Preparation method of cigar tobaccoleaves

A technology for cigar tobacco leaves and tobacco leaves, which is applied in the preparation of tobacco, tobacco, application and other directions, can solve the problems of inconsistent yellowing speed of cigar tobacco leaves, uneven air drying of leaves, and high content of green on the back, so as to shorten the drying time and improve the evaluation of smoking. Quality, effect of low green content in tobacco leaves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

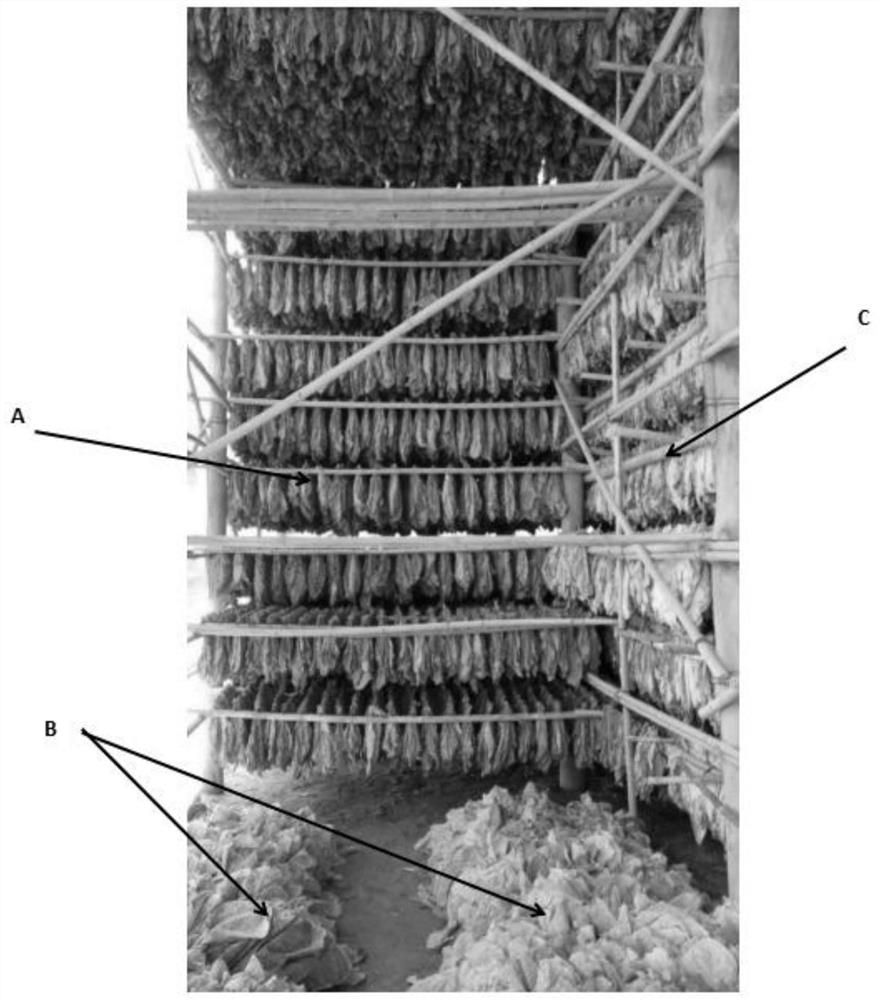

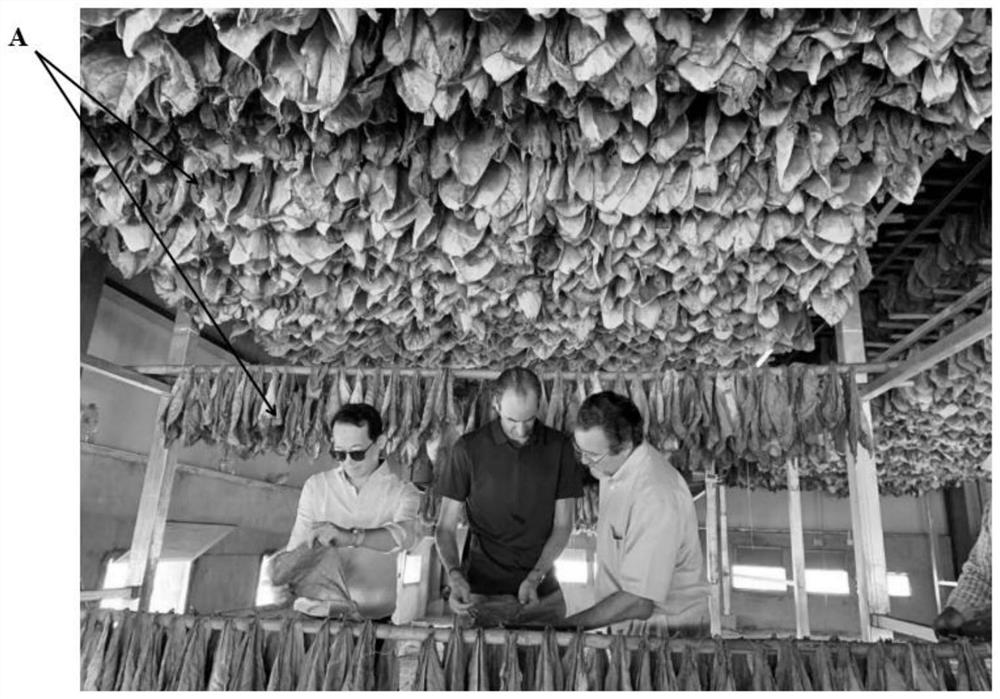

[0021] The invention provides a kind of preparation method of cigar leaf, comprises the following steps:

[0022] 1) Pile up the fresh cigar tobacco leaves at a temperature of 20-35°C and a humidity of 60%-90%, until the tobacco leaves turn yellow to yellow pieces and veins;

[0023] 2) Air-curing the cigar leaves after stacking to obtain cigar leaves.

[0024] In the present invention, the fresh cigar leaves are preferably mature fresh cigar leaves, and the harvesting standard is preferably the following standard: the lower leaves of the cigar leaves turn greenish yellow (the tip of the leaf and the edge of the leaf appear yellow, and the green of the entire leaf surface starts turn into green-yellow), the main veins begin to shine, and the hairs are partly harvested when the hairs fall off; the green color of the middle leaves fades obviously, with light yellow to light yellow as the main color, the tip and edge of the leaves are yellowish-white, and the main veins Bright, ...

Embodiment 1

[0040] 1. Mature harvest

[0041] Harvesting begins when the cigar leaves reach maturity.

