracting the waste tobacco leaf material obtained in the cigarette production process with a solvent to obtain a tobacco extract; immersing tobacco stems in the tobacco extract, so that the fibers of the tobacco stems swell; and immersing until the moisture content of the tobacco stems reaches 45-50 %; pressing the steeped tobacco stems until no clear water seeps out; drying and shredding the stem slices obtained by pressing the stems to obtain shredded stems. In the present invention, the tobacco stems are soaked in the tobacco extract solution, and then the excess water is removed by low-intensity treatment, and then the cut stems are processed, so that the effective tobacco components in the tobacco extract solution are retained in the cut stems, and the effective aroma in the cut stems is increased. ingredients, to reduce miscellaneous gas, improve aroma and taste, and increase the application ratio in cigarettes.

Owner:HUBEI CHINA TOBACCO IND

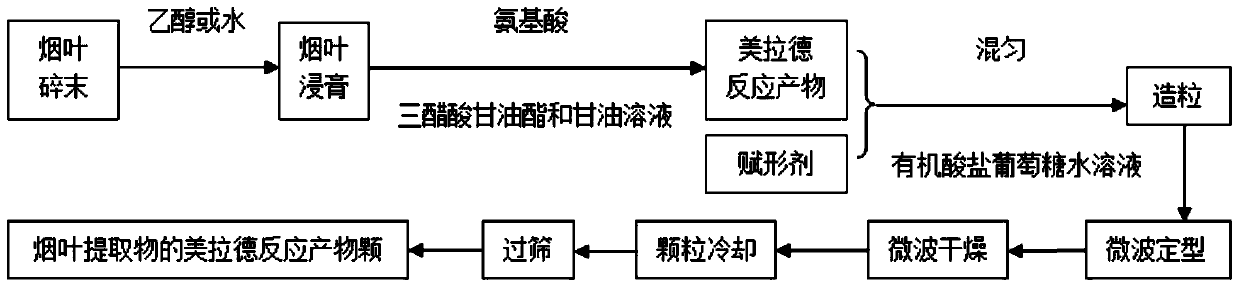

A kind of preparation method of Maillard reaction product particles of tobacco leaf extract

ActiveCN104031741BIncrease aromaSweet aftertasteTobacco smoke filtersEssential-oils/perfumesMaillard reactionParticulates

The invention discloses a preparation method of Maillard reactant particles of tobacco leaf extract. Tobacco leaves are firstly taken and chopped, heated and extracted with water or ethanol as a solvent, the tobacco leaf extract is obtained by hot filtration and refrigerated sedimentation filtration, and concentrated to obtain tobacco leaf extract; then the mixture of tobacco extract and amino acids is added to glycerol triacetate and mixed In the solvent, the heating time at 80-100°C is 3-12 hours to obtain the Maillard reaction product of the tobacco leaf extract; the Maillard reaction product of the triacetin layer is a yellow or brownish-yellow transparent liquid, the same as the excipient material Stir and mix to form wet composite powder, and obtain Maillard reaction product granules of tobacco leaf extract through granulation, microwave setting, microwave drying, granule cooling and sieving. The Maillard reactant of granular tobacco leaf extract prepared by the invention is applied to cigarette filter sticks, which can effectively compensate for the decline in cigarette aroma caused by filter stick filtration and perforation dilution, and improve the smoking quality of cigarettes.

Owner:CHINA TOBACCO GUANGXI IND

Processing method of reconstituted tobacco leaves with homogeneous papermaking method

ActiveCN104041933BLittle fluctuation in qualityImprove adaptabilityTobacco preparationProduction lineLiquid ratio

The invention discloses a method for processing reconstituted tobaccos through a homogeneous and isogenous paper-making process. The method comprises the following steps: step 1, collecting reconstituted tobacco raw materials with same marks and same dimensions on a cigarette on-line production line; step 2, extracting the reconstituted tobacco raw materials by using water according to the extracting solid-to-liquid ratio of 1:6 to 10 at an extracting temperature of 65 to 75 DEG C for 15 to 30 min; step 3, modulating and preparing a coating liquid through enzyme treatment and concentration on an extracting solution obtained; extracting residual solid matters to pulp and make a film base, coating the coating liquid onto the film base in a dipping manner through a papermaking and forming process, and drying so as to prepare the reconstituted tobaccos through the homogeneous and isogenous paper-making process. According to the method provided by the invention, after collecting, extracting on the reconstituted tobacco raw materials with the same marks and same dimensions is performed, the quality of the manufactured reconstituted tobaccos is smaller in volatility, the reconstituted tobaccos are better in suitability with the tobaccos with the same marks, sensory evaluation on cigarettes cannot be influenced when the use ratio of the reconstituted tobaccos reaches more than 20 percent, and the cost for the cigarettes is reduced.

Owner:CHONGQING CHINA TOBACCO IND CO LTD +1

Method for solid-liquid separation during sheet production through papermaking process

ActiveCN101744357BImprove the quality of smokingIncrease profitTobacco preparationCentrifugal force sediment separationFiberSlag

The invention discloses a method for solid-liquid separation during tobacco sheet production through papermaking process, which includes steps: respectively extracting the fragments of tobacco stalk and tobacco leaf through hot water; respectively implementing horizontal centrifugal separation on the mixture of the fragments of tobacco stalk or tobacco leaf, and water, moving solid slag to the working procedure of defibrination, and moving the extract liquor eliminating coarse slag into a disc type separator, and feeding the obtained clear liquid into the working procedure of concentrating innext section; then concentrating the extract liquor, and spraying or coating the concentrated extract liquor on a formed fiber sheet substrate, drying, tabletting and forming. The production technique method adopted by the invention improves the use ratio for sheet production concentrators through papermaking technique and increases the inherent quality of the concentrated liquor, thereby improving the inherent quality of sheet products through papermaking technique.

Owner:CHINA TOBACCO HUNAN INDAL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com