A Processing Technology for Improving the Smell of Cut Stem Tobacco

A processing technology and tobacco technology, which is applied in the fields of tobacco, tobacco processing, and tobacco preparation, can solve the problems of ordinary smoking and high weight of cigarette products, and achieve the effects of improving aroma and taste, increasing effective aroma components, and reducing miscellaneous gases Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

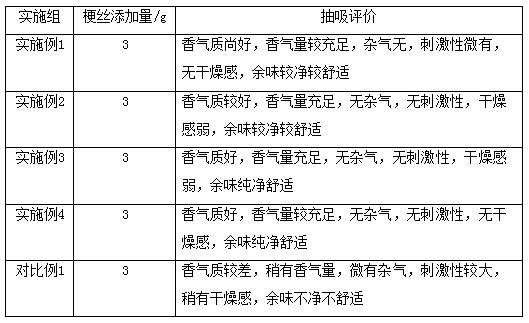

Examples

Embodiment 1

[0037] A processing technique for improving the smell of cut stem tobacco, comprising the following steps:

[0038] (1) The waste tobacco leaf material produced in the cigarette production process and the ethanol solution with a concentration of 60% are mixed at a material-to-liquid ratio of 1:10, placed in a water bath at 60 ° C for oscillating extraction for 60 min, and then filtered to remove solids, the obtained The filtrate is the tobacco extract.

[0039] The tobacco extract was heated, evaporated and concentrated to a solid content of 35%, and then mixed with water at 25°C in a mass ratio of 1:2.33 to serve as an impregnation solution for tobacco stem impregnation.

[0040] (2) After sieving the tobacco stems to remove the thin stems and stems with diameters less than 3 mm, wash the floating ash on the surface of the tobacco stems with normal temperature water at 25 ° C, and then immerse them in the above-mentioned dipping solution. The mass ratio of the tobacco stems t...

Embodiment 2

[0046] A processing technique for improving the smell of cut stem tobacco, comprising the following steps:

[0047] (1) The waste tobacco leaf material produced in the cigarette production process and the ethanol solution with a concentration of 50% are mixed at a material-to-liquid ratio of 1:15, placed in a water bath of 70 ° C for 90min shaking extraction, and then filtered to remove solids, the obtained The filtrate is the tobacco extract.

[0048] The tobacco extract was heated, evaporated and concentrated to a solid content of 30%, and then mixed with water at 20°C in a mass ratio of 1:2 to serve as an impregnation solution for tobacco stem impregnation.

[0049] (2) Screen the tobacco stems to remove the thin stems and stems with diameters less than 3 mm, and then wash off the floating ash on the surface of the tobacco stems with normal temperature water at 20°C. Then, the tobacco stems were heated to 50°C, and in a closed environment, ammonia water with a concentratio...

Embodiment 3

[0054] A processing technique for improving the smell of cut stem tobacco, comprising the following steps:

[0055] (1) The waste tobacco leaf material produced in the cigarette production process and the ethanol solution with a concentration of 70% are mixed at a material-to-liquid ratio of 1:8, placed in a water bath of 60 ° C for extraction for 80 minutes, and then filtered to remove the solid matter, the obtained filtrate That is tobacco extract.

[0056] The tobacco extract was heated, evaporated and concentrated to a solid content of 40%, and then mixed with water at 30°C in a mass ratio of 1:3 to serve as an impregnation solution for tobacco stem impregnation.

[0057] (2) Screen the tobacco stems to remove the thin stems and stems with diameters less than 3 mm, and then wash the floating ash on the surface of the tobacco stems with normal temperature water of 30°C. Then heat the tobacco stems to 60°C, and in a closed environment, firstly spray ammonia water with a con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com