[0042] The lower leaves turn greenish-yellow (leaf tips and leaf edges appear yellow, and the green of the entire leaf surface begins to turn into greenish-yellow), the main veins begin to shine, and they are harvested when the hairs fall off; Light yellow to light yellow is the main color, the tip and edge of the leaf are yellow-white, the main vein is bright, most of the hairs fall off, and the leaves are harvested when there are yellow to yellow-white mature spots appearing; the upper leaves turn light yellow, The leaf surface is wrinkled, the leaf tips and margins are whitish and drooping, the main veins are milky white and shiny, the hairs fall off, and the yellow-white mature spots are obvious. Harvesting begins about 50 days after transplanting and surviving, harvesting leaf by leaf from bottom to top, and picking 2-3 pieces each time. Harvest every 5 days or so. Harvesting sh...

Embodiment 2

[0068] 1. Mature harvest

[0069] Harvesting begins when the cigar leaves reach maturity.

[0070] The lower leaves turn greenish-yellow (leaf tips and leaf edges appear yellow, and the green of the entire leaf surface begins to turn into greenish-yellow), the main veins begin to shine, and they are harvested when the hairs fall off; Light yellow to light yellow is the main color, the tip and edge of the leaf are yellow-white, the main vein is bright, most of the hairs fall off, and the leaves are harvested when there are yellow to yellow-white mature spots appearing; the upper leaves turn light yellow, The leaf surface is wrinkled, the leaf tips and margins are whitish and drooping, the main veins are milky white and shiny, the hairs fall off, and the yellow-white mature spots are obvious. Harvesting begins about 50 days after transplanting and surviving, harvesting leaf by leaf from bottom to top, and picking 2-3 pieces each time. Harvest every 5 days or so. Harvesting sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com