Method for solid-liquid separation during sheet production through papermaking process

A technology of solid-liquid separation and papermaking, which is applied in the direction of separation of sediments by centrifugal force, tobacco, food science, etc., can solve the problems of low and single solid-liquid separation, and achieve the reduction of cigarette costs, increase of yield, and saving resource effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

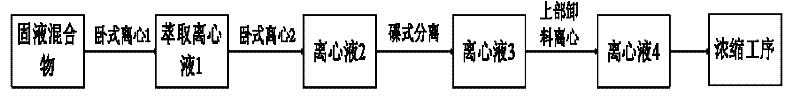

Embodiment 1

[0020] 600kg tobacco stems and 600kg tobacco leaf fragments were soaked in hot water at 40°C and 30°C for 1.5 hours, respectively, and extracted. The tobacco leaf fragments were directly pumped into a decanter centrifuge. After the tobacco stems were initially defibrated, they were pumped into a decanter centrifuge and centrifuged separately The solid tobacco stem residue and the solid tobacco leaf fragment residue are obtained, and the filtrate is combined to obtain the extract centrifugal liquid 1. The absolute dry solid content of the solid slag is 28.3% (using oven method to dry at 105°C to constant weight detection), and the liquid slag content is 1.2%. The solid slag is made into a thin substrate. The extract centrifugal liquid 1 is passed through the decanter centrifuge again to obtain the centrifugal liquid 2 with a residue content of 0.50%. The centrifugal liquid 2 is passed through the disc separator to obtain the centrifugal liquid 3 with a slag content of 0.08%. Th...

Embodiment 2

[0024] 600kg tobacco stems and 600kg tobacco leaf fragments were soaked in hot water at 40°C and 30°C for 1.5 hours, respectively, and extracted. The tobacco leaf fragments were directly pumped into a decanter centrifuge. After the tobacco stems were initially defibrated, they were pumped into a decanter centrifuge and centrifuged separately The solid tobacco stem residue and the solid tobacco leaf fragment residue are obtained, and the filtrate is combined to obtain the extract centrifugal liquid 1. The absolute dry average solid content of the solid slag is 28.4%, and the liquid slag content is 1.3%. The solid slag is made into a thin substrate. The extracted centrifugal liquid 1 is passed through the decanter centrifuge again to obtain the centrifugal liquid 2 with a residue content of 0.51%. The centrifugal liquid 2 is passed through the disc separator to obtain the centrifugal liquid 3 with a slag content of 0.07%. The centrifugal liquid 3 is pumped into the flat top disc...

Embodiment 3

[0028] 600kg tobacco stems and 600kg tobacco leaf fragments were soaked in hot water at 40°C and 30°C for 1.5 hours, respectively, and extracted. The tobacco leaf fragments were directly pumped into a decanter centrifuge. After the tobacco stems were initially defibrated, they were pumped into a decanter centrifuge and centrifuged separately The solid tobacco stem residue and the solid tobacco leaf fragment residue are obtained, and the filtrate is combined to obtain the extract centrifugal liquid 1. The absolute dry solid content of the solid slag is 28.3%, and the liquid slag content is 1.2%. The solid slag is made into a thin substrate. The extract centrifugal liquid 1 is passed through the decanter centrifuge again to obtain the centrifugal liquid 2 with a residue content of 0.50%. The centrifugal liquid 2 is passed through the disc separator to obtain the centrifugal liquid 3 with a slag content of 0.08%. The centrifugal liquid 3 is pumped into a three-foot upper discharg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com