Tobacco leaf curing method and application

A curing method and technology of tobacco leaves, applied in the field of tobacco processing, can solve the problems of weak tobacco production, unclear reasons, and poor results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

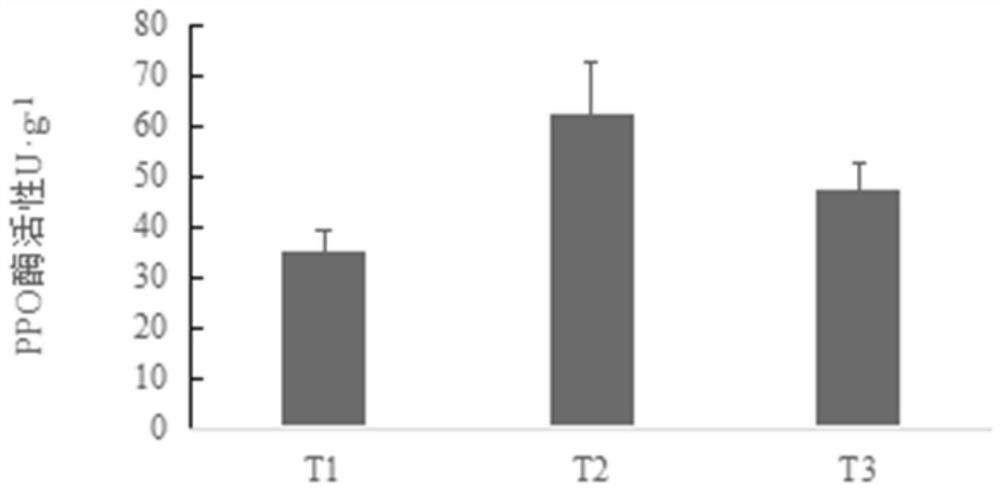

[0034] Example 1 Effects of different baking environments on the browning of tobacco leaves during the yellowing period

[0035] 1) Experimental design

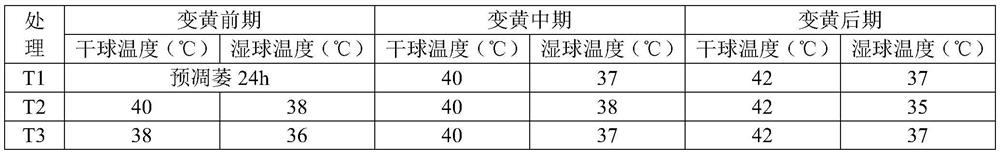

[0036] Tobacco leaves with the same quality of fresh smoke are selected from the same field and baked in a small oven. According to the dry and wet bulb temperatures at different stages of the yellowing period during baking, the setting process is as follows:

[0037] Table 1 Temperature and humidity settings for each test treatment

[0038]

[0039] The temperature stabilization time of each stage is 24h, 24h, and 18h respectively, and the heating rate is 0.5°C / h. The pre-withering operation method is to use intermittent ventilation and heat supply after loading the tobacco, maintain the temperature in the curing room at 30-34°C, and switch to normal heating and baking after 24 hours. After each treatment turns yellow to 90% yellow (yellow slices and blue veins), turn to the heat and carry out conventional baking.

[...

Embodiment 2

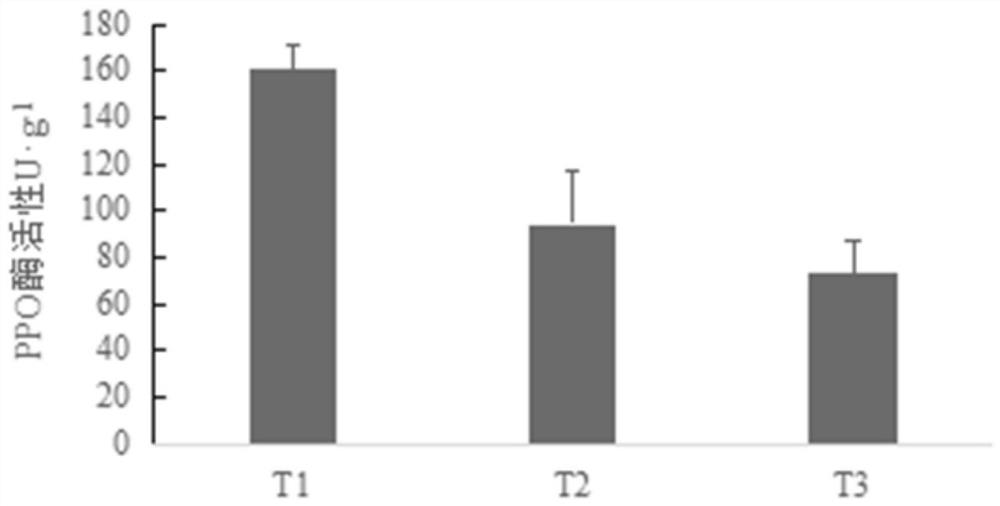

[0071] Example 2 Effects of different temperature and humidity environments on tobacco leaf browning in the early stage of color fixation

[0072] 1) Experimental design

[0073] Tobacco leaves with the same quality of fresh smoke are selected from the same field and baked in a small oven. According to the temperature and humidity in the early stage of color fixing, the temperature stabilization time of each stage is the same, both are 12h, and the heating rate is 0.33°C / h. The setting process is as follows:

[0074] Table 8 Temperature and humidity settings for each test treatment

[0075]

[0076]

[0077] The treatment process in other stages of each treatment group is the same, and the conventional process or the optimized process as mentioned above can be used for baking, and the different treatment groups are consistent. The relative humidity in the curing room in the early stage of color fixing was 56.53%, 56.01%, and 55.46%, respectively, with little difference...

Embodiment 3

[0109] Example 3 Effect of non-enzymatic browning on the content of aroma substances in tobacco leaves after dry flakes

[0110] 1) The test was carried out in Lichuan in 2018. The variety is Yunyan 87, and the upper leaves 13-16 that are prone to browning are selected as the test material. Tobacco leaves with the same quality of fresh smoke are selected from the same field and baked in a small oven. The specific process is as follows:

[0111] Table 15 Temperature and humidity settings for each test treatment

[0112]

[0113] 2) Measurement items and methods:

[0114] Determination of neutral aroma-inducing substances: metabolite extraction, take 100 μL of the liquid sample to be tested (0.1 mg tissue liquid nitrogen grinding) and place it in an EP tube, add 400 μL of 80% methanol aqueous solution (4 times the volume of methanol), vortex, and place Let stand at -20°C for 60min, centrifuge at 14000g, 4°C for 20min, take a certain amount of supernatant and put it in a 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com