Tobacco cut stem preparation method

A technology of tobacco stems and tobacco stems, which is applied in the fields of tobacco, tobacco preparation, and tobacco treatment, and can solve problems such as large differences, affecting the stability of rolling quality such as cigarette draw resistance, and congenital defects in the sensory quality of cut stems, etc. Achieve the effect of reducing the cost of cigarettes, controlling harmful components and tar release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

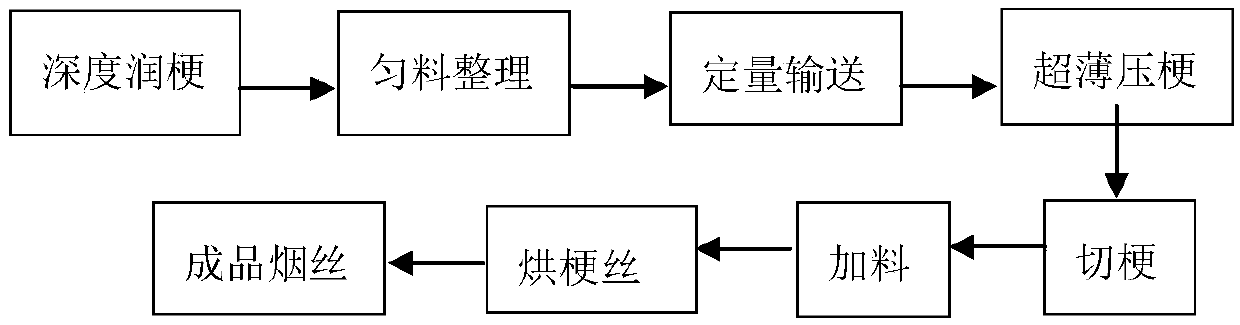

Method used

Image

Examples

Embodiment 1

[0021] Tobacco stem raw materials are washed by conventional equipment sink type tobacco stem rejuvenation machine, the soaking water temperature is 50°C, and the soaking time is about 3-5s, and the tobacco stems with a surface moisture of 30% are made.

[0022] The washed tobacco stems are transported to the first-level stem storage cabinet for water balance, and the storage time is about 2 hours.

[0023] The tobacco stems processed in the first-level stem storage cabinet are transported to the box-type soaking machine for soaking, and the stems are deeply moistened.

[0024] After the water in the water tank is heated to the specified temperature by steam, the water pump starts to work, and the hot water is pumped into the immersion tank. At the same time, the tobacco stems enter the immersion tank through the feeding hood, and the flip-type scraper driven by the chain in the immersion tank Mechanism, press the tobacco stems under the flap, the water level of the hot water ...

Embodiment 2

[0033] Tobacco stem raw materials are steeped with a pot-type soaking machine, soaked in 50°C water for 60 minutes, and the moisture is increased to 65%, and then dried by a centrifuge, the moisture of the tobacco stem reaches 40%-45%, and then passed through the storage Cache in the cabinet for 30 minutes, so that the water can be fully absorbed, and the tobacco stems are moistened and soft.

[0034] Mainly, the tank-type soaking machine is three parallel vertical tanks connected with a mesh belt conveyor and a centrifugal dehydrator. In order to ensure the consistency of the tobacco stem moisture, the mixture of tobacco stems and hot water enters each tank separately for soaking, Each tank works crosswise and discharges separately. While the tobacco stems are soaked in hot water in the tank, they are stirred by the stirring rod, so that the tobacco stems are evenly soaked. The discharge end of the tank has a screw conveyor, and the bottom of the tank is closed by an electri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